Closed loop mrp system

-

Upload

nisha-agarwal -

Category

Business

-

view

886 -

download

1

Transcript of Closed loop mrp system

ByNisha Agarwal (DM-11-008)

Lavanya (DM-11-054)Jagadish (Dm-11-042)

Material Requirements Planning was introduced in the 1970’s. Much of the credit goes to three individuals by the names of Joseph OrlickyGeorge PlosslOliver WightAmerican Production and Inventory Control Society

Material Requirements Planning (MRP) is a computer-based production planning and inventory control system. MRP is concerned with both production scheduling and inventory control.

or Material requirements planning (MRP) is

a production planning, scheduling, and inventory control system used to manage manufacturing processes.

Ensure the availability of materials, components, and products for planned production and for customer delivery

Maintain the lowest possible level of inventory.

Plan manufacturing activities, delivery schedules, and purchasing activities.

1. MRP is a method for ordering components than the independent demand inventory models

2. MRP : It is a phase in the development of computerized methods for planning the use of company resources , including scheduling raw materials, vendors, production equipment and processes.

3. MRP provides a method that helps keep order due dates valid even after the orders have been released to the shop floor or outside vendor.

4. MRP systems can detect when the due date of an order – the date the order is scheduled to arrive- is out of alignment with its need date , the date the order is actually required.

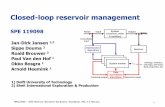

Product Structure

File

Master Production Schedule

Inventory Master File

Material Requirements

Planning

Manufacturing Orders

Purchase Orders

Various Reports

MRP

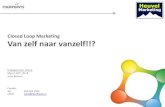

Closed Loop MRP

MRP II

ERP

Schedule Materials

Schedule Materials

Incorporate Feedback

Schedule & Purchase Materials

Coordinate w/ Mfg Resources

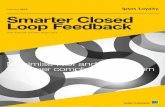

Closed loop MRP is a system which grew out of ‐material requirements planning (MRP) and which primarily allows plans to be checked against capacity to determine whether they are realistic and achievable.

Closed loop MRP is the intermediate stage between ‐material requirements planning and manufacturing resources planning

Production PlanningMaster Production SchedulingMaterial Requirements PlanningCapacity Requirements Planning

Realistic?No

Feedback

Execute:Capacity PlansMaterial Plans

Yes

Feedback

Closed loop MRP is used to determine how well the planning factors & tools are working, MRP planners need feedback from the shopkeeper and purchasing department.

With effective feedback MRP planner can revise the planning factors and techniques so that better materials can be developed for future.

Availability of the right materials required for production, on time

Little, if any, excess inventory can be reduced

Timely delivery of manufactured goods to customers

Optimal use of manufacturing resources (equipment downtime reduced)

Decrease in capital cost due to decreased inventory levels and optimal use of production resources

Collecting the business data for analysis and better planning

High costs and technical complexities in implementation. In addition, organizations, which use an MRP system need to spend considerable effort on installing necessary equipment (computers), training personnel, modifying the software to serve their specific needs, validating, testing, and eliminating possible errors, and maintaining the software.

The time required for planning and implementing an MRP system is generally very long.

Data entry and file maintenance requires considerable inputs in the form of training and education of the personnel.

Dependence on forecast values and estimated lead-time can sometimes be misleading.