Circuit Breaker Selection

-

Upload

cinar-inal -

Category

Documents

-

view

380 -

download

17

Transcript of Circuit Breaker Selection

Section 3Contents

3-1

Section 3Circuit Breaker Selection

PageINTRODUCTION .............................................................................................. 3-2

CIRCUIT BREAKER RATINGS ........................................................................ 3-2

SELECTION CONSIDERATIONS .................................................................... 3-2 Circuit Voltage .............................................................................................. 3-2 System Frequency ........................................................................................ 3-5 Short-circuit Current ...................................................................................... 3-5 Closing and Latching Current ....................................................................... 3-5 Continuous Current ....................................................................................... 3-5 Rated Interrupting Time ................................................................................ 3-5

SPECIAL SWITCHING APPLICATIONS .......................................................... 3-6 Repetitive Switching ..................................................................................... 3-6

Arc Furnace Switching ................................................................................. 3-6 Reactor Switching ......................................................................................... 3-6 Capacitor Switching ...................................................................................... 3-8

Automatic Transfer ....................................................................................... 3-9Fast Bus Transfer ....................................................................................... 3-10

SERVICE CONDITIONS................................................................................. 3-12 Usual Service Conditions ........................................................................... 3-12 Unusual Service Conditions ....................................................................... 3-13

Temperature ..................................................................................... 3-12 High Altitude ..................................................................................... 3-13

BREAKER-MOUNTED ACCESSORIES ........................................................ 3-15

LIFT TRUCK ................................................................................................... 3-15

REFERENCES .............................................................................................. 3-17

Contents

Circuit Breaker Selection

3-2

INTRODUCTION

A circuit breaker’s function and intended useare established in ANSI-C37.100-1992, Definitionsfor Power Switchgear, which defines a circuitbreaker as:

“A mechanical switching device, capable ofmaking, carrying, and breaking currentsunder normal circuit conditions and also,making, carrying for a specified time andbreaking currents under specified abnormalcircuit conditions such as those of short-circuit.”

In addition, it is noted that a circuit breaker isintended usually to operate infrequently, althoughsome types are suitable for frequent operation.

A circuit breaker is applied generally to carryand switch load current and to interrupt short-circuitcurrent when required. The application process issimple: each of the duty requirements is specifiedor calculated and is then compared to thecorresponding capability of the circuit breaker. Thefundamental rule for selection of the proper circuitbreaker is that the ratings or related capabilities ofthe circuit breaker must equal or exceed each ofthe calculated or specified duty requirements ofthe circuit in which it is applied.

CIRCUIT BREAKER RATINGS

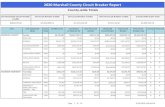

Power/Vac circuit breaker ratings with K=1are shown in Table 3-1.1. Table 3-1.2 listsPower/Vac circuit breakers with ratings basedon the previous revision of ANSI C37.06(1987), with K factors greater than 1.0.Interrupting ratings are for 60-HZ and 50-HZapplications. For more complete informationconcerning service conditions, definitions,interpretation of ratings, tests, and qualifyingterms, refer to the applicable ANSI and NEMAstandards listed in Table 1-1, Page 1-3.

SELECTION CONSIDERATIONS

Application of the proper circuit breakerrequires a definition of its duty requirements, whichcan then be compared with the choice of a Power/Vac circuit breaker with ratings and capabilitiesshown in Table 3-1.1 or 3-1.2. It is recommendedthat ANSI Standard C37.010 (see Ref.2 of thissection) be consulted for guidance in properdetermination of duty requirements. Circuitcharacteristics that must be considered arediscussed in the following paragraphs. Circuitcharacteristics which must be defined andcompared to the circuit breaker’s capabilities (givenin the various Tables in this Section) are:

Circuit voltage System frequency Continuous current Short-circuit current Closing and latching current

In addition, certain special application conditionscan influence circuit breaker selection. Specialapplications include the following:

Repetitive switching duty (except arcfurnaces)Arc furnace switchingReactor switchingCapacitor switchingFast bus transferUnusual service conditions

This section of the Power/Vac ApplicationGuide provides specific parameters and guidelinesfor circuit breaker selection and application.Specifically, those circuit parameters and specialapplications noted in the proceeding paragraphare addressed.

CIRCUIT VOLTAGE

The nominal voltage classes of medium-voltagemetalclad switchgear based on ANSI standardsare 4.16 kV, 7.2 kV and 13.8 kV. Power/Vacswitchgear may be applied at operating voltagesfrom 2400 volts through 15,000 volts, provided themaximum circuit operating voltage does notexceed the Power/Vac rated maximum voltage,see Table 3-1.1 or Table 3-1.2 .

Section 3

GE

PO

WE

R/V

AC

Po

wer

Cir

cuit

Bre

aker

Ch

arac

teri

stic

s

Sym

etri

cal R

atin

gs

Bas

is p

er A

NS

I C37

.06

- 20

00

2400

1200

-400

031

.55

or

331

.582

4160

1200

-400

040

5 o

r 3

4010

4

4200

1200

-400

050

5 o

r 3

5013

0

1200

-400

063

*5

6316

4

6600

1200

-400

040

5 o

r 3

4010

4

6900

1200

-400

050

*5

or

350

130

7200

1200

-400

063

*5

6316

4

1200

012

00-4

000

205

or

320

52

1247

012

00-4

000

255

or

325

65

1320

012

00-4

000

31.5

5 o

r 3

31.5

82

1380

012

00-4

000

405

or

340

104

1440

012

00-4

000

505

or

350

130

1200

-400

063

563

164

No

tes:

1 M

axim

um

vo

ltag

e fo

r w

hic

h t

he

bre

aker

is d

esig

ned

an

d u

pp

er li

mit

of

op

erat

ion

.

2 A

vaila

ble

cu

rren

t ra

tin

gs

are

1200

A, 2

000A

, 300

0A, 3

500A

an

d 4

000A

. 4

000A

rat

ing

is f

orc

ed-a

ir c

oo

led

, in

do

or

con

strc

uti

on

on

ly.

3

500A

is a

vaila

ble

in o

utd

oo

r co

nst

ruct

ion

, bu

t m

ust

be

der

ated

to

325

0A.

3 A

t sy

stem

op

erat

ing

vo

ltag

es e

qu

al t

o o

r le

ss t

han

rat

ed m

axim

um

vo

ltag

e.

AV

AIL

AB

LE

RA

TIN

GS

4.76

8.25 15

6019

Rat

ed

Per

mis

sib

le

Tri

pp

ing

Del

ay, Y

(Sec

on

ds)

Rat

ed In

terr

up

tin

g

Tim

e (C

ycle

s)

36

2 S

ec S

ho

rt

tim

e C

urr

ent

Car

ryin

g

Cap

abili

ty

(kA

)

36

95 95

2 2 2

Typ

ical

Sys

tem

Op

erat

ing

Vo

ltag

es (

kV)

Pea

k C

lose

an

d

Lat

ch

(2.6

K x

sh

ort

circ

uit

cu

rren

t

rati

ng

)

(kA

)

Rat

ed M

axim

um

rms

Vo

ltag

e (k

V)

(1)

Rat

ed V

olt

age

Ran

ge

Fac

tor,

K

Rat

ed W

ith

stan

d

Tes

t V

olt

age

Co

nti

nu

ou

s rm

s

Cu

rren

t R

atin

g a

t

60H

z (a

mp

eres

)

(2)

Rat

ed S

ho

rt

Cir

cuit

Cu

rren

t

(Max

imu

m

Inte

rru

pti

ng

Cap

abili

ty)

(kA

) (

3)

Lo

w F

req

uen

cy

rms

Vo

ltag

e (k

V)

Cre

st Im

pu

lse

Vo

ltag

e (k

V)

No

min

al A

NS

I

Vo

ltag

e C

lass

(kV

)

1.0

1.0

1.0

4.16 7.2

13.8

Tab

le 3

-1.1

Po

wer

/Vac

® P

ow

er C

ircu

it B

reak

er C

har

acte

rist

ics,

K =

1.0

3-3

Not

es:

1

Max

imum

vol

tage

for

whi

ch t

he b

reak

er is

des

igne

d an

d up

per

limit

of o

pera

tion.

2 A

vaila

ble

curr

ent

ratin

gs a

re 1

200A

, 20

00A

, 30

00A

, 35

00A

and

400

0A.

4000

A r

atin

g is

for

ced-

air

cool

ed,

indo

or c

onst

ruct

ion

only

.

3

500A

is a

vaila

ble

in o

utdo

or c

onst

ruct

ion,

but

mus

t be

der

ated

to

3250

A.

3

At

syst

em o

pera

ting

volta

ges

equa

l to

or le

ss t

han

rate

d m

axim

um v

olta

ge.

*

Rat

ings

offe

red

in a

dditi

on t

o th

e A

NS

I pr

efer

red

valu

es

Po

wer

/Vac

Po

wer

® C

ircu

it B

reak

er C

har

acte

rist

ics

Sym

etri

cal R

atin

gs

Bas

is p

er A

NS

I C37

.06

- 200

0

Circuit Breaker Selection

3-4

Tab

le 3

-1.2

Po

wer

/Vac

® P

ow

er C

ircu

it B

reak

er C

har

acte

rist

ics,

K>1

.0

PO

WE

R/V

AC

Po

wer

Cir

cu

it B

reaker

Ch

ara

cte

risti

cs

Sym

metr

ical R

ati

ng

s B

asis

AN

SI C

37.0

6 (

1987)

(kA

)(k

A)

4.1

6250

1.2

41200-4

000

29

3.8

536

36

58

97

350

1.1

91200-4

000

41

4.0

49

49

78

132

450 (

6)

1.0

01200-4

000

63

4.7

663

63

101

164

500

1.2

51200-4

000

33

6.6

41

41

66

111

785 (

6)

1.0

01200-4

000

63

8.2

563

63

101

164

500

1.3

01200-4

000

18

11.5

23

23

37

62

750

1.3

01200-4

000

28

11.5

36

36

58

98

1000

1.3

01200-4

000

37

11.5

48

48

77

130

1500 (

6)

1.0

01200-4

000

63

15

63

63

101

164

Note

s:

(1)

Maxim

um

voltage for

whic

h the b

reaker

is d

esig

ned a

nd the u

pper

limit for

opera

tion.

(2)

K is the r

atio o

f th

e m

axim

um

voltage to the low

er

limit o

f th

e r

ange o

f opera

ting v

oltage in w

hic

h the r

equired s

ym

metr

ical and a

sym

metr

ical in

terr

upting

capabili

ties v

ary

in invers

e p

roport

ion to the o

pera

ting v

oltage.

(3)

To o

bta

in the r

equired s

ym

metr

ical in

terr

upting c

apabili

ty o

f a c

ircuit b

reaker

at an o

pera

ting v

oltage b

etw

een 1

/K tim

es r

ate

d m

axim

um

voltage a

nd r

ate

d m

axim

um

voltage,

the follo

win

g form

ula

shall

be u

sed: R

equired S

ym

metr

ical In

terr

upting C

apabili

ty =

R

ate

d S

hort

-Circuit C

urr

ent X

(R

ate

d M

axim

um

Vo

lta

ge

)

(

Opera

ting V

oltage)

For

opera

ting v

oltages b

elo

w 1

/K tim

es r

ate

d m

axim

um

voltage, th

e r

equired s

ym

metr

ical in

terr

upting c

apabili

ty o

f th

e c

ircuit b

reaker

shall

be e

qual to

K tim

es the r

ate

d s

hort

-circuit c

urr

ent.

(4)

With the lim

itation s

tate

d in 5

.10 o

f A

NS

I-C

37.0

4-1

991, all

valu

es a

pply

for

poly

phase a

nd lin

e-t

o-lin

e faults. F

or

sin

gle

phase-t

o-p

hase faults, th

e s

pecific

conditio

ns

sta

ted in 5

.10.2

.3 o

f A

NS

I-C

37.0

4-1

991 a

pply

.

(5)

Curr

ent valu

es in this

colu

mn a

re n

ot to

be e

xceeded e

ven for

opera

ting v

oltages b

elo

w 1

/K tim

es m

axim

um

voltage.

(6)

MV

A C

lass lis

ted for

refe

rence o

nly

. N

ote

4160V

-450M

VA

, 7.2

KV

-785M

VA

and 1

3.8

KV

-1500M

VA

are

not lis

ted a

s p

refe

rred r

atings a

ccord

ing to table

2.1

of A

NS

I-C

37.0

6-1

987.

For

these r

atings the S

hort

Tim

e c

urr

ent is

on a

2 s

ec b

asis

, and the p

eak C

&L is 2

.6 X

S/C

rating.

(7)

Availa

ble

curr

ent ra

tings a

re 1

200A

, 2000A

, 3000A

, 3500A

and 4

000A

. 3

500A

is indoor

constr

uction o

nly

.

(8)

4000A

bre

aker

is forc

ed-a

ir c

oole

d, and indoor

constr

uction o

nly

.

(9)

3 c

ycle

inte

rrupin

g r

atings m

ay b

e a

vaila

ble

, consult F

acto

ry.

(10)

Non-s

tandard

, hig

h C

lose &

Latc

h r

atings m

ay b

e a

vaila

ble

, consult F

acto

ry.

4.7

6

8.2

5

15

K t

imes R

ela

ted

Sh

ort

cir

cu

it r

ms C

urr

en

t

Rated Interrupting Time (Cycles) (9)

Insu

lati

on

Level

Rela

ted

Req

uir

ed

Cap

ab

ilit

ies

Clo

sin

g a

nd

L

atc

hin

g

Cap

ab

ilit

y r

ms

Cu

rren

t (k

A)

(10)

Peak C

lose

an

d L

atc

h

(2.7

K x

max

S/C

rati

ng

)(k

A)

(6)

Rate

d

Maxim

um

rm

s

Vo

ltag

e

Div

ided

by K

(k

V)

Rated Permissible Tripping Delay, Y (Seconds)

36

36

19

95

95

Sh

ort

Cir

cu

it

rms C

urr

en

t R

ati

ng

(at

Rate

d

Max. kV

) (k

A)

(3)

(4)

Co

nti

nu

ou

s r

ms

Cu

rren

t R

ati

ng

at

60H

z

(am

pere

s)

(7)

& (

8)

Rate

d W

ith

sta

nd

T

est

Vo

ltag

e

Iden

tifi

cati

on

R

ate

d V

alu

es

No

min

al

rms

Vo

ltag

e

Cla

ss (

kV

)

No

min

al

MV

A C

lass

(6)

Rate

d

Maxim

um

V

olt

ag

e r

ms

(kV

) (1

)

Rate

d

Vo

ltag

e

Ran

ge

Facto

r, K

(2)

Vo

ltag

e

13.8

7.2

Maxim

um

S

ym

metr

ical

Inte

rru

pti

ng

C

ap

ab

ilit

y (

5)

3 S

ec S

ho

rt

tim

e C

urr

en

t C

arr

yin

g

Cap

ab

ilit

y (

5)

Low Frequency rms Voltage (kV)

Crest Impulse Voltage (kV)

52

60

Cu

rren

t

Not

es:

(1)

Max

imum

vol

tage

for

whi

ch t

he b

reak

er i

s de

sign

ed a

nd t

he u

pper

lim

it fo

r op

erat

ion.

(2)

K is

the

ratio

of t

he m

axim

um v

olta

ge to

the

low

er li

mit

of th

e ra

nge

of o

pera

ting

volta

ge in

whi

ch th

e re

quire

d sy

mm

etric

al a

ndas

ymm

etric

al i

nter

rupt

ingc

apab

ilitie

s va

ry i

n in

vers

e pr

opor

tion

to t

he o

pera

ting

volta

ge.

(3)

To o

btai

n th

e re

quire

d sy

mm

etric

al in

terr

uptin

g ca

pabi

lity

of a

circ

uit

brea

ker

at a

n op

erat

ing

volta

ge b

etw

een

1/K

tim

es r

ated

max

imum

vol

tage

and

rat

ed m

axim

um v

olta

ge,

the

follo

win

g fo

rmul

a sh

all

be u

sed:

Req

uire

d S

ymm

etric

al I

nter

rupt

ing

Cap

abili

ty =

Rat

ed S

hort

-Circ

uit

Cur

rent

X (

Rat

ed M

axim

um V

olta

ge)

(O

pera

ting

Vol

tage

)F

or o

pera

ting

volta

ges

belo

w 1

/K t

imes

rat

ed m

axim

um v

olta

ge,

the

requ

ired

sym

met

rical

inte

rrup

ting

capa

bilit

y of

the

circ

uit

brea

ker

shal

l be

equ

al t

o K

tim

es t

he r

ated

sho

rt-c

ircui

t cu

rren

t.(4

)W

ith t

he li

mita

tion

stat

ed in

5.1

0 of

AN

SI-

C37

.04-

1991

, al

l val

ues

appl

y fo

r po

lyph

ase

and

line-

to-li

ne f

aults

. F

or s

ingl

e ph

ase-

to-p

hase

fau

lts,

the

spec

ific

cond

ition

s st

ated

in

5.10

.2.3

of

AN

SI-

C37

.04-

1991

app

ly.

(5)

Cur

rent

val

ues

in t

his

colu

mn

are

not

to b

e ex

ceed

ed e

ven

for

oper

atin

g vo

ltage

s be

low

1/K

tim

es m

axim

um v

olta

ge.

(6)

MV

A C

lass

lis

ted

for

refe

renc

e on

ly.

Not

e 41

60V

-450

MV

A,

7.2K

V-7

85M

VA

and

13.

8KV

-150

0MV

A a

re n

ot l

iste

d as

pre

ferr

edra

tings

acc

ordi

ng to

tabl

e 2.

1 of

AN

SI-

C37

.06-

1987

. F

or th

ese

ratin

gs th

e S

hort

Tim

e cu

rren

t is

on a

2 s

ec b

asis

, and

the

peak

C&

L is

2.6

X S

/C r

atin

g.(7

)A

vaila

ble

curr

ent

ratin

gs a

re 1

200A

, 20

00A

, 30

00A

, 35

00A

and

400

0A.

3500

A a

nd 4

000A

are

indo

or c

onst

ruct

ion

only

.(8

)40

00A

bre

aker

is

forc

ed-a

ir co

oled

, an

d in

door

con

stru

ctio

n on

ly.

(9)

3 cy

cle

inte

rrup

ing

ratin

gs m

ay b

e av

aila

ble,

con

sult

Fac

tory

.(1

0)N

on-s

tand

ard,

hig

h C

lose

& L

atch

rat

ings

may

be

avai

labl

e, c

onsu

lt F

acto

ry.

Po

we

r/V

ac

® P

ow

er

Cir

cu

it B

rea

ke

r C

ha

rac

teri

sti

cs

Sym

met

rica

l R

atin

gs

Bas

is A

NS

I C

37.0

6 (1

987)

Section 3

SYSTEM FREQUENCY

The frequency rating of Power/Vac metalcladswitchgear should coincide with the nominalfrequency of the power system. Standard Power/Vac is rated at 60-Hz (Tables 3-1.1 and 3-1.2) perANSI standards, however can typically be appliedat 50-Hz as well. Special frequency applicationsshould be referred to the nearest GE Office.

SHORT-CIRCUIT CURRENT

Quick interruption of short-circuit current isusually considered the primary function of a circuitbreaker. The fault-current interrupting capabilityof Power/Vac circuit breakers is stated in three-phase, symmetrical, rms AC amperes.Accordingly, calculation of the maximum availablefault duty of a circuit breaker assumes a three-phase bolted fault.

After calculation of short-circuit currentduty, choose a Power/Vac breaker of the propervoltage class and which has a short-circuit currentcapability that equals or exceeds the expectedduty. If applying breakers with K factors > 1.0,remember to consider the circuit operating voltagewhen evaluating the circuit breaker’s interruptingcapability. For example: a 4.16 kV- 350 MVA-class circuit breaker has a rated short-circuitcurrent of 41 kA at a maximum rated voltage of4.76 kV, but has a short-circuit capability of 47 kAsymmetrical rms current at 4.16 kV. However whenapplied on a 2.4 kV system, the interruptingcapability increases to 49 kA, which is themaximum symmetrical interrupting capabilitylisted in the rating tables, because 2.4 kV is lessthan 4.76 kV divided by “k”, or 4.76/1.19 = 4.0 kV.(See footnote No. 5, Table 3-1.2).

CLOSING AND LATCHING CURRENT

Circuit breakers are designed to staylatched, or to close and latch, against a first-cyclemaximum asymmetrical rms current which isapproximately 1 1/2 times the maximumsymmetrical rms interrupting capability of thecircuit breaker. This close and latch capability issatisfactory for most applications (Table 3-1.1 and3-1.2). However there are some applications inwhich the calculated rms value of first-cycleasymmetrical short-circuit current, exceeds theclosing and latching capability of the otherwisesuitable circuit breaker. Applications which includelarge motor loads may generate these higher first-cycle currents. In these cases, breaker selectionmay depend on closing and latching capability

3-5

rather than symmetrical short-circuit capability.The breaker selected may have the next highershort-circuit current capability.

For circuit breakers with K factor =1.0,the closing and latching capability (kA, rms) ofthe circuit breaker is equal to 1.55 K times ratedshort-circuit current. If close & latch is expressedin peak amperes, the value is equal to 2.6 K timesrated short-circuit current.

For circuit breakers with K > 1.0, closingand latching capability (kA, rms) of the circuitbreaker is equal to 1.6 K times rated short-circuitcurrent and if expressed in peak amperes, thevalue is equal to 2.7 K times rated short-circuitcurrent (see ANSI C37.06-2000 for details)

CONTINUOUS CURRENT

Feeder and main breaker loadingdetermines the required continuous current duty.For continuous loads, select a Power/Vac breakerwith rated continuous current (defined at 60-Hz)equal to or greater than load current.

Note that Power/Vac circuit breakers are100% rated, and have no continuous overloadrating. When considering circuit breakerapplications with a generator, a motor, atransformer, or other apparatus having a long-timeoverload rating, the circuit breaker (and switchgearequipment) must have a continuous-current ratingat least equal to the overload rating of the servedapparatus. When applied with a forced-air cooledtransformer, the switchgear continuous-currentrating must equal or exceed the transformer forced-air cooled current rating.

Circuit breakers may be operated for shortperiods, in excess of their rated continuous current.This covers such operations as starting motors orenergizing cold loads. Consult ANSI C37.20.2 foroverload current capability guidelines.

RATED INTERRUPTING TIME

Power/Vac circuit breakers are availablewith interrupting ratings of 5-cycles or 3-cycles,as stated in Tables 3-1.1 and 3-1.2. For additionalinformation contact your GE Sales Engineer.

Circuit Breaker Selection

3-6

DUTY CYCLE

Power/Vac circuit breakers have a rated dutycycle of: O – 0 sec – CO – 15 sec – CO. Power/Vac vacuum breakers do not require derating forreclosing duties.

SPECIAL SWITCHING APPLICATIONS

Application of power circuit breakers forswitching duty may require derating of the circuitbreaker, or increased maintenance. Power/Vaccircuit breakers do not require derating whenapplied in automatic reclosing duty.

Particular attention should be given to breakersintended for use in any of the following switchingapplications:

• Repetitive switching (except arc furnace)• Arc furnace switching• Reactor switching• Capacitor switching• Fast bus transfer

For these applications, the usual practice isto first select a circuit breaker based on the criteriaprovided under “SELECTION CONSIDERATIONS”of this section. Then consider the switching dutyand, if necessary, redetermine the circuit breakercapabilities (continuous-current rating, interruptingrating, etc.), and factor in any modified operatingor maintenance requirements. Recheck the circuitbreaker’s evaluation capabilities against all thebasic duty requirements under “SELECTIONCONSIDERATIONS.”

If the circuit breaker selected initially, and asderated (or otherwise modified), no longer meetsthe duty requirements of the application, choosethe next-higher rated breaker. Repeat the deratingor rating adjustment process to confirm that thenew breaker has adequate capability.

REPETITIVE SWITCHING(EXCEPT ARC FURNACE)

Power/Vac circuit breakers can be applied onmost power circuits without concern to frequencyof operation, since highly repetitive switching dutyis uncommon. Typical switching duties includemotor starting, switching of distribution circuits,transformer magnetizing current, and othermiscellaneous load-current switching. While themagnitude of current switched in these

applications can vary from very light load to themaximum permissible for a particular circuitbreaker, switching is generally infrequent; thus,no derating is required.

Standard Power/Vac circuit breakers may beoperated (open-close) as often as 20 times in 10minutes, or 30 times in one hour without adverseeffect. Further frequency of operation capabilitiesare given in Table 3-2. When operated under usualservice conditions and for other than arc furnaceswitching, standard Power/Vac circuit breakers arecapable of operating the number of times shownin the table. Operating conditions, servicingrequirements and permissible effects on thebreakers are specified in Table 3-2.

ARC FURNACE SWITCHING

Arc furnace switching duty is more repetitivethan normal switching duty. The circuit breaker isapplied on the primary side of a relatively high-impedance transformer and the usual applicationrequires frequent switching (50 to 100 times perday) of the transformer magnetizing current.Switching is required when the transformer is de-energized for tap changing, when taking meltsamples, or when adding alloys. In addition tothis switching duty, transformer through-faultsmust occasionally be interrupted

This heavy-duty application requires circuitbreaker capabilities and maintenance schedulesdifferent from those required for other switchingduty.

Power/Vac circuit breakers designed for arcfurnace switching are capable of operating thenumber of times given in Table 3-3, providing theyare operated under usual service conditions.Operating conditions, servicing requirements, andpermissible effects on the breakers are given inthe table.

REACTOR SWITCHING

Standard Power/Vac circuit breakers arecapable of switching reactive load current up thefull continuous current rating of the breaker.

Consult the nearest GE Sales Office foradditional information on reactor switching.

Section 3

�

BREAKER NUMBER OF OPERATIONS

TYPE CONTINUOUS RATING (AMPERES)

ARE FURNACE FULL-LOAD RATING

(AMPERES)

MAXIMUM NUMBER OF OPERATIONS BETWEEN

SERVICING

NO-LOAD MECHANICAL SWITCHING AND INTERRUPTING

COLUMN 1

COLUMN 2 COLUMN 3 COLUMN 4 COLUMN 5 COLUMN 6

A. Servicing consists of adjusting, cleaning, lubrication, tightening, changing parts, as recommended by the Company. The operations listed are on the basis of service in a mild environment.

H. If the weighted average of the currents interrupted during load and secondary furnace cave-ins is equal to the breaker continuous current, this column applies.

I. After 15 full short circuit faults check the contact erosion.

B. When closing and opening no-load.

C. Within 90 to 100% of rated control voltage.

D. Frequency of operation not more than 20 in 10 minutes or not more than 30 in 1 hour.

E. Servicing at no greater interval than shown in Column 4.

F. No parts replacement.

G. Breaker meets all current, voltage, interrupting current ratings.

C. Applies

D. Applies

E. Applies

F. Applies

G. Applies

I. Applies

J. At the first servicing interval, the amount of vacuum interrupter contact erosion should be used to estimate the additional life at that continued duty.

18-40kA All All 10,000 or 10 years 10,000 minimum

50 & 63kA

All All 5,000 or 10 years 5,000 minimum

Table 3-2 Repetitive Duty and Normal Maintenance for Power/Vac®

Breakers used in Mild Environments other than for Arc Furnace Switching

3-7

�

BREAKER MAXIMUM NO. OF NUMBER OF OPERATIONS (EACH = 1 CLOSE PLUS 1 OPEN OPERATION)

KA Rating CONTINUOUS RATING

- AMPS

OPERATIONS BEFORE SERVICING

NO-LOAD MECHANICAL CONTINUOUS CURRENT SWITCHING

INRUSH-CURRENT SWITCHING

COLUMN 1 COLUMN 2 COLUMN 3 COLUMN 4 COLUMN 5

A. Servicing consists of adjusting, cleaning, lubrication, changing parts, as recommended by the Company. The operations listed are on the basis of service in a mild environment.

B. Close and trip, no-load. E. Rated control voltage. F. Frequency of operation

not more than 20 in 10 minutes or not more than 30 in 1 hour.

G. Servicing at intervals

given in Column 2. H. No parts replacement. I. Breaker meets all

current, voltage, interrupting current ratings.

C. Close and trip within rated current, rated maximum voltage and 80% PF or greater.

E. Applies F. Applies G. Applies H. Applies I. Applies J. At the first servicing

interval, the amount of vacuum interrupter contact erosion should be used to estimate the additional life at that continued duty.

K. After 15 full short circuit

faults check the contact erosion.

D. Closing 600% of rated current or less at no less than 30% PF. Otherwise, same as C.

E. Applies F. Applies G. Applies H. Applies I. Applies J. Applies K. Applies

20-40kA All 10,000 or 10 years 10,000 minimum 10,000 10,000

50 & 63kA All 5,000 or 10 years 5,000 minimum 5,000 5,000

Table 3-3—Repetitive Duty and Maintenance Requirements forPower/Vac® Circuit Breakers Applied to Arc Furnace Switching

Circuit Breaker Selection

Breaker Rated

Maximum Voltage

(kV RMS)

Breaker Rated

Short Circuit

Current (kA RMS)

Breaker Continuous Current Rating

(Amps)

1200 2000 - 4000

Isolated-Capacitor Bank or Back-to-

Back Switching Amps

4.76 29 - 50 1200 1200

4.76 63 1200 1850 rev 8/2009

8.25 33 - 40 1200 1200

8.25 50 - 63 1200 1850 rev 8/2009

15 18 & 20 1200 120015 25 - 40 1200 1200

15 50 - 63 1200 1850 rev 8/2009

3-8

CAPACITOR SWITCHING

Capacitor banks are generally applied on bothutility and industrial power systems to improvevoltage regulation and system stability. Power/Vac circuit breakers properly equipped areapplicable as General Purpose circuit breakersfor shunt-capacitor-bank switching, or as DefinitePurpose Circuit Breakers with back-to-backcapacitor switching capabilities as listed in Table3-4.

Table 3-4 Power/Vac® Breaker Capacitor Switching Capabilities rev 8/2009

Shunt-bank capacitor switching means onebreaker feeding one 3-phase capacitor bank. Ifthis circuit is closely paralleled by another switchedcapacitor bank, the duty is considered back-to-back. These situations require evaluation of suchfactors as local high-frequency equalizing currentsflowing between the separated, switched capacitorbanks.

Footnote — The capacitor bank rating is subject to the following conditions:

1. The transient voltage from line-to-ground, shall not exceed 3 times the maximum design line-to-groundcrest voltage measured at the breaker terminals.

2. The number of re-strikes or re-ignitions shall not be limited as long as the transient voltage to grounddoes not exceed the value given in footnote 1.

3. Interrupting time shall be in accordance with the rated interrupting time of the circuit breaker.4. Maximum Capacitor Bank KVAR rating is calculated as follows:

System Voltage (kV) x Cap. Switching Current (A) x

1.25 (for ungrounded banks) or 1.35 (for grounded banks)

5. For Back-to-Back switching, the bank inrush currents are limited to 15KA at 2000hz.6. For capacitor switching requirements other than shown above, consult GE.

3

Section 3

3-9

AUTOMATIC TRANSFER

To improve system reliability and ensuresupply to critical loads, primary or secondaryselective system designs are often utilized. Inthese configurations, two or more otherwise typicalradial buses are connected together via tiebreakers. In normal operating mode, each bus isserved by it’s own source through normally closedmain breakers, with the bus tie breaker open. Ifan outage occurs on one of the incoming supplies,the incoming breaker connected to that supply isopened, and then the bus is re-energized byclosing the bus tie breaker to transfer the deadbus to the live (alternate) source. To protectagainst damage to motors connected to the deadbus, the bus tie breaker is typically not allowedto close until the residual voltage on the effectedbus has decayed to a safe level. After the lostsource has been reestablished, the schemeprovides two methods (auto and manual) to restorethe system to normal configuration. If the sourcescannot be synchronized, the bus tie breaker mustbe manually opened before the open incomer canbe manually closed. In this procedure the incomerwill only be allowed to close if the incoming source(line VT) voltage is above a ‘live’ threshold andthe load (bus VT) voltage is below a ‘dead’ thresholdvalue. If the sources are synchronized, it ispossible to manually close the open incomer withsynchcheck supervision to parallel all threebreakers; the scheme will then automatically opena breaker which had been previously selected totrip if all breakers become closed, in this instancethe bus tie breaker. Note that if momentaryparalleling is utilized, the equipment and breakersmust be rated for the total available fault currentfrom the combined sources.

The detection of a undervoltage event and theresulting transfer logic can be accomplished usingeither discrete protective relays, auxiliary relaysand timers, or with a PLC and programming, orby using the various protective relay and logicfeatures contained in today’s multifunction relays,

such as the GE Multilin SR750. In addition to aprotective relay required for each of the three circuitbreakers (both mains and the tie), it is required toconnect one contact from a three-position switch toeach breaker. This switch (device 43/10) is used toselect the breaker that will trip after all breakers areclosed. It is generally recommended that a two-position switch (device 43/83) with three contacts,be connected to each relay as an “Auto-Off” transferscheme selector.

Because a relay is required for each the threecircuit breakers, it allows bus-splitting operation.This is accomplished by setting the time overcurrentelements in the relay on the bus tie breaker to tripfaster than the incomers, opening the bus tie beforean incomer when operating from only one source.

FAST BUS TRANSFER

Fast bus transfer (FBT) is an option used whenthere is a need for transferring from a normal powersource bus to an emergency or alternate powersource upon failure of the normal source of power orvice-versa, as quickly as possible withoutparalleling, typically within a maximum of 3 cycles(50 milliseconds). It is utilized when servingessential loads such as motors and pumpapplications.

During this transfer, it is essential that bus “deadtime” be as short as possible to prevent loss ofdownstream critical auxiliary functions, such ascontactors and relays. It is important that the mainand alternate breakers are not closed at the sametime since the sources may not be synchronous oreven if they are, some short circuit conditions mayresult in the loss of both sources, if they are bothclosed at the same time. Also, when both are closedat the same time, system short circuit currents canexceed the feeder breaker rating.

Circuit Breaker Selection

3-10

In order to provide the utmost assurance that onebreaker will be open before the other is closed,accepted practice requires that the first breaker’sprimary contacts have started to open before thesecond breaker is given a closing signal. “Fast”transfer means there is no intentional time delayin the transfer of a bus or load from one source ofpower to another.

Representative timing sequences usingML-18/18H breaker mechanisms for both standardand fast bus transfer equipped breakers are shownin Figures 3-1 and 3-2.

The amount of dead bus time depends uponwhether the Power/Vac breaker is standard, or isequipped for FBT capability (provided with an early“b” (faster) contact and/or special closing coil). Abreaker “b” contact is open when the breakerprimary contacts are closed.

Fast bus transfer using Power/Vac circuitbreakers with the ML-18 or 18H mechanisms donot utilize an early “b” contact. The standard “b”contact is already sufficiently fast - approximately10 milliseconds from main contact part to “b”contact close. They are equipped with a specialclose coil, which reduces closing time to as littleas 40 milliseconds.

Power/Vac circuit breakers with an ML-17 or17H mechanism, a special early “b” contact isprovided. This “b” contact closes 3 millisecondsafter the vacuum interrupter main contacts openon the opening breaker, which initiates a closingof the second breaker. The other breaker (tie orincoming breaker) must have a special close coilthat closes the main interrupter contact inapproximately 50 milliseconds.

Typical dead times for fast bus transfer, usingstandard and special Power/Vac breakers for theML-18 mechanism are shown in Table 3-5. Fastbus transfer is only offered for 1200, 2000 and3000 ampere breakers having 125 VDC or 250VDC control voltages.

Fast bus transfer breakers must be specified whenplacing an order. Fast Bus Transfer does notrequire the use of circuit breakers rated for 3-cycle interrupting, as interruption speed doesnot impact the amount of dead bus time.

Table 3-5—Typical Dead-Times for Fast TransferUsing Power/Vac Circuit Breakers

Footnotes:(1) Control voltage at rated value.(2) Main contact parting to main contact making.(3) End of arcing to main contact making. Dead bus times noted include allowable + operational tolerances.

Nominal Dead Bus Times (Milliseconds)Trip then close using:

Power/VacBreakers

Mechanism ControlVoltage

(volts) (1)

Early “b” contact &Special closing coil

Standard “b” contactSpecial closing coil

Standard “b” contactStandard closing coil

No Arcing(2)

No Arcing(2)

No Arcing(2)

With Arcing(3)

With Arcing(3)

All RatingAll Rating

ML-17ML-18

125/250 DC125/250 DC

62 5060 48

9085

7873

With Arcing(3)

N/A N/A

N/A N/A

Section 3

Tra

nsfe

r In

itia

tion -

Energ

ize T

rip C

oil

of

Outg

oin

g B

reaker

Outg

oin

g B

reaker

Conta

cts

Part

Outg

oin

g B

reaker

Cle

ars

Incom

ing B

reaker

Conta

cts

Make

Mill

iseconds

Opening Time (35ms*)

Arching

(12ms)

(10ms)

Dead Bus Time - No Arching

(55ms*)

Dead Bus Time - With Arching

(43ms*)

Closing Time (45ms*)

Aux "

b"

Conta

ct M

akes

50 60 70 8010 20 30 40 90 100

0

Tra

nsfe

r In

itia

tion -

Energ

ize T

rip C

oil

of

Outg

oin

g B

reaker

Outg

oin

g B

reaker

Conta

cts

Part

Outg

oin

g B

reaker

Cle

ars

Incom

ing B

reaker

Conta

cts

Make

Mill

iseconds

Opening Time (35ms*)

Arching

(12ms)

Dead Bus Time - No Arching

(70ms*)

Dead Bus Time - With Arching

(58ms*)

Closing Time (60ms*)(10ms)

Aux "

b"

Conta

ct M

akes

50 60 70 8010 20 30 40 90 100

0

110

3-11

Figure 3-1ML-18/18H Transfer Timing Sequence - 5 Cycle Interrupting - Standard Close Coil

*Dead Bus and Closing Times can Vary Based on Allowable Tolerances.Opening - 32-45 ms. Closing 60 +/- 15 ms.

Figure 3-2ML-18/18H Fast Bus Transfer Timing Sequence - 5 Cycle Interrupting -

FBT Breaker with Special Close Coil

*Dead Bus and Closing Times can Vary Based on Allowable Tolerances.Opening: 32-45 ms. Closing: 22-55 ms.

Circuit Breaker Selection

3-12

SERVICE CONDITIONS

Power/Vac metalclad switchgear ratings andcapabilities are based on operation under certainspecific service conditions, defined by ANSI as“usual.” Conditions other than usual are considered“unusual” or “harsh”. Factors used to classifyservice conditions are altitude, ambienttemperature, and a variety of others, such as thepresence of atmospheric contaminants, unusualstorage conditions, and requirements for tamper-resistance. These factors are specified for circuitbreakers in ANSI-C37.04-1999 (Circuit BreakerRating Structure) and for equipment in ANSI-C37.20.2 -1999 (Metalclad Switchgear), and aresummarized here for application guidance.

Application of Power/Vac circuit breakersunder conditions other than “usual” may requiresignificant derating, special construction or use ofspecial protective features.

USUAL SERVICE CONDITIONS

Power/Vac circuit breakers (and switchgearassemblies) are suitable for operation at theirstandard nameplate ratings:

• Where ambient temperature is not above40°C or below -30°C (104° F and -22° F)

• Where the altitude is not above 1000 meters(3300 feet).

NOTE: For switchgear assemblies (breakers andhousings combined) there is one additionalstipulation:

• Where the effect of solar radiation is notsignificant. (See Ref. 5 on page 3-14.)Where radiation is significant the user isresponsible for specifying the cooling/ventilation required to limit the temperaturerise.

UNUSUAL SERVICE CONDITIONS

Abnormal Temperature

The planned use of Power/Vac circuit breakersand switchgear outside the normal ambienttemperature range (-30°C to +40°C) shall beconsidered special. Reference should be madeto ANSI C37-20.2, Table 10. Example: if installedin a 50°C ambient temperature, the switchgearcontinuous current ratings must be derated by 8%,per ANSI Table 10. Such applications of increasedtemperature should be referred to GE for evaluation.

Temperature Rise

Per the ANSIC37.20.2 standard, thetemperature rise of buses and bolted connectionsunder rated full load current in an enclosedswitchgear assembly, above the ambient airtemperature outside the enclosure, must notexceed 65°C, and the total hot spot temperaturemust not exceed 105°C. Connections to insulatedcables must not exceed a 45°C temperature rise,and a 85°C hot spot temperature when operatedat rated continuous current in rms amperes atrated frequency.

The maximum rated ambient temperature is40°C. The temperature of the air surrounding alldevices in an enclosed switchgear assembly,considered in conjunction with their standard ratingand loading as used, will not cause these devicesto exceed their maximum allowable temperaturewhen the switchgear assembly is surrounded byair at the maximum average ambient temperatureof 40°C.

The average temperature of the air surroundingprimary insulated cables in any compartment ofan enclosed switchgear assembly will not exceed65°C when the assembly is equipped with themaximum rated current devices for which it isdesigned.

Section 3

High Altitude

Medium voltage metal-clad switchgear isdesigned and tested in conformance to ANSIStandards. Inherent is these standards is the useof air as a heat transfer and dielectric medium. Inthe application of metalclad switchgear at highaltitudes, there are two characteristics whichdegrade above 1000 meters (3300ft). They are thecontinuous current rating and the dielectricwithstand capability, which may result in excessivecorona at operating voltages and an inability tooperate due to the dielectric breakdown of the airinsulation due to the reduced air density.

Power/Vac circuit breakers and switchgearassemblies utilize air for an insulating and coolingmedium. Operation at altitudes above 1000 meters(3300 ft) will result in a higher temperature rise andlower dielectric withstand capability because theair is thinner at the higher altitudes. Forapplications at higher altitudes, the rated 1 minutepower-frequency withstand voltage, the impulsewithstand voltage, and continuous current rating ofthe switchgear should be multiplied by thecorrection factors listed in Table 3-6 to obtain themodified or derated ratings.

When the Voltage Correction Factor isapplied to the maximum designed voltage rating of15 kV, 8.25kV or 4.76 kV for metal-clad switchgear,the derating may not permit the equipment to beinstalled at altitudes above 1000 meters, at theirrespective typical nominal system voltages.

Since it is more realistic to apply these correctionfactors to the BIL rating (impulse withstand voltage)of the switchgear, an industry accepted option is

to apply the equipment at their rated nominalvoltages, with no change in clearances, by theaddition of lighting arresters to protect theequipment.

The recommended practice is to apply theVoltage Correction Factor to the rated BIL level ofthe equipment, and provide surge protection onthe load side of the switchgear using station typelightning arresters (Tranquell® arresters), selectedsuch that the maximum discharge voltage of thearrester is about 20% less than the modifiedimpulse voltage rating of the switchgear. (SeeANSI C37.010-1999, 4.2.2)

The Current Correction Factor is applied tothe continuous current rating of the equipment only.It is necessary to derate the continuous currentrating, because switchgear assemblies depend onthe air for cooling and will have a higher temperaturerise when operated at altitudes above 1000 meters.The short-time and interrupting current ratings onvacuum breakers are not affected by altitude.Since the Current Correction Factor is small andthe actual continuous current duty is usually lessthan the equipment rating, current correction istypically not as serious a consideration as thevoltage correction. An additional consideration isthat often at higher altitude, the ambient is reduced,which can offset the higher altitude continuouscurrent derating effect.

NOTE: The recommendations are subject tomodification depending on the actual systemconditions.

3-13

Circuit Breaker Selection

Table 3-6Altitude Correction Factors for Power/Vac Circuit Breakers and Switchgear

Rated Continuous Current

Rating Correction Factors*

1.000.9950.9910.9870.9850.9700.9650.9600.9500.9400.935

3300ft - 1000m4000ft - 1200m5000ft - 1500m6000ft - 1500m7000ft - 2100m8000ft - 1500m9000ft - 1500m10000ft - 3000m12000ft - 3600m13000ft - 4000m14000ft - 4300m

Rated Voltage

1.000.980.950.920.890.860.830.800.750.720.70

Altitude(feet / meters)

Application of metal-clad switchgear above 1000 meters (3300 ft) should be referred to GE. It should becautioned that the correction factors of power transformers are different than those for switchgear.

Besides abnormal temperature and high altitude there are other unusual service conditions, whichmay require special protecting features or affect construction. Some of these are:

• Exposure to corrosive atmosphere, explosive fumes, excessive dust (e.g., coal dust, paper fibers)or particulate contamination, salt spray, steam, dripping water, and other similar conditions.

• Exposure to abnormal vibration, shock, unusual transportation, or special storage conditions.

• Installations accessible to the general public.

• Special duty/operating requirements of equipment.

BREAKER MOUNTED ACCESSORIES

Each Power/Vac breaker has two “a” and three“b” breaker auxiliary contacts wired from thebreaker-mounted auxiliary switch for thePurchaser’s use. Additional breaker contacts fromoptional compartment mounted switches areavailable, see Section 7.

A redundant tripping circuit on Power/Vaccircuit breakers can also be furnished via anoptional second or “dual” trip coil. This option was

3-14

designed specifically for use on utility breakersand on breakers applied in power-stationswitchgear applications. This feature is seldomused in industrial or commercial applications sincethe standard Power/Vac trip circuit is extremelyreliable.

Power/Vac circuit breakers can be providedwith an optional direct-acting undervoltage tripdevice. The undervoltage trip device is a factory

* From ANSI C37.20.2 - 1999, Table 8.

Section 3

Figure 3-3

3-15

installed unit, which is an integral part of thebreaker mechanism. Its function is to monitor thetrip circuit control voltage and to mechanically tripthe breaker if that control power drops below apreset value. (See page 4-5.) Refer to InstructionBook GEK-105393 for additional details.

Note that the options for a dual trip coil andthe undervoltage trip device are mutually exclusive.Both cannot be utilized on the same breaker.

Standard Power/Vac design uses a lift truck,for lifting and inserting/removing the circuit breakersfrom the breaker cells. For designs using only 1-high breaker arrangements, with the breakerslocated in the bottom compartments, GE offersan option for roll-in breakers. Roll-in breakers havea wheeled undercarriage bolted to the bottom ofthe breaker frame, which raises the breaker to theproper height to interface with the breaker cellconnections. The breaker cell floor frame ismodified to allow the breaker to roll directly fromthe finished floor into the cell, without the need forthe lift truck described in the following section.Note roll-in breakers cannot be inserted into a“standard” breaker cell without removing the bolt-on undercarriage, and using the lift truck.

BREAKER LIFT TRUCKS

GE offers two basic styles of lift trucks forhandling Power/Vac circuit breakers, ground andtest devices, roll-out transformer trays and fuseroll-outs. The first is a double masted truck thatis available with two swivel casters in the rear andtwo straight wheels in the front. This truck iscompatible with indoor switchgear and providedas a standard with every order. However, to reachthe top rollout drawer in an upper compartment, adifferent single masted truck is required. Thedimensions of the double masted truck carriageare width of 47 inches and a total width of 50 incheswith the winch handle installed. The depth witharms extended is 46 inches, and the standingheight is 86 inches. This style of truck cannot beused with outdoor aisle-less switchgear. SeeFigure 3-3.

The second style is a single-masted truck thatis available with all swivel casters. As shown inFigure 3-4. This truck is compatible with outdoorswitchgear and is required to reach the uppercompartment rollout on indoor equipment. Themaximum handle load is 15 lb. with a 850 lb. load.The typical dimensions of the single masted truckare width 36.5 inches, depth is 47 inches (witharms extended 55.5 inches), and the standingheight is 79.5 inches extendible to 137.5 inches.The legs at the base of the lift truck are adjustablein width from 31.5 inches to 58 inches. This allowsthe legs to be narrowed to the width of the breakerfor moving through doorways. Caution; whilelowering the breaker from the cubicle to thefloor the width of the legs must maintain aminimum width of 44 inches.

The single-mast lift truck can be collapsed forstorage. The width is 39 inches with arms andlegs collapsed, the depth is 29 inches and theheight is 77 inches.

Circuit Breaker Selection

Both style of lift trucks are provided with interlocksto retain the device being handled and to lock thelift truck to the switchgear while a device is beinginserted or removed. The carriage, which lifts adevice, is raised or lowered by means of a winchand cable. When the winch handle is releasedthe carriage is held in that position by means of aclutch-brake internal to the winch. Two arms areattached to the carriage for engaging the trackrollers on the sides of each device.

The lift trucks are functional for both theupper and lower compartments of Power/Vacprovided the equipment is mounted on nomore than a 4 inch housekeeping pad. Padcannot extend beyond the front frame of theequipment more than 3 inches.

REFERENCES

1. ANSI Standard C37.06-2000, Schedules ofPreferred Ratings and Related RequiredCapabilities for AC High Voltage CircuitBreakers Rated on a SymmetricalCurrentBasis.

2. ANSI Standard C37.010-1999, ApplicationGuide for AC High Voltage Circuit Breakers.

3. ANSI Standard C37.04-1999, Circuit BreakerRating Structure.

4. ANSI Standard C37.20.2-1999, MetalcladSwitchgear Assemblies.

5. ANSI Standard C37.24-1986, Guide forEvaluating the Effect of Solar Radiation onOutdoor Metalclad Switchgear.

6. ANSI Standard C37.100-1992 Definitions forPower Switchgear.

7. Power/Vac Manual Ground and TestDevice Instruction Book, GEK-39686.

8. Power/Vac Electrical Ground and TestDevice Instruction Book, GEK-39684.

9. Power/Vac Circuit Breakers using ML-17Mechanism, GEK-39671.

10. Power/Vac Circuit Breakers using ML-18/18HMechanism, GEK-86132.

11. Power/Vac Breaker Lift Truck, GEK-90214

3-16

Figure 3-4

Recommended minimum working accessrequirements for the lift trucks of indoor switchgearis a 78 inch front aisle space with an 18 inch rightside and a 12 inch left side clearance. Outdoorswitchgear requires a 66 inch front aisle spacewith a 36 inch left side and a 18 inch right sideclearance required as standard minimum space.Smaller front aisles may be used if the requiredright side space is available but the factory mustbe consulted for an engineering evaluation.

Consult Instruction Book GEK-90214 foradditional information on Lift Truck models anduse.