Characterization of titania hydrosol and its influence on light fastness of polyester fabric

Transcript of Characterization of titania hydrosol and its influence on light fastness of polyester fabric

Procedia Engineering 18 (2011) 307 – 311

1877-7058 © 2011 Published by Elsevier Ltd.doi:10.1016/j.proeng.2011.11.048

Available online at www.sciencedirect.com

Available online at www.sciencedirect.com

Procedia

Engineering Procedia Engineering 00 (2011) 000–000

www.elsevier.com/locate/procedia

The Second SREE Conference on Chemical Engineering

Characterization of titania hydrosol and its influence on light fastness of polyester fabric

Ran Wanga*, Yanqiu Wangb, a* aSchool of Material Science and Engineering, Beijing Institute of Fashion Technology, Beijing 100029, China

bSchool of Science, Hebei University of Science & Technology, Shijiazhuang 050018, China

Abstract

A titania hydrosol was prepared by a sol-gel method to enhance the light fastness of PET fabric, in which tetrabutyl titanate (TTB) was used as precursor. The sol and its gel were characterized by photo correlation spectroscopy (PCS), digital camera, FT-IR, and XRD, respectively. The size of nanoparticles in the sol was all not more than 6.0 nm and distributed uniformly. The nano-sol has good transparent property. Alkoxy groups linked with Ti atoms hydrolyze completely. The crystallization of formed titania gel is anatase. Light fastness of dyed polyester fabrics improves significantly. © 2010 Published by Elsevier Ltd. Selection and/or peer-review under responsibility of Society for Resources, Environment and Engineering Keywords: light fastness; Polyester fabric; titanium hydrosol

1. Introduction

Light fastness improvement of polyester fabrics has been to be a subject of great interest in textile industry since the fabrics are widely used in automobile coloured upholstery and are exposed to direct sunlight and temperature above 50oC [1]. Researches show that the light-induced fading of dyes in the presence of air usually entails oxidation and such photo-oxidation reactions [2,3]. Those reactions of dyes are generally considered to occur on exposure to UV radiation and prevented by the addition of UV absorbers or antioxidants. As to antioxidants, relatively few chemical classes are effective. Thus, lots of organic UV-absorbers were used in the dyeing of polyester fabrics with disperse dyes [1-4]. Those indeed

* Corresponding author. Tel.: +86-01-6428 8274; fax: +86-01-6428 8274. E-mail address: [email protected].

308 Ran Wang and Yanqiu Wang / Procedia Engineering 18 (2011) 307 – 3112 Author name / Procedia Engineering 00 (2011) 000–000

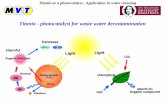

provided an enhanced photochemical stability. In fact, nano-titania is an effective UV-absorber and can be prepared easily. Especially, titania sols are able to form well-adhering transparent oxide layers on textiles. Therefore, much work on TiO2 sols has been reported on preparation, UV-resistance properties and thermal stabilities in recent years [5-7]. In our previous paper, the influence of a titania nanosol on the light fastness of reactive dyes was examined on the lightweight cotton fabric [8]. It was found that the titania coating is a good ultraviolet radiation (UVR) protection for the treated fabric, especially in the range of 200-315nm.

In this study, a titania nanosol was prepared by the sol-gel method using tetrabutyl titanate (TTB) as precursors. The sol and its gel were characterized by photo correlation spectroscopy (PCS), digital camera, FT-IR, and XRD, respectively. Polyester fabrics, dyed with three disperse dyes of low light fastness, respectively, were treated with the sol by a dipping-padding process. Changes of fabrics light fastness were investigated.

2. Experimental

2.1. Materials

A commercial polyester fabric (133g/m2) was used in this study. Tetrabutyl titanate (TTB) was purchased from Shanghai Chemical Reagent Co. Ltd, Shanghai, China. All reagents were used without purification.

2.2. Preparation of sol

The mixture of H2O/TTB was agitated under acidic condition. The titanium hydrosol was thus obtained. The reaction is represented by:

Ti(OC4H9)4

H+

+ H2O Ti(OH)4 + C4H9OH4 (1)

2.3. Sol-gel treatment

The polyester fabric samples were dip-and-nipped twice in the TiO2 sol with a pick up of 70%. The treated samples were dried at 80°C for 3 min and then rinsed with distilled water to remove excessive acid to avoid the damage of fabric when heated at higher temperature. Subsequently, the samples were cured at 140°C for 3 min.

2.4. Characterization

The size of particles in the sol was measured by Zetasizer Nano 300 (Malvern, UK) (PCS). The crystallization of TiO2 heated at 140℃ for 2h and ground to powders was investigated by X-ray diffraction (XRD) with a diffractometer (D/max-RA model, Rigaku, Tokyo, Japan) employing Cu Kα radiation. The FT-IR spectra of the samples (gel powder, KBr pellets) were recorded using a NEXUS-670 spectrometer (Nicolet, U.S.). The IR spectra were collected using 32 scans at 2 cm-1 spectral resolution

309Ran Wang and Yanqiu Wang / Procedia Engineering 18 (2011) 307 – 311 Author name / Procedia Engineering 00 (2011) 000–000 3

between 400 and 4000 cm-1. Light fastness tests were carried out according to ISO 105/BS 1006: 1992 B02 in a XENOTEST 150S + (Atlas, US) apparatus with a Xenon lamp.

3. Result and discussion

The dimension dispersion of the formed titanium hydrosol by Nanosizer is shown in Fig.1, where the x-axis is the tested diameter of hydrosol (nm), and the y-axis is the corresponding number percentage (%). It was observed that the size of nanoparticles in the sol was all not more than 6.0 nm and distributed uniformly. As a consequence of small particles sizes, the nano-sol revealed transparent property which was confirmed by its camera photo (Fig. 2).

0 1 2 3 4 5 6 7 8 9 1005

101520253035

Num

ber (

%)

Diameter (nm)

Fig.1 Particle size distributions of the titania sol

Fig.2 Optical characteristics of the titania sol

310 Ran Wang and Yanqiu Wang / Procedia Engineering 18 (2011) 307 – 3114 Author name / Procedia Engineering 00 (2011) 000–000

Fig.3 shows FT-IR spectra of powders of gels which were dried at 120oC for 1 h in air. The absorption

peaks at 551 cm-1 and 746 cm-1 are attributed to stretch vibration of Ti-O. The 1205 cm-1 band assigned to Ti-O-C is not observed. It indicates that alkoxy groups linked with Ti atoms hydrolyze completely.

4000 3500 3000 2500 2000 1500 1000 500Wavenumber (cm-1)

Inte

nsity

Fig. 3 FT-IR spectra (KBr pellets) of the titania gel

In order to establish a possible crystallization of titania prepared by sol-gel process, XRD analysis was

carried out on TiO2 powder heated at 120℃ which conformed to the curing temperature of fabrics. Typical diffraction pattern obtained from samples is shown in Fig. 4. The XRD peaks at 25.3o, o, o, and o correspond to anatase (1 0 1), (0 0 4), (2 0 0), and (1 0 5) crystal planes, respectively, while no rutile phases are observed.

10 20 30 40 50 60

(105

)

(200

)

(004

)

2θ/ o

Inte

nsity

(101

)

Fig.4 X-ray diffraction pattern of the TiO2 gel

The light fastness of the treated fabric was evaluated according to the ISO 105-B02: 1994. As shown

in Table 1, after the sol-gel treatment, light fastness of dyed fabrics improves significantly. Tensile

311Ran Wang and Yanqiu Wang / Procedia Engineering 18 (2011) 307 – 311 Author name / Procedia Engineering 00 (2011) 000–000 5

strength of fabric was also tested in the Table 1. It can be seen that the tensile strength changed a little, which illustrates that the sol-gel treatment has no affect on the mechanical property of the fabric.

Table 1 Influence of titania hydrosol on light fastness and tensile strength of polyester fabric

Fron Blue RD-E Fron Red RD-S Fron Pink S-WF

Before treatment

After treatment

Before treatment

After treatment

Before treatment

After treatment

Light Fastness(grade) 4 6 4 6 3 5.5

Tensile Strength (N) 1103.0 1121.8 1103.0 1119.8 1103.0 1120.2

4. Conclusions

A titania nanosol was prepared by a sol-gel method. The size of nanoparticles in the sol was all not more than 6.0 nm and distributed uniformly. Therefore, the sol has good transparent property. FT-IR spectrum depicts that alkoxy groups linked with Ti atoms hydrolyze completely and Ti-O-Ti bonds formed. The crystallization of TiO2 heated at 140℃which conformed to the curing temperature of fabrics is anatase. The gel shows very good ultraviolet radiation (UVR) protection for the treated fabric and little influence on the tensile strength.

Acknowledgement

This work was financially supported by Beijing Municipal Commission of Education, No. KM201110012003.

References

[1] Tsatsaroni EG, Eleftheriadis IC. UV-absorbers in the dyeing of polyester with disperse dyes. Dyes and Pigments 2004;61:141-7.

[2] Hironori Oda. An approach to the photostabilization of dyes: the effct of UV absorbers containing a built-in photostabilizer moiety on the light fastness of acid dyes. Dyes and Pigments 2001;48:151-7.

[3]Daniela Cristea, GerardVilarem. Improving light fastness of natural dyes on cotton yarn. Dyes and Pigments 2006;70:238-45. [4]Hironori Oda. Photostabilization of organic thermochromic pigments: Action of benzotriazole type UV absorbers bearing an

amphoteric counter-ion moiety on the light fastness of color formers. Dyes and Pigments 2008;76:270-6. [5] Peng Xu, Xiaoyan Liu, Wei Wang, Shuilin Chen. Improving the antibacterial and UV-resistant properties of cotton by the

titanium hydrosol treatment. Journal of Applied Polymer Science 2006;102: 1478-82. [6] Noureddine Abidi, Eric Hequet, Sowmitri Tarimala, Lenore L. Dai. Cotton fabric surface modication for improved UV

radiation protection using sol-gel process. Journal of Applied Polymer Science 2007;104:111-7. [7] Daoud WA, Xin JH. Low temperature sol-gel processed photocatalytic titania coating. Journal of Sol-Gel Science and

Technology 2004; 29:25-9. [8]Ran Wang. Enhancement of light fastness of cotton fabric treated with Titania sol. Proceedings of 2009 International

Conference on Advanced Fibers and Polymer Materials Shanghai, 2009.