Chapter Six Constructing the Wall Collector - Build-It-Solar · Chapter Six Constructing the Wall...

Transcript of Chapter Six Constructing the Wall Collector - Build-It-Solar · Chapter Six Constructing the Wall...

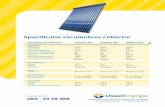

111

Chapter SixConstructing the Wall Collector

IntroductionA wall collector has several advantages over a

roof collector. First, since it is close to theground, it is accessible by staging. It is easierto build. Second, during the heating season thevertical collector can gain from sunl ight reflectedfrom snow on the ground, or 1ight colored gravel ifthere is no snow. The double glazed system meansbetter performance than a single glazed system, sothe collector square footage can be smaller, yetgather the same amount of heat. Third, since thesummer sun is higher than the winter sun, much of thesunl ight will be reflected off the glazing (ratherthan passing through it), resulting in lower stagna-tion temperatures. This means the power venting modein the summer can be el iminated, saving money not onlyin installation costs, but also in the annual opera-ting costs.

The instructions on how to build the MODEL-TEAwall collector are meant for those persons famil iarwith wood frame construction -- skilled contractors,carpenters, or owner-builders. The key word is skill-- the ability to perform the tasks, based on workingknowledge gained from carpentry experience. Themore experience, the easier these instructions wil Ibe to follow.

This chapter, plus Chapter Seven on Constructing

112 CONSTRUCTING THE WALL COLLECTOR

the Rock Bin (if there will be remote storage), andChapter Eight on the MODEL-TEA System Control Wiring,should all be read through thoroughly. This should bedone before beginning to order materials, and beforebeginning any stages of construction.

The experienced carpenter will have most of thetools necessary to bui ld this collector, but may haveto borrow or rent a few of the special ones. Among thetools needed are:

hammer, screwdriver, tapes, pI iers, tinsnips, etc.

plumb bob, levels, chalk 1ine, caulking gun,staple gun

Hand saws, circular saw, table saw, sabresaw (optional~ soldering iron (optional),paint sprayer, route~ power screwdriver orvariable speed/reversible dri 11

The MODEL-TEA can be bui It into new constructionor retrofitted into existing buildings. The instruc-tions are directed toward new construction, with in-dented sections if there are additional special in-structions for retrofit.

Figure 6.1

www.BuildItSolar.com for more projects

I l3

RETROFIT: The instructions for re-trofit begin with the word RETROFIT, andare indented to set them apart from thenormal instructions. These indented sec-tions must be read by those who are re-trofi tt ing the MODEL-TEA, and can beskipped by those building into new con-struction.

The collector will either be connected to remotestorage, or be connected directly to a 1iving space.The drawings and instructions assume that ducts willconnect to the bottom of the manifold pans (see walldrawing no. 2, detail 4); the ducts running to remotestorage or to a 1iving space. The duct "co llar s"penetrate the floor and connect to the manifold panslocated in the wall cavities at either end of thecollector. This floor could be the first floor, withthe ducts runn ing into the basement where the remotestorage is located. Or this floor could be the secondfloor of a two story house, with the ducts runningabove the first floor ceiling, connecting the collec-tor to the 1iving space. Another option is for thecollector to be on the wall of the first floor, butconnect the duct collars to the tops of the manifoldpans. Again the ducts could be run in the secondfloor. If the wall the collector is built into sitson a slab, the duct collars can either enter at thetop of the manifold pans, or enter through the backof the pans. In the latter case, the ducts wi 11 in-trude upon the Iiving space, and will have to beboxed in and finished to match the space. These ductscan either run across the floor or across or into thecei 1ing.

There are many variations which can be made, de-pending on the site, the location in relation toliving spaces, framing, or even personal taste. Ifmaking a change to the collector, think the changesall the way through, and mark those changes on thedrawings before beginning the constructing process.

Before installing the col lector on the wall,certain calculations must be done, and decisionsmust be reached. First, the system must be sizedaccording to the percentage of the heating load it [sto provide. This should be done using the rules ofthumb in Section 4.I, resulting in a square foot area

114. CONSTRUCTING THE WALL COLLECTOR

for the collector.

Second, the size of the glazing must be select-ed to fit the square foot size of the collector, and tofit on the wall. The glass comes in two standard sizes(in inches): 34 x 76 and 46 x 96. In conjunction withthe CY/RO Universal Glazing System, you must al low 3/4in. between each sheet of glass, plus an additional3-1/4 in. for the sides (or top and bottom, not includ-ing the cant strip or the sill), plus the width orheight of the glass itself. Use the following formulasto calculate the width and height of the col lector:

Collector width in inches = (glass width ininches x no. of panels) + (3/4 x no. ofpanels) + 2:t in.

Collector height in inches = (glass panelheight in inches) + 3~ in.

For example if the collector were to be glazedwith four panels of 46 in. wide glass side-by-side, thecollector would be:

If the collector were to be glazed verticallywith one panel of 96 in. high glass, the collectorwould be:

,(96 x I) + 3~ = 9%" 0 r 8 I -8~" .

Although it is possible to bui ld a two storycollector, the drawings only show a one story highcollector. We recommend building the two collectorsas separately manifolded units, or inserting a ductconnection (much Iike the duct collar detail des-cribed in Section 6,2 and on wall drawing number 2)the floors as shown in the sketch below. Support isneeded across the bottom of each pane of glass, andthat support must have setting blocks and weep holes(see sketch).

Compare the calculated width to the width of thespace the collector is to fit into. A minimum dis~tance should be left between the side of the collectorand the end of the wall to allow for the intersect ion

www.BuildItSolar.com for more projects

115

Figure 6.2 vertical Section of Two Story Wall Collectorat Intersection with Floor

of the east or west wal I with the south wall. Allowapproximately 9 inches above the collector for the cantset and flashing.

Third, determine the number of manifold pans thatwill be needed, and their size. Inan average widthcollector (about 24 feet wide) there are two manifoldpans built into the wall: one to supply cool air tothe collector, and one to take the hot air away. Themanifold pan which is closest to the remote storage,or living area to be heated, will be the return pan.The shorter the duct run, the less the heat loss. Itis next to this pan that the temperature sensors (dis-cussed below) will be located. The maximum distance

116 CONSTRUCTING THE WALL COLLECTOR

between the outsides of the supply and return manifoldpans should be 26 feet. If the collector is longer thanthis, additional manifold pans must be introduced atthe center-line of the col lector. The two manifoldpans at the sides of the collector will be the supplypans, and the two at the center of the collector willbe the return pans. In this case, the temperature sen-sors (discussed below) will be located next to one ofthe center pans.

The size of the manifold pans depends on thearea of the col lector. Section 4.1 discusses how tosize the manifold pans. Two things must be remem-bered when sizing the pans for a wall collector. One,the actual depth of the pan in a 2x6 stud wall will be4-3/4 inches, and in a 2x4 wall it will be 2-3/4 inches.This dimension all~ws for the 3/4 inch thick insulationthat is located between the back of the manifold pansand the interior face of the studs. The second thingto remember is that the area of the collector used inthe calculations is the area between manifold pans.If there is one supply and one return manifold pan,the area used in the calculations is the full area ofthe collector. If there are two supply pans and tworeturn pans, then the area used in the calculationswill be half the actual area of the collector.

The dimensions arrived at in Section 4.1 will bethe inside dimensions of the pans. Allow for thethickness of the pan material itself when determiningthe actual "manifold pan width" used so often lateron.

Fourth, determine the width of the rib on theindustrial siding used as the absorber plate (seeSection 6.5). If the collector is less than 16 feetwide, the 4 in. rib should be used. If the collectoris equal to or greater than 16 feet, the rib shouldbe 8 inches. The 4 in. rib comes in sheets that are45-5/8 in. wide, with an "actual coverage" of 44 in.(the sheets are overlapped when put together). The 8in. rib comes in sheets that are 49-5/8 in. wide, withan "actual coverage" of 48 inches.

Fifth, decide whether the system wil] have re-mote storage or not, and if it will have a domestichot water (DHW) pre-heating system. If the collec-tor is connected directly to the living space without

www.BuildItSolar.com for more projects

117

using remote storage, it is called a "Daytime System,"These systems will have a relatively small collectorarea (less than 200 square feet), and the domestichot water pre-heating mode will probably not be in-cluded, because .it wouldn't be cost effective. Thismeans that only one temperature sensor will be connec-ted in the collector. If there is a domestic hotwater pre-heating system, there will be two sensorsconnected to the plate. These sensors wTTT be locatednear the return manifold, as discussed above.

It is very important to remember that unless thepieces are put together very ca refu 11y, the g l.ass pan-els will not fit into the spaces allotted for them.There is a 1/4 in. gap (shown on the drawings andcal led for in the instructions) around each panel ofglass. This is vital to al low space for the glassto expand. If it is not allotted, the glass wi 11crack. Therefore, be absolutely sure that all dimen-sions are correct, and that all blocking is square.The constant use of a plumb bob and 1ine level ishighly recommended. Check at the end of each stepthat the materials put on in that step are square and1evel .

Go through the drawings step-by-step with theinstructions, until everything is clear. The draw-ings are not meant to be used without the instructions,nor are the instructions meant to be used without thedrawings. Make notes on the drawings of those thingsthat are changed due to site conditions. Write in theactual dimensions found above. Determine how much ofeach material needs to be ordered, and order throughthe manufacturers found in Appendix A.2, and in thesequence described in Section 4.4, Purchasing Materialsand Schedul ing Construction. Read through the des-criptions in Appendix A.l to become familiar with thematerials. Such things as which types of caulk shouldbe used with which type of joint are discussed there.

The following step-by-step instructions arekeyed to the construction drawings at the end of thechapter. Each construction step has a key number, anda corresponding key sketch in the margin where thestep begins. Each construction step also has a corres-ponding drawing with the same key number, and the samekey sketch in the upper right hand drawing of the page.

118 CONSTRUCTING THE WALL COLLECTOR

--- ....••.

~ r-I ~

\ J= '--,

""""./

As you read each section, you will be asked torefer to details on the construction drawings. Forexample, you might see (3-w6) at the end of a sentence.This would mean, refer to Detail 3, on Wall Collectordrawing number 6. Turn to Wall Col lector drawing num-ber 6, and you wi II see a number 6 in the upper righthand corner with the word "WALL" below it . The keysketch is there, as well as the title of the page andthe step: BATTENS. As you refer back and forth frominstructions to drawings look for these four things:the drawing number, the word WALL, the key sketch andthe title of the page. It is important that the in-structions and the drawings are used together.

6.1 Framing

The framing doubles as a wall of the house andas the foundation of the MODEL-TEA collector (I-WI).The outer-manifold studs mark where the sides of thecol lector will be attached, and the horizontal blockingmarks where the top and bottom wi 11 be attached. It isimportant to note that the studs be plumb (use a plumbbob to check) and the horizontal blocking be level(use a level) for the collector perimeters to start outsquare.

The manifold bays will house the manifold pans(2, 3-WI), so be sure they are a little wider than theoutside manifold pan dimension. The insulation be-tween the headers over the pan will help reduce heatloss directly through the wood (3-RI). The slot cutthrough the shoe plate and the subfloor is for the ductcollar insert that will be attached to the pan. Thelnsu la t ion below it will help reduce heat loss from theduct collar to the outside.

STUDS: Layout the 2x6 (nominal) wall plates(top and shoe) side by side, and mark across bothwhere the center-I ine of the center stud. The twoouter-most studs under the side edges of the collectorwill be the "outside collector studs." To locate thesetwo studs, divide the total width of the collector inhalf, subtract 1-1/4 inch, and measure out this dis-tance to each side of the center-I ine of the centerstud. Mark the center-l ines of the two outer col lector

www.BuildItSolar.com for more projects

119

studs at these points. Mark the center~line of onestud, which will be flush inside each of the collectorstuds. These wi 11 be the "outer manifold studs"(2-Wl). The distance from center-line to center-l ineof the studs is the same as the distance from outsideedge to outside edge, or inside edge to inside edge.

The next studs to the inside of these will be the"inner manifold st uds ;!' Add 3 in. to the outside mani-fold pan width, determined in Section 4.1, and measurein this distance from the center-l ines of the outermanifold studs. Mark the center-l ines of the innermanifolds studs here. The sp~ce between the outer andinner manifold studs is the "manifold bay." This spacemust be as wide, or wider, than the outer dimension ofthe manifold pan (not including the nail ing flanges).

If the manifold bay (pan) width plus 1-1/2 inchesis greater than 24 inches on center, double the innermanifold stud, outside the manifold bay. These manifoldbays will have to be framed with headers, whose sizesdepend on the width of the bay. Use Table 6.1 to deter-mine the size header needed (1, 3-Wl).

Table 6.1 Header Sizes for Loads and Spans

SIZE LOAD/SPAN

two headers on edge two floors and roof one floor and roof roof only

2x4 2 ft. 3 ft. 4 ft.2x6 4 5 6

If the collector width is great enough towarrant inner manifold pans (greater than 26 ft.),mark manifold bays to each side of the center stud,as described above. If the manifold bay width isgreater that 24 in. on center, triple the center stud,and double the outer manifold studs outside the mani~fold bays.

Layout the glazing studs from the center-l ine ofthe collector, at a distance on center equal to theglazing width plus 3/4 inch. Mark the center-l ine onthe plates. Fill in with studs between the glazing

120 CONSTRUCTING THE WALL COLLECTOR

studs, so that no distance will be greater than 24 in.on center, except in the manifold bays (I-WI).

Frame the 2x6 nominal studs between the twoplates, on the center-lines marked, with 10d commonnails. Fasten the headers (with 2-1/2 in. of rigidinsulation and blocking in between them) over themanifold studs (3-wl). Tip the wall into place,brace and plumb.

RETROFIT: IMPORTANT: Turn off theelectricity feeding to the south wall.Remove the siding 'in the general areawhere the collector is to be. Layout theperimeter lines of the collector on thesheathing, using a line level and a plumbbob. Check the diagonals to be sure the1ines are square. The width and heightwill be the full collector width and height.

Mark the center-l ine of the collectorwidth on the sheathing, at a point 4 in.above and below the perimeter lines.Measure the width of the manifold pans plus4-1/4 inches in from the side lines. Snaptwo vertical chalk lines at these points,parallel with the side lines. Set a cir-cular saw to the depth of the sheathing,cut down the four side 1ines, and acrossthe manifold width at the top and bottombetween each pair of side lines. Removethe sheathing between the side lines.Remove anything within these spaces, in-cluding studs, blocking, insulation,electrical wires or boxes.

If the sheathing is uneven, removeall of it within the collector perimeterchalk lines. An uneven surface couldcause the Thermo-ply to buckle and latercause problems with the air flow throughthe collector.

If the collector is long enough tohave center manifolds, snap a chalk linedown the center 1ine of the collector.Snap one 1ine to each side of it, at adistance of the manifold pan width plus 3

www.BuildItSolar.com for more projects

121

inches. (If the manifold pan width plus3 inches is greater than 24 inches, measureover an additional 1-1/2 in. for ah addi·tional stud.)

BLOCKING: The location of the collector vertical-lyon the wall depends on the height of the glazingbeing used and the sill to header height of the wall.Looking at (3-WS), and the relationship between thetop and bottom of the absorber plate to the manifoldpan, the collector can move up or down on the wall.But the top and bottom rib of the absorber plate mustbe overlapped at least S in. over the manifold pans.If either full rib width [s above or below the mani-fold pan, air will not be able to enter the spacebehind the rib, and this part of the collector will bewasted. The drawings show the vertical layout based onthe bottom 1imit of the collector being the top of theshoe plate. This can be varied by moving the col lectordown on the wall (as long as continuous blocking issupplied across the top as a fastener base), or upon the wall (as long as continuous blocking is suppliedacross the bottom as a fastener base).

Layout the locations of the top and bottom ofthe collector vertically on the wall, using the actualheight of the collector found in the introduction.Snap a chalk line across the studs at these points.Snap another chalk 1ine horizontally across the studs,2-1/2 in. inside the top and bottom of the collector.These 1ines are the upper and lower boundaries of thecollector sheathing and the absorber plate. Theremust be solid continuous blocking across the top of thecollector (whether actual blocking, plates or headers),from a point 1-1/2 in. above, to a point 3-1/2 in.below, the top of the collector. There must also besol id continuous blocking across the bottom of thecollector (whether actual blocking, plates or headers),from a point 3-1/4 in. above, to a point 3 in. below,the bottom of the collector (3-Wl).

The line chalked 2-1/2 in. inside the bottomboundary will be the center-line of the lowest hori-zontal 2x6 nominal blocking, shown as the shoe plateon the drawings (2-W1). This blocking will be in acontinuous straight 1ine from one outer manifold studto the other. Since the blocking will not be staggered,toe-nail the blocking at one end. Make sure the 1-1/2

122 CONSTRUCTING THE WALL COLLECTOR

in. face of the blocking is flush with the outer faceof the studs. Fasten a 2x4 (nominal) continuous 1ineof blocking below the 2x6 (nominal), with its 3-1/2 in.face flush with the outer face of the studs if there isno blocking there already,

Measure from the center-l ine of the 2x6 (nominal)blocking a distance equal to the "coverage" width ofindustrial sheet siding that will be used as the absor-ber plate. Fasten the center-line of a line of 2x4(nominal) blocking here, with its 3-1/2 in. faceflush with the outer face of the studs. Again, theblocking joints will not be staggered, so toe-nailone end. Do not fasten this blocking in the manifoldbays. Continue this blocking up the face of the studswith the on-center distance equal to the width of theabsorber plate sheets, until the top of the collectoris reached. Block behind the top of the collector froma point 1-1/2 in. above it to a point 3-1/2 below it(3-wl) .

A slot must be cut (for the duct collars,Section 6.2) in the manifold bays through the bottom2x6 (nominal) blocking and/or shoe plate. Cut the2 in. wide slot, 2-1/2 in. back from the outer faceof the studs, from manifold stud to manifold stud.Make the cut through the sub-floor as we 11 (2, 3-Wl).Fit 1 in. thick pieces of rigid fiberglass against theband joist below the manifold bays. This will lessenthe heat loss from the duct connection. If the lowestpiece of 2x6 (nominal) blocking is above the shoe plate,fit insulation between that blocking and the shoe plate.

If the wall is built on a slab, the duct collarentrance (4-W2) must be made through the inside surfaceof the wall rather than through the floor. The ductcollar would be attached on one end to the back side ofthe manifold pan, and on the other to a duct that wouldrun against the wall. The duct would have to befinished to match the finish of the living space, orinsulated if it is in a util ity space.

RETROFIT: Carefully cut slots in theplates within the manifold bays, 3/4 in,back from the front face of the studs. Becareful to leave 3/4 in. of shoe plate infront and in black of the slot. Carefullychisel away 3/4 in. of the band joist width

www.BuildItSolar.com for more projects

below the slot.

123

6.2 Manifold Pans

The purpose of the manifold pans is to distributeair the full height of the collector. The supply andreturn ducts are connected to the manifold pans. Theair from the supply duct flows through the duct collar( 4-W2) and fills the manifold pan, supplying the airto the full height of the col rector. At the returnmanifold side, the hot air from behind the absorberplate will first fill the return manifold pan, and thenbe drawn away by the duct collar at the bottom of thepan. The duct collars must be connected to the mani-fold pans with an air-tight seal, or leakage will occur,and performance will be lost.

Prefabricate the manifold pans and duct collarinserts to the dimensions determined in Section 4.1.Have them made of 30 gauge galvanized sheet metal,with 1-1/2 in. nail ing flanges. Overlap the horizon-tal corners over the vertical corners. Solder alljoints and all overlaps.

Soldering the ,-,..•ct: Collar to the Manifold Pan

124 CONSTRUCTING THE WALL COLLECTOR

Decide which manifold will be closest to thestorage rock bin. Make the return duct connectionopening in that manifold pan, so that the duct runwill be the shortest possible to storage. The ductconnection opening and duct collar should be sizedaccording to Section 4.1. If there are four manifolds,the return duct connection should be in the two innermanifold bays, and the supply duct connections in thetwo outer manifold bays.

Place the manifold pans into the manifold bays,with the nailing flanges over the studs. Fasten thepans with I in. galvanized rooffng nails at 6 in. oncenter around the nailing flanges (3, 4-W2).

There are two ways to fasten the duct collarinserts to the manifold pans. One is to drop theinserts into the pans, and solder the insert to thepan. The other is to lay a 1/4 in. continuous beadof caulk around the duct connection openings insidethe manifold pans, and drop the duct collar insertsinto the openings (2, 3-R2). Fasten with #6xl/4 in.Phillips pan head sheet metal screws at 6 fn. on center.

Cut two pieces of 3/4 in. thick rigid fiberglassinsulation measured to fit behind each manifold pan.Cut them just big enough to fit snugly behind the pansand wedge them in place.

RETROFIT: If the room behind thecollector is finished, the piece of 3/4 in.thick fiberglass insulation that will fitbehind the manifold pan must be placed inthe manifold bay before the pan is. Cutthe piece just big enough that it will fitsnugly in the bay. Wedge it into the backof the manifold bay, and place the manifoldpan in front of it.

6.3 Sheathing

The air from the supply manifold pan flowsthrough slots cut in the collector sheathing (I-W3).The air flows across the face of the collector, betweenthe sheathing and the absorber plate. Therefore, the

www.BuildItSolar.com for more projects

125

seams between the sheathing must be air-tight, to keepthe air from leaking through the back of the collector.For the same reason, the edge of the collector sheath-ing and the roof sheathing must be air-tight. This isaccompl ished with caulk, but also with support fromstuds and horizontal blocking. Caulk is also appliedaround the nailing flanges of the manifold pans, sothat air cannot leak between the pans and the sheathing.

THERMO-PLY COLLECTOR SHEATHING: Thermo-plysuper strength (Blue) sheathing, 1/8 in. foil-facedstructurallinsulative sheathing, is shown as the collec-tor sheathing on the drawings. (See Appendix A.)

It is important that the four edges of the sheath-ing be supported be either blocking or the studs, hori-zontally and vertically. This is for ~tructural reasons,and to minimize air leakage between the sheets of sheath-ing and the back of the collector.

The collector sheathing will run horizontallyfrom the outside edge of one outer manifold stud tothe outside edge of the other, and vertically from thecenter-l ine of the bottom 2x6 (nominal) to a pointabove it equal to the height of the glazing minus 1inch. Fasten with 1 in. galvanized roofing nails or7/16 in. crown divergent staples at 4 inches on centeraround the panel edges, and 8 inches on center at theintermediate supports. Run a continuous bead of caulkalong the edge of each sheet before butting the edge ofanother against it. Begin fastening the sheets from thecenter-l ine of the collector. If the collector hascenter manifolds, cut manifold slots in the sheet toeach side of the center stud, before mounting thesheets on the wall. Use a plumb bob to make sure thatthe sheets are being fastened vertically.

Cut the sheets so that the edges fall over thestuds or over the blocking. Measure and cut the widthsof the two end sheets, but cut the manifold slots inthem before mounting on the wall. Apply a 1/4 in.continuous bead of urethane caulk around the edge ofthe manifold pan nailing flanges just before layinga sheet of Thermo-ply over them (3-A3). It is vitalnot to apply this caulk until you are ready to lay asheet of sheathing over it. The caulk will hardenquickly, especially on hot sunny days, and must bereplaced if it skins over before the sheathing goeson. (See Appendix A for urethane caulk recommendations.)

126 CONSTRUCTING THE WALL COLLECTOR

MANIFOLD SLOTS: Cut manifold slots in those sheetsof Thermo-ply that will layover manifold pans. Theslots are cut in the pattern called out sa that everyrib in the absorber plate will be fed air from the mani-fold pan. Measure in 3 in. from the outside of thesheet and snap a chalk line parallel to the side andrunn ing the 1ength of the sheet. If the co 11ector hascenter manifolds, cut manifold slots in the two sheetsthat will go over the manifolds, treating the sidea long the co 11ector center-l ine as the "out s Ide" of thesheet. Snap three more lines, parallel to the firstand spaced 3 in. apart. Beginning at the center-lineof the sheet and working first up and then down fromit, mark the following 1ines between the pair of chalklines closest to the edge of the sheet: 4-1/2 inches,S inches, 9 inches, 8 inches, 9 inches.

Cutting the Manifold Slots

www.BuildItSolar.com for more projects

127

Beginning again at the center-line of the sheet and work-ing first up and then down from it, mark the fol lowinglines between the pair of chalk lines furthest fromthe edge of the sheet: 4 inches, 9 inches, 8 inches,9 inches, 8 inches. Mark one 1ine 2 in. inside the topand bottom edge of the Thermo-ply (2-W3). With a sabresaw or util ity knife, carefully cut out the rectanglesthat measure 3 in. by 9 inches, and the odd shapedrectangle at the top and the bottom of the inner set.repeat this process on the other end sheet of sheathing(and the center sheets, if there are center manifolds),and fasten them to the wall, as described in the sectionabove (1, 3-W3).

Thermo-Ply Sheathing with Manifold Slots

In the sheet of Thermo-ply over the return mani-fold (the manifold closest to storage). drill one 1/8 in.diameter hole for every temperature sensor to be used(I-W3). These holes will be I[ned up with the innermanifold slots, beginning with the bottom slot, onehole per slot. They should be located horizontally ata distance in from the side of the collector (or fromthe collector center-l ine, if the center manifolds are

128 CONSTRUCTING THE WALL COLLECTOR

return manifolds) equal to the manifold pan plus 4inches. These holes are for the wires from the tempera-ture sensors that will be attached to the back of theabsorber plate.

Drilling the Hole for the Temperature Sensor Wire

WALL SHEATHING: Sheathe the rest of the wall asusual, with 1/2 in. CDX plywood, caulking continuouslybetween the edges of the collector sheathing and thewall sheathing (2-AI4). Mark the center-line of thecollector on the wall sheathing, 4 in. above and belowthe Thermo-ply perimeter. If the collector has innermanifold pans, snap a chalk Iine down the center-lineof the collector between the two pairs of manifoldslots.

RETROFIT: Sheathe the wall, as above,fastening the Thermo-ply to the existingwall sheathing. The Thermo-ply will runhorizontally from the outside of one outermanifold stud to the other, and vertically

www.BuildItSolar.com for more projects

129

from the center-line of the bottom 2x6(nominal) blocking (or shoe ) to a pointabove it at a distance equal to the glazing'he ight minus 1 inch (the two ins ide 1lnessnapped horizontally on the sheathing).This will leave a 2 in. gap at each side,2-1/2 in. at the top, and 2-1/2 in. at thebottom, between the Thermo-ply and theexisting wall sheathing. Cut 1/2 in. COXplywood to fill these gaps, caulking eachside edge of the plywood as it goes in.Be sure each edge of the plywood is beingsupported by the studs ~r blocking.

/'

Thermo-ply Sheathing and Manifold Slotsin Place

6.4 Perimeter Blocking

The perimeter blocking not only sets the bounda-ries for the absorber plate to be fastened within, butis also the beginning of the framework of the glazing.It is vital that these pieces be plumb, horizontal, andsquare--and be fastened to the exact dimensions calledfor. Therefore, follow the sequence of laying out,

130 CONSTRUCTING THE WALL COLLECTOR

plumbing,Check thecorrect.won I t f i.t

leveling, and checking diagonals carefully.dimensions several times to be sure they areAny miscalculation now could mean the glasslater.

TOP: Tack Ix2 (nominal) blocking across the topedge of---"thecollector, with its bottom edge flush withthe edge of the plywood. The blocking will run contin-uously from 2 in. outside one side of the Thermo-ply to2 in. outside the other (1, 3-w4). Use aline level tomake sure the blocking is horizontal.

SIDES: Tack 3/4 in. x 2 in. (actual) blockingdown the sides of the collector, w it h its side flushwith the side edge of the plywood. The blocking willrun continuously from the bottom edge of the top peri-meter blocking to the bottom edge of the Thermo-ply(1,2-w4). Use a plumb bob to be sure the blockingis ve rt ica I.

BOTTOM: Cut a 1/2 in. x 4-3/4 in~ (actual) con-tinuous rectangular section from a 2x6 (nominal) (3-W4).The resulting piece will run continuously from the out-side edge of one side perimeter blocking to the outsid~edgeof the other. Tack the piece across the bottom, withits top edge flush with the edge of the plywood. Use aIine level to make sure the blocking is horizontal.

It is essential that tbese pieces are square witheach other, so that the glass will fit later. Check thediagonals from the outside corners of the perimeterblocking. The bottom outside corners of the bottomshelf cut out of the bottom 2x6 (nominal) blocking willbe considered the bottom outside corners of the diagonals(3-w4) .

The vertical height from the bottom edge of thebatten shelf to the top edge of the Ix2 (nominal) block-ing should equal the glazing height plus 1/2 inch.Without this extra 1/2 in. space (1/4 in. allowed forabove and below the glass), the glass might crack whenit expands. The horizontal distance must be equal tothe width of the collector, which takes into account theexpansion spaces needed for the panels of glass. There-fore, the blocking must be fastened to the required di-mensions, as weI I as have equal diagonals.

www.BuildItSolar.com for more projects

131

The air from the supply manifold pan passesthrough the manifold slots in the Thermo-ply into theribs of the absorber plate. It flows between the backsurface of the plate's ribs and the face of the Thermo-ply,carrying away the heat from the two surfaces as it passesby. It then is pulled through the slots into the returnmanifold pan. The absorber plate is painted black toabsorb more of the sun's 1ight, and reflect less back tothe outside.

6.5 Absorber Plate

It is very important that every edge of theabsorber plate, including the overlaps, be air-tight.Leakage through the absorber plate can mean the dif-ference between a good collector and a poor one.Therefore, be generous with the urethane caulk. Anddon't skimp on the screws. The number called for willhelp keep the aluminum's expansion to a minimum. Theless the plate moves, the longer the seal of the caulkwill ho ld.

Don't forget to attach the temperature sensorsnow, or to pass the wires through the Thermo-ply; itcould save some costly (and embarrasing) tearing apartlater. Identify which is which with a felt marker onthe back of the Thermo-ply.

The absorber plate is made of 4 in. or 8 in.ribbed aluminum industrial siding sheets. If the col-lector is less than 16 ft. from inner supply manifoldslot to inner retu rn man ifo 1d slot, use 4 in. rib. Ifthe collector is equal to or greater than 16 feet, use8 in. rib. The 4 in. rib comes in 45-5/8 in. overallwidths, which actually cover 48 inches.

Decide which sheet width wi 11 be used, and orderit in the .032 in. thickness with the mill finish.Enough sheets will be needed to cover the collectorvertically from the bottom to the top edge of theThermo-ply (3-W5). The sheets will be as long as thehorizontal distance from side to side of the Thermo-ply(2,W5). Use the fol lowing two equations to determinethe number of sheets to order, and their length:

No. of sheets (round off to the next highest

132 CONSTRUCTING THE WALL COLLECTOR

whole number} = (collector height in inches- 5 in.) / 48 in. (for 8 in. rib) or 44 in.(for 4 in. rib)

Sheet width (round off to the next highest6 in.)= (collector width in inches - 4 in.)

For example, if the collector were the same oneused as the example in the introduction (15'-%11 wide x8'-3t" high) and the 8 in. rib sheets were being used,the number of sheets ordered would be:

(9%"-511) /48" = 1.97 or 2 sheets.

If the 4 in. rib sheets were being use, the number ofsheets ordered would be:

Notice the amount of aluminum that would have tobe wasted if the 4 in. rib sheet is used. Only 6-1/2 in.of the last sheet would be used, and the rest would bewasted.

In either case, the actual sheet width would be:

The sheets come in standard lengths up to 30feet, in incremen ts of 6 inches. If the co 11ector islonger that 30 feet, divide the collector width in halfand use two sheets to cover the width. The sheets willbutt together at the center-line of the collector, be-tween the two inner manifold pans.

At the ends of each sheet there will be a EPDMend closure strip. Order enough "inside" end closurestrips by the linear foot to close off all the ends ofthe sheets. For example, if the col lector is one sheetwide, order two times the height of the collector. Ifit is two sheets wide, order four times the height, be-cause there will be two sets of EPDM end closure stripsat the center-line of the collector.

The sheets of siding will be fastened with therib running horizontally across the collector, and the1-3/8 in. rib valley fastened against the Thermo-ply(3-W5).

www.BuildItSolar.com for more projects

133

/

Aluminum Industrial Siding and EPDM EndClosure Strips

The sheets will probably have to be cut bothhorizontally and vertically. Horizontal and verticalcuts can be made with a hand-held circular saw (using acarbide blade). Cuts across the rib can also be made

I with a pair of tin snips. Cuts along the rib or ribvalley can be scored with a utility knife, and the sid-ing is then bent back and forth until the metal breaksclean. When using the circular saw, wear eye and earprotection while cutting, as well as a respiration mask.Cutting the sheet may raise or bend the edge sl ightly.Remove the raised edges with a file or utility knife,and straighten the edge with a pair of pliers.

Cut the sheets to the length required to fithorizontally across the collector (e.g. 151-5ill). Savea ful I piece of ribbed scrap, cut from the end of onesheet, to be used later. Cut off 3/8 in. from thebottom horizontal edge of the first sheet of siding,removing the curved portion and leaving 3/4 in. offlat metal before the rib begins. The top of the last

134 CONSTRUCTING THE WALL COLLECTOR

sheet will be cut after all the other sheets are in placeon the wall and an actual measurement can be taken.

cutting the Absorber Plate Along the Rib

Cutting the Absorber Plate Across the Rib

www.BuildItSolar.com for more projects

135

SHEET PREPARATION: To remove the thin film ofoil that will be found on the sheets and prepare themfor painting, sponge down the outside of the sheets witha solution of TSP powder Ctri-sodium-phosphate} dissolvedin water. Next, etch the sheets with muriatic acidaccording to manufacturer's instructions. The TSPpowder and the muriatic acid are both available athardware or building supply stores.

Washing the Absorber Plate

Using the scrap piece of siding as a guide, anda 1/4 in. continuous bead of urethane caulk as the"adhesive," layout and stick the end closure strips

136 CONSTRUCTING THE WALL COLLECTOR

for the first sheet of ribbed siding to the wall (2-WS).The caulk must still be "we t " for it to act 1ike a glue,so don't let it skin over before pushing the closurestrips into it. Fit the ribs of the closure stripinto the ribs in the scrap piece. Following the formof the siding will keep the closure strip from be-coming stretched out as it is stuck in the caulk.Begin at the bottom perimeter seam between the Thermo-plyand the plywood, and 1ine the strips up with the sideseams of the Thermo-ply (or the center-line of thecollector if there are two sheets per width of collector).

Laying out the EPDM End Closure Strips with a Scrap of Industrial Siding

If the collector has center manifolds, run onestrip down each side of the collector center-l ine (theseam in the Thermo-ply). Do not let the caulk skinover before covering it with the strips. If it does,remove it and caulk again. (See Appendix A for urethanecaulk recommendations.)

The temperature sensors will be located on theback of the sheets of siding located over the holesdrilled in the Thermo-ply for the sensor wires. Beforemounting those sheets on the wall, see TEMPERATURE SENSORbelow.

Just before the first sheet is ready to befastened to the wall, run a 1/4 in. continuous beadof caulk over the inside top edge of the EPDM end

www.BuildItSolar.com for more projects

137

Fastening the Temperature Sensor to the Back of the Rib

closure strips. Run the same size continuous beadacross the bottom of the collector, along the bottomperimeter seam. Butt the bottom edge of the first

Caulking the EPDM End Closure Strip

138 CONSTRUCTING THE WALL COLLECTOR

sheet against the edge of the plywood at the perimeterof the col lector, laying the sheet carefully over theend closure strips (3-wsl. Make sure the end closurestrips fit snugly into the ribs.

Fasten the sheet across the bottom edge, with#12xl-1/4 in. Phi 11 ips pan head aluminum or .18-8 stain-less steel sheet metal screws at 6 in. on center.Fasten vertically through every rib valley at the endsof the sheet, and through every other rib valley atevery stud. The studs can be found by noticing wherethe nails or staples are in the Thermo-ply. Do notfasten across the top of the sheet yet. -----

Layout and caulk the EPDM end closure stripsfor the next sheet. Apply extra caulk where thesestrips butt against those already on the wal I. Run a1/4 in. continuous bead of caulk across the top edgeof the overlap strip of the sheet already on the wall(at the top edge of the top rib valley) (3-RS). Placethe bottom rib valley of the second sheet over it. Posi-tion the second sheet over the end closure strips. Wipeoff any caulk that has been forced out before it skinsover. Follow the same fastening schedule as on the firstsheet. Continue this process for all sheets except thetop sheet.

TEMPERATURE SENSORS: There are two temperaturesensors that will be located near the return manifoldpan. The first one is for controll ing the normal opera-tion of the collector. This sensor is mandatory. Thesecond sensor, which operates the domestic hot watermode, should be mounted only if there is to be a DHWpre-heating system. It is Iikely that these sensorswi 11 be too thick to fit between the top of the rib ofthe absorber plate and the Thermo-ply. Therefore, theyshould be located over the manifold slots, allowingthem to extend beyond the Thermo-ply if necessary.Attach each one to the back of a rib, located over eachinner manifold slot that has a hole dril led next to itfor the sensor wires (Section 6.3 and detail l-W3).Each sensor should be fastened according to manufacturer'sinstructions. Attach wires to the sensors if they arenot already attached. Check with the manufacturer forthe type of wire, because some sensors require shieldedwire. Fasten the bottom edge of the sheet to the wall.Tie a knot in each wire, and position it over its re-spective 1/8 in. diameter hole in the Thermo-ply (3-WS).

www.BuildItSolar.com for more projects

139

This will keep the wires from being pul led out of thesensors, after the wires are fed through the holes.Feed the wires through each hole, and then caulk theholes in the Thermo-ply and the absorber. Write with afelt marker on the back side of the Thermo-ply whichsensor is which (e.g. "Tc' for normal winter operationand "Tchw" for DHW control). Finish attachingthe absorber plate sheets.

Once the second to last sheet is on, measurefrom the bottom edge of the last rib valley to the topperimeter seam between the Thermo~ply and the plywood.This distance wi 11 be the width to cut the last sheet.If the top of the last sheet is cut across a rib valley,fol low the lay-out of the end closure strips and thesame fastening schedule as the other sheets. Run a 1/4in. continuous bead of caulk along the bottom edge ofthe Thermo-ply. Lay the ribbed siding over it andfasten at 6 in. on center.

If the top edge of tbe last sheet is cut acrossa rib, follow the lay-out of the end closure strips andthe same fastening schedule as the last sheets. Cut acontinuous piece of 1 in. by 1 in. fir or spruce block-ing. Run a 1/4 in. continuous bead of caulk along thetop perimeter edge of the Thermo-ply. Lay the contin-uous blocking in the caulk, and butt its length againstthe side of the plywood edge, and against the endclosure strips at each end. Caulk again along the topedge of the blocking and lay the edge of the lastsheet over it. Fasten with #12x2-1/2 in. Phillips panhead aluminum or 18-8 stainless steel sheet metalscrews at 6 in. on center.

Check the four corners of the collector. Theend closure strips may raise the ends of the top andbottom edges slightly, which will cause leaks. Ifnecessary, loosen the screws, add more caulk, thentighten and add more screws.

PRIMING AND PAINTING: Prime and paint theabsorber plate with one coat of primer and one coat ofpaint. (See Appendix A for manufacturers recommendations.)Paint the inside surfaces of any wood exposed around theperimeter of the plate, with one coat also. Allow thepaint to dry completely, a minimum of two full days.Standard enamel paints dry by solvent evaporation, aprocess that should be allowed to finish before the

140 CONSTRUCTING THE WALL COLLECTOR

Painting the Absorber Plate

glazing goes on. If there is not enough time to allowfor this, an epoxy based paint must be used. Once theabsorber plate is painted, be careful not to scratch it.Precautions, such as srapping ladder legs with rags,should be taken. Touch up any scratches with paint,before the glazing is installed.

The Absorber Plate

www.BuildItSolar.com for more projects

141

6.6 Battens

The battens are those vertical members that theglazing system is attached to, so they must be securelyfastened to the absorber plate or the side blocking.They must also be plumb, and exactly the distance apartcalled for, or the glass will not fit. Check the dimen-sions, plumb, and diagonals carefully. Then check themagain.

Cut lx3 (nominal) fir or spruce battens (l-w6)whose heights are equal to the glazing height minus Iinch. Paint with two coats of flat black paint. (SeeAppendix A for paint recommendations.)

Tack the two outside battens down the sides ofthe collector first, lining up their outside edges withthe outside edge of the perimeter blocking. Use a plumbbob to be sure the battens are vertical (2-w6). The out-side to outside dimension should equal the collectorwidth. Cut a piece of plywood with a horizontal dimen-sion equal to the glazing height minus 1-3/4 inches,and a vertical dimension equal to the glazing widthminus 1-3/4 inches. This is used as a guide to makesure the battens will be the correct distance fromeach other, so be sure the sides are square and thedimensions exact--especially at the corners.

Fasten the first vertical batten down the center-line of the collector. Check the diagonals to be sureit is square with the perimeter battens. Layout thebattens to each side, fastening down each batten as theplywood guide is run down between it and the one alreadyfastened next to it. Fasten with #14xl-l/2 in. alumi-num or 18-8 stainless steel Phillips flat head woodscrews through every other rib. By the time the lastone is layed out, the plywood guide should fit betweenthis batten and the one preceeding it, and between thissame batten and the one fastened to the perimeter block-ing. Fasten the two outside battens with 3 in. drywallscrews at 1 '-a" on center.

142 CONSTRUCTING THE WALL COLLECTOR

Fastening the CenterBa tten

lx3 Fir or SpruceBattens

www.BuildItSolar.com for more projects

143

6.7 Glazing Preparation

The glazing preparation consists of severalinportant parts. The first is weather-proofing the topand sides of the col lector perimeter with blocking andflashing. The blocking,or cant set, across the top ofthe col lector is sloped to allow for drainage. Thesecond step is fabricating and attaching the sill, thepiece of wood that will bear the weight of the glass.This sill is cut with channels that will allow condensa-tion to escape from between the glazing and the absorberplate. The sill must be securely fastened, for eachpanel of glass can weigh from 72 pounds (34 in. x 76 in.)to 120 pounds (46 in. x 96 in.). Before it is fastenedcheck and double check its position. The dimensionfrom its top surface to the bottom surface of the cantset must equal the glass height plus 1/2 inch. Toosmall, and the glass might not fit, or worse it mightcrack later when it expands in the heat.

The smoke test is vital to the performance ofthe collector. The col lector must be thoroughlychecked for leaks. As will be seen on the first test,no matter how well the collector was caulked, therewi 11 still be spots that were missed. But don't getdiscouraged--the leaks are not difficult to seal.More than one test, however, will surely be needed tofind and seal them all.

The pre-shimmed glazing tape acts not only as aseal between the edge of the glass and the interior ofthe collector, but also as a cushion against windpressure.

The glazing will be protected around the col lec-tor perimeter by a cant strip and blocking set acrossthe top, and blocking down the sides. Across the bottomit is protected and supported by a sill. It is held outfrom the battens with pre-shimmed glazing tape (I-W7).

CANT STRIP: The cant strip and blocking setconsists of two 2x3's (nominal), the top piece rippedacross the long side with a side angle cut at a minimumof 4 in 12 (18.50). The blocking and cant strip extendto the outside edges of the side battens. Tack thefirst 2x3 (nominal) across the top of the perimeterblocking, with its 1-1/2 in. face against the plywood

144 CONSTRUCTING THE WALL COLLECTOR

sheathing. Tack the cant strip above the blocking withits 2-1/2 in. face flush with the 2-1/2 in. face of theblock ing (3-w7).

The cant Set

SID E BL0 C KING : Tack lin. x I-3/4 in. (act ua I)continuous blocking down the sides of the collector with

The Side Blocking

www.BuildItSolar.com for more projects

145

the outside edges flush with the outer edges of thebattens. The blockfng will run from the undersideof the cant strip set, and its height is equal tothe height of the glazing plus 6 inches. The cleardistance from inside to inside of this blocking mustbe equal to the collector width minus 2·1/2 in. toallow for glass expansion (2-W7).

SILL: The 2x6 (nominal) finish grade cedar sillwill run horizontally across the bottom of the collec-tor, from inside to inside of the side blocking. Thetop edge of the blocking will fit into the rectangularnotch in the bottom perimeter blocking. Its top edgemust be at a distance down from the cant strip set equalto the glazing height plus 1/2 inch (I-W7).

The sill should be prepared before mounting with1/4 in. square condensation and drip channels set back1/2 in. from its front face. Rout out the channels.Cut 1 in. deep by 1/2 in. wide vertical saw kerfs fromthe back of the sill at 11-0" on center, beginning atthe cen t e r+line of the sill (3-W]). The kerf shall becontinuous from channel to channel.

The Sill

146 CONSTRUCTING THE WALL COLLECTOR

Tack the sill across the bottom of the collec-tor, using a line level to be sure it is horizontal.Check the dimensions from the inside edge of the cantstrip set to the inside edge of the sill, at severalpoints. The clear distance must equal the glazingheight plus 1/2 inch all the way across to allow forglass expansion. Check the diagonals also, as well asplumb and level lines.

Once the pieces are square, fasten them.Fasten the 2x3 (nominal) top blocking with 30d commonnails at 11-0" on center, and the cant strip with 10dcommon nails at the same spacing. Fasten the sideblocking with 16d common nails at 11-0" on center.Fasten the sill with 1/2 in. x 4 in. hexhead lag screws,countersunk, at 1 I -0" on center. Do not fasten the lagscrews through any of the weep slots.

FLASHING: Bend 10 in. wide 0.019 in. aluminumflashing around the side blocking and onto the wall,beginning at the center-line of the side blocking.Start at a po int 1-3/4 in. be low the top of the sill,and carry the flashing up the side, bending over theend of the cant strip. Fasten with 1 in. galvanizedroofing nails at 11-0" on center.

Bend 10 in. wide 0.019 in. aluminum flashingaround the cant strip and up the wall, beginning at thecenter-line of the 2x3 (nominal) blocking across the topof the collector. The flashing should be continuousfrom one side of the collector to the other. Bend theflashing over the wall with 1 in. galvanized roofingnai Is at 11-0" on center.

SMOKE TEST: Before installing the glazing tape,or the glazing, it is necessary to check for leaks inthe system. This is important, since even small leakswill reduce the efficiency of the collector dramatically.One method of checking for leaks is a smoke test. Thiscan be done using a metal paint can and a smokebomb. (See Appendix A for smoke bomb recommendations.)Follow manufacturerls warnings on the smoke bombs.

It is helpful at this point to have the supplyand return ducts attached to the duct collars, tocheck for leaks at the connections.

Seal off the duct connections to one manifold

www.BuildItSolar.com for more projects

147

Smoke Bomb

or duct using polyethylene film (or cardboard) andduct tape. Leave a hole at the other manifold duct toput the paint can through. Place the smoke bomb in thepaint can, ignite it, and place it into the duct.

It will not be unusual for the collector toleak sl ightly around the edges of the absorber plateand at the overlaps, and these leaks must be completelysealed. Adding extra clear sil icone caulk and morescrews at these seams will help stop the leaks. Paintover any new screws and touch up any scratches.

Also check the back of the collector for leaksat the manifolds, ducts or those made by any fastenersthat punctured the Thermo-ply. Caulk all leaks withsilicone caulk.

Several tests may be required before all theleaks are sealed.

GLAZING TAPE: Just before glazing each 'bay' withan insulated glass panel, run 1/8 in. by 1/2 in. pre-shimmed ·glazing tape vertically down the inside edges ofthe front face of the battens, horizontally across thebottom edges of the front face of the top perimeterblocking, and the top edge of the front face of thebatten shelf (2, 3-W7).

148 CONSTRUCTING THE WALL COLLECTOR

6.8 Glazing and Finishing

~he insulated glass panels allow the sun's lightto pass through and hit the absorber plate, but slow thetransfer of the resulting heat back to the outside. Theglass must be able to expand and contract freely withthe extreme temperature changes. Therefore, the 1/4 in.gap allowed around each panel is vital to the survivalof the glass. Each panel of glass rests on two settingblocks. These blocks support both pieces of glass, butallow them each to move independently with the expansionand contraction. The inner layer of glass will movemuch more than the outer, because it is experiencinghigher temperatures. This is the reason why insulatingglass panels with metal or glass fused edges cannot beused.

The aluminum clamping bars with built-in gasketsprovide support along with an almost caulk-free, weatherproof seal. The only place caulk is needed is at theintersections of the clamping bars, where water couldleak in under the bars and rot the wood.

GLAZING: The rest of the glazing process in-volves mounting insulated glass panels to the collectorwith the CY/RO Universal Glazing System. (See AppendixA.) The total CY/RO U.G.S. consists of a lower EPDMgasket, an aluminum clamping bar and two upper EPDMgaskets. The lower gasket has been replaced on thewall collector by pre-shimmed glazing tape (Section 6.7).Therefore, do not order the lower gasket (4-w8).

Cut two sections of the clamping bar I in.longer than the width of the collector (from outsideedge to outside edge of the side blocking) for the topand bottom. Miter the corners so that the outside lengthof the bars equals the width of the collector. Cut twosections of the clamping bar, 1 in. longer than theheight of the collector (equal to the glazing panelheight in inches plus 3-1/2 in.), for the two sides ofthe collector. Miter the corners so that the outsideheight of the bars equals the height of the collector.Cut the rest of the vertical clamping bars, to beplaced over the battens, the height of the collectorminus 5 in. (l-w8).

www.BuildItSolar.com for more projects

149

If the col lector is wider than 25 feet, the hori-zontal bars may have to be done in pieces. The clampingbar only comes in stock sizes of 25 foot lengths. Tryto keep the spl ices to a minimum.

Pre-drill the clamping bars at 8 in. on centeralong the center-l ine of the bars, with holes no morethan 1/2 in. from the ends. Feed the upper gasketsinto the channels extruded into the under side of thebars. Run the gaskets continuously through any spl icesof the clamping bars.

Line up the bottom horizontal clamping bar alongthe sill, with its top edge 3/4 in. above the top edgeof the sill. Fasten with #12x2 in. aluminum or 18-8stainless steel Phi 11 ips pan head sheet metal screws,with neoprene washers. Fasten all the screws part way,leaving enough room to set 'the glass on the sill withoutdisturbing the glazing tape. Repeat this process up oneside of the collector, 1ining up the inside edge 3/4 in.to the inside of the inner face of the perimeter block-ing.

SETTING BLOCKS: Each panel of glass will be cen-tered between vertical strips of glazing tape. Placetwo 1/4 in. x 1 in. neoprene (70-90 Shore-A-Durometer)setting blocks on the sill at the quarter points ofeach of the bays (1,3-W8). The setting blocks areavailable from local glazing dealers.

GLAZING: Special precautions must be taken whenhandl ing large panes of insulating glass. If a unit isleaned against a vertical support, provide one supportunder both panes of glass to keep them from sl idingapart. Take care not to damage the edges, and do notpivot the glass panels on their corners. The glazingrecommended in Appendix A comes with a stencil in onecorner. This stencil should be glazed to the insidebottom left hand corner when instal led. Clean the in-side of the glass thoroughly before pressing the glassinto place against the tape.

In the corner framed by the two clamping bars inplace, carefully slide the first panel of glass under-neath the two glazing bars on the wall. Center theglass inside the boundaries set by the clamping bar andthe batten, I ining up the free edge with the edge of the

150 CONSTRUCTING THE WALL COLLECTOR

glazing tape nearest the center-line of the batten.(The glass must be 3/8 in. from the center-l ine of thebatten.) Tighten the screws on the two clamping barsalready in place. Center the next vertical clampingbar over the next batten, covering the free edges ofthe glass. Partially fasten the screws. Do not fas-ten the top clamping bar at this time.

Center the next panel of glass in the same way.Fasten the screws across the bottom of the glass, andup the batten between the two panels. Partially fastenthe next vertical clamping bar to the batten. Continuethis process across the collector until the last verti-cal clamping bar is fully fastened. Fasten the tophorizontal batten across the collector, overlappingthe clamping bar 1/2 in. over the glass.

Caulk all the intersections of the clamping bars:horizontal and vertical joints, splices and miteredcorners. (See Appendix A for silicone caulk recommenda-tions.) This caulk will keep water from leaking throughthe intersections and under the clamping bars.

INTERIOR FINISHING: Cut rigid fiberglass insula-tion the width and length necessary to fit behind themanifold pans, from manifold stud to manifold stud, andfrom top to bottom blocking. Make the insulation asthick as will fit,without protruding beyond the studs.Locate the sensor wires that were fed through theThermo-ply. Attach more wire (shielded wire if manu-facturer calls for it), and run to the air handling con-trol panel (see Figure 8.15 and 8.16 or 8.23 and 8.26).It is important to tag the wires so that they don't be-come confused with each other. Insulate between theother studs with full depth fiberglass batt insulation.Staple a 6 mil polyethylene vapor barrier to the studs,overlapping the sheets 6 inches and taping the upperedges down. Finish the interior surface as desired.

www.BuildItSolar.com for more projects