Chapter 4. Chapter 4 Learning Objectives Describe steps in the production planning process of a high...

-

Upload

simon-wood -

Category

Documents

-

view

219 -

download

2

Transcript of Chapter 4. Chapter 4 Learning Objectives Describe steps in the production planning process of a high...

Chapter 4

Chapter 4 Learning Objectives

• Describe steps in the production planning process of a high volume manufacturer like Fitter Snacker

• Describe Fitter Snacker’s production and materials management problems

• Describe how a structured process for production and materials management planning enhances efficiency and decision making

Chapter 4 Learning Objectives

• Describe how production planning data in an ERP system can be shared with suppliers to increase supply-chain efficiency

Production and Materials Management at Fitter Snacker

• Must answer the following questions:– How much of each bar should be produced?– What quantities of raw materials should be

ordered?– When should raw materials be ordered

General Approaches to Production

• Make-to-stock: Items produced in anticipation of orders

• Make-to-order: Items produced to meet specific customer orders

• Assemble to order: Final product assembled from make-to-stock items

Fitter Snacker Manufacturing Process

Raw

Mat

eria

l War

ehou

se Mixer

Mixer

Mixer

Mixer

Form Bake Pack

Fin

ishe

d G

oods

War

ehou

se

Snack Bar Line

Fitter Snacker Production Problems

• Communications– Marketing does not share data with production (sales

promotions and large, unexpected orders)

• Inventory– True inventory status not known– No real-time data on actual sales

• Accounting and Purchasing– Difficulty forecasting raw material and labor costs– Adjusting accounts for actual vs. standard costs time

consuming and done infrequently

Production Planning Process

• Work from sales forecast to create aggregate production plan

• Break down aggregate plan into more specific plans

• Use production plan to determine raw material requirements

SAP R/3 Approach to Production Planning

Sales and Operations Planning

Demand Management

MRPDetailedScheduling

Sales Forecasting

PurchasingProduction

Sales Forecasting

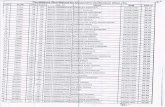

Jan. Feb. March April May JunePrevious Year (cases) 5734 5823 5884 6134 6287 6435Growth: 3.0% 172 175 177 184 189 193Base Projection (cases) 5906 5998 6061 6318 6476 6628Promotion (cases) 500Sales Forecast (cases) 5906 5998 6061 6318 6476 7128

Sales Forecasting

Sales and Operations Planning

Sales and Operations Planning Jan. Feb. March April May June1) Sales Forecast 5906 5998 6061 6318 6476 71282) Production Plan 5906 5998 6061 6318 6900 67003) Stock Level 0 0 0 0 424 -44) Working Days 22 20 22 21 23 215) Capacity (Shipping Cases) 7333 6667 7333 7000 7667 70006) Utilization 81% 90% 83% 90% 90% 96%7) NRG-A (cases) 70.0% 4134 4199 4243 4423 4830 46908) NRG-B (cases) 30.0% 1772 1799 1818 1895 2070 2010

Sales and Operations Planning

Sales and Operations Planning

Sales and Operations Planning

Sales and Operations Planning

Demand Management

Week 1 Week 2 Week 3 Week 4 Demand Management 1/2 - 1/5 1/8 - 1/12 1/15 - 1/19 1/22 - 1/26 1/29 - 1/31 2/1 - 2/2 Monthly Demand NRG-A 4134 4134 4134 4134 4134 4198

NRG-B 1772 1772 1772 1772 1772 1799 Working Days in Week 4 5 5 5 3 2 Working Days in Month 22 22 22 22 22 20 MPS NRG-A 752 940 940 940 Weekly Demand NRG-B 322 403 403 403

Demand Management Jan 2 Jan 3 Jan 4 Jan 5 Jan 6 Monthly Demand NRG-A 4134 4134 4134 4134 4134

NRG-B 1772 1772 1772 1772 1772 Working Days in Month 22 22 22 22 22 MPS NRG-A 188 188 188 188 188 Daily Demand NRG-B 81 81 81 81 81

Week 5

984422

Demand Management

• Calculation for Week 5

4,134 cases in Jan. x 3 days in week 5 ÷ 22 working days in Jan.= 563.7 cases

4,1984 cases in Feb. x 3 days in week 5 ÷ 20 working days in Feb.= 419.8 cases

Total = 983.5 cases

MRP

• Bill of MaterialIngredient NRG-A NRG-BOats (lb) 300 250Wheat germ (lb) 50 50Cinnamon (lb) 5 5Nutmeg (lb) 2 2Cloves (lb) 1 1Honey (gal) 10 10Canola Oil (gal) 7 7Vit./Min. Powder (lb) 5 5Carob Chips (lb) 50Raisins (lb) 50Protein Powder (lb) 50Hazelnuts (lb) 30Dates (lb) 70

Quantity

MRP

• MRP Record

Oats Lead Time = 2 weeks Week 1 Week 2 Week 3 Week 4 Week 5MPS NRG-A 752 940 940 940 984(cases) NRG-B 322 403 403 403 422MPS NRG-A 108 135 135 135 142(500 lb. batches) NRG-B 46 58 58 58 61Gross Requirements (lb) 44,070 55,087 55,087 55,087 57,667Scheduled Receipts 44,000 44,000Planned Receipts 88,000 44,000 44,000On Hand 11,650 11,580 493 33,406 22,319 8,652Planned Orders 88,000 44,000 44,000

MRP List in SAP R/3

Stock Requirements List in SAP R/3

Detailed Production Scheduling

• Snack bar production line is bottleneck

• Scheduling of production line is key to determining detailed production schedule

Detailed Production Scheduling

• Length of production runs– Longer runs reduces cost of setups

– Longer runs increase capacity utilization

– Shorter runs reduces cost of inventory

Providing Production Data to Accounting

• Production data does not get entered into an ERP system directly– Many methods of gathering shop floor data are

available– ERP allows shop floor data to be collected once

for production and accounting purposes, and data is consistent in both areas

ERP in Supply Chain Management

Supplier

Raw

Mat

eria

ls

Manufacturer Wholesaler Retailer

Cus

tom

erGoods Goods Goods Goods Goods

$$ $ $ $

Information Information Information Information Information

Supply Chain Management and ERP

• ERP not required for Supply Chain Management (SCM)

• ERP can facilitate sharing information in real time

• Use of internet can reduce communication costs

Supply Chain Metrics

• Total Supply Chain– Cash-to-cash cycle time: Time from paying for

raw materials to the time when cash is collected from the customer

– Total supply chain costs

Supply Chain Metrics

• Buyer-Supplier– Initial fill rate– Initial-order lead-time– On-time performance

Chapter Summary

• An ERP system can improve the efficiency of the production and purchasing processes. Efficiency begins with Marketing sharing sales forecasts with Production, which shares its production plans with Purchasing

Chapter Summary continued

• Production planning can be done without an ERP system, but and ERP system allows production to be linked to Purchasing and Accounting. This data sharing increases a company’s overall efficiency

Chapter Summary continued

• Companies are building on their ERP systems to practice supply chain management. In doing this, the company looks at itself as part of a large process that includes customers and suppliers. Using information more efficiently along the supply chain can significantly reduce costs.