Cathodoluminescence-Activated Nanoimaging: Noninvasive ... · XXXX, XXX, XXX−XXX. beams with the...

Transcript of Cathodoluminescence-Activated Nanoimaging: Noninvasive ... · XXXX, XXX, XXX−XXX. beams with the...

Cathodoluminescence-Activated Nanoimaging: Noninvasive Near-Field Optical Microscopy in an Electron MicroscopeConnor G. Bischak,† Craig L. Hetherington,†,§ Zhe Wang,⊥ Jake T. Precht,† David M. Kaz,†,§,○

Darrell G. Schlom,⊥,¶ and Naomi S. Ginsberg*,†,‡,§,∥,∇

†Department of Chemistry and ‡Department of Physics, University of California, Berkeley, California 94720, United States§Physical Biosciences and ∥Materials Sciences Divisions, Lawrence Berkeley National Laboratory, Berkeley, California 94720, UnitedStates⊥Department of Materials Science and Engineering, Cornell University, Ithaca, New York 14853, United States¶Kavli Institute at Cornell for Nanoscale Science, Cornell University, Ithaca, New York 14853, United States∇Kavli Energy NanoSciences Institute, University of California, Berkeley, California 94720, United States

*S Supporting Information

ABSTRACT: We demonstrate a new nanoimaging platformin which optical excitations generated by a low-energy electronbeam in an ultrathin scintillator are used as a noninvasive,near-field optical scanning probe of an underlying sample. Weobtain optical images of Al nanostructures with 46 nmresolution and validate the noninvasiveness of this approach byimaging a conjugated polymer film otherwise incompatiblewith electron microscopy due to electron-induced damage.The high resolution, speed, and noninvasiveness of this“cathodoluminescence-activated” platform also show promisefor super-resolution bioimaging.

KEYWORDS: cathodoluminescence, nanoimaging, nanostructures, soft materials, super-resolution imaging, resonant near-field coupling

The emergence of far-field super-resolution techniques,such as stochastic localization,1−4 stimulated emission

depletion (STED),5 and structured illumination6 microscopieshas revolutionized the fluorescence imaging of labeled bio-logical structures. Yet, capturing nanoscale biological dynamicsand imaging systems using their endogenous chromophoresboth remain challenging for these methods. Near-field opticalprobes7−17 have proved valuable for the characterization ofcomplex structures and of processes in solid state materials, softmatter, and biological samples that occur over length scalessmaller than the wavelength of light. In most variants of near-field scanning optical microscopy (NSOM), an optical probe isintegrated with a scanning tip and rastered over a sample toform an image. Yet, images acquired with NSOM requiremechanical scanning and can contain artifacts from tip−sampleinteractions. On the other hand, in scanning electronmicroscopy (SEM), a focused electron beam is electronicallyscanned over a sample to obtain nanoscale images bycorrelating the detected scattered electrons with the positionof the beam, recently achieving the resolution to image singleatoms.18 Traditional electron microscopy is incapable ofspectrally specific excitation and damages soft materials suchas biological samples. One can, however, detect light generatedin the sample by the electron beam in a process calledcathodoluminescence (CL), which has been used historically toinvestigate the nanoscale properties of solid luminescent

materials19 and more recently to characterize a variety ofmetallic nanostructures.20−24 New CL approaches have enabledboth mapping directional emission with angular-resolveddetection,25 spatially resolving carrier transport throughintegration of electron and near-field optics,26,27 and hyper-spectral imaging on the nanometer scale.28 CL has been used toimage biological samples. Yet, direct CL of stained dehydratedsamples29,30 did not hold up well to electron damage, andalthough inorganic cathodoluminescent nanoparticle labels31−33

are more robust, imaging with nanoparticle labels remainsinvasive because the electron beam must penetrate into thesample, precluding repeated measurements or observations ofdynamics.By contrast, to take advantage of the tight focus of an

electron beam for spectrally specific and noninvasive imaging,our aim is to use optical excitations generated by a nanoscaleelectron beam in a cathodoluminescent material above thesample as a noninvasive, near-field optical scanning probe.Although some efforts have been exploring using quantum dotfilms34 or moderately cathodoluminescent materials35 togenerate hybrid electron and optical scanning probes, werecently proposed to combine the nanoscale focus of electron

Received: February 20, 2015Revised: April 2, 2015

Letter

pubs.acs.org/NanoLett

© XXXX American Chemical Society A DOI: 10.1021/acs.nanolett.5b00716Nano Lett. XXXX, XXX, XXX−XXX

beams with the noninvasiveness of optical approaches usingvery bright ultrathin scintillating films composed of cerium-doped yttrium aluminum perovskite (YAlO3:Ce, or YAP:Ce).

36

In our previous work, we prepared, characterized, and patternedYAP:Ce films on solid substrates, though at that point thepresence of the underlying substrate precluded using thesescintillating films for imaging. We found that the YAP:Ce filmshave a single CL emission peak centered at 370 nm, a 16 nsexcitation lifetime, high spatial uniformity of CL, as we show inSupporting Information Figure S1, and a very low surfaceroughness. Here, we report the first realization of ournoninvasive nanoimaging proposal by integrating this filminto an imaging device and using this device to capture its firstsuper-resolution imagesin this case, Al nanostructures andconjugated polymer films. Using the fast-scanning capability ofthe electron beam and the noninvasiveness that we achieve byexciting only the scintillator film and not the sample itself withthe electrons, this CL-activated approach could be furtherextended for imaging biological processes in crowded environ-ments with nanoscale resolution, high contrast, and video framerates.

To create a nanoscale excitation spot in a YAP:Ce film, afocused, low-energy (1−2 keV) electron beam in a SEMscatters within the YAP:Ce film and locally excites the film’sCe3+ dopants (Figure 1a). To use the scintillator film as anexcitation source for noninvasive near-field nanoimaging, thefocused electron beam must access the film from one side whilethe sample is positioned directly adjacent to the scintillator filmon the opposite side. As the result of our fabrication process, asshown in Supporting Information Figure S2, the scintillatingfilm is supported by a Si frame and by buffer layers of 20 nm ofLaAlO3 and 5 unit cells of SrTiO3.

37−39 A SEM image of fourimaging “windows” fabricated on a silicon chip is shown inFigure 1b. As the electron beam scans above the encapsulatedsample, light emitted from YAP:Ce on the Ce3+ allowed 4f−5dtransitions is collected by a parabolic mirror (Figure 1c) anddirected to a photomultiplier tube (PMT) or spectrometer. Togenerate an image, the signal from the PMT is correlated withthe electron beam position. Due to the fast-scanning capabilityof the electron beam, images can be acquired at ratesapproaching those of other rapid imaging techniques, such asdark-field scattering microscopy or total internal reflection

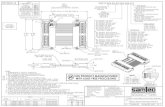

Figure 1. (a) Imaging chips consisting of a YAlO3:Ce scintillator film supported by LaAlO3 and SrTiO3 buffer layers and a Si frame. Alnanostructures embedded in SiO2 are positioned below and directly against the scintillator film. The ProTEK B3 layer serves as a protective layerduring the Si wet etch. (b) Secondary electron (SE) image of the imaging device showing four separate “windows” for imaging. (c) Far-field radiationemitted from the scintillator film is collected by a parabolic mirror positioned above the imaging chip and is then directed outside the scanningelectron microscope (SEM) to a photomultiplier tube (PMT) or spectrometer. (d) Close-up of the extent of electron scattering above a SiO2/Alboundary demonstrates that the electrons do not interact directly with the Al, but excite the Ce3+ dopants in the YAP:Ce layer within the volumedelineated by the red dotted line. Atomic force microscopy (AFM) (e) and SE (f) images of the Al nanostructures deposited on YAP:Ce prior toencapsulation in SiO2 show that they are 50 nm thick with a point-to-edge distance of approximately 270 nm.

Nano Letters Letter

DOI: 10.1021/acs.nanolett.5b00716Nano Lett. XXXX, XXX, XXX−XXX

B

fluorescence (TIRF) microscopy. Unlike these techniques,however, the electron-beam-induced lateral imaging resolutionis not restricted by the diffraction limit and the resolution in theaxial direction is defined by the near-field interactions betweenthe film and the sample to provide far better backgroundrejection than the evanescent field used in TIRF microscopy(70−250 nm).We call this imaging scheme “CL-activated imaging” because

the low-energy electrons excite the Ce3+ dopants in the YAP:Cefilm but do not penetrate into the sample beneath (Figure 1d).Instead, the optical excitations in the film noninvasively interactwith the sample to produce contrast, which comes fromdifferences in the photoemission rates of the Ce3+ dopants orthe sample rather than differences in the number of scatteredelectrons. The differences in Ce3+ emission arise due toresonant energy transfer, which can in principle quench orenhance the Ce3+ luminescence, depending on the nature of thesample. Here, we first demonstrate in detail CL-activatedimaging of Al nanostructures via Ce3+ luminescence enhance-ment and corroborate this contrast mechanism with simu-lations. Alternatively, when the Ce3+ luminescence is quenchedvia Forster resonance energy transfer (FRET) to a luminescentsample, the red-shifted emission from the sample canfurthermore be correlated to the position of the electronbeam to form its own image in tandem with the image formedfrom the scintillator luminescence. Second, we thus demon-strate unequivocally the noninvasiveness of CL-activatedimaging on conjugated polymer films that are too delicate tobe directly imaged with an electron beam. We do so by forminga CL-activated image of the polymer luminescence and byshowing that its intensity variation is spatially anticorrelated tothat of the tandem image formed from the scintillator CL. Onecomponent of the polymer film quenches Ce3+ luminescence

via FRET, as evidenced by its own spatially anticorrelatedluminescence.First, we demonstrate CL-activated imaging of Al nanostruc-

tures encapsulated in SiO2 directly below the YAP:Ce film(Figure 1a). The Al nanostructures are 50 nm thick roughlytriangular prisms and have a point-to-edge distance ofapproximately 270 nm, as determined before encapsulationby atomic force microscopy (AFM) (Figure 1e) and SEM(Figure 1f). They demonstrate the characteristic pattern oftriangular nanostructures generated with nanosphere lithog-raphy. A CL-activated image resolving Al nanostructuresembedded under the YAP:Ce with a 1.8 kV, 1.2 nA electronbeam is shown in Figure 2a. The inset shows a highermagnification CL image of an arrangement of six nanostruc-tures and the corresponding SEM secondary electron (SE)image. Because primary electrons do not reach the Alnanostructures, no additional detectable SEs are generateddue to the presence of Al, and the Al nanostructures are notvisible in the SE image. Spectra from the yellow- and red-boxedregions of the CL image are shown in Figure 2b. Clearly, whenthe electron beam is positioned above an Al nanostructure, thecollected far-field radiation from the YAP:Ce film increasesrelative to an area with no Al. Our imaging approach, thus,enables nanoscale mapping of underlying samples by using thescintillating film as a high-resolution optical transducer thatprevents electrons from reaching the sample.Characterizing this new imaging approach requires quantify-

ing the resolution and contrast obtained in the CL-activatedimages. To determine our spatial resolution at 1.8 kV, weconsider the YAP:Ce luminescence measured along the yellowline across the edge of an Al nanostructure (Figure 2c). The80/20 width of the corresponding line-cut is 46 nm (Figure2d), which is well below the diffraction limit. The luminescenceintensity collected above the Al nanostructures is distinct from

Figure 2. (a) Cathodoluminescence (CL)-activated image of Al nanostructures under the YAP:Ce scintillator film (scale bar, 1.0 μm). The insetshows a CL-activated image of a cluster of six Al nanostructures and the corresponding secondary electron (SE) image. (b) CL spectra of an areaabove an Al nanostructure (red) and an area with no Al nanostructure present (yellow), which correspond to the red and yellow boxes in part a,respectively. (c) CL-activated image of a single Al nanostructure. (d) Line-cut corresponding to the yellow line in the CL-activated image in panel cover the edge of a nanostructure, with a sigmoidal fit shown in red. The 80/20 width is 46 nm. (e) Photoluminescence (PL) lifetime measurementsof YAP:Ce thin film (blue) and YAP:Ce thin film over an array of Al nanostructures (red). An additional 7.8 ns contribution to the PL decay emergeswhen the Al nanostructures are present in addition to the isolated YAP:Ce PL lifetime of 16.1 ns. The PL instrument response function (IRF) isindicated in gray.

Nano Letters Letter

DOI: 10.1021/acs.nanolett.5b00716Nano Lett. XXXX, XXX, XXX−XXX

C

that collected above SiO2, so that the nanostructures are easilydiscerned from background luminescence. The combination ofhigh resolution and high contrast thus demonstrates theviability of CL-activated imaging.The high contrast and resolution of our imaging platform

results from the near-field interactions between Ce3+ dopants inthe scintillating film and the adjacent Al nanostructures. Weelucidate the nature of these interactions with a combination oftime-resolved photoluminescence (PL), spectrally resolved CL,control imaging measurements, and finite-difference time-domain (FDTD) simulations. As shown in Figure 2e, anadditional 7.8 ns contribution to the PL decay of YAP:Ce(typically 16.1 ns) emerges when the Al nanostructures arepresent. When the electron beam is positioned over an Alnanostructure in our imaging configuration, the luminescenceapproximately doubles (Figure 2b). Furthermore, a “control”imaging chip identical to that shown in Figure 1a, but withoutYAP:Ce, was also studied. No detectable luminescence fromthe Al nanostructures was observed up to an acceleratingvoltage of 5.0 kV, implying that the observed enhancement at1.8 kV cannot be caused by direct electron excitation.In addition to these experimental observations, a model of a

CL line-cut across an entire Al nanostructure, obtained withFDTD simulations, agrees with the corresponding experimentalline-cut through our CL image (Figure 3). The orientation of

the nanostructure in the CL image was determined based on itsposition with respect to adjacent Al nanostructures. Tosimulate the experimental line-cut, we modeled the lumines-cence of a single radiating Ce3+ dipole placed above an Alnanostructure, and we scanned its position in 20 nmincrements along a 750 nm long line running through theedge, center, and tip of the nanostructure at a range of heightsabove the scintillator-sample interface. At each point, and forthree orthogonal dipole orientations, the radiative enhancementfactor was calculated based on the radiative power flux througha surface positioned above the dipole to mimic light collection.

To mimic the fact that the electron beam activates adistribution of Ce3+ dopants, a weighted average of theradiative enhancement of a three-dimensional distribution ofdipoles centered on a given pixel’s beam center position wascalculated (see Supporting Information Figure S3). Theresulting line-cut from the FDTD simulations matches boththe width and shape of the experimental line-cut (Figure 3).The above experimental and theoretical observations are

consistent with the following physical interpretation based onthe fact that the detected luminescence from the Ce3+ dopantsin the scanned excitation volume of the YAP:Ce film maps theelectromagnetic density of states (LDOS) over top of the Alnanostructure.40−50 Depending on the location of a given Ce3+

relative to an Al nanostructure, its emission could be enhanced,quenched, or even possibly reflected. The total Ce3+

luminescence collected over the course of a pixel dwell-timeis altered in proximity to the Al nanostructures because a Ce3+

transition dipole induces a macroscopic polarization in thenearby metal nanostructure.40 The in-phase contribution to thispolarization increases the Ce3+ emission rate and amplitude. Asignificant portion of the enhancement that we observe couldarise from the edges and vertices of the Al nanostructure. Forexample, the shoulder peak on the right-hand side of theexperimental line-cut in Figure 3 is reproduced in our FDTDsimulations due to a higher degree of enhancement from the Alnanostructure vertex. Separately, a subpopulation of Ce3+

emitters closest to the Al surface may be quenched. Bothenhancement and quenching effects could lead to the observedshortened lifetime component in Figure 2e. The excitationenergy in the near-field of some Ce3+ dopants further away(∼10−15 nm from the surface) could, in principle, be radiatedand detected in the far field through “reflection” off of the Alsurface due to induced optical oscillations of bound electrons,though such reflection cannot entirely account for the observedincrease in detected CL over top of the Al structures or for theshortened PL lifetime component. The enhancement along theperimeter of the nanostructure is well-resolved in the FDTDsimulations of individual Ce3+ emitters nearby the nanostruc-ture (Supporting Information Figure S3); the enhancementonce averaged over the multiple emitters present in the electronbeam excitation volume and plotted in Figure 3 is lesspronounced along the perimeter of the structure. Yet, the factthat the simulations agree well with our experimentalobservations and also resolve the CL enhancement along theperimeter of the nanostructure shows that reflection alonecannot be responsible for the contrast in our experimental CL-activated images. In any case, each of these possibleenhancement, quenching, and “reflective” contributions to theobserved signal is a manifestation of a near-field interactionbetween the Al nanostructure sample and the scintillating filmthat can give rise to subdiffraction imaging contrast.The near-field imaging mechanism also explains the

measured spatial resolution, which results from convolvingthe electron beam excitation volume in the scintillator (∼20 nmacross36) with the distance-dependent profile of the electro-magnetic interaction between the nanostructure and a singleCe3+ emitter, as shown in Supporting Information Figure S3. Assuch, the measurable resolution for imaging this particular typeof nanostructure is likely lower than the resolution achievablewith other samples. Regardless, our resolution, signal-to-noiseratio, and contrast, in addition to the advantage of avoidingmechanical scanning, demonstrate that CL-activation is apromising alternative to other imaging approaches.

Figure 3. Experimental line-cut from edge to tip of an Alnanostructure (green) and the simulated FDTD line cut (blue). Thedots on the simulated line-cut indicate the location of the center of themodeled dipole distribution for each position on the line-cut. Theyellow line in the inset CL-activated image indicates the position of theexperimental line-cut. The directionality of the line-cut is known dueto the relative position of the metal nanoparticles with respect to oneanother in nanosphere lithography, as shown in Figure 1.

Nano Letters Letter

DOI: 10.1021/acs.nanolett.5b00716Nano Lett. XXXX, XXX, XXX−XXX

D

Further optimization of our nanoimaging could be achievedby adjusting the electron accelerating voltage and scintillatorfilm thickness, because both impact the contrast and resolutionof the acquired images through the spatial distribution of Ce3+

excitations in the scintillator. To characterize how the imagingcontrast depends on Ce3+ activation at different electronpenetration depths into the YAP:Ce film, images of Al

nanostructures were acquired at accelerating voltages rangingfrom 1.0 to 3.0 kV. A plot of the CL enhancement factor versusaccelerating voltage is shown in Figure 4a, with representativeimages in Figure 4b−e at 1.0 kV, 1.6 kV, 2.2 kV, and 2.8 kV,respectively. Here, the enhancement factor represents the Ce3+

CL intensity measured above the Al nanostructures ascompared to baseline YAP:Ce CL levels at each measured

Figure 4. (a) Plot of the enhancement factor versus the electron beam accelerating voltage. As the accelerating voltage increases, the enhancementfactor increases linearly (1.0−2.0 kV) and then plateaus (2.0−3.0 kV). (b)−(e) Representative images at 1.0, 1.6, 2.2, and 2.8 kV, respectively. (f)Monte Carlo simulations of electron trajectories at 1.0 kV, 1.8 kV, and 2.2 kV. At 1.8 kV, the enhancement factor is within error of the plateau valueand the electrons do not penetrate past the interface between the YAP:Ce film and the Al nanostructures.

Figure 5. (a) Schematic showing the geometry for imaging a luminescent polymer film. (b) CL-activated image of scintillator film quenching due tothe presence of the adjacent luminescent polymer sample. (c) CL-activated image of emission from the luminescent polymer (PFO). Theanticorrelation of panels b and c demonstrates that quenching of the scintillator film in the presence of the polymer is proportional to energy transferfrom the scintillator film to the polymer, resulting in polymer emission. (d) YAP:Ce film CL emission is shown in purple, the overlapping absorptionof the PFO luminescent polymer is shown in blue, and its photoluminescence (PL) emission is shown in green. (e) Fluorescence lifetime of YAP:Ce(purple) decreasing in the presence of PFO (green). The instrument response function (IRF) is shown in gray. (f) line-cut of the image in panel b atthe position of the yellow line has an 80/20 width of 68 nm.

Nano Letters Letter

DOI: 10.1021/acs.nanolett.5b00716Nano Lett. XXXX, XXX, XXX−XXX

E

accelerating voltage (see Supporting Information Figure S4).The enhancement factor increases linearly as the acceleratingvoltage increases from 1.0 to 2.0 kV, and it plateaus beyond 2.0kV. By consulting Monte Carlo simulations51 (Figure 4f) ofelastic and inelastic electron scattering as a function ofaccelerating voltage, we attribute the linear increase in Figure4a to a progressive increase in the number of activated Ce3+

emitters that are located close enough to the Al nanostructureto be enhanced. More of these dopants are reached and excitedas the electrons penetrate deeper into the film. Thus, between1.0 and 2.0 kV the signal-to-noise ratio and enhancement factorboth improve. Yet, beyond 2.0 kV, the enhancement factorplateaus because there are no additional Ce3+ to be excited. Theplateau could also be caused by a balance of CL enhancementof some Ce3+ emitters and CL quenching of others closer to theAl surface. In any case, the Monte Carlo simulation at 1.8 kVshows that very few electrons reach the Al even though theyapproach the interface. Thus, moving toward more delicatesamples, 1.8 kV would be the ideal accelerating voltage at thisfilm thickness because the near-field interaction is maximizedwith a very low probability of electrons interacting directly withthe sample (see Supporting Information Figures S5 and S6).Although our imaging study of Al nanostructures enables us

to determine the measurement parameters required fornoninvasive imaging, we chose to demonstrate unequivocallythat CL-activated imaging can be successfully used to measuremore delicate samples that could not be imaged with traditionalCL microscopy. To show that CL-activated nanoimaging canalso be performed on soft materials that are easily damaged bydirect excitation with an electron beam, a conjugated polymerblend of polyfluorene (PFO) and poly(9,9-dioctylfluorene-alt-benzothiadiazole) (F8BT), as one might find in bulkheterojunction organic solar cells,52 was encapsulated forimaging using a scheme similar to that used with the Alnanostructures (Figure 5a). Here, the imaging contrastmechanism relies on FRET between the scintillator (donor)and the PFO in the polymer film (acceptor), which is facilitatedby physical proximity and by strong spectral overlap betweendonor emission and acceptor absorption (Figure 5d). Thisnear-field, nonradiative transfer of excitation energy from donorto acceptor requires that the amount of luminescenceoriginating from a spot in the polymer film should beaccompanied by a proportional decrease in the amount ofluminescence from the adjacent spot in the scintillator, which isprecisely what we observe. By recording in parallel the emissionof YAP:Ce (Figure 5b) and the red-shifted emission of PFO(Figure 5c), we find that the spatial maps of polymer andscintillator emission are anticorrelated in intensity. Areas of lowCL emission in Figure 5b appear where the scintillator film cantransfer significant excitation energy to nearby PFO; thecorresponding regions in Figure 5c PFO channel are verybright. In contrast, high intensity YAP:Ce luminescence areasshow that PFO is too far from the YAP:Ce surface forsignificant amounts of energy transfer to occur, and correspondto regions of low intensity in Figure 5c. Our contrastmechanism interpretation is supported by the time-resolvedPL measurements in Figure 5e that show that the YAP:Celifetime is reduced from 16.5 to 10.2 ns when PFO is applied tothe surface. Additionally, a line-cut across a gradient inluminescence in Figure 5b has an 80/20 width of 68 nm(Figure 5f), which is well below the diffraction limit and is thusconsistent with a near-field, rather than far-field, interactionbetween the scintillator and polymer film. The intensity

variations observed on this length scale could be due to ripplesin the film surface or due to the presence of F8BT, which couldalso act as a FRET acceptor to PFO. Importantly, these imagesalso demonstrate that CL-activated imaging is nondamaging tosoft materials. By contrast, attempts at direct imaging of similarpolymer films with an electron beam do not yield CL imagesdue to instantaneous bleaching of the organic chromophoresupon interaction with the electrons.In sum, we have introduced subdiffraction optical imaging

using a CL-activated near-field scanning optical microscopy thatemploys the nanoscale excitation volume generated by a low-energy electron beam in a thin YAP:Ce scintillator film. Wehave demonstrated its capability by mapping the luminescenceenhancement of Ce3+ dopants in the scintillator film due to thepresence of Al nanostructures with 46 nm resolution and bymapping the Ce3+ luminescence quenching in tandem with theluminescence of conjugated polymers with 68 nm resolution.Because CL-activated nanoimaging maps how the presence ofthe sample affects the emission of nearby Ce3+ emitters, thisapproach provides information that is complementary to typicalelectron imaging techniques used to study the opticalproperties of nanostructures. For example, the more highlyspatially resolved electron energy loss spectroscopy and directCL measurements both rely on direct interactions betweenelectrons and the sample. We have shown, however, that CL-activated imaging can additionally resolve nanoscale features inmaterials that cannot be imaged using these traditional electronmicroscopies due to damage induced by direct electronexcitation. In particular, we have demonstrated that the Ce3+

luminescent centers excited by an electron beam can transferenergy via FRET to samples with endogenous chromophoressuch as polymer blends, whose red-shifted emission iscorrelated with the position of the electron beam to form animage. Furthermore, our CL-activated approach can be used fornanoimaging of a large class of samples with endogenouschromophores, such as soft, functional materials found, forexample, in organic and hybrid organic−inorganic solar cellsand light emitting diodes. This capability puts it at a greatadvantage over traditional super-resolution fluorescence mi-croscopy, whose average spatial resolutions are comparable, insituations where one cannot use exogenous fluorescent orphotoswitchable labels.Moreover, by fabricating free-standing membranes of

YAP:Ce, we could create an imaging device that also servesas a liquid sample cell containing biomolecules, where theYAP:Ce free-standing film would act as a barrier between thevacuum environment of the SEM and the aqueous environmentof the sample. In this fashion, the YAP:Ce film could FRET tothe sample’s spectrally compatible fluorescent labels in thesame way that we have shown with the polymer film.Specifically, small dye molecules or fluorescent proteinsconjugated to the biomolecules of interest should couple tothe scintillator film in precisely the same way as do thechromophores in the polymer film. Using this cell incombination with the fast-scanning capability of the electronbeam, one could resolve the real-time dynamics of biomolecularinteractions under physiological conditions and at theircharacteristic length scales. For example, the nanoscaledynamics of deoxyribonucleic acid (DNA) repair could bevisualized by tethering DNA to the surface of the scintillatorfilm and imaging a labeled protein diffusing in one-dimensionalong the DNA. One could also observe the two-dimensionaldiffusion of labeled membrane proteins on a crowded lipid

Nano Letters Letter

DOI: 10.1021/acs.nanolett.5b00716Nano Lett. XXXX, XXX, XXX−XXX

F

membrane or the light-induced reorganization of proteincomplexes in a densely packed thylakoid membrane to unravelthe regulation of energy flow in photosynthesis.

■ ASSOCIATED CONTENT

*S Supporting InformationThe Supporting Information contains a quantitative measure ofthe brightness uniformity of the scintillator thin film, a signal-to-noise ratio discussion, a description of the materials andmethods, an explanation of the finite-difference time-domain(FDTD) calculations, a discussion regarding how we calculatedour experimental CL enhancement factor, and a discussion ofbalancing the imaging brightness, damage, and resolution as afunction of accelerating voltage. This material is available free ofcharge via the Internet at http://pubs.acs.org.

■ AUTHOR INFORMATION

Corresponding Author*E-mail: [email protected].

Present Address○KLA Tencor, 1 Technology Drive, Milpitas, California 95035,United States.

Author ContributionsN.S.G. conceived of and supervised the project. C.G.B., C.L.H.,D.M.K., and N.S.G. designed the research. C.G.B. grew theYAP:Ce films, fabricated the Al nanostructures and the imagingdevice for the Al nanostructures and polymer blends, acquiredand analyzed SE and CL images and PL lifetime measurementsand performed CASINO and FDTD simulations. C.L.H.performed the PECVD nitride deposition step of the imagingdevice fabrication. Z.W. grew the Si/SrTiO3/LaAlO3 substrates.J.T.P. acquired AFM images of the Al nanostructures. C.G.B.,C.L.H., and J.T.P. analyzed the data. D.G.S. advised on SrTiO3/LaAlO3 film preparation. C.G.B. and N.S.G. wrote themanuscript, and all authors revised and approved themanuscript.

NotesThe authors declare no competing financial interest.

■ ACKNOWLEDGMENTS

YAP:Ce film deposition and CL characterization weresupported by the National Science Foundation under GrantNumber 1152656. Nanofabrication was supported by theChemical Sciences, Geosciences and Biosciences Division,Office of Basic Energy Sciences, Office of Science, U.S.Department of Energy, FWP number SISGRN. Devices werefabricated both at the Marvell Nanofabrication Laboratory andBiomolecular Nanotechnology Center at UC Berkeley. CL andtime-resolved fluorescence at the LBL Molecular Foundry wereperformed as part of the Molecular Foundry user program,supported by the Office of Science, Office of Basic EnergySciences, of the U.S. Department of Energy under Contract No.DE-AC02-05CH11231. Z.W. and D.G.S. acknowledge supportunder the AFOSR Grant No. FA9550-10-1-0123, C.G.B.acknowledges an NSF Graduate Research Fellowship (DGE1106400) and N.S.G. acknowledges a David and Lucile PackardFellowship for Science and Engineering. We thank S. Aloni andD. F. Ogletree for providing technical and theoretical advice,and we thank R. Ramesh for access to PLD facilities.

■ REFERENCES(1) Betzig, E.; Patterson, G. H.; Sougrat, R.; Lindwasser, O. W.;Olenych, S.; Bonifacino, J. S.; Davidson, M. W.; Lippincott-Schwartz,J.; Hess, H. F. Science 2006, 313 (5793), 1642−1645.(2) Rust, M. J.; Bates, M.; Zhuang, X. Nat. Methods 2006, 3 (10),793−796.(3) Hess, S. T.; Girirajan, T. P. K.; Mason, M. D. Biophys. J. 2006, 91(11), 4258−4272.(4) Pavani, S. R. P.; Thompson, M. A.; Biteen, J. S.; Lord, S. J.; Liu,N.; Twieg, R. J.; Piestun, R.; Moerner, W. E. Proc. Natl. Acad. Sci.U.S.A. 2009, 106 (9), 2995−2999.(5) Hell, S. W. Science 2007, 316 (5828), 1153−1158.(6) Gustafsson, M. G. L. Proc. Natl. Acad. Sci. U.S.A. 2005, 102 (37),13081−13086.(7) Garcia-Parajo, M. F. Nat. Photonics 2008, 2 (4), 201−203.(8) Kawata, S.; Inouye, Y.; Verma, P. Nat. Photonics 2009, 3 (7),388−394.(9) Novotny, L.; van Hulst, N. Nat. Photonics 2011, 5 (2), 83−90.(10) Lewis, A.; Isaacson, M.; Harootunian, A.; Muray, A. Ultra-microscopy 1984, 13 (3), 227−231.(11) Pohl, D. W.; Denk, W.; Lanz, M. Appl. Phys. Lett. 1984, 44 (7),651−653.(12) Betzig, E.; Trautman, J. K.; Harris, T. D.; Weiner, J. S.; Kostelak,R. L. Science 1991, 251 (5000), 1468−1470.(13) Zenhausern, F.; O’Boyle, M. P.; Wickramasinghe, H. K. Appl.Phys. Lett. 1994, 65 (13), 1623−1625.(14) Hartschuh, A.; Sanchez, E. J.; Xie, X. S.; Novotny, L. Phys. Rev.Lett. 2003, No. 9, 095503−1.(15) Kuhn, S.; Hakanson, U.; Rogobete, L.; Sandoghdar, V. Phys. Rev.Lett. 2006, 97 (1), 017402.(16) Neacsu, C. C.; Berweger, S.; Olmon, R. L.; Saraf, L. V.; Ropers,C.; Raschke, M. B. Nano Lett. 2010, 10 (2), 592−596.(17) Weber-Bargioni, A.; Schwartzberg, A.; Cornaglia, M.; Ismach,A.; Urban, J. J.; Pang, Y.; Gordon, R.; Bokor, J.; Salmeron, M. B.;Ogletree, D. F.; Ashby, P.; Cabrini, S.; Schuck, P. J. Nano Lett. 2011,11 (3), 1201−1207.(18) Zhu, Y.; Inada, H.; Nakamura, K.; Wall, J. Nat. Mater. 2009, 8(10), 808−812.(19) Yacobi, B. G.; Holt, D. B. Cathodoluminescence microscopy ofinorganic solids; Plenum Press: New York, 1990.(20) Yamamoto, N.; Araya, K.; García de Abajo, F. J. Phys. Rev. B2001, 64 (20), 205419.(21) Vesseur, E. J. R.; de Waele, R.; Kuttge, M.; Polman, A. NanoLett. 2007, 7 (9), 2843−2846.(22) Knight, M. W.; Liu, L.; Wang, Y.; Brown, L.; Mukherjee, S.;King, N. S.; Everitt, H. O.; Nordlander, P.; Halas, N. J. Nano Lett.2012, 12 (11), 6000−6004.(23) Sapienza, R.; Coenen, T.; Renger, J.; Kuttge, M.; van Hulst, N.F.; Polman, A. Nat. Mater. 2012, 11 (9), 781−787.(24) Kociak, M.; Stephan, O. Chem. Soc. Rev. 2014, 43 (11), 3865−3883.(25) Coenen, T.; Arango, F. B.; Koenderink, A. F.; Polman, A. Nat.Commun. 2014, 5, 3250.(26) Haegel, N. M.; Chisholm, D. J.; Cole, R. A. J. Cryst. Growth2012, 352 (1), 218−223.(27) Haegel, N. M. Nanophotonics 2013, 3 (1−2), 75−89.(28) Zagonel, L. F.; Mazzucco, S.; Tence, M.; March, K.; Bernard, R.;Laslier, B.; Jacopin, G.; Tchernycheva, M.; Rigutti, L.; Julien, F. H.;Songmuang, R.; Kociak, M. Nano Lett. 2011, 11 (2), 568−573.(29) Hayes, T. L.; Pease, R. F. Adv. Biol. Med. Phys. 1967, 12, 85−137.(30) Herbst, R.; Hoder, D. Scanning 1978, 1 (1), 35−41.(31) Niioka, H.; Furukawa, T.; Ichimiya, M.; Ashida, M.; Araki, T.;Hashimoto, M. Appl. Phys. Express 2011, 4 (11), 112402.(32) Glenn, D. R.; Zhang, H.; Kasthuri, N.; Schalek, R.; Lo, P. K.;Trifonov, A. S.; Park, H.; Lichtman, J. W.; Walsworth, R. L. Sci. Rep.2012, 2, 865.(33) Furukawa, T.; Niioka, H.; Ichimiya, M.; Nagata, T.; Ashida, M.;Araki, T.; Hashimoto, M. Opt. Express 2013, 21 (22), 25655.

Nano Letters Letter

DOI: 10.1021/acs.nanolett.5b00716Nano Lett. XXXX, XXX, XXX−XXX

G

(34) Yoon, H. P.; Lee, Y.; Bohn, C. D.; Ko, S.-H.; Gianfrancesco, A.G.; Steckel, J. S.; Coe-Sullivan, S.; Talin, A. A.; Zhitenev, N. B. AIPAdv. 2013, 3 (6), 062112.(35) Inami, W.; Nakajima, K.; Miyakawa, A.; Kawata, Y. Opt. Express2010, 18 (12), 12897−12902.(36) Kaz, D. M.; Bischak, C. G.; Hetherington, C. L.; Howard, H. H.;Marti, X.; Clarkson, J. D.; Adamo, C.; Schlom, D. G.; Ramesh, R.;Aloni, S.; Ogletree, D. F.; Ginsberg, N. S. ACS Nano 2013, 7 (11),10397−10404.(37) Kumaran, R.; Webster, S. E.; Penson, S.; Li, W.; Tiedje, T. J.Cryst. Growth 2009, 311 (7), 2191−2194.(38) Warusawithana, M. P.; Cen, C.; Sleasman, C. R.; Woicik, J. C.;Li, Y.; Kourkoutis, L. F.; Klug, J. A.; Li, H.; Ryan, P.; Wang, L.-P.;Bedzyk, M.; Muller, D. A.; Chen, L.-Q.; Levy, J.; Schlom, D. G. Science2009, 324 (5925), 367−370.(39) Warusawithana, M. P.; Richter, C.; Mundy, J. A.; Roy, P.;Ludwig, J.; Paetel, S.; Heeg, T.; Pawlicki, A. A.; Kourkoutis, L. F.;Zheng, M.; Lee, M.; Mulcahy, B.; Zander, W.; Zhu, Y.; Schubert, J.;Eckstein, J. N.; Muller, D. A.; Hellberg, C. S.; Mannhart, J.; Schlom, D.G. Nat. Commun. 2013, 4, 2351.(40) Gersten, J.; Nitzan, A. J. Chem. Phys. 1981, 75 (3), 1139−1152.(41) Moskovits, M. Rev. Mod. Phys. 1985, 57 (3), 783−826.(42) Ebenstein, Y.; Mokari, T.; Banin, U. J. Phys. Chem. B 2004, 108(1), 93−99.(43) Lakowicz, J. R. Anal. Biochem. 2005, 337 (2), 171−194.(44) Anger, P.; Bharadwaj, P.; Novotny, L. Phys. Rev. Lett. 2006, 96(11), 113002.(45) Pompa, P. P.; Martiradonna, L.; Torre, A. D.; Sala, F. D.;Manna, L.; Vittorio, M. D.; Calabi, F.; Cingolani, R.; Rinaldi, R. Nat.Nanotechnol. 2006, 1 (2), 126−130.(46) Willets, K. A.; Van Duyne, R. P. Annu. Rev. Phys. Chem. 2007, 58(1), 267−297.(47) Kinkhabwala, A.; Yu, Z.; Fan, S.; Avlasevich, Y.; Mullen, K.;Moerner, W. E. Nat. Photonics 2009, 3 (11), 654−657.(48) Masiello, D. J.; Schatz, G. C. J. Chem. Phys. 2010, 132 (6),064102.(49) Munechika, K.; Chen, Y.; Tillack, A. F.; Kulkarni, A. P.; Plante, I.J.-L.; Munro, A. M.; Ginger, D. S. Nano Lett. 2010, 10 (7), 2598−2603.(50) Dionne, J. A.; Atwater, H. A. MRS Bull. 2012, 37 (08), 717−724.(51) Drouin, D.; Couture, A. R.; Joly, D.; Tastet, X.; Aimez, V.;Gauvin, R. Scanning 2007, 29 (3), 92−101.(52) Yu, G.; Gao, J.; Hummelen, J. C.; Wudl, F.; Heeger, A. J. Science1995, 270 (5243), 1789−1791.

Nano Letters Letter

DOI: 10.1021/acs.nanolett.5b00716Nano Lett. XXXX, XXX, XXX−XXX

H

![Digital Aerial Photogrammetry (DAP) and Airborne Laser ......biomass [30,31], and estimation of subcanopy solar radiation [32]. Due to the noninvasiveness, speed Due to the noninvasiveness,](https://static.fdocuments.us/doc/165x107/5ff5ac8f7f39a511756fc3e7/digital-aerial-photogrammetry-dap-and-airborne-laser-biomass-3031.jpg)