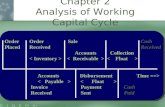

Raking in Revenue: Optimizing Order-to-Cash Cycle (O2C) by Automating Accounts Receivable

Cash Order Cycle

-

Upload

ram-mohan-reddyp -

Category

Documents

-

view

224 -

download

0

Transcript of Cash Order Cycle

-

8/8/2019 Cash Order Cycle

1/25

In this Document Purpose Scope and Application Order To Cash Flow Cycle In Order Management Create customer Create Item

Organization Overview Create stock for item using Miscellaneous Receipt Assign item to Price List Defaulting Rules Create Order Pick Release Ship Confirm Invoice

Platforms: 1-914CU;

This document is being delivered to you via Oracle Support'sRapid Visibility (RaV) process and therefore has not been subject to an independenttechnical review.

Applies to:

Oracle Order Management - Version: 11.5.7 to 12.1.1 - Release: 11.5Information in this document applies to any platform.

Purpose

The purpose of this page is to help Customers and Support Engineers build an basic Order to Cashtestcase.

Scope and Application

This note is intended for any users who tries to a basic Order to Cash cycle in Order Management. Thisscope of this note is to create a basic testflow in Order Management (OM), from sales order entry toinvoicing. It is intended to help new Support Engineers in OM and Support Engineers of other productsthat integrate with OM.

Examples are provided here works in Internal Instance and can be used on a caveat emptor basis. Thescreenshots were taken from an 11.5.10 CU3 instance.

Order To Cash Flow Cycle In Order Management

Use the responsibility Order Management Super User, Vision Operations (USA).Create your own user from the Sysadmin responsibility and assign this responsibility. Otherwise, find thisresponsibility already assigned to users such as OPERATIONS/WELCOME or MFG/WELCOME.

https://support.oracle.com/CSP/main/article?cmd=show&type=NOT&doctype=BULLETIN&id=985504.1#PURPOSEhttps://support.oracle.com/CSP/main/article?cmd=show&type=NOT&doctype=BULLETIN&id=985504.1#SCOPEhttps://support.oracle.com/CSP/main/article?cmd=show&type=NOT&doctype=BULLETIN&id=985504.1#BODYTEXThttps://support.oracle.com/CSP/main/article?cmd=show&type=NOT&doctype=BULLETIN&id=985504.1#aref1https://support.oracle.com/CSP/main/article?cmd=show&type=NOT&doctype=BULLETIN&id=985504.1#aref2https://support.oracle.com/CSP/main/article?cmd=show&type=NOT&doctype=BULLETIN&id=985504.1#aref3https://support.oracle.com/CSP/main/article?cmd=show&type=NOT&doctype=BULLETIN&id=985504.1#aref4https://support.oracle.com/CSP/main/article?cmd=show&type=NOT&doctype=BULLETIN&id=985504.1#aref5https://support.oracle.com/CSP/main/article?cmd=show&type=NOT&doctype=BULLETIN&id=985504.1#aref6https://support.oracle.com/CSP/main/article?cmd=show&type=NOT&doctype=BULLETIN&id=985504.1#aref7https://support.oracle.com/CSP/main/article?cmd=show&type=NOT&doctype=BULLETIN&id=985504.1#aref8https://support.oracle.com/CSP/main/article?cmd=show&type=NOT&doctype=BULLETIN&id=985504.1#aref9https://support.oracle.com/CSP/main/article?cmd=show&type=NOT&doctype=BULLETIN&id=985504.1#aref10https://support.oracle.com/CSP/main/article?cmd=show&type=NOT&doctype=BULLETIN&id=985504.1#SCOPEhttps://support.oracle.com/CSP/main/article?cmd=show&type=NOT&doctype=BULLETIN&id=985504.1#BODYTEXThttps://support.oracle.com/CSP/main/article?cmd=show&type=NOT&doctype=BULLETIN&id=985504.1#aref1https://support.oracle.com/CSP/main/article?cmd=show&type=NOT&doctype=BULLETIN&id=985504.1#aref2https://support.oracle.com/CSP/main/article?cmd=show&type=NOT&doctype=BULLETIN&id=985504.1#aref3https://support.oracle.com/CSP/main/article?cmd=show&type=NOT&doctype=BULLETIN&id=985504.1#aref4https://support.oracle.com/CSP/main/article?cmd=show&type=NOT&doctype=BULLETIN&id=985504.1#aref5https://support.oracle.com/CSP/main/article?cmd=show&type=NOT&doctype=BULLETIN&id=985504.1#aref6https://support.oracle.com/CSP/main/article?cmd=show&type=NOT&doctype=BULLETIN&id=985504.1#aref7https://support.oracle.com/CSP/main/article?cmd=show&type=NOT&doctype=BULLETIN&id=985504.1#aref8https://support.oracle.com/CSP/main/article?cmd=show&type=NOT&doctype=BULLETIN&id=985504.1#aref9https://support.oracle.com/CSP/main/article?cmd=show&type=NOT&doctype=BULLETIN&id=985504.1#aref10https://support.oracle.com/CSP/main/article?cmd=show&type=NOT&doctype=BULLETIN&id=985504.1#PURPOSE -

8/8/2019 Cash Order Cycle

2/25

Create customer

Define a customer that you will enter in the sales order. You could use an existing customer defined in theVision Database, in which case this step would be optional for this testflow. However, it is highly

recommended that you create your own customer if you need to make changes to customer specificsetup.

Some common customers used often for testing OM in Vision are :A. C. Networks, AT&T Universal Card, Business World (Customer Number 1608)

1. Navigate to Customers -> Standard.

Enter a new customer name in the Name field, and press Find.

Press the 'New' button when you get the below decision window. If the customer name alreadyexists, go back and enter a name that does not already exist.

does not already exist.

2. In the Addresses tab, click on New.

3. Enter the following information in the Customer Addresses screen.

Address : Enter the required fields (they will fist appear in yellow).

-

8/8/2019 Cash Order Cycle

3/25

Usage = Bill To : Check the Primary flag. Save.

Usage = Ship To : Check the Primary flag.

Select the Bill to Location created above from the LOV. Save

4. Notice the 'Open' button in the screenshot above. This is where you can enter additional details specificto the business purpose. So, if the cursor is on the 'Ship To' row as seen here, clicking on Open will allowto enter information specific to the Ship To Location. This can be examined further in the Defaulting Rulessection.

Create Item

Create an item that will be entered in the sales order. Use existing items defined in the Vision Database,in which case this step would be optional for this testflow. However, it is highly recommended to createown item if needed to make changes to item specific setup.

Some commonly used items in the Vision Database for testing in OM are :AS54888, CM13139, CM18759

1. Navigate to Inventory > Items > Master Items

2. When prompted, select 'M1 Seattle Manufacturing' from the Organizations list. If this list did not comeup, go to Inventory > Change Organization, and make sure you select this organization.

Notice when the screen opens, the Organization field shows V1 (Vision Operations). This isbecause we have opened the Master Items form, and V1 is the master organization of M1. Seethe Organization Overview section for more details on this relationship.

-

8/8/2019 Cash Order Cycle

4/25

3. Enter a name for the Item and Description.

4. Go to Tools > Copy From...Select the Template 'Purchased Item'.Click on 'Apply' and then click on 'Done'.

5. The seeded template 'Purchased Item' will assign the necessary item attributes to go through this basic

OM testflow. For example, check some of the following item attributes that you did not need to setmanually because they were assigned from the template.

Inventory Item, Stockable, Transactable, Reservable (click on the arrow to the right of all the tabs)Customer Ordered, Customer Orders Enabled, Shippable, OE Transactable

6. So far defined the item in the Item Master Organization, V1. Next, go to Tools > OrganizationAssignment. Alternatively, click on the 3rd tab on the left side of the screen as circled in red in the belowscreenshot.This is where you will find a list of organizations (child organizations) that have V1 as their masterorganization. M1 shows at the top because we had selected it in Step 2. The item attributes defined in V1can be assigned to the child organizations by checking the Assigned box.

Check the Assigned box for the organization M1. Items needs to be enabled in the organizationsin which they will be transacted.

-

8/8/2019 Cash Order Cycle

5/25

SQL Tip:

1. Finding the inventory_item_id and organization assignment of the item

select inventory_item_id, segment1, organization_id from mtl_system_items_bwhere segment1 = 'YS Item';

INVENTORY_ITEM_ID SEGMENT1 ORGANIZATION_ID----------------- ---------------------------------------- ---------------43817 YS Item 20443817 YS Item 207

2. Finding the organization code of the organization_id's from Inventory parameters

select organization_id, organization_code from mtl_parameterswhere organization_id in (204,207);

ORGANIZATION_ID ORG--------------- ---

204 V1207 M1

7. The item attributes can be changed at each individual child organization level by clicking on the OrgAttributes button in the screenshot above, or by going to Inventory > Items > Organization Items. Note,however, that this depends on whether the item attribute is controlled at the master org level or the childorg level, which is defined in Inventory > Setup > Items > Attribute Controls. This is not within the scope ofthis testflow.

-

8/8/2019 Cash Order Cycle

6/25

-

8/8/2019 Cash Order Cycle

7/25

4. Place the cursor on the classification Inventory Organization again, click on the Others button andselect 'Inventory Information' from the list.

Notice this is where the Inventory organization parameters are defined.

This screen can also be accessed directly from Inventory > Setup > Organizations > Parameters.

Notice this is where the organization code 'M1' is specified, and the Item Master Organization isspecified as 'Vision Operations' (V1). This sets the relationship for Seattle Manufacturing (childorg) and Vision Operations (master org).

-

8/8/2019 Cash Order Cycle

8/25

5-a. As an optional step, you can query the organization 'Vision Operations' and check that it is classfiedas both a Legal Entity and Operating Unit (see Step 3) as well as an Inventory Organization. If you checkthe Inventory Organization Parameters for 'Vision Operations' you will notice that the organization code isdefined as 'V1'. The master org is itself.

5-b. As another optional step, you can go to Edit > Preferences > Profiles, and run a query with the profilename 'MO:%'. You will see the value for the profile option 'MO: Operating Unit' being 'Vision Operations'.This is the Operating unit in which the OM transactions are created when logged into the responsibilityused in this testflow (for R11i).In R12, the Multi-Org Access Control (MOAC) feature enables users to access to one or more OperatingUnits within one user responsibility.

Create stock for item using Miscellaneous Receipt

-

8/8/2019 Cash Order Cycle

9/25

1. Make sure you are in the organization M1. If not, navigate to Inventory > Change Organization, andselect the organization M1 Seattle Manufacturing.

2. Navigate to Inventory > Transactions > Miscellaneous Transaction, and enter the following information:Type : Miscellaneous receiptClick on the Transaction Lines button

3. In the Miscellaneous receipt (M1) form, enter the following information:Item : Subinventory : FGIQuantity : 100Account : Invoke the LOV and enter the Account Alias 'Miscellaneous'Save changes.

4. (Optional) Check the material transaction that was just created.- Navigate to Inventory > Transactions > Material Transactions- Enter your item in the Find Material Transactions screen and click on Find.- Verify that the Miscellaneous Receipt transaction exists.

5. (Optional) Check the On-hand quantity for your item.

- Navigate to Inventory > On-hand, Availability > On-hand Quantity- Enter your item in the Query Material screen and click on Find.- Verify that the On-hand quantity exists.

Assign item to Price List

1. Navigate to Pricing > Price Lists > Price List Setup. You could create a new price list, but in this

testflow, we will assign your item to an existing price list 'Corporate'.

Query the price list 'Corporate'.

2. Move the cursor to the List Lines section, and add a new line using Ctrl + Down Arrow on your

keyboard, or by going to File > New. Enter the following information :

Product Context : Item

Product Attribute : Item Number

Product Value :

Value : 100

The rest of the required fields should default in

-

8/8/2019 Cash Order Cycle

10/25

Defaulting Rules

Defaulting rules determine the values that you want to get defaulted into a sales order to reduce

the amount of information you need to enter manually. You could create and modify defaulting

rules, in which case the Defaulting Generator concurrent program needs to be run.In this testflow, however, we will only look at an existing seeded defaulting rule for the field Order

Type. Based on that, we will set up a default value for the Order Type at the customer's Invoice

To location level.

1. Navigate to Setup > Rules > Defaulting.

-Click on the Flashlight icon, and select the entity Order Header.

-

8/8/2019 Cash Order Cycle

11/25

- In the Attributes section, place the cursor on the line with Attribute = Order Type, and click on

the Defaulting Rules button.

-

8/8/2019 Cash Order Cycle

12/25

2. Examine the setup from the following screenshot. This is saying that when entering a sales

order, the Order Type will default to the value set up at the Invoice To, Ship To, and finally the

Customer, wherever it is found first in that sequence.

-

8/8/2019 Cash Order Cycle

13/25

3. So, let's set up a default value for Order Type at the customer's Invoice To level.

Navigate to Customers > Standard.

In the Find/Enter Customer screen, enter your customer name and click on Find.

In the next Match Results screen, make sure you place the cursor on the row with a value in theCustomer Number field, and click on OK.

In the Addresses tab, place the cursor on the row for your address and click on Open.

In the Business Purpose tab, place the cursor on the row for the usage 'Bill To' and click onOpen. This is the 'Invoice To' level we saw in the previous step.

Go to the Order Management tab, and enter the Order Type 'Mixed'. Save.

-

8/8/2019 Cash Order Cycle

14/25

4. In the next 'Create Order' section, you will notice that the Order Type will default to Mixed, due to thissetup.

Create Order

We are now ready to create a sales order.

1. Navigate to Orders, Returns > Sales Orders and make sure the following information is

entered. Notice how some of these fields (in addition to others), get defaulted due to the

Defaulting Rules setup.

*Order Information tab (Order Header)

Customer Name :

Make sure the Ship To/Bill To Locations are defaulted in.

Order Type : Mixed

Price List : Corporate

Salesperson : No Sales Credit

Payment Terms : N30

Warehouse : M1

Save

-

8/8/2019 Cash Order Cycle

15/25

2. Go to the Line Items tab, and enter the following information.

*Line Items tab (Order Lines)

Ordered Item :

Qty : 10UOM : Defaults to Ea

Save.

* In the Pricing tab, notice that the Price List Corporate has defaulted from the Header, and that

the List Price 100 is the price you set up in the price list. The Unit Selling Price is the same as the

List Price in this example, but it will show a different value if there is a discount or surcharge

applied to the list price. For example, if you apply a 10% discount modifier, the List Price will be

100 and the Selling Price will be 90.

-

8/8/2019 Cash Order Cycle

16/25

* In the Shipping tab, notice that the Warehouse is M1. This is the warehouse from which the item

will be shipped out to the customer.

3. Book the Order.

Click on the button 'Book Order' in the header or lines.

*You should see a note saying Order has been booked. Notice the status of the order header has

changed from Entered to 'Booked', and the status of the line (check the Status field in the Maintab of the lines) has changed from Entered to 'Awaiting Shipping'.

SQL Tip:

select order_number, header_id, flow_status_code from oe_order_headers_allwhere order_number = 58095;

ORDER_NUMBER HEADER_ID FLOW_STATUS_CODE--------------------- ------------- ------------------

58095 98956 BOOKED

--note, order_number may be same across orders but header_id is unique

select header_id, line_id, line_number, flow_status_code from oe_order_lines_all whereheader_id = 98956;

-

8/8/2019 Cash Order Cycle

17/25

HEADER_ID LINE_ID LINE_NUMBER FLOW_STATUS_CODE---------- ---------- ----------- ------------------------------98956 201594 1 AWAITING_SHIPPING

*This is the point that a 'delivery detail' will be created in Shipping that is associated with this order line.As an optional step, you can check the following.Navigate to Shipping > TransactionsEnter your order number and click on FindIn the Lines/LPNs tab, you should find the delivery detail withLine Status = Ready to Release and Next Step = Pick Release, which we will do next.

SQL Tips:

select source_header_number, source_header_id, source_line_id, delivery_detail_id,released_statusfrom wsh_delivery_details

where source_code = 'OE' and source_line_id = 201594;

SOURCE_HEADER_NUMBER SOURCE_HEADER_ID SOURCE_LINE_IDDELIVERY_DETAIL_ID RELEASED_STATUS

58095 98956 201594 279193 R

--R=Ready to Release

*Optional : Run the following queries to understand the distinction between the shipping warehouse andoperating unit columns in the order header/lines tables. Refer to the Organization Overview section forconcepts. 207 is the ID for Seattle Manufacturing. 204 is the ID for Vision Operations.

SQL Tips:ORG_ID = Operating Unit which performed this transactionSHIP_FROM_ORG_ID = Ship From Organization Id - Warehouse (the Inventory Organization)

select order_number, header_id, ship_from_org_id, org_idfrom oe_order_headers_all where header_id = 98956;

ORDER_NUMBER HEADER_ID SHIP_FROM_ORG_ID ORG_ID------------ ---------- ---------------- ----------58095 98956 207 204

select header_id, line_id, line_number, ship_from_org_id, org_idfrom oe_order_lines_all where header_id = 98956;

HEADER_ID LINE_ID LINE_NUMBER SHIP_FROM_ORG_ID ORG_ID---------- ---------- ----------- ---------------- ----------98956 201594 1 207 204

Pick Release

1. Navigate to Shipping > Release Sales Orders > Release Sales Orders

-

8/8/2019 Cash Order Cycle

18/25

In the Order tab, enter your order number.

In some cases, you may need to remove the defaulted 'To' value for 'Scheduled Ship Dates' and'Requested Dates' fields, if the order line you created has a future date for these fields. Pickrelease will only consider lines within the dates specified.

you created has a future date for these fields. Pick release will only consider lines within the datesspecified.

Inventory tab and enter the warehouse M1. Set the following value if it is not defaulted.

Auto Allocate = Yes

-

8/8/2019 Cash Order Cycle

19/25

*Go to the Shipping tab. Set the following value if it is not defaulted.

Autocreate Delivery = Yes

Auto Pick Confirm = Yes

2. Click on the Concurrent button

-

8/8/2019 Cash Order Cycle

20/25

Ship Confirm

1. Navigate to Shipping > Transactions.

In the Query Manager screen, enter your order number in the From Order Number field and tabout. Then, click on the Find button.

2. Notice the following in the Lines/LPNs tab.

Detail : The delivery detail of the shipment

Delivery : The delivery that got autocreated during pick release

Line Status : Staged/Pick Confirmed

Next Step : Ship Confirm/Close Trip Stop

SQL Tip:

Note, the same query as before shows that the released_status is now Y (Staged).select source_header_number, source_header_id, source_line_id, delivery_detail_id,released_statusfrom wsh_delivery_detailswhere source_code = 'OE' and source_line_id = 201594;

-

8/8/2019 Cash Order Cycle

21/25

SOURCE_HEADER_NUMBER SOURCE_HEADER_ID SOURCE_LINE_ID DELIVERY_DETAIL_IDRELEASED_STATUS

58095 98956 201594 279193 Y

select wnd.delivery_id, wnd.status_codefrom wsh_new_deliveries wnd, wsh_delivery_assignments wda, wsh_delivery_details wddwhere wdd.delivery_detail_id = wda.delivery_detail_idand wda.delivery_id = wnd.delivery_idand wdd.delivery_detail_id = 279193;

DELIVERY_ID STATUS

----------- ---------

106904 OP

3. Go to the Delivery tab and click the Ship Confirm button. In the Confirm Delivery window,

accept the default parameters and click on OK.

*Not checking the Defer Interface checkbox, as shown here, ensures that the next step, running

the Interface Trip Stop (ITS) concurrent program, happens automatically. Deferring ITS (checking

-

8/8/2019 Cash Order Cycle

22/25

this box) means you need to run the concurrent in a separate step. That can be done from

Shipping > Interfaces > Run (Interface Trip Stop - SRS).

*You will get a message that the delivery has been confirmed. (Sometimes it could show some

warning message that could be ignored for the purposes of this test).

4. Go to View > Requests, and verify that the Interface Trip Stop completed successfully.

SQL Tip:

select delivery_detail_id, released_status, oe_interfaced_flag, inv_interfaced_flagfrom wsh_delivery_detailswhere source_code = 'OE' and source_line_id = 201594;

DELIVERY_DETAIL_ID R O I

------------------ - - -

279193 C Y Y

* released_status = C (Shipped) -- becomes Shipped after ship confirm, even before ITS

* oe_interfaced_flag = Y -- signifies ITS has interfaced shipping data to OM

* inv_interfaced_flag = Y -- signifies ITS has interfaced shipping data to INV

5. As an optional step, you can check if the item has actually been shipped out of inventory.

*Make sure you are in the organization M1. If not, navigate to Inventory > Change Organization

and select M1.

*Navigate to Inventory > Transactions > Material Transactions

*Enter the following information in the Find Material Transactions screen and click on Find

Transaction Date : Ensure the transaction date is within the range specified

Source Type : Sales Order

Source :-Evoke the LOV and click on the button Combinations

-Enter your Sales Order Number and Order Type Mixed, then click OK

-Example : 58095.Mixed.ORDER ENTRY

*Go to the Transaction Type tab, and notice the line with Transaction Type = Sales Order Issue.

This is the Inventory Transaction that happened when the item was shipped out of the warehouse

M1, hence the negative quantity -10.

*The other two lines with Transaction Type = Sales Order Pick, are for the move order transaction

-

8/8/2019 Cash Order Cycle

23/25

that happened automatically during Pick Release (automatic as per the pick release parameters

we had set in this testflow), when the item was moved from the pick-from subinventory to the

staging subinventory. Hence there is one line each for a negative and positive transaction from/to

each subinventory. The final shipment to the customer (sales order issue) is made from the

staging subinventory.

Invoice

1. First let's check the status of the order line.

*Navigate to the sales order form, and query your sales order. Go to the Line Items tab and check

that the status of the line is 'Shipped'.

*While still on the line, go to Tools > Workflow Status.

-

8/8/2019 Cash Order Cycle

24/25

2. Navigate to Reports, Requests > Run Requests.

*Run the Workflow Background Process with the following parameters.

Item Type : OM Order Line

Process Deferred : Yes

Process Timeout : No

3. Go to View > Requests, and verify that the Workflow Background Process (WFBP) has

completed successfully. In addition, notice that the AR concurrent requests Autoinvoice andAutoinvoice Import Program get kicked off automatically to import the invoices into AR. OM

inserts invoice data into the AR interface tables through 'Invoice Interface', which runs in the

background (notice the workflow activity 'Invoice Interface' in the screenshot from Step 4 below).

AR picks up the data from the interface tables through the 'Autoinvoice' concurrent program.

*In case you find that the invoice did not get imported into AR (as shown in Step 5 below), run

Autoinvoice manually by navigating to Receivables > Interfaces > Autoinvoice, and selecting the

Autoinvoice Master Program.

Enter the following parameters and submit the concurrent request :

Invoice Source : ORDER ENTRY

Default Date :

-

8/8/2019 Cash Order Cycle

25/25

4. Query the order in the sales order form, and go to the lines. Notice the status is now Closed.

Note that the Closed status in the order lines signifies that OM has successfully passed the

invoice data into the AR interface tables, and does not necessarily signify that the invoice has

been successfully imported into AR (in case there was some error during that process).

*The workflow status for the order line (go to Tools > Workflow Status) should now show the

following progression

SQL Tip :

Finding the status and invoice_interface_status_code of the order line

select line_id, open_flag, flow_status_code, invoice_interface_status_codefrom oe_order_lines_allwhere line_id = 201594;

LINE_ID O FLOW_STATUS_CODE INVOICE_INTERFACE_STATUS_CODE

---------- - ------------------------------ ------------------------------

201594 N CLOSED YES

5. While on the sales order line, click on the Actions button and select 'Additional Line

Information'.

*Go to the Invoices / Credit Memos tab. If the invoice data is shown here, this means that the

invoice was created in AR. Click on the Invoice Details button to view the invoice.

Here the O2C cycle end.