Carbonate Cement and Concrete: A Disruptive Technology · PDF fileCarbonate Cement and...

Transcript of Carbonate Cement and Concrete: A Disruptive Technology · PDF fileCarbonate Cement and...

Carbonate Cement and Concrete:A Disruptive Technology For

CO2 Utilization and theConstruction Business

Richard E. Riman1, Nick DeCristofaro2, and Kevin Blinn1

November 8, 2013

1Department of Materials Science and Engineering, Rutgers: The State University of NJ

2Solidia Technologies, Piscataway, NJ 1

2

Outline

• Motivation / Background

• Reactive Hydrothermal Liquid Phase Densification (rHLPD)

• Carbonate construction materials

– Carbonate cement

– Concrete with carbonate cement

– Comparisons with current Portland Cement technologies

• Understanding and Improving Carbonation

• Summary

3

Why disrupt the construction industry?

• Est. world cement production: 3.4 Gt in 2011ǂ

(68.4 Mt in U.S.)

• ~ 1 ton of cement creates ~0.81 ton of CO2 gas

– Energy consumed is 3-6 GJ/t cement#

• Wiping out the cement industry would not solve the global warming problem (estimated 5-10 % all CO2 emissions at the very most)

• BUT - the CO2 burden of cement is significant –large enough to make a difference

ǂ U.S.G.S. Mineral Commodity Survey, 2012# H.G. van Oss and A. C. Padovani, J. of Industrial Ecology, 7 [1] 93-126 (2003).

4

Game Changing Tech: CO2-consuming cement

– Solid mixture is carbonated under a gaseous CO2

atmosphere

– Improvement in chemical and physical properties results due to carbonate cementation

– Prolific activity in the cement industry

– At best, this will still be carbon positive even if all the calcium is carbonated

Proposed mechanism for accelerated carbonation*

One approach: Accelerated carbonation of Portland Cement (C2S / C3S)

* Fernandez B. M. et al,, Journal of Hazardous Materials B112 (2004) 193-205. 4

5

Carbonate Cement: A Different Approach

Less CO2 , Hg Generated from Limestone;Less Energy Consumed; Less Wear on Kiln

Carbonate Cement (CaSiO3)

Portland Cement(Ca3SiO5-Ca2SiO4)

The Abundance Problem:

Availability of Natural Wollastonite

The Abundance Solution:

Carbonate cement (CaSiO3) can be made in

typical cement kilns!

5

Portland Cement CarbonateCement

(Wollastonite)

Chemistry Ca2SiO4 - Ca3SiO5 CaSiO3

Manufacturing Made in Cement Kilns(108T/yr in N.A.)

Naturally Mined(106 T/yr in N.A.)

Limestone ~ 80% ~ 50%

Shale/Clay/Sand ~ 20% ~ 50%

Reaction Temp. 1450 oC(1723 oK)

<1200 oC(<1473 oK)

6

Solidia offers a low-cost inorganic material manufactured using a scalable and

energy efficient process. Its properties can be controlled to engineer outstanding

performance for a broad spectrum of building material applications.

Curing of Carbonate Cement

Reactive hydrothermal liquid phase densification (rHLPD):

enables production of versatile building and construction materials

• Water Dissolves the Calcium from the Matrix and CO2 from the Pores• CO2 and Calcium React to Form Calcium Carbonate

• Bonds the Matrix Together• Little/no hydration!

“Low Temperature Solidification” (LTS) Method6

7

7

CharacteristicsMade from minerals & waste

Consumes CO2

Water is not a reactant

Low temperature process

Rapid solidification process

Net-shape process

No hydraulic bonds

Unique microstructure

Benign Processing Environment

BenefitsLow-cost raw materials

Low carbon footprint

Conserves water

Low energy consumption

No long “curing” period

No shrinkage

Strong & chemically durable

Advantageous Properties

New composites – Aesthetics & Function

Advantages of rHLPD

A novel “green” method for densification of ceramics in general

8

Novel Microstructure

10 µm

5 µm 1 µmCaSiO3 Grain

Silica layer

CaCO3 Encapsulation

Fractured Surface of Carbonate Cement Unique grain structure (Yellow – CaSiO3, red – SiO2, and green – CaCO3)

8

9

CO2

TGA-FTIR

TGA/DSC

H2O

Only CO2 phase is detected

throughout decomposition

process at elevated

temperatures (>150 ºC)

Hydrate-free Cement

9

10

(b)(a)

Higher Strength, Shorter Reaction Time

– Pure Portland Cement: ~7000 PSI in 28 days

– Carbonate Cement: >20,000 PSI in <20 hours!

(a) 5 samples (1” diameter cylindrical) were tested for each data point. (b) Mindess, S., Young, J.F., and Darwin, D. (2003), Concrete, Second Edition, Prentice-Hall, Upper Saddle, River, NJ.

10

11

Carbonate Cement Concrete: A New Class of Building and Construction Material

US Concrete Industry Next Generation

BinderPortland CementCa3SiO5 + Ca2SiO4

Carbonate CementCaSiO3

Filler Sand + Aggregate Sand + Aggregate

Reactant H2O CO2

ProcessHydration of Portland

CementCarbonation of Cement

ProductPortland Cement

Concrete (PCC)Carbonate Cement Concrete

End Result Federal Highway

Administration (FHWA)

Grade 1 Properties

FHWA Grades 3/4 @

PCC cost

Lowest Carbon

Footprint in Class

11

12

Carbonate Cement Concrete

200 µm200 µm

1 cm

Typical cross-section of carbonate cement concrete

Chemical Mapping

Sand

SolidiaCement

12

13

Concrete With Significant CO2 Reduction

US Concrete Industry Carbonate Concrete

Binder Portland CementCa3SiO5 + Ca2SiO4

Carbonate CementCaSiO3

a) CO2 emitted / mT of binder produced

0.81 mT 0.58 mT

Reactant H2O CO2

b) CO2 absorbed / mT of binder reacted

0 0.30 mT

Net CO2 emitted / mT of binder used (a - b)

0.81 mT 0.28 mT

The Path to Zero:Use of alternative pozzolanic materials and fuels

Replacement of limestone and shale with recycled materials

60-70% reduction in net CO2 emission!

13

14

Mixing Casting &

Curing

Packaging

Finishing /

De-molding

Final Product

Minimal Change To Existing Processes

CO2

• Carbonate Cement

• Aggregates

Minimal modifications on

existing equipment to

introduce CO2 for curing

14

15

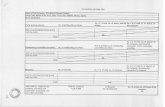

Carbonate Cement Concrete Properties

15

Properties Test MethodPortland Cement Concrete Carbonate Concrete

300 kg/m3

Portland Cement (Type I Pavement)

400 kg/m3

Carbonate Cement

Compressive Strength ASTM C39 5600 PSI 8250 PSI

Flexural Strength ASTM C78 >700 PSI >850 PSI

Coefficient of Thermal Expansion CRD C39 ~8 to 10 x 10-6 / K ~7 to 9 x 10-6 / K

Shrinkage ASTM C157 70 x 10-6 90 x 10-6

Young’s Modulus ASTM C469 ~35 GPa ~35 GPa

Poisson’s Ratio ASTM C469 0.15 0.22

16

Understanding Carbonation: In situ ATR/FTIR

Track the formation of CaCO3 and SiO2 over the course of carbonation

17

In situ X-ray Diffraction

What conditions result in accelerated curing?

• Stainless Steel

• Kapton (window)

• Ports for liquid and gas delivery

• Temperatures from 25 to 100°C

• Pressures up to 30 PSIg

4% Add.

18

Summary

• rHLPD is a versatile low-temperature solidification method applicable to a variety of systems, particularly building and construction materials

• Carbonate cement is a potentially disruptive technology for the building and construction industry due to its intrinsically lower CO2 footprint and superior properties

• This technology is easily adopted since the only step in the manufacturing process that changes is curing

19

Acknowledgments

• DOE National Energy Technology Laboratory

• Solidia Technologies, Inc.

• Thank you for your attention!