Natural Grass –Made Better. Fieldturf Duraspine Monofilament.

Calibration and testing of optical single-particle-size spectrometers with monofilament fibers as...

Transcript of Calibration and testing of optical single-particle-size spectrometers with monofilament fibers as...

Calibration and testing of optical single-particle-size spectrometers with monofilament fibers as substitute particles

Richard K. Jeck U.S. Naval Research Laboratory, Washington, D.C, 20375. Received 6 July 1979. Common to all optical particle counters is the need for a

periodic check of the calibration for particle size. Current practice for counters sensitive to particle diameters in the ~0.1-50-μm range involves the use of glass beads or nearly monodisperse latex spheres as calibration particles. Disadvantages of these methods are that the latex spheres require special equipment such as nebulizers, drying chambers, and air pumps and the procedure is sufficiently tedious that most instrument owners rely on the manufacturers to provide the primary calibration service. Glass beads, though somewhat easier to use, are less accurate and are suitably mondisperse only above 10-μm diam and in only one or two sizes. Neither method is convenient for field use, since, in addition to the special equipment required, the particle counter must normally be dismounted from its place of deployment (tower, ship, aircraft, roof, etc.) and brought indoors.

Besides the size calibration checks, occasional operational difficulties or apparent malfunctions1 may call for a check of the depth of field (sensitive length of the particle illuminating beam) in some models or for a test of the instrument's performance in accurately registering all validly sampled particles. Depth-of-field (DOF) checks generally require access to the sensor electronics, as with the Particle Measuring Systems2 axially scattering spectrometer probe (ASSP), for example, and are therefore inconvenient in the field as well. Until now there has been no known technique for providing an exactly countable sequence of individual test particles with diameters smaller than ~100 μm for testing the single-particle-counting accuracy of these instruments.

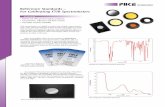

The purpose of this Letter is to describe the use of monofilament fibers as test particle substitutes for making quick and easy but accurate routine checks of the calibration, DOF, and particle-counting capability of appropriate single-particle counters. In Fig. 1 are shown two forms of a simple device consisting of one or more uniform fibers held in place across an obscured opening in an opaque frame. The fibers are typically 20-30-μm diam clear nylon filaments from strands

of dental floss, for example, but other materials and colors may be used as long as the optical properties of the fiber are uniform along its length. The dimensions and shape of the holder are determined mainly by the size and shape of the sample inlet orifice for the sensor in use.

A given test fiber will produce an optical signal of fixed repeatable amplitude each time the fiber is passed through the sensitive volume of the particle illuminating beam. The fiber will thus simulate a single-particle event that should be registered in the data-readout system as a count corresponding to some, perhaps originally undetermined, particle size. If the instrument is in proper calibration when the response to one or more test fibers is first documented, the test fiber(s) will serve as an accurate transfer standard for future calibration checks and adjustment. If the optical signal arising from the test strands is greater than the instrument detection system is designed to accommodate, an optical filter of appropriate density is simply inserted (during the test only) somewere in the light path away from the sensitive volume.

The devices illustrated in Figs. 1(a) and (b) have been tested by the author for use with the PMS ASSP and the Royco3

model 241 optical particle counter, respectively, The test demonstrated that counts from identical fibers could be reproduced accurately in a narrow interval of indicated particle diameters with an apparent monodispersity rivaling that of latex spheres. The number of counts within the narrow interval was incremented reliably by five counts (the number of fibers) each time the device was passed through the beam within the DOF, thus verifying the counting accuracy of the instruments while they were in good operating condition. The DOF itself may be easily checked in the ASSP simply by passing the fibers across the beam at various positions along its length while observing the instrument readout for an indication of particle counts. Within the typical 4.5-mm DOF each test fiber will be counted as a valid particle event. Outside the DOF no counts will be registered. It should be

Fig. 1. Typical shape and dimensions of test fiber holders for use with (a) the PMS axially scattering spectrometer probe (ASSP) and

(b) the Royco model 214 optical particle counter.

1 March 1980 / Vol. 19, No. 5 / APPLIED OPTICS 657

noted that with the ASSP the velocity-reject feature must be temporarily switched off during any of these tests, and with the Royco models the cone-shaped inlet must be removed to gain access to the light beam with the holder shown in Fig. 1(b). In both cases a simple neutral-density (ND) filter, such as a Kodak no. 96, ND 1.00 or 2.00, Wratten filter, is needed to reduce the optical signal intensity reaching the detector. With the ASSP a small circular filter can easily be placed in front, of the detector cartridge, and with the Royco model 241 one need only remove the sensor cover to insert a filter in the beam emerging from the light source.

Specific advantages of these new devices in relation to their use with suitable optical single-particle-size spectrometers are summarized as follows. The devices constitute an extremely portable stable reliable easy-to-use particle simulator providing for the first time a test sample having a known fixed number of particle events of controlled and repeatable size. They serve as an accurate transfer standard for checking or adjusting size calibration, as a convenient method for measuring the optical DOF in suitable particle counters, and as a means for checking the. single-particle counting accuracy of single-particle counters. In addition, the devices permit these tests to be performed without removing the sensor from its mounting location in field installations as long as the sensor is accessible to an attendant. The need for elaborate particle-generating and dispensing equipment is also eliminated once the sensor has been initially calibrated. By selecting the fiber diameter and color or by combining the fibers with simple optical filters, one can simulate monodisperse particles of any diameter down to at least the 0.1-μm practical limit of a conventional light-scattering particle-sizing techniques.

References 1. R. K. Jeck, in Aerosol Measurement, D. A. Lundqren et al., Eds.

(U. of Florida Press, Gainesville, 1979), pp. 294-311. 2. Particle Measuring Systems (PMS), Inc., 1855 South 57th Ct.,

Boulder, Colo. 80301. 3. Royco Instruments, Co., 141 Jefferson Dr., Menlo Park, Calif.

94025.

658 APPLIED OPTICS / Vol. 19, No. 5 / 1 March 1980