bse-re-003_1996_75_a_035_d

-

Upload

mandregomes -

Category

Documents

-

view

213 -

download

0

Transcript of bse-re-003_1996_75_a_035_d

-

8/18/2019 bse-re-003_1996_75_a_035_d

1/9

Design handbook for frame design includingjoint behaviour

Autor(en): Jaspart, Jean-Pierre / Maquoi, René

Objekttyp: Article

Zeitschrift: IABSE reports = Rapports AIPC = IVBH Berichte

Band (Jahr): 75 (1996)

Persistenter Link: http://dx.doi.org/10.5169/seals-56927

PDF erstellt am: 15.03.2016

Nutzungsbedingungen

Mit dem Zugriff auf den vorliegenden Inhalt gelten die Nutzungsbedingungen als akzeptiert.Die ETH-Bibliothek ist Anbieterin der digitalisierten Zeitschriften. Sie besitzt keine Urheberrechte anden Inhalten der Zeitschriften. Die Rechte liegen in der Regel bei den Herausgebern.Die angebotenen Dokumente stehen für nicht-kommerzielle Zwecke in Lehre und Forschung sowie fürdie private Nutzung frei zur Verfügung. Einzelne Dateien oder Ausdrucke aus diesem Angebot könnenzusammen mit diesen Nutzungshinweisen und unter deren Einhaltung weitergegeben werden.Das Veröffentlichen von Bildern in Print- und Online-Publikationen ist nur mit vorheriger Genehmigungder Rechteinhaber erlaubt. Die Speicherung von Teilen des elektronischen Angebots auf anderenServern bedarf ebenfalls des schriftlichen Einverständnisses der Rechteinhaber.

Haftungsausschluss

Alle Angaben erfolgen ohne Gewähr für Vollständigkeit oder Richtigkeit. Es wird keine Haftungübernommen für Schäden durch die Verwendung von Informationen aus diesem Online-Angebot oder

durch das Fehlen von Informationen. Dies gilt auch für Inhalte Dritter, die über dieses Angebotzugänglich sind.

Ein Dienst der ETH-Bibliothek ETH Zürich, Rämistrasse 101, 8092 Zürich, Schweiz, www.library.ethz.ch

http://retro.seals.ch

http://dx.doi.org/10.5169/seals-56927http://dx.doi.org/10.5169/seals-56927

-

8/18/2019 bse-re-003_1996_75_a_035_d

2/9

371

DESIGN

HANBOOK

FOR FRAME

DESIGN

INCLUDING

JOINT

BEHAVIOUR

Jean-Pierre JASPART

Research

Associate

FNRS

Doctor

Engineer

University

of

Liege

Liege

BELGIUM

Rene

MAQUOI

Professor

Doctor

Engineer

University

of

Lege

Liege

BELGIUM

Jcan-Picrrc

Jaspart,

born 1962,

got

his

Civil

Engineering

Degree

in 1985

and

his Ph.D

Thesis

in

1991.1 lc

is the

author

of

more

than

60

papers

on

connection

and frame

design,

member

ofthe

Drafting

Group

of

Annex

J

of

Eurocode

3 and

Chairman

ofthe

COST

Cl

Working

Group

on

Steel

and

Composite

Connections .

Rene

Maquoi,

born

1942,

got

his

Civil

Engineering Degree

in

1965

-and

his

Ph.D

Thesis

in

1973.

Hc

is

the

author

or

coauthor

of

more

than 200

papers

mostly

devoted

to

stability

problems

and

design

of

comicetions.

Hc

is

involved

in

various international

activities:

preparation

of

Eurocode

3,

chairmanship

or

membership

of

ECCS

and

SSRC,

task

working

groups,...

Summary

In

this

paper,

a

design

handbook

for

designers

of

steel

building

frames

is

presented.

This

handbook

gives

a

quite

compiete

overview

ofthe

design

procedures

for

frame

design

-

including

joint

behaviour

-

which

are

included

in

Eurocode

3

Part

1-1[1].

In

its

first

part,

a

background

information

is

given.

The

second

part

focuses

on

application

rules

for

daily

practice

and

a

particular

attention

is

paid to

structural

joints. Finally,

worked

examples

for

compiete

frame

design are

presented

in

the

third

part.

1.

Introduction

Traditionally

the

analysis

and the

design

of

steel

frame

structures

is

based

on

the

assumption

that the

constitutive

beam-to-column

joints,

splices

and column

bases

are

perfectly

pinned

or

perfectly

rigid.

However

studies

performed

in

the

last

decade

have

clearly

shown

that:

•

Most

ofthe

joints

used

in

daily

practice

are not

fülfiilling

the

requirements so

to

be

characterized

by

such

idealized

responses;

they

are

said

«semi-rigid»

and

«partial strength»

when

their

resistance

is

lower

than

that

ofthe

connected

members.

The

fulfillment

of

these

requirements

is

often

involving

extra

fabrication

or

erection

costs

-

8/18/2019 bse-re-003_1996_75_a_035_d

3/9

372

DESIGN

HANDBOOK

FOR FRAME DESIGN

INCLUDING JOINT

BEHAVIOUR

Through

economical

investigations,

it

has

also been

progressively

demonstrated

that:

The

traditional

rules

for

design

of

joints are

rather conservative.

The

use

of

semi-rigid

joints

instead

of

pinned

ones

results in

a

decrease

ofthe

weight

ofthe

structure,

and

therefore

of

their

total

cost

(5

to

10

%)

including

fabrication,

transportation

and

erection

costs.

The

use

of

semi-rigid

joints

instead

of

rigid

ones

sometimes

results

in

an

increase

ofthe

amount

of

steel

needed,

but

also

to

a

strong

decrease

ofthe

fabrication

costs

through

a

simplified detailling

ofthe

joints

(less

stiffening

for

instance).

The

benefits

varies

here

from

10

to

25

%.

To

profit

from

these

potential

benefits

requires

new

design

methodologies

for what

regards

design assumptions,frame analysis

and

verification

ofthe

ultimate

and

serviceability

limit

states.

This

need

is

now

widely

expressed by designers,

what has

engendered,

at

the

european

level,

different actions

in

the

last

years

Among

these

ones,

let

us

mention:

•

The

füll

revision

ofthe

Annex

J

of

Eurocode

3

on

Steel Joints

in

Building

Frames

[

2].

•

The

SPRINT

european

project

where

simplified

design

procedures

for

joint

design

and

tables

of

standardized

joints,

all in

agreement

with

EC3

Annex

J,

have

been

suggested

[3].

The

first

one

provides

a

legal

frame

for

the

use

ofthe

new

design

techniques

for

joints

while

the

second

focuses

more

on

the

practical

aspects

to

which

the

designer

is

likely

to

be

faced in

his

daily

practice.

In

the

frame

ofa

recent

ECSC

project

(contracts

7210-SA/212

and

320),

the

SPRINT action

has

been

prolonged

so

to

cover

also the

implications

ofthe

Joint

behaviour

on

the

structural

frame

analysis

and

design.

The

guide

for

users

resulting

from this action

is

briefly presented

in

the

following

pages.

The

partners

in

this

project

are:

University

of

Liege

in

Belgium

as

coordinator

(R.

MAQUOI

and

J.P.

JASPART),

CT1CM

in

France

(B.

CHABROLIN,

I.

RYAN

and

A.

SOUA),

CRIF

in

Belgium (D.

VANDEGANS),

TNO

Delft

in

The Netherlands

(M.

STEENFIUIS)

and

RWTH

Aachen

in

Germany

(K.

WEYNAND).

2.

Content

of

the

design

handbook

The

ECSC

user's

manual

Covers

the

following

three

main

aspects

:

The

design

of

commonly

used

beam-to-column

joint

configurations

such

as

welded

ones

or

bolted

end

plate

and

flange

cleated

ones.

Beam

splices

are

also

covered.

•

Guidelines

on

how

to

incorporate

joint

behaviour in the

structural

analysis

(both

Ist

order

and

2nd

order,

elastic

and

plastic).

•

Design

checks

for

the

ultimate

limit

states

(frame

and

member

resistance and

stability,

member

and

joint

section

checks,

-

8/18/2019 bse-re-003_1996_75_a_035_d

4/9

-

8/18/2019 bse-re-003_1996_75_a_035_d

5/9

374 DESIGN HANDBOOK

FOR FRAME

DESIGN

INCLUDING

JOINT

BEHAVIOUR

ik

-

beam-to

column

joints

with

extended

endplates;

beam-to

column

joints

with

flush

endplates

(2 types);

beam

splices

with

flush

endplates

(2

types);

-

beam-to

column

joints

with

angle flange

cleats.

These

simplified

procedures

strongly

reduce the

amount

of

calculation

in

comparaison

with

the

application

of

EC3

Annex

J

but

are

anyway

in

agreement

with

the

EC3

design

philosophy

An

example

of

such

a design

sheet

is

shown

in

Annex

1

of

the

present

paper.

design

tables

These

are

tables

covering

standardized

joints

and

providing

the

user

with

joint

detailing

and stiffness

/

resistance

properties

(see

Annex

2);

information

allowing

to

classify

the

joints

as

pinned,

semi-rigid

or

rigid,

partial

strength

or

füll

strength

is

also

given.

Software

This

PC

Software

called

DESIMAN

is able

to

characterize

the

mechanical

properties

ofa

wide

range

of

usual

or

non-usual

types

of

joints

subjected

to

bending

moments

and

shear

forces.

It

includes

graphical

pre-

and

post-

processors

(see

Annex

3).

The

pre-processor

allows

a

user's

friendly

introduction

ofthe

data.

It

is connected

to

bolt,

plate,

material

and

profile

databases, so

allowing

a

decrease

ofthe

time

required

to

introduce

the

data.

It

is

also

connected

to

another

database

in

which

all the

calculations

made

can

be

stored,

in

order

to

be

used

further

if

needed.

The post-processor

of

DESIMAN

produces

four

main

files

:

-

A

short

one

just

giving

the main results

ofthe

computation

:

design

resistances

in

bending

and

shear,

initial

stiffness,

collapse

mode,

ductility,

class

for

frame

analysis (1/2

page).

The

previous

one

to

which

the

resistance

and the

stilTness

of

all

the

constitutive

joint

components

are

added.

Such

a

file

allows

the

designer

to

modify

in

an Optimum

way

its

joint

when

the

design

requirements

are

not

fulfilled

(1

page).

A

calculation

note

(±

5

pages)

presenting

more

detailed

results

ofthe

calculations,

for

each

component

and

for

thejoint.

This

note

is

useful

when,

for

instance,

the

design

has

to

be

checked

by

a

control

office.

A

füll

calculation

note

just

like

that

which

could

be

produced

by

hand,

and

in which

the results

of

all

the

intermediate

calculations

are

given.

4.

References

[1]

Eurocode

3:

Design

of

Steel

Structures,

Part

1-1;

General

Rules

and

Rules for

Buildings,

ENV

1993-1-1,

1992.

[2]

New

revised

Annex

J

of

Eurocode

3

Joints

in

Building

Frames ,

Doc.

CEN/TC250/SC3-N419E,

Brüssels,

June 1994.

[3]

SPRINT

Contract

RA351

on

Steel

Moment

Connections

according

to

Eurocode

3.

Simple

Design

Aids for

Rigid

and

Semi-Rigid

Joints ,

1992-1996.

-

8/18/2019 bse-re-003_1996_75_a_035_d

6/9

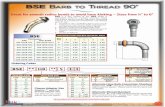

J-P.

JASPART,

R.

MAQUOI

Annex

1:

Example

of

simplified

design

procedure

375

Boam

webs

Beam

Hanges

Lnd-platcs

Bol's

Joint

Beams

Mechanical

characteristics

Yield

stresses

If

hot-rolled

profiles

:

fvwb

fy(b

Geometrical

characteristics

./Tk

r_i_

T

;-¦:

/

\f

MrFh

End-plates

3=t'fb

wb

0,8

vTa,

mP2

#

SS.

tjt

p

\

r0,8V2aw

Ultimate

stresses

n£

Bolts

dw

:

see

figure

or

dp

if

no

washcr*

As:

resistance

area

ofthe

bolt

d,

is

recommended

in

EC3

Annex

J, and

not

dp

As

df is

not

given

in

all

die

catalogs

for

bolts.

d„

is

chosen

here

(safe

assumption).

3

Vfl

+

*-

LI

I

i

I

i

h*t*i

m

-

8/18/2019 bse-re-003_1996_75_a_035_d

7/9

376

DESIGN

HANDBOOK

FOR

FRAME

DESIGN

INCLUDING

JOINT

BEHAVIOUR

ik

STIFFNESS

RESISTANCE

Beam

flanges

in

k

-

°°

3

FRU

^«JM

'

mplp

+

2

B>«<

np

epRd.l

p\

p

n

min

[ e

;

1,25m

1

e„

'äM

~

°4f.wb*

twb

fym*

'

Yifa,

b*ff*>.<

lrfP.'

Initial

stiffness

:

F*<

»*»

l

Fmaj

1

'=¦3.4.7.«

Plastic

design moment

resistance

:

MRd

F*4

h

JOINT

Nominal

stiffness :

Elastic

moment

resistance

:

SJ

-

S»nl

1

^

3

M

-

8/18/2019 bse-re-003_1996_75_a_035_d

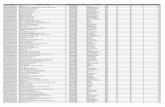

8/9

•8

c

u

O

c

O

u

S

2?

55

o>

o

*-

o

ü

5.

3

X

N

X

H-6

Ol

Hl

11

^C

Ol

H-l

Ol

a-o

oi

H-OH

-t

8

a-8

9

H-9e

-ze

et

'S»

-li

-9e

qn

(IU;?DU3J3J?J

3p

jnanifucrj

UH

d3d3

d3

d3

d3

d3

d3

d3

Ld3

cl3

Ld3

d3d3

pojjrudru

papoW

ZSC

S

TSC

SC

S1

»z

n

S\

n

s\

SI

ph7

i

»

SOII

98

C»

Sl

Z9

SS

CC

ZS

66Z

SZ

SC

9

1Z

181

*IL

oci

S9

ZI1

C6

9S

C6

Z8

OS

'8.1

C£

CS

»rc

q

Mn

]U3U131|IVSSI3

3U3U10J\

ajueisis?^

LWS

UOI13BJ1

U3

aunodejapamv

JxO

uopöy

f

srumos

inoqe.p

ißy

ia

U01PBJJ

asuoinog

.1J8

uoissajduico

l»

aijnod

B|

ap

3||3ui^

aper)

ajnidnj

ap

»po|\

»»S6C

S0»S

os

ozes

08tCZ»6C

0811'

CZ0»

zz9z

»S8Z

0ZIC

8Z0Z

.980Z

99»Z

0Z61

81Z

»68

CC98II

Z.IZ9I

azsi

196S1

6C»01

83811

690Z1

1998£

»9S8

Z9C6

80909Z9

i09i..g

9S9C600Z

CKl

e/w'rs

mpjr

(PBJ/IU^)

pnaou

np

9iipiSiy

(UHU)

sjnpnos

JL.

Z

yi

Z

Z

3

Z

3

OS

9

Z.

9

S

9

»t

z

001

11

U

6

6

11

6

66

66

6

S6

L.

L

8LL

L

L

9

9

08C

0£

»€

»C

SZ

LZ

6Z

SZ

CZ

SZZZ61

91

»

ZI

SLLLL9

9

i*r

(tum)

pn-xw

np

\m?Q

06»

0»

0»

sese

cC

6Z9Z

0»Z

CZ

CZ

ZZ

zz

IZ

1Z

81

Sl

sz

Z

Z

Z

Z

(IUU1)

SCZS

inoqc.p

ibij

h

-rrx

KT

n

av.

JIM

\

d

_

+

Id.

4i

Z.Ü1N

ZW

1MZW

ZK

1K

ZW

n\

IW

ZVi

1W

3

0

o

00S3dI

S»3dI

0»3dl

9C3dl

0C3dI

aiZHdl

0tc3dl

sCZS

o

Iw

M

W

-

8/18/2019 bse-re-003_1996_75_a_035_d

9/9

378

DESIGN

HANDBOOK

FOR

FRAME

DES

Annex

3:

Input

and

Output

scrcens

of

DesiMan

2.3

[

File

Qesign

Databascs

fclelp

':

¦

Xm^u^m

Nat«e

j

welded

jmnt

^X

••;:,

:.

*•-*

Ipi

JIpe

[JH80

~]

Column-.-:

IILQ

100

:

TypB&,i>

Joint

rorilig«mte

Single

sided

bcnnrto-column

joint

configu

Welded

connedion

/-iii^catftJwa^

jtC

3

-

AnnexJ

J

KUtfsrtctJ

nniumn weh

7'

XI

tla