APM200 Outdoor Power Supply System User Manua.pdf

-

Upload

anon870676650 -

Category

Documents

-

view

223 -

download

1

Transcript of APM200 Outdoor Power Supply System User Manua.pdf

-

8/10/2019 APM200 Outdoor Power Supply System User Manua.pdf

1/39

APM200 Outdoor Power Supply System

User Manual

Version V1.2Revision date Sept 17, 2007BOM 31011189

Emerson Network Power provides customers with technical support. Users may contact the nearestEmerson local sales office or service center.

Copyright 2005 by Emerson Network Power Co., Ltd.

All rights reserved. The contents in this document are subject to change without notice.

Emerson Network Power Co., Ltd.

Address: No.1 Kefa Rd., Science & Industry Park, Nanshan District 518057, Shenzhen China

Homepage: www.emersonnetworkpower.com.cn

E-mail: [email protected]

-

8/10/2019 APM200 Outdoor Power Supply System User Manua.pdf

2/39

Safety Precautions

To reduce the chance of accidents, please read the safety precautions carefully before operation. The Caution,Notice, Warning and Danger in this manual do not represent all the safety points to be observed, and are onlyused as supplement to various operation safety points. Therefore, the installation and operation personnel mustbe strictly trained and master the correct operations and all the safety points before actual operation.

When operating Emerson products, the safety rules in the industry, the general safety points and special safetyinstructions specified in this manual must be strictly observed.

Electrical Safety

I. ESD

Notice

The static electricity generated by the human body will damage the static sensitive elementson PCBs, such as large-scale ICs, etc. Before touching any plug-in board, PCB or IC chip,ESD wrist strap must be worn to prevent body static from damaging the sensitive elements.The other end of the ESD wrist strap must be well earthed.

II. Shortcircui t

Danger During operation, never short the positive and negative poles of the DC busbar or thenon-earthing pole and the earth. The power system is a constant voltage DC powerequipment, short circuit will result in equipment burning and endanger human safety.

Check carefully the polarity of the cable and connection terminal when performing DC live operations.

As the operation space in the DC distribution unit is very tight, please carefully select the operation space.

Never wear a watch, bracelet, bangle, ring, or other conductive objects during operation.

Insulated tools must be used.

In live operation, keep the arm muscle tense, so that when tool connection is loosened, the free movement of the

human body and tool is reduced to the minimum.Others

I. Safety requ irement

Notice Please use the same model MCB to replace the MCB.

II. Sharp object

Waring When moving equipment by hand, protective gloves should be worn to avoid injury by sharpobject.

III. Cable con nectio n

Notice Please verify the compliance of the cable and cable label with the actual installation prior tocable connection.

IV. Binding the signal lines

Notice The signal lines should be bound separately from heavy current and high voltage lines, withminimum 150mm binding interval.

-

8/10/2019 APM200 Outdoor Power Supply System User Manua.pdf

3/39

ContentsChapter 1 Overview .......................................................... ........................................................................... ....................... 1

1.1 Theory................................................... ........................................................ ........................................................ 1 1.2 System Features........................... ........................................................... ............................................................. 1 1.3 System Function ......................................................... .................................................................... ...................... 1

1.3.1 Protective Function ............................................................ ...................................................................... .. 1 1.3.2 Alarm Function .......................................................... ..................................................................... ........... 2 1.3.3 Communication Function ........................................................ .................................................................. . 4

1.4 System Composition................................................. ....................................................................... ..................... 4 1.4.1 Embedded Power Supply ..................................................... .................................................................... . 4 1.4.2 Heat Exchanging Equipment And External Fan.................................................................. ....................... 4 1.4.3 Heaters................................................. ........................................................ ............................................. 4

Chapter 2 Installation ....................................................... ................................................................... ................................ 5 2.1 Precautions........... ........................................................... ........................................................................ ............. 5 2.2 Preparations .................................................... ...................................................................... ............................... 5

2.2.1 Inspecting Location................................ ........................................................ ............................................ 5 2.2.2 Distributing Goods ..................................................... ..................................................................... ........... 5 2.2.3 Unpacking.............................................................. ........................................................................ ............ 5 2.2.4 Preparing Tools ................................................... ........................................................................... ........... 5 2.2.5 Preparing Cables.... ............................................................ ..................................................................... .. 6 2.2.6 Opening The Cabinet Door.......... ........................................................... ................................................... 6

2.3 Installing Cabinet .................................................... ........................................................................ ...................... 7

2.4 Installing Battery ..................................................... ........................................................................ ...................... 9 2.5 Installing Rectifiers.............................. ........................................................... ....................................................... 9 2.6 Connecting Cables............................................................... ........................................................................... .... 10

2.6.1 Precautions............................................................ ............................................................................. ..... 10 2.6.2 Cable Tube ................................................... ........................................................... ................................ 10 2.6.3 Connecting Power Cables ............................................................. .......................................................... 11 2.6.4 Connecting Battery Cables .......................................................... ............................................................ 13

2.7 Installation Inspection ................................................ ......................................................................... ................ 13 2.7.1 Cabinet Inspection............... ............................................................ ........................................................ 13 2.7.2 Cable Connection Inspection................. ........................................................... ....................................... 14

Chapter 3 Testing................................... ........................................................... ................................................................ 15 3.1 Introduction ........................................................... ........................................................................... ................... 15 3.2 Testing AC Distribution ....................................................... ............................................................................ .... 15 3.3 Testing Rectifier ....................................................... ........................................................................ ................... 15 3.4 Testing Monitoring Module................................... ............................................................................... ................ 15

3.4.1 Setting System Parameters ............................................................... ...................................................... 16 3.4.2 System Function Test ............................................... ........................................................................... .... 18

Chapter 4 Maintenance........................................................... ....................................................................... ................... 19

4.1 Embedded Power Supply System Maintenance ........................................................... ...................................... 19 4.1.1 System Operation...... ........................................................ ...................................................................... 19

4.1.2 Indicator Description............. ........................................................... ........................................................ 19

-

8/10/2019 APM200 Outdoor Power Supply System User Manua.pdf

4/39

-

8/10/2019 APM200 Outdoor Power Supply System User Manua.pdf

5/39

Chapter 1 Overview 1

APM200 Outdoor Power Supply System User Manual

Chapter 1 Overview

APM200 outdoor power supply system can be used directly outdoors. It can supply as much as 60A electric current.There are two models: north model and south model. North model has an extra heating unit.

1.1 Theory

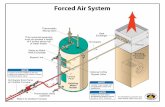

The simplified theoretical block diagram is shown in Figure 1-1. The detailed theoretical diagram is shown inSchematic Diagram and Wiring Diagram .

Embedded power

supply

220

-48Vdc

Load 1Vac

48Vdc220Vac

Distribution unitLoad 1

Load 11

220Vac

Figure 1-1 Simplified theoretical block diagram

The embedded power system rectifies the 220V AC power into -48V DC power and exports the DC power to thedistribution unit. It has functions of battery management, LLVD (load low voltage disconnection), BLVD (battery lowvoltage disconnection), data acquisition, alarm, and communication with the host.

The distribution unit connects to AC mains and feeds the AC power to the embedded power supply. In addition, it hasroutes of -48V DC output for the loads.

1.2 System FeaturesPower factor of the rectifier can reach 0.99. The efficiency is higher than 90%.

Wide AC input voltage range from 90V to 290V. When the input voltage is between 90~175Vac, the rectifierexports power- limited output. When the input voltage is 90Vac, the minimum output power of the rectifier is37.5% of the rated power.

Perfect battery management. The system has BLVD function, and can perform functions such as temperaturecompensation, auto voltage regulation, stepless current limiting, battery capacity calculation, and online batterytest etc.

Rectifiers are hot pluggable. It takes less than 1min to replace a rectifier.

Network design: Providing multiple communication ports, which enables flexible networking and remotemonitoring.

Perfect lightning protection at both AC side and DC side.

Complete fault protection and fault alarm functions.

All system components are accessible from the front.

The safety guideline satisfies IP55, and satisfies GR487 waterproof requirement.

1.3 System Function

1.3.1 Protective Function

LLVD and BL VD

When mains failure occurs, the battery will supply power. When the battery voltage drops to 47.5V (by default,adjustable), the monitoring module will cut off the non- priority loads. When the battery voltage drops to the BLVDvoltage (default: 46.5V), the monitoring module will cut off all the loads to avoid battery over- discharge. When themains resumes, the power system will go back to normal state.

-

8/10/2019 APM200 Outdoor Power Supply System User Manua.pdf

6/39

2 Chapter 1 Overview

APM200 Outdoor Power Supply System User Manual

Over- temperature protection

If the temperature of the equipment compartment remains over the protection point (55C by default) for 30 secondsconstantly, the monitoring module will cut off the non- priority loads until the ambient temperature drops below 45C. If

AC side failure occurs, all the loads will be cut off.

This function is inhibitive by default, though the user can activate or prohibit it through the host command.

Input under-voltage protectionsWhen the AC input voltage is over 290Vac or below 90Vac, the rectifier will perform self- protection. It can recoverautomatically, and the return difference is more than 5Vac.

Output over-voltage protections

When the DC output voltage is over 60V, the rectifier will stop exporting voltage or current. This protection cannotrecover automatically.

Output current- limit protection

The APM200 system can perform current- limited protection.

Output short- circuit protection

The APM200 system can perform short- circuit protection. It can short circuit for a long while and recoverautomatically.

1.3.2 Alarm Function

The system provides alarm functions. It annunciates alarm in the event of mains failure, mains over/ under- voltage,DC output over/ under- voltage, charging over- current, load over- temperature protection, ambient over- temperature,module failure, module protection, as shown in table 1-1.

Table 1-1 Alarm functions

Remote communication values DescriptionMains shortage Alarm is raised when mains is below 50V, and resumes when mains is above 60V

Mains over- voltage

1. Setting range: between the under- voltage alarm point and 300V. The mains over- voltage alarmpoint must be set above the AC over- voltage alarm point, and the mains over- voltage alarm pointis 280V by default.2. Alarm recovery conditions:When the mains is below the alarm point minus 3V for 10 minutes constantly, the alarm recovers.3. The mains over- voltage alarm point can be set through the host. AC over/ under- voltage alarmand module alarm are shielded when mains shortage

Mains under- voltage

1. Setting range: between 60V and the over- voltage alarm point. The mains under- voltage alarmoccurs when mains is below the under- voltage alarm point, and the default mains under- voltagealarm point is 180V.2. Alarm recovery conditions:When the mains is above the alarm point plus 3V for 10 minutes constantly., the alarm recovers.3. The mains over- voltage alarm point can be set through the host. Mains under- voltage alarm isshielded when mains shortage

DC over- voltage

1. The alarm point is settable. The setting range is 58V~60V, and the alarm point must be abovethe boost charging voltage plus 1V. The alarm return difference is 0.5V.2.Default: 58V. DC over- voltage alarm occurs when the busbar voltage is over 58V, and vanisheswhen the busbar voltage is below 57.5V

DC under- voltage

1. The alarm point is settable. The setting range isbetween the low- voltage disconnection pointand float charging voltage minus 2V. The alarm return difference is 0.5V.2.Default: 48.5V. DC under- voltage alarm occurs when the busbar voltage is below 48.5V, andvanishes when the busbar voltage is over or equal to 49V.3. The lower limit voltage is LLVD voltage when load low- voltage disconnection is permitted.4. The lower limit voltage is BLVD voltage when load low- voltage disconnection is prohibited andBLVD is permitted.5. The lower limit voltage is 35V when both load low- voltage disconnection and BLVD are

prohibited

Charging over- current1. The charging over- current alarm will plus 5A when charging current is over the current- limitpoint for 5 minutes constantly..2. Alarm recovers when charging current is below the current- limit point for 5 minutes constantly

-

8/10/2019 APM200 Outdoor Power Supply System User Manua.pdf

7/39

Chapter 1 Overview 3

APM200 Outdoor Power Supply System User Manual

Remote communication values Description

Load over- temperatureprotection

1.The non- priority load over- temperature protection can be set activated or not through the hostsettings. It is prohibited by default.2. If the function is activated and the circumambient temperature is over the over- temperatureprotection point for 30s constantly, the monitoring module will cut off the non- priority loadsautomatically. And the power will resume on automatically when the circumambient temperature islower by 10C than the protection point.3. Setting range: 50C ~70C. The protection point is 65C by default.4. The temperature sampling point is the external temperature sensor.5. The non- priority load over- temperature protection can be set controllable by the host. Ifcontrollable, the load over- temperature protection can be activated through the host command

Battery over- temperatureprotection

1.The battery over- temperature protection can be set activated or not through the host settings. Itis prohibited by default.2. If the function is activated and the circumambient temperature is over the over- temperatureprotection point for 30s constantly, the monitoring module will perform battery disconnectionautomatically. And the battery will resume power- on automatically when the circumambienttemperature is lower by 10C than the protection point.3. Setting range: 40C ~70C. The protection point is 53C by default.4. The temperature sampling point can be set to be battery temperature 1, and is subject to thetemperature compensation value

Circumambience over-temperature

The available setting range is -50~100C. When over the over- temperature alarm point, the alarmreturn difference is 3C. The alarm point can be set respectively, and is 50C by default

Circumambience under-temperature

The available setting range is -50~0C. When under the over- temperature alarm point, the alarmreturn difference is 3C. The alarm point can be set respectively, and is 0C by default

n# rectifier failure n# rectifier failure (output over- voltage, output shortage, fan failure)n# rectifier protection n# rectifier protection (over- temperature, intput over/ under- voltageprotection)

Battery loop disconnection1. One battery- string loop alarms.2. Battery loop disconnection (MCB/ fuse, contactor or internal wiring disconnection) brings alarm.3. The battery loop is the path between the battery string MCB and the battery string contactor

BLVD

LLVD

1. Low- voltage disconnection (LVD) activation and LVD voltage can be set through the host. LLVDis inhibited by default, and BLVD is activated by default.2. The available setting range of BLVD voltage is between 35V and LLVD voltage, and BLVD

voltage is 46.5V by default.3. The available setting range of LLVD voltage is between BLVD voltage and DC under- voltagealarm point, and BLVD voltage is 47.5V by default.4. LVD criterion1) The system has either following setting cannot perform LVD control: the number of system andpower module is set zero or battery string capability is set zero.2) LVD is activated in accordance with LVD conditions and the host command

Door status sensor The dry contact is disconnected upon alarmSPD failure alarm Check the two- route SPDs. The dry contact disconnects when SPD exports alarms

Fan failure alarm

If the fan rev. is measurable and the fan rev. is set to be maximum, the virtual fan rev. is less than80% of the normal rev., fan failure alarm should be raised.If the fan rev. is un measurable, fan failure alarm performs in accordance with failure description byfan manufacturer

Heater failure alarm of thestorage battery compartment

When the mains is in normal state and the storage battery temperature is below 5C for an hourconstantly, heater failure alarm of the storage battery compartment is raised

Test on backup digital data

1. 3 routes altogether. The monitoring module supplies 24Vdc or 12Vdc operation power for theswitchable signal examination, disconnect the correlative low power level (0V ~ 1V) and connectthe correlative high power level (9V ~ 24V).2. 8/20 s impulse current can endure 300A, without damage (bio- transient suppressor with modelof 1.5SMC39CA is commeded).3. Alarm power level is adjustable

Note

Alarm levels can be set through the host. The alarm levels are divided as critical alarm, observation alarm, and inhibit alarm.Alarms that may cause load power interruption are defined as critical alarm by default, and the rests are observation alarms. Door

status sensor alarms, humidity alarms and backup equipment alarms can be set as non- alarm and be shielded, while the otheralarms cannot. Except exposited ones, the alarm affirmance time is 10 seconds.

-

8/10/2019 APM200 Outdoor Power Supply System User Manua.pdf

8/39

4 Chapter 1 Overview

APM200 Outdoor Power Supply System User Manual

1.3.3 Communication Function

The system can communicate with the user host through communication port RS232 or RS485, and report samplingdata and alarm data to the host. The APM200 system can report some alarms information to the host through the 4couples of dry contacts.

1.4 System CompositionThe APM200 outdoor power supply is constructed by an equipment compartment and a battery compartment. Theequipment compartment consists of embedded power supply, heat exchanging equipment, external fan anddistribution unit etc. The battery compartment has two layers, and a set of batteries that supplies backup power can beplaced in each layer. Each heater is placed in the equipment compartment and in the battery compartment in the Northmodel system. See Figure 1-2.

Rings(4 pieces)Heat exchanging equipment

External fan

Monitoring expansion board

Reserved

Embedded power supply

Distribution unit

Heater in equipmentcompartment (behind

distribution unit)

Battery string I

Heater in batterycompartment (under

the plate)

Floorstand

Battery

compartmentdoor

Battery string II

Equipment

compartmentdoor

Figure 1-2 Structure of APM200 outdoor power supply system

1.4.1 Embedded Power Supply

The embedded power supply consists of three rectifiers, one monitoring module, one distribution subrack and onemonitoring expansion board. It switches the 220V AC voltage to -48V DC voltage, and delivers the -48V DC voltage tothe distribution units of the system and then to the loads through its distribution subrack.

1.4.2 Heat Exchanging Equipment And External Fan

The heat exchanging equipment dissipates the heat inside the cabinet with the external fan. It consists of an internalfan and a heat exchanger. The external fan aspirates the cold air outside and feeds it to the heat exchanger, while theinternal fan expels the heat air inside the cabinet to the heat exchanger. The heat exchanger exchanges the heatbetween cold air and hot air in it to dissipate the heat.

1.4.3 Heaters

The two heaters will start to work when the environment temperature is below 5C 5C to ensure the normaloperation of the North model system segments in low temperature environment.

-

8/10/2019 APM200 Outdoor Power Supply System User Manua.pdf

9/39

Chapter 2 Installation 5

APM200 Outdoor Power Supply System User Manual

Chapter 2 Installation

2.1 Precautions

1. Only qualified technical person can do the system installation and maintenance.

2. Avoid fire or body injuries.

3. Provide suitable AC mains supply to the system.

4. Earth the system according to the requirement.

5. Keep the environment of the system clean and dry.

6. Avoid touching the bare part of a circuit.

7. Switch off the circuit breakers in case of system failure .

2.2 Preparations

2.2.1 Inspecting Location

Before installation, please inspect:

1. The cable routing such as cable tunnel and so on.

2. The conditions required for the normal operation of the system, such as AC mains supply, earth cable and so on.

2.2.2 Distributing Goods

The user needs to distribute the goods if several systems with same model are purchased at the same time. Everysystem has been tested and gone through the burn-in test strictly before delivery. In order to ensure the optimizedoperation and track the product quality conveniently, the components should be installed in their corresponding cabinet,even though these components can be installed in other systems.

Ensure that all components in the same system have the same No. that is marked on the packing case.

2.2.3 Unpacking

Inspect the equipment strictly after unpacking to ensure successful installation.

Unpack and inspect the equipment only after it arrives at the installation site. The user representative and therepresentative from Emerson Network Power Co., Ltd. shall inspect the equipment together.

Open the packing case with a packing list in it first, take out the packing list, and inspect according to the packing list,including customer name, customer address, machine No., quantity, case No., contract No., and others.

Check the goods one by one according to the packing list after unpacking. The procedures are as follows.

Step 1: Check the quantity and serial number marked on the packing cases according to the actual quantity of the

packing cases.Step 2: Check the correctness of the equipment packing according to the packing list.

Step 3: Check the quantity and model of the accessories according to the packing list.

Step 4: Check the correctness of equipment configuration according to the system configuration.

Step 5: Check the goods visually. For example, check if the cabinet or enclosure is distorted or affected with damp;shake gently the rectifier and the monitoring module to see if there is any loose component or connection caused byshipment.

Step 6: The user representative signs the packing list.

Do not unpack the components before installing them to avoid accessory loss.

2.2.4 Preparing Tools

The installation tools include electric drill, wire cutters, crimping tools, wrench set, screwdriver, and electric knife. Thetools must be insulation and ESD-proof processed before they are used.

-

8/10/2019 APM200 Outdoor Power Supply System User Manua.pdf

10/39

6 Chapter 2 Installation

APM200 Outdoor Power Supply System User Manual

2.2.5 Preparing Cables

The cables to be installed include AC power cables, DC power cable and grounding cable.

RVVZ cables such as flame retardant PVC insulation or jacket soft cable with copper conductors are recommended.

The cables should be able to withstand at least +70C temperature. The colors of AC phase cable, neutral cable andgrounding cable shall be red, Cambridge blue and green and yellow respectively. If the cables have the same color,

they should be identified with IDs or color labels.The sectional area of the AC power cable depends on the current, temperature rise, voltage drop and mechanicalstrength of the cable. The 2.5A/mm 2 current density is recommended to estimate the sectional area of the AC powercables and the cable with less than 10mm 2 sectional area is not recommended.

The sectional area of the DC power cable is shown in Table 2-1.

Table 2-1 Sectional area of the DC power cable

Rated current Max. output current Min. sect. area Max. cable l. with 0.5V voltage drop and Min. sect. area50 A 50 A 2 10 mm 2 14 m40 A 40 A 10 mm 2 14 m25 A 12.5 A 6 mm 2 11 m16 A 8 A 4 mm 2 11 m

If the rated capacity of a MCB is much bigger than the actual output current, the MCB will not trip when overloadhappens. So the recommended MCB capacity is 1.5 to 2 times of the maximum load current.

Note

The maximum output current that flows in the DC power cable is calculated according to the full load of the system.

If the acceptable voltage drop is not 0.5V, determine the sectional area of the DC power cable according to thefollowing expression.

A= I L/(K U)

Where:

Asectional area of a cable (m 2)

Itotal current that flows in the cable (A)Lcable length (m)

U acceptable voltage drop in the cable (V)

Kelectric conduction coefficient, here K Copper =57

Recommended color labels for the positive and negative DC power cables:

Positive cable black

Negative cable blue

The sectional area of the grounding cable should be at least 16mm 2. A green and yellow cable should be used as thegrounding cable.

Prepare the cables according to the cabling specification and quantity. Do not join two separate cables together toform one cable. The blue and black cables should be used as DC power cables. If the cables are routed outside, theyshould be inserted into a corrugation sleeve.

2.2.6 Opening The Cabinet Door

The user needs to open the cabinet door when carrying out system installation or maintenance. The openingprocedures are follows:

1. Undo the hexagon- socket- head- cap screw in the keyhole sheet widdershins with the hexagon key. Remove thekeyhole sheet. Insert another key into the keyhole and turn the key clockwise until the handle pops out, as shown inFigure 2-1.

-

8/10/2019 APM200 Outdoor Power Supply System User Manua.pdf

11/39

Chapter 2 Installation 7

APM200 Outdoor Power Supply System User Manual

Handle

Keyholesheet

Figure 2-1 Unlock sequence

When you turn the key, lay your hand down to prevent being hit by the handle, as shown in Figure 2-2.

Figure 2-2 Unlock illustration

2. Turn the handle counter clockwise to the position shown in Figure 2-3, and then open the door.

Handle

Figure 2-3 Handle position

3. Insert the door stay bar into the positioning pole to fix the door position, as shown in Figure 2-4.

Door stay bar

Figure 2-4 Door stay bar

4. To close the door, uplift the bar for 2mm- 3mm, place the handle to its original position, cover the keyhole with thekeyhole sheet and undo the hexagon- socket- head- cap screw in the keyhole sheet clockwise with the hexagon key.

2.3 Installing Cabinet

The APM200 outdoor power supply system uses bottom cabling method. The cabinet should be installed on thefloorstand (accessory). The installation procedures are as follows.

-

8/10/2019 APM200 Outdoor Power Supply System User Manua.pdf

12/39

-

8/10/2019 APM200 Outdoor Power Supply System User Manua.pdf

13/39

Chapter 2 Installation 9

APM200 Outdoor Power Supply System User Manual

2.4 Installing Battery

Open the battery compartment door according to the method introduced in Opening The Cabinet Door .

The battery compartment has two floors. Each floor can be placed with one battery string that has four cells. Install thebattery cells according to the battery user manual delivered with the battery.

The battery cells should be installed as close to the right side and rear side of the cabinet as possible. Attach the acidand alkali integration box on the side panel of the cabinet.

Loosen the two baffles in the front of the battery compartment after installing the battery cells, and then move thebaffles vertically about 10mm and screw the screws solidly to block the battery cells, as shown in Figure 2-7.

The installation tools must be insulation processed. Do not damage the plastic cover of the battery cells and theiroutput terminals during the installation.

Batterycompartment

Battery string IBaffle

Battery string II

Baffle Figure 2-7 Installing battery strings

2.5 Installing Rectifiers

The subrack of the embedded power supply has been installed in the cabinet of the outdoor power supply system.While the rectifiers of the embedded power supply are packed and delivered separately and need to be installed onspot.

Rectifiers should be installed in the three left slots of the subrack. Install the rectifiers from left to right when there areless than three rectifiers to be installed and mount dummy plate at the remaining position. The installation proceduresare as follows.

Step 1: Place the rectifier to the position shown in Figure 2-8.

Handle

Rectifier

Figure 2-8 Positions of the rectifier and the handle

Step 2: Push the handle into the panel.

Step 3: Push the rectifier inward until it stops going forward. The rectifier is fixed in the subrack.

Step 4: The procedures to unplug the rectifier-move the latch to Unlock position first, and pull out the rectifier then.

-

8/10/2019 APM200 Outdoor Power Supply System User Manua.pdf

14/39

-

8/10/2019 APM200 Outdoor Power Supply System User Manua.pdf

15/39

Chapter 2 Installation 11

APM200 Outdoor Power Supply System User Manual

2.6.3 Connecting Power Cables

Step 1: Remove the panel of the di stributio n unit

The panel is shown in Figure 2-10.

The panel of the distribution unit

Figure 2-10 Panel of the distribution unit

Step 2: Load Distribut ion

The system can supply 11 routes of loads. The MCBs (LOAD1 ~ LOAD6) of the distribution unit in the embeddedpower supply controls the 11 loads. The positions of the MCBs in the subrack are shown in Figure 2-11, and therelationship between these two levels of MCBs is shown in Figure 2-12. The specifications of the MCBs are shown inTable 2-2.

Table 2-2 MCB Specifications

MCB in subrackMCB in distr.

unitMCB cap. in

distr. unitCable size in

distr. unitRemark

LOAD 1 1, 2, 3 16A 25mm 2 Total output of three MCBs should be less than 16ALOAD 2 4, 5 25A 25mm 2 Total output of two MCBs should be less than 25ALOAD 3 6, 7 25A 25mm 2 Total output of two MCBs should be less than 25ALOAD 4 8, 9 25A 25mm 2 Total output of two MCBs should be less than 25ALOAD 5 10 40A 25mm 2 Total output of the MCB should be less than 40ALOAD 6 11 50A 25mm 2 Total output of the MCB should be less than 50A

Load MCB Battery force- on buttonBattery MCB

Figure 2-11 MCBs in subrack of embedded power supply system

LOAD2

Route 1 2 4 5 6 7 8 9 10 11

LOAD4 LOAD5 LOAD6LOAD1 LOAD3

3Route Route Route Route Route Route Route Route Route Route

Figure 2-12 Relationship between two levels of MCBs

-

8/10/2019 APM200 Outdoor Power Supply System User Manua.pdf

16/39

12 Chapter 2 Installation

APM200 Outdoor Power Supply System User Manual

The embedded power supply system has LLVD and BLVD functions. When the battery voltage is less than 47.5V(default), the embedded power supply system will disconnect the load connected to the LOAD2 ~ LOAD6 MCBsautomatically without interrupting the power to the load connected to the LOAD1 MCB. LOAD1 will be disconnectedautomatically when the battery voltage is less than 46.5V (default) to avoid battery overdischarge. At this time, allloads are disconnected.

So the priority loads should be connected to the MCB of LOAD1, that is the Route1 to Route 3 in Figure 2-12. The

normal loads should be connected to the Route 4 to Route 11 in Figure 2-12.

Step 3: Connect l oads

As shown in Figure 2-13, connect the negative polarity of every load to the lower terminal of the MCB with a negativecable, and connect the positive polarity of the load to the bolt on the positive busbar that has one M6 bolt and sevenM4 bolts.

Note

The tools and body shall be insulated strictly before applying a load when the system is powered on to avoid shortcircuit.

Terminal forconnecting load Positive busbar Grounding bar AC phase line (L) Neutral line (N)

Figure 2-13 Terminals for connecting load and AC power

Note

The L & N terminals above are divisional interface of AC SPD and power subracks instead of AC input terminals.

Step 4: Connect AC power cabl es

Connect the AC input grounding cable to the grounding bar shown in Figure 2-13 or the grounding bar outside thebattery compartment of the cabinet.

Connect the AC input neutral line to the wiring point below the MCB N shown in Figure 2-13.

Connect the AC input phase line to the wiring point below the MCB L shown in Figure 2-13.

Note

1. The grounding cable shall be connected first, then the neutral line and finally the phase lines.2. The AC cables should be routed from the MCB in the external distribution equipment prepared by user. They should beconnected to the MCB just before the system is powered on. The external distribution equipment should have some protectiondevices to fulfill the overcurrent, shortcircuit and lightning protection functions.3. The AC cables should be identified with color labels to identify the phase line, neutral line and grounding cable.4. The AC cables should be routed away from the DC cables.

Step 5: Re-install t he cover

Re-install the cover to the distribution unit after completing the connection.

-

8/10/2019 APM200 Outdoor Power Supply System User Manua.pdf

17/39

-

8/10/2019 APM200 Outdoor Power Supply System User Manua.pdf

18/39

14 Chapter 2 Installation

APM200 Outdoor Power Supply System User Manual

2. Check if all the screws are screwed down, especially the screws in electrical connections. Check if all the bolts haveplain washers and spring washers and if the bolts are reversely fastened.

3. Check if there are unwanted materials inside the cabinet. Clear up the unwanted materials.

4. Check if the cabinet is collided to injury and if the paint is intact (If there is injury, repaint it immediately to preventcorrosion).

5. Clean up the cabinet. Remove dust and feculence in time.

6. Check if the door is unjamming, if the lock is in good condition and if the door stay bar is fixed.

7. Check if the dummies are installed at the reserved space where no customer device is installed. If the dummies arenot installed, install them immediately.

2.7.2 Cable Connection Inspection

1. Measure the resistance value between the positive terminal and negative terminal and phase- to - phase resistancevalue in the AC loop. Make sure there is no shortcircuit.

2. Check the AC input and distribution. Check if the AC cable color is normative, if the cables are made fast, and if thesafety labels are complete. Please refer to Appendix 4 Wiring Diagram and check the AC cable connection.

3. Check if the connection point, line sequence and polarities of DC and battery cables. Check if the connection points

are fixed and the cable connections are correct and reliable.4. Check if the SPD PE cable and grounding cable are correctly connected and if the contacts are reliable.

5. Check the communication cables of the monitoring module. Check if the rectifiers are fastened down.

6. Check if the SPD MCB is switched on and other MCBs are switched off.

7. Check if the cables are tidy, and if the cable binding is normative.

-

8/10/2019 APM200 Outdoor Power Supply System User Manua.pdf

19/39

-

8/10/2019 APM200 Outdoor Power Supply System User Manua.pdf

20/39

16 Chapter 3 Testing

APM200 Outdoor Power Supply System User Manual

3.4.1 Setting System Parameters

Upon delivery, the default parameters of the monitoring module may be inconsistent with the actual situation or yourneeds. In that case, you should configure the system parameters through the host before the system testing.

According to the communication protocol, the parameters that you can query through the host are listed in thefollowing table.

Table 3-1 Parameters that can be queried

R e m o

t e l y a c q u

i r e

d a

l a r m

/ d i g i t a l s i g n a

l1) AC Mains On/Off2) AC Mains Status3) DC Bus Voltage Status4) Load MCB Status5) System Current-Limiting Status6) Load Connection/Disconnection Status7) Battery Connection/Disconnection Status8) Battery MCB Status9) Ambient Temperature/Humidity Status10) Door Status Sensor11) Water Sensor Status12) Smoke Sensor Status13) Rectifiers Operation Status14) System Control Mode and Battery BC/FC Status

R e m o

t e l y a c q u

i r e

d a n a

l o g s i g n a

l

1) AC Input Voltage2) DC Busbar Voltage3) Rectifier Total Output Current4) Battery String Current5) Ambient Temperature/Humidity6) Battery Temperature

R e m

o t e l y a c q u

i r e

d a

l a r m

/ d i g i t a l s i g n a

l

15) 7 Standby Digital Signal Status16) 2 Digital Signal Output Status17) Battery Discharge Test Phase Status18) Battery Charge Over-Current Status

R e m o

t e - c o n

t r o

l p a r a m e

t e r s

1) Rectifier On/off Control2) BLVD & LLVD3) FC/BC Status Control4) Start/End Battery Capacity Test

According to the communication protocol, the parameters that you can configure through the host are listed in thefollowing table.

Table 3-2 Configurable parameters

Parameter Range Default value AC Input Under-Voltage Alarm Point > 60V and lower than AC Over-Voltage Alarm Point 180V AC Input Over-Voltage Alarm Point Between AC Under-Voltage Alarm point and 300V 280V

DC Busbar Low Voltage Point1, When LLVD enabled: LLVD Voltage2, When LLVD disabled but BLVD enabled: BLVD voltage3, When both LLVD and BLVD disabled: 35V

46.5V/47.5V/35V(depending on the BLVDStatus and LLVD Status)

DC Busbar Under-Voltage Alarm Point Between DC Busbar Low Voltage Point and 2V below FCvoltage

48.5V

DC Busbar Over-Voltage Alarm Point 58V ~ 60V and 1V higher than BC voltage 58VLLVD Status Disabled, Enabled Disabled

LLVD Voltage * Between BLVD voltage (when BLVD is disabled: >35V) andDC Busbar Under-Voltage Alarm Point

47.5V

BLVD Status Disabled, Enabled Enabled

BLVD Voltage * 35V but lower than LLVD voltage (when LLVD is disabled,lower than DC Busbar Under-Voltage Alarm Point)

46.5V

Ambient Temp Alarm Lower Limit -50C ~ 100C and lower than upper limit 0C Ambient Temp Alarm Upper Limit -50C ~ 100C and higher than lower limit 50C Ambient Humidity Alarm Lower Limit 0%RH ~ 100%RH and lower than upper limit 10%RH Ambient Humidity Alarm Upper Limit 0%RH ~ 100%RH and higher than lower limit 80%RHStandby Digital Signal Alarm Level High level alarm 1, low level alarm 0 High level alarm 1Number and Addresses of Rectifiers (1, 1), (2, 1, 2), (3, 1, 2, 3) (3, 1, 2, 3)System Control Mode Host Control, Auto Auto

-

8/10/2019 APM200 Outdoor Power Supply System User Manua.pdf

21/39

Chapter 3 Testing 17

APM200 Outdoor Power Supply System User Manual

Parameter Range Default valueFC/BC Status BC, FC FC

BC voltage43.2V ~ 57.6V, between FC voltage and 1V below DC BusbarOver-Voltage Alarm Point

56.5V

FC voltage43.2V ~ 57.6V, between BC voltage and 2V below DC BusbarUnder-Voltage Alarm Point

53.5V

Number of Battery Strings 0 ~ 1 1

Capacity of Battery String 30Ah ~ 600Ah100Ah (when no specificrequirement is made)

Coefficient of Charge Current LimitingPoint

0.1 ~ 0.25 0.15

Scheduled BC Interval 30 days ~ 240 days 60 daysTemp Compensation Coef. of BatteryString

0mV/C ~ 500mV/C 80mV/C

Temp Measurement Lower Limit -50C ~ 0C -50CTemp Measurement Upper Limit 0 C ~ 100 C 50 CHumidity Measurement Lower Limit 0%RH ~ 100%RH and lower than Upper Limit 0%RHHumidity Measurement Upper Limit 0%RH ~ 100%RH and higher than Lower Limit 100%RHPower Distribution Analog Signal

Calibration CoefficientNot configurable by the user

Battery Over-Temp Protection Point 40C ~ 70C 53CNote *: The LLVD voltage and BLVD voltage should be set according to battery manufacturer instructions

When setting system parameters through the host, please note that:

1. Make sure that the power system address set at the host is identical with the address set through the DIP switch, orthe communication will fail.

2. Make sure that the rectifier number is set consistent with the actual condition. After a rectifier is added to or removedfrom the power system, the rectifier number parameter must be accordingly modified, or a rectifier alarm will be raised.

3. The battery string capacity setting is customized according to order requirement before delivery. If there is nospecific capacity requirement in the order, the default battery string capacity is 100Ah. If the actual battery capacity isdifferent from that, reset it through the host to make the configuration consistent with the actual situation and preventimproper battery management. Note: the battery string capacity (200Ah and 100Ah) can be set by DIP switch.

4. The DIP switch is in the PCB board of the monitoring module, as shown in Figure 3-2. Pull out the monitoringmodule (hot pluggable) before changing the DIP switch settings. Then you can change the DIP switch settings.

Description of DIP switch settings are given in Table 3-3.

Table 3-3 Description of DIP switch settings

DIP switch Description Settings Default setting1~4 Communication address ON: 1; OFF: 0

5 Reserved

6 Dry contact statusON: dry contact switched- off is normal; switched- ongenerates alarm. OFF: dry contact switched- on is normal,switched- off generates alarm

OFF

7 Battery capacity ON: battery capacity 200Ah; OFF: battery capacity 100Ah 100Ah8 Communication protocol ON: GSM protocol; OFF: WCDMA protocol WCDMA protocol

Note:Communication address setting uses 8421 code. DIP switch 4 corresponds to 8, DIP switch 3 corresponds to 4, DIP switch 2corresponds to 2, DIP switch 1 corresponds to 1

DIP switch

Communicationaddress

Communication protocolBattery capacity

ReservedDry contact status Figure 3-2 DIP switch

-

8/10/2019 APM200 Outdoor Power Supply System User Manua.pdf

22/39

18 Chapter 3 Testing

APM200 Outdoor Power Supply System User Manual

3.4.2 System Function Test

After setting the system parameters, you can go on to carry out the system function test.

For the requirements of the test on system AC over/under-voltage alarm and protection are rather strict, you do notneed to do them. After all, the system has passed strict tests before delivery.

Battery auto-management test

Cut off AC mains supply and power the load with the battery for above 15 minutes ( 1 minute), then recover the ACmains, all rectifiers will be in current-limiting BC status.

During the current-limiting BC status, it is normal that the rectifier output voltage is sometimes below 53.5V.

For the test of battery auto-management has strict requirements for the system, it is not necessary to carry out this testif your test conditions are limited.

Rectifier on /off test

Set the control mode to background control through the host software and try turning on/off each module. Thecorresponding module should act correctly.

Note to change the control mode to automatic control after the test is finished.

Under-voltage alarm and L LVD/BLVD test

Cut off the AC power and power the load with batteries. Set the DC under-voltage alarm point, LLVD and BLVD voltageto higher values to shorten the test duration. Then observe the battery under-voltage alarm, LLVD and BLVD situation.The monitoring module should send out the corresponding alarms one by one. The red indicator on the front panel ofmonitoring module should be on, and the dry contact controlling the external audible/visual alarm equipment shouldoutput alarm signal.

Recover the AC power, restore the settings of under voltage alarm point, LLVD and BLVD voltage, and the abovealarms should disappear.

Rectifier on po sition test

Set the power system address and rectifier number correctly, insert and pull out the rectifiers one by one, and the hostshould display the communication state of corresponding rectifiers correctly.

Battery MCB off alarm test

Connect the battery to the system, and switch off its MCB. There should be a corresponding battery MCB off alarmraised at the host. The alarm will disappear when the MCB is turned on.

Load MCB off alarm test

Connect a load to the system and switch off its MCB. There should be a corresponding load MCB off alarm raised atthe host. The alarm will disappear when the MCB is turned on.

Note

1. If the terminal of corresponding load and battery route is not connected with load or battery during the test, but is suspended,the MCB Off Alarm for corresponding load or battery may not be reported accurately.2. Make sure that system configurations are restored to normal status after the test.

Viewing o peration in formation

After the system power on, you can get simple operation information through the indicators on the monitoring modulefront panel. For detailed information, you must query through the host.

Canceling b attery pr otection

If you think it more important powering the loads than protecting the battery, thus do not want the battery protection inthe case of mains failure, you can set the LLVD and BLVD status to Disabled through the host.

Note

When the battery is discharged to the BLVD voltage, the battery backup time is very short. It is impossible to obtain long timeoperation of loads by sacrificing the battery.

-

8/10/2019 APM200 Outdoor Power Supply System User Manua.pdf

23/39

-

8/10/2019 APM200 Outdoor Power Supply System User Manua.pdf

24/39

20 Chapter 4 Maintenance

APM200 Outdoor Power Supply System User Manual

Indicator description of the monitoring module

The appearance of the monitoring module is shown in the following figure. There are 2 indicators on the panel: RUN(power indicator) and ALM (alarm indicator). Descriptions are as shown in Table 4-1.

Figure 4-2 Appearance of monitoring module

Table 4-1 Monitoring module indicator descriptionIndicator

Meaning RUN indicator (green) ALM indicator (red)

Normal Slow blinking (Once per second) OffNo system alarm, with abnormal communication Fast blinking (Once per 120ms) OffSystem alarm, with normal communication Slow blinking (Once per second) OnSystem alarm, with abnormal communication Fast blinking (Once per 120ms) On

4.1.3 Routine Maintenance

Fan maintenance

Dust will accumulate on the baffle plate if the rectifier works in a dusty and windy environment. To ensure long-termreliable and smooth operation of the rectifier, it is necessary to clean the fan regularly (once 6 months).

In addition, the fan performance will deteriorate after long-term operation. You need to replace the fan regularly (onceevery 3-5 years).

Fan replacing method:

1. Remove the fan baffle plate

2. Remove the screws on the top right corner of the fan

3. Pull out the power cable

4. Replace the fan with a new one

5. Connect the power cable, and fix the fan with the screw on the top right corner

6. Mount the baffle plate back

-

8/10/2019 APM200 Outdoor Power Supply System User Manua.pdf

25/39

-

8/10/2019 APM200 Outdoor Power Supply System User Manua.pdf

26/39

22 Chapter 4 Maintenance

APM200 Outdoor Power Supply System User Manual

4.1.4 Common Faults Handling

Fault Symptom1:

The rectifier quits operation automatically and a corresponding alarm is raised at the host.

Solution: replace the faulty rectifier.

Fault Symptom2:

Rectifier(s) is/are shut down upon over-voltage and the corresponding alarm is raised at the host.Solution: 1) Upon single rectifier shutdown: Switch off the faulty rectifier. Wait till its indicators are off, and switch it onagain. If the over-voltage still exists, the rectifier may have been damaged and need replacing. 2) Uponmultiple-rectifier shutdown: Pull output all rectifiers and insert them one by one to find out the real faulty one. Replacethe faulty rectifier after confirmation.

4.2 Battery Maintenance

Refer to the battery user manual supplied with the battery. (Note: It is recommended to use T12V100SEF/A batterywithin this system. If you choose to use battery of other models, please consult with Emerson to prevent improperconfiguration.)

4.3 Heat Exchanging Equipment

The heat exchanging equipment consists of an internal fan and a heat exchanger. Its position is shown in Figure 4-5.

Heatexchangeequipment

Cableconnector

Fixing

screws

Figure 4-5 Position of heat exchanging equipment

The internal fan rev is settable. The higher the temperature of the equipment compartment is, the larger the internalfan rev is.

Replace the internal fan or adjust the fan position if it stops running or there is an abnormal noise in it. And clean theheat exchanger if there is much dust on it. The procedures are as follows.

Step 1: Disconnect the cable connector at the left side of the heat exchanging equipment, as shown in Figure 4-5. Donot disconnect when power is on.

Step 2: Remove the fixing screws shown in Figure 4-5 and then remove the heat exchanging equipment from the

cabinet.Step 3: Remove the screws that fix the cover and the internal fan baffle and then remove the cover and the baffle, asshown in Figure 4-6.

Cover

Screws for fixing thecover (4 pieces)

Fan baffle

Screws for fixing thebaffle (3 pieces)

Figure 4-6 Remove the cover and baffle

-

8/10/2019 APM200 Outdoor Power Supply System User Manua.pdf

27/39

Chapter 4 Maintenance 23

APM200 Outdoor Power Supply System User Manual

Step 4: Remove the fixing screws of the internal fan shown in Figure 4-7. Adjust the fan position or replace the fan witha new one. Take out the heat exchanger to clean it if there is much dust on it.

Heat exchanger

Fan screws(4 pieces)

Internal fanposition

Figure 4-7 Remove internal fan and heat exchanger

Step 5: Follow step 5 to step 1 to install the new fan and the clean heat exchanger into the cabinet. Take care wheninstalling the heat exchanger to avoid damaging the waterproof bar on it.

4.4 External Fan Maintenance

The external fan rev is settable. The higher the temperature of the equipment compartment is, the larger the externalfan rev is. Replace the external fan or adjust the fan position if it stops running or there is an abnormal noise in it. Theprocedures are as follows.

Step 1: Disconnect the cable connector at the left side of the heat exchanging equipment, and disconnect the fancables from the terminals, as shown in Figure 4-8. Do not disconnect when power is on.

Heat ex-changeequipment

Cable con-nector of theheat exchangeequipment

Fixingscrews

Cable con-nector of theexternal fan

Fixingscrews

External fan

Figure 4-8 Positions of heat exchanger and external fan

Step 2: Remove the fixing screws of the heat exchanging equipment shown in Figure 4-8, and then remove theequipment.

Step 3: Remove the fixing screw of the fan box shown in Figure 4-4 and then remove the fan box.

Step 4: Remove the fixing screw of the external fan shown in Figure 4-9. Adjust the fan position or replace it with a newone.

External fan

Fixing screwsof externalfan (4 pieces)

Figure 4-9 Remove the external fan

-

8/10/2019 APM200 Outdoor Power Supply System User Manua.pdf

28/39

24 Chapter 4 Maintenance

APM200 Outdoor Power Supply System User Manual

Step 5: Follow step 4 to step 1 to install the new fan into the cabinet. Install the heat exchanging equipment into thecabinet. Take care when installing the heat exchanging equipment to avoid damaging the waterproof bar on it.

4.5 Replace Heaters And Relays

The two heaters of the system do not need to be repaired. Be sure to pay attention to their operation status. The

heaters will heat when the environment temperature is below 5C5C, and stop heating above 15C5C. If theyoperate abnormally, check the heater relays (refer to section 4.6.3). If the relays operate abnormally, replace them.Otherwise, replace the heaters.

4.5.1 Replace The Heater In Equipment Compartment

Step 1: Switch off the AC MCB and the heater fuse, as shown in Figure 4-10.

Heater MCB AC input MCBPanel of distribution unit

Figure 4-10 Position of AC MCB and heater MCB

Step 2: Remove the panel of the distribution unit, as shown in Figure 4-11. The position is shown in Figure 4-10.

Figure 4-11 Remove the panel of the distribution unit

Step 3: Unscrew the 4 pieces of screws on the panel of the distribution unit and then remove the right segment of the

distribution unit. Do not disconnect its components and cables and be sure to pay attention to personnel safety.

Screw 1

Screw 2 Screw 3

Screw 4

Figure 4-12 Screw positions

-

8/10/2019 APM200 Outdoor Power Supply System User Manua.pdf

29/39

Chapter 4 Maintenance 25

APM200 Outdoor Power Supply System User Manual

Step 4: Unscrew the fixing screws of the heater cover and disconnect the cable connector from the heater relays. Theheater relays are the two cables marked L and N in Figure 4-14. Remove the heater cover. The heater is fixed on theheater cover, as shown in Figure 4-13.

Heater of the equipmentcompartment

Screws

Heater

Heater cover

Figure 4-13 Disassembly of the equipment compartment heater

Cable connector ofthe heater

Cable connector ofthe heater

Figure 4-14 Heater relays

Step 5: Unscrew the fixing screws of the heater on the heater cover and then remove the damaged heater, as shown inFigure 4-12.

Step 6: Fix the new heater on the heater cover and mount the cover on the cabinet. Connect the cable connector to the

heater relay. Finally, mount the distribution unit on the cabinet.Step 7: Check if each cable connector is tight and the connection is reliable. Switch on the AC MCB and heater fuseafter making sure every thing is OK.

4.5.2 Replace The Heater In Battery Compartment

Step 1: Switch off the AC MCB and the heater fuse, as shown in Figure 4-10.

Step 2: Take out the battery string on the lower floor of the battery compartment.

Step 3: Disconnect the cable connector from the heater relay. Remove the heater cover after removing the screws onthe cover, as shown in Figure 4-15.

Heater of the batterycompartment

Figure 4-15 Position of the heater in battery compartment

Step 4: Replace a new heater and fix it. Connect the cable connector to the heater relay. Move the battery string to itsoriginal position.

-

8/10/2019 APM200 Outdoor Power Supply System User Manua.pdf

30/39

26 Chapter 4 Maintenance

APM200 Outdoor Power Supply System User Manual

Step 5: Check if each cable connector is tight and the connection is reliable. Switch on the AC MCB and heater fuseafter making sure every thing is OK.

4.5.3 Replace Heater Relays

There are two heater relays in one heater circuit. When the environment temperature is below 5C 5C, the relaycontacts are closed to switch on the heater circuit. When the environment temperature is above 15C 5C, the relaycontacts are opened to switch off the heater circuit. Replace the relay if its contact cannot be closed or openednormally. Every compartment has two heater relays that are connected in series in the phase line and the neutral lineseparately, as shown in Schematic Diagram .

The position of the heater relay in equipment compartment is shown in Figure 4-14, and that of the heater relay inbattery compartment is shown in Figure 4-16.

Heater relay of thebattery compartment

Figure 4-16 Position of the heater relay in battery compartment

Replacement processes:

Step 1: Switch off the AC MCB and the heater fuse, as shown in Figure 4-7.

Step 2: Disconnect the cable connector of the relay and remove the screws.

Step 3: Replace a new relay and connect the cable connector of the relay to its terminal.

Step 4: Switch on the AC MCB and the heater fuse.

4.6 Replace Door Status Sensors

There is one door status sensors installed in the equipment compartment and the battery compartment separately fordetecting the close or open status of the compartment doors. The two sensors are connected in series, so themonitoring module will generate an alarm when one of the doors is open. The alarm will be eliminated only when bothdoors are closed.

The door status sensors are not intended for service or repair, just replace them when they are damaged. If the doorsare closed, when the door status sensor alarm occurs, the sensors must have been damaged. The positions of thesensors are shown in Figure 4-17.

Remove the sensor cap and then the two pieces of screws. Replace the old sensor with a new one and finally fix thesensor and the signal cables with the screws.

-

8/10/2019 APM200 Outdoor Power Supply System User Manua.pdf

31/39

Chapter 4 Maintenance 27

APM200 Outdoor Power Supply System User Manual

Door statussensor A inequipmentcompartment

Door statussensor B inequipmentcompartment

Door statussensor A inbatterycompartment

Door statussensor B inbatterycompartment

Figure 4-17 Replace door status sensor

4.7 SPD MaintenanceThe AC SPD is behind the distribution unit. The appearance is shown in Figure 4-18.

Figure 4-18 AC SPD

Check the SPD indicator on the monitoring expansion board, as shown in Figure 4-19. The position of the monitoring

expansion board is shown in Figure 1-2.

Alar m ind icato r of DC SPD

Alar m ind icato r of AC SPD

Figure 4-19 AC/ DC SPD indicator

If the indicator on the left is on, the DC SPD fails and needs replacement. The replacement procedures of the DC SPDare easy to take and not expatiated on here. If the indicator on the right is on, the AC SPD fails and needsreplacement.

The replacement procedures of AC SPD are as follows:

Step1: Switch off the AC MCB. The position is shown in Figure 4-10.

Step 2: Remove the cover of the distribution unit. The position is shown in Figure 4-10.

-

8/10/2019 APM200 Outdoor Power Supply System User Manua.pdf

32/39

28 Chapter 4 Maintenance

APM200 Outdoor Power Supply System User Manual

Step 3: Remove the 4 screws shown in Figure 4-12, pull out the SPD alarm interface and remove the right segment ofthe distribution unit, as shown in Figure 4-20.

Alarm interface

Figure 4-20 Pull out the SPD alarm interface

Step 4: Remove the four fixing screws of the SPD shown in Figure 4-21. Disconnect the cables connected to the SPD.

SPD fixing screws

Figure 4-21 SPD and heater

Step 5: Reverse previous steps 4~1 and replace the new SPD. Connect the cables; fix the screws and the SPD.

Step 6: Fix the distribution unit to the cabinet.

Check if each cable connector is tight and the connection is reliable. Switch on the AC MCB and restart operation aftermaking sure everything is OK.

-

8/10/2019 APM200 Outdoor Power Supply System User Manua.pdf

33/39

Appendix 1 Technical Data 29

APM200 Outdoor Power Supply System User Manual

Appendix 1 Technical Data

Environmental parameters

1. Operating temperature:North model: -40C to +45C; South model: -5C to +45C;

2. Storage temperature: -40C to +70C

3. Relative humidity: 5% to 100%, no condensing

4. Altitude: 0 to 2000m. The system should be derated where the altitude is higher than 2000m. The highest operatingtemperature should be reduced by 1C at every 200m higher. And the highest altitude is 4800m.

5. Solar radiation

Direct radiation: 1120W/m 2 Dispersion radiation: 224W/m 2

Electrical parameters

1. Rated input voltage: 220Vac

2. Input voltage range: 90Vac to 290Vac, single phase three wire. When the voltage input is between 90Vac~176Vac,the rectifiers output is allowed of linear derating. When the voltage input is 90Vac, the minimum rectifier output poweris 37.5% of rated power.

3. Maximum input current of the system: 25A (with no user connector- jack output)

4. Maximum output current of standard configuration: 60A

5. Rated frequency: 50Hz

6. Input frequency range: 40Hz to 65Hz

Mechanical parameters

APM200 dimensions (H W D): 1600mm 600mm 600mm (without base)

APM200 weight: 450kg

Battery compartment dimensions (H W D): 280mm 490mm 520mm Audibl e no ise

65dB.

Anti -erosive perfor mance

Coating:

1. Adhesion test satisfies ISO2409 Class 0.

2. The pencil rigidity test satisfies ASTM D3363 2H.

3. Shock test satisfies 50kg.cm according to ASTM D2794.

4. The coating is not changed after 500 hours salt-fog test according to ASTM B117.

5. The coating of the external surface of the cabinet is suitable at the -40C to +55C environmental temperature and

1120W/m 2 solar radiation. The coating should not blister, flake or flaw after 250 hours test according to ASTM D822.But it is allowed to have slight pulverization, that is, a l ittle paint particle is allowed to adhere when the coating is wipedat full tilt. The slight change of color is allowed, that is, it is acceptable if the color difference value (NBS) is less than6.0.

Protection r equirement

1. The cabinet of the equipment compartment satisfies GB4208 IP55.

2. The cabinet of the battery compartment satisfies GB4208 IP34.

Lightning protection

1. The system has a Level B+C SPD on AC side.

2. The AC input can withstand the maximum strike through current capacity of 60kA, and the nominal through current

capacity is 25kA. The simulated lightning strike is carried out in term of YD1235.1 and YD1235.2.3. The test of which the DC side can withstand through current capacity of 10kA requires: -48V-RTN can withstand the

strike of 10kV with the waveform 8/20 s 5 times, for positive and negative polarity respectively 5 times, and the

-

8/10/2019 APM200 Outdoor Power Supply System User Manua.pdf

34/39

30 Appendix 1 Technical Data

APM200 Outdoor Power Supply System User Manual

interval between every two tests is one minute; RTN-PE can withstand the strike of 10kV with the waveform 8/20 s 5

times, for positive and negative polarity respectively 5 times, and the interval between every two tests is one minute.

-

8/10/2019 APM200 Outdoor Power Supply System User Manua.pdf

35/39

Appendix 2 Definitions Of The Monitoring Expansion Board Interface 31

APM200 Outdoor Power Supply System User Manual

Appendix 2 Definitions Of The Monitoring Expansion

Board Interface

All the sensors are connected to the monitoring expansion board. The screen print diagram of the wiring port of themonitoring expansion board is as follows.

Screen print of Monitoring expansion board socket

Figure 1 Screen print diagram of the monitoring expansion board

Connector models of the monitoring expansion board terminals and recommended connection cables are in thefollowing table.

Table 1 Connector models and recommended connection cables

Signal port Screen print marks Socket- connector model commended cables (AWG)Waterlogging J_WATER P2500-4 26~22

Circumambient temperature/ humidity TEM_HU P2500-4 26~22main distribution frame J_WIRE P2500-2 26~22

Smoke sensor J_SMOKE P2500-2 26~22Door status sensor JTM1 P2500-2 26~22 Alarm dry contact JK1,JK2 P2500-2 26~22

Optical- coupler output JAC1,JAC2 P2500-2 26~22Backup digital data input J9 MSTB2.5/2-ST-5.08 26~22

RS422 communication port J8 MSTB2.5/4-ST-5.08 26~22Preset dry contact port J12 MSTB2.5/2-ST-5.08 26~22

The functional definitions of port- pins of the monitoring expansion board are shown in the following table.

Table 2 Port- pin definitions of the monitoring expansion board

Port name Screen print marks Correlative pins Signal properties Remark1,3,5 +24V output

Backup digital value J9

2,4,6 Input of the signal cable1 +12V output2 Input of the signal cable3 Earth cable

Waterlogging sensor port J_WATER

4 None1 +24V output2 Input of the temperature signal cable3 +24V output

Port of the circumambienttemperature/ Humiditysensor

TEM_HU

4 Humidity signal cable input1 Earth cable2 Battery- temperature signal cable input3 +12V output

Battery- temperaturesensor port

BAT_WE

4 +12V output

Check the battery-compartmenttemperature.Connected before

delivery.1 Optical- coupler1 controlling outputOptical- coupler1

controlling output portJAC1

2 Optical- coupler1 controlling output

-

8/10/2019 APM200 Outdoor Power Supply System User Manua.pdf

36/39

32 Appendix 2 Definitions Of The Monitoring Expansion Board Interface

APM200 Outdoor Power Supply System User Manual

Port name Screen print marks Correlative pins Signal properties Remark1 Optical- coupler2 controlling outputOptical- coupler2

controlling output portJAC2

2 Optical- coupler2 controlling output1 main distribution frame signal inputPort of mains distribution

frame sensorJ_WIRE

2 +48V power output1 Door status sensor signal input

Door status sensor port JTM12 +24V power output1 Smoke signal inout

Smoke sensor port J_SMOKE2 +24V power output1 dry contact1 output

Alarm dry contact port JK12 dry contact1 output1 dry contact2 output

Alarm dry contact port JK22 dry contact2 output1 Earth cable

2Signal cable input of equipmentcompartment temperature

3 +12V output

Port of the Equipment-compartment temperatureSensor

EQU_WE

4 +12V output1 BUS+ input

2 BAT1 mid- voltage input3 BAT2 mid- voltage input4 BUS- input5 None

Battery- balance test port J4

6 NoneLoad MCB switchable testport

J3 1~7 7 Load MCB monitoring signal input

1 -48V power outputSPD failure test port onDC side

J52 SPD failure of the DC side signal input

Connected beforedelivery

1 -48V power outputSPD failure test port on ACside

J62 SPD failure of the AC side signal input

Connected beforedelivery

1 Power output

2 Signal output of fan speedTo internal fan.Connected beforedelivery

3 Signal input of fan failure4 Power- earth cable5 Power output

6 Fan speed signal outputTo external fan.Connected beforedelivery

7 Signal input of fan failure

Fan- control port J_FAN

8 Power- earth cable

1 TX+2 TX-3 RX+

RS422 communicationport

J8

4 RX-

Preset dry contact port

J12 1~8 RLn+,RLn-

1 Busbar+Expansion board powerinput port

J22 Busbar-

Remark

:

The descriptions of the dry contact port presetting is as follows:

When the DIP switch 6 is switched to OFF, the dry contacts are closed when normal and are open upon alarms.

When the DIP switch 6 is switched to ON, the dry contacts are open when normal and are closed upon alarms. Thefollowing description are given in case of DIP switch 6 switched to OFF.

Dry contact 1: dry contact of AC/ DC SPD alarm are preset closed (normal state), and open upon AC/ DC SPD alarms.

-

8/10/2019 APM200 Outdoor Power Supply System User Manua.pdf

37/39

Appendix 2 Definitions Of The Monitoring Expansion Board Interface 33

APM200 Outdoor Power Supply System User Manual

Dry contact 2: dry contact of mains failure alarm are preset closed (normal state), and open upon mains shortage,mains over/ under- voltage alarm occurs.

Dry contact 3: dry contact of DC under- voltage alarm are preset closed (normal state), and open upon DC under-voltage alarm occurs.

Dry contact 4: dry contact of system power alarm are preset closed (normal state), and open upon rectifier failure,rectifier protection, rectifier communication abnormal, busbar output over/ under- voltage alarm, charging over- current

alarm, battery string route disconnection or internal/ external fan fault alarm occur.

-

8/10/2019 APM200 Outdoor Power Supply System User Manua.pdf

38/39

34 Appendix 3 Schmatic Diagram

APM200 Outdoor Power Supply System User Manual

Appendix 3 Schematic Diagram

S

XT1

HEATER 1

HEATER 2

Heater of theequipmentcompartment

Heater of thebatterycompartment

Monitoringtransferboard

Door sensor of theequipment compartment

Temperature sensor of thebattery compartment

Temperature sensor of theequipment compartment

OUTPUT

DC

MONITOR

AC/DC

INPUT

AC

Internal fanExternal fan

LOAD 4

0V busbar

-48V output

XT2 1 42 3 765

LOAD 1 LOAD 2 LOAD 3

PE busbar outside the cabinetPE busbar inside the cabinet

SPD11DZF2

Door sensor of the battery compartment Alarm

-48V111098

0V

BATT.2BATT.1

LOAD 6LOAD 5

2QF425A

2QF116A

2QF225A

2QF325A

48V+-

AC/DC

AC input

PE

N

L

4 3

PE

NoutNinPE

2

1QF11

F1

LoutLin

SPD

Alarm

Standby digital value

RS485 port

PSM

2QF62QF540A 50A

KM1

2QF780A

KM2

FL2FL1

FAN1 FAN2

AC/DC AC/DC

EMI

Dry contact

Thermostat

Thermostat

NN N

1QF31 2

1 1QF2

LPE

XS

KT3

2

KT1

Thermostat

Thermostat

KT4

KT2

Figure 2 Schematic diagram of APM200 outdoor power supply system

-

8/10/2019 APM200 Outdoor Power Supply System User Manua.pdf

39/39

Appendix 4 Wiring Diagram 35

Appendix 4 Wiring Diagram

FAN1

-

+

J 2

J 5

J T M1

J 7

E Q U _WE

B A T _WE

J 9

J 6

J _ S M OK E

J _WI RE

T E M

_H U

J K 1

J K 2

R S 4 8 5 J _W

A T E R J A

C 2

J A C 1

L N

J 1

39W8

W08 38

W10

W13 50

W10 45A

11B

W02

40

Standbytemperaturemeasurement ofequipmentcompartment

Temperaturemeasurement ofequipmentcompartment

Battery temperaturecompensation

Heater of thebatterycompartment

PE busbar Bottom doorsensor

Upper doorsensor

Cross-door cable(up and down)

To AC output cable of the subrack

Heater of theequipmentcompartment

W01

c+

c cFAN2

-

AC INPUT

L

1# Battery

- +

2# Battery

- +

c

W04

W02

W08 38

0VDC BUS

-48VDC OUTPUT

W11 47

PSM-BB

W05

W06

W06

W06

W08

W08

W09

W09

W10

W03

W12

W03

BATT.(+)LOAD+

B2+B1+

01 02 03 04 05 06 08 10 41 11A

W02 07 09 12,13

14

15

181921

20

22

23

24

25

26

27

28

31

2932

30

34

33 35

36

39

4244

W10 46

W10 45

W11 47

48

49

Screen print of themonitoring expansionboard socket

05SOCKET LCB

06TEM.

07MCB

08MCB

09SPD2

0402

03

PD01

PSM22

FAN21

PCB

20

BAT.19

HEATER16

KT314

KT415

PE17

MJ18

SPD110

HEATER11

KT112

KT213

W03 17

W03 16Equipotential cable

W 08 37

43

W12

W12

-48V

0V

J _F A N

J 8 J 1 1

J 3

J 4

J 1 2

SPD1

PE busbar outside the cabinet

1 2 3 4 5 6 7 8 9 10 11

W03

W07

0V

SPD2

-48V

PE Alarm

NKT4

KT3

L

KT1

L

KT2

N

LOAD3-LOAD1- LOAD2- BATT.(-)L OA D4 - L OA D5 - L OA D6 - SPD-

B2-B1- - +

Figure 3 Wiring diagram of APM200 outdoor power supply system