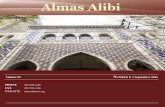

Almas Tower Atkins

Transcript of Almas Tower Atkins

-

7/22/2019 Almas Tower Atkins

1/10

STRU

CTURES

65

Abstract

Atkins Middle East

Senior StructuralEngineer

Farshad

Berahman

Atkins Middle East

Senior StructuralEngineer and Associate

RanjithChandunni

Introduction

The Dubai Multi Commodity CentresAlmas Tower is a 360m high slenderoffice tower located in the JumeirahLake Towers development in Dubai,United Arab Emirates (UAE) (Figure1). The building consists of fivebasements, two podium levels,60 storeys of offices and threemechanical floors. It has a total floorarea of approximately 85,000m.

A typical tower floor plan is in theform of two diagonally offset ellipses,with a floor plate approximately

64m long and 42m wide (Figure2). The floor plan from level 53to level 64 consists of only one ofthe two ellipses. An 81m slenderspire peaks at 360m, forming thehighest point in the development.

The building was completed inSeptember 2008 and accordingto the Council for Tall Buildingsand Urban Habitat (CTBUH),was the worlds second tallestbuilding completed that year.

Structural systemThe following constraints had asignificant impact on the structuraldesign of the tower and wereconsidered at concept stage design

the office floors to have anefficiencyof not less than 80%

flexible column-free andwall-free office space

final sellable area to be within2.5% of the area sold by theclient to ultimate office owners

each office floor to be capableof supporting a 2.5t safe placedanywhere within an office space.

The principal structural framingconsists essentially of a tube-in-tube system. This is made up of areinforced concrete peripheral frameand a central core wall, which areconnected to each other by centralspine beams on each floor andoutrigger walls at service floor levels.

A parametric study of theeffectiveness of differentarrangements of the externalframe, belt walls and outriggerwalls was carried out and thefindings are shown in Table 1.

The peripheral frame consists of1000mm deep, 500mm wide beamssupporting precast units whichspan onto peripheral columns. Thecolumns are at a maximum spacingof 5m and form part of the lateralload resisting system. The columns

are designed compositely in thelower half of the building to keep thecolumn sizes small compared to whatwould be needed for a reinforcedconcrete column alone (Figure 3).

A typical floor slab consists of 320mmthick hollow-core precast panels with80mm thick structural topping. Itties the external frame to the centralreinforced concrete core walls orcentral spine beam. The floor is alsodesigned to act as a diaphragm,transferring lateral wind and

The Almas Tower is a 360m high office tower in Dubai, UAE. The designcomprises two intersecting elliptical towers located on a sculpted three-storeypodium. The architectural form and clients requirement for floor efficienciesof 80% resulted in significant challenges for the structural design team.This paper discusses the structural framing adopted, wind-tunnel studiesundertaken including building acceleration, lateral movements and column-shortening effects and mitigation measures introduced. It also describesthe design of the towers spire, which features tuned mass dampers.

The structural design of Almas Tower, Dubai, UAE 89

Parameters Core wall Core wall + peripheral frame Core wall + peripheral frame

+ belt walls + outriggers

Natural period: s 14.6 12.2 9.6

50y windsway: mm

1785 1258 771

Table 1 - Parametric analysis to study the effectiveness of the structural system

-

7/22/2019 Almas Tower Atkins

2/10

STRUCT

URES

66

89 The structural design of Almas Tower, Dubai, UAE

seismic forces to the central coreand external frame. The precastslab option was chosen because

of programme benefits: they arecomparatively lightweight and provideuninterrupted space for services.

The plant floors at levels 42, 121, 212and 279m above ground are 450mmthick solid reinforced concrete slabs,with the roof to the plant floorsbeing a 400mm thick solid reinforcedconcrete slab (except the top plantfloor) to provide an acoustic barrierto the floor immediately above.

The building was designed to Britishstandards, while UBC-977was

used for seismic load assessmentin accordance with local authorityrequirements. The concrete gradesrange from 45 to 70MPa cubestrength with a reinforcement grade460 (f

y= 460 MPa) and structural

steelwork S355 (fy= 355 MPa).

Finite-element modelling

A three-dimensional finite-elementmodel of the tower and podium wasgenerated in Etabs5, which includedthe raft slab on spring supports tosimulate the piles although theraft weight was not considered forthe purpose of assessing the seismicbase shear. An allowance was madein the section properties for crackingunder ultimate limit state accordingto UBC-97 and it was assumedthat all loads would be transferredto the ground through the piles.

The spring stiffness for the pileswas based on the pile workingload capacity and the theoreticalsettlement of the pile under that

load, which was taken from thegeotechnical assessment. The effect ofthe podium on the lateral movementwas considered by modelling lateralsprings at various levels based on thestiffness of the podium structure.

The belt walls and outrigger wallsinclude large service openings toallow for air intake and dischargeas well as to allow for ductworkand piping routing (Figure 4).

The outrigger walls, if constructedalong with the floors, would have

transferred significant dead loads fromthe peripheral columns onto the core,in addition to which the outriggerswould have attracted forces due todifferential axial shortening betweenthe core and the peripheral frame. To

Figure 1 - The 360m high Almas Tower in Dubai, UAE was completed in 2008

-

7/22/2019 Almas Tower Atkins

3/10

STRU

CTURES

67

89The structural design of Almas Tower, Dubai, UAE

overcome this, the outrigger wallswere disconnected from the floor slababove and on one vertical side untilall of the floor slabs were cast, whichsignificantly reduced the load transferdue to dead load and minimiseddifferential shortening between thecore and the frame (Figure 5).

Wind engineering

Wind tunnel testing was carriedout by Rowan Williams Davies &Irwin Inc.9using a high-frequencyforce-balance model (Figure 6)with wind loads based on a 3s gustwind speed of 37.7m/s for openterrain at 10m height, in accordance

with measurements at DubaiInternational airport between 1983and 1997. The proximity modelwas based on a 575m radius.

The model was placed on a turntableand was rotated at 15 intervalsto determine wind loads for 24

directions. Structural propertiessuch as mass, mass distribution,mode shapes and frequencies wereobtained from the structural analysismodel and input to assess overallstructural loads, building accelerationand cladding pressures. A dampingvalue of 2% was assumed for thecalculations. The tests providedoverall structural loads using 24 loadcombinations taking into accountdirectional effects for each sector.

The expected deflections under 50year winds were greater than H/500.

As a result, soft joints are providedbetween the blockwork walls andthe structure in accordance withBS 8110-22- to allow for rackingmovement between adjacentstoreys under wind loads.

The expected building accelerationsat the top floor for a 10 year returnperiod were 18.7mg, which is withinthe commonly accepted threshold of23.4mg (Table 2) as per ISO criteria.A sensitivity check for a 1.5%damping resulted in an acceleration

of 21.6mg or an increase by afactor of (2/1.5) which wasstill within acceptable limits.

The overall cladding pressureresults gave a maximum value of4.5MPa in certain local areas.

Figure 2 - Typical structural floor plan up to level +232m showing hollow core slab supported on external beams to core walls and internal beams

Figure 3 - Cross section through a typical composite column (dimensions in mm)

-

7/22/2019 Almas Tower Atkins

4/10

STRUCT

URES

68

Seismic design

Seismic loads used were based on

UBC-97 zone 2A in accordancewith local authority requirements.A response spectrum analysisbased on UBC-97 was carriedout with appropriate scalefactors used to obtain memberforces and associated drifts.

Section modifiers as per UBC-97were applied to the design, thatis, 0.7 for uncracked walls andcolumns, 0.35 for cracked walls and0.35 for beams. Ductile detailingfor the coupling beams using

diagonal reinforcement was specifiedaccording to UBC-97, althoughthis is not required for zone 2A.

Foundation system

The foundation for the tower is a3m thick piled raft supported on1200mm diameter friction piles,which are approximately 40mlong. To mitigate the effect of theheat of hydration, 50% of the raftcement was replaced with groundgranulated blastfurnace slag (ggbs).

Appropriate concrete cover wasprovided for the foundation andperimeter retaining walls to achievethe intended building design life.

The columns and walls in thepodium area are supported byslabs spanning between pile capsand, to reduce the slab thickness,tension piles are designed to resistuplift in the podium basementcaused by the high water table.

Vertical asymmetry

The tower has an inbuilt verticalasymmetry due to one part of thetower extending 12 floors above theother while connected to one corethroughout the height of the building.It was realised early on in the designthat there could be lateral movementin the building that would be inexcess of sways in a conventional,symmetrically loaded building.

Building movement monitoring wasincluded in the specification to allowthe structural designers to compare

actual movements with thoseestimated. This required survey pointsat each floor, which were monitoredby laser surveying instruments (LeicaTPS700) for lateral drift against afixed benchmark located at groundlevel outside the building. Further

Figure 4 - Extract of three-dimensional finite-element model of a plant floorshowing core walls, outriggers with openings and external belt walls

Figure 5 - Elevation of a typical outrigger wall with service openings gaps in thewall adjacent to slab and belt wall were provided to disengage outrigger duringconstruction to minimise differential shortening effects (dimensions in mm)

The structural design of Almas Tower, Dubai, UAE89

-

7/22/2019 Almas Tower Atkins

5/10

STRU

CTURES

69

points were located at the core andperiphery of each floor to monitormovement due to axial shortening.

The results from the three-dimensionalanalysis model indicated that thehorizontal gravity load sway wouldbe of the order of 225mm (shortterm) at the uppermost floor level.This value is an overestimate asthe model assumes the structure isbuilt and then all loads are appliedinstantaneously a phenomenon

known as switch-on gravity whichis obviously not realistic and requiredfurther investigation. Furthermore,

the analysis model does not takeinto account the fact that:

all floors are cast horizontally atthe level shown on the designdrawings, thereby reducingthe differential shorteningcalculated in the analysis model

vertical elements are builtplumb with reference to a fixedbenchmark at ground level,thereby reducing the swaycalculated in the analysis model

effects of time-dependentfactors such as creep, shrinkageand age of concrete

modulus of elasticity achievedfor concrete is usually 30%higher than codified values

compressive strength of concreteachieved is normally 10%higher than specified values.

Long-term dead load sway

Whereas a long-term dead loadsway of H/1000 would be deemedacceptable, further assessments werecarried out to get a better estimateof the anticipated gravity load sway.

The following procedure wasundertaken to estimate dead

load sway of the building.Sway analysis was carried out usinga full model of the building, withconstruction sequence analysisperformed from levels +236mto +279m. The instantaneousdead load sway was 150mmat +236m and 225mm at theuppermost floor (+279m).

The effect of time-dependent creepwas allowed for by a reductionin the effective elastic modulus.Calculations were carried out based

on the principle of area momentto work out a multiplier on lateralmovement. This resulted in a netincrease of 110% on the calculatedvalue of lateral movement due toload from level +236m and above.

In applying a creep coefficient of 1.1,long-term deflections were found tobe 472mm (H/590) at level +279mand 315mm (H/750) at level +236m.

As a result of the calculatedlong-term sway values based oncodified material properties, the

core walls in the taller portion ofthe building were thickened.

Figure 6 - Scaled model of Almas Tower used in wind tunnel studies

Table 2 - Predicted building acceleration

Return Period: y Peak total acceleration: milli-g ISO criteria: milli-g

1 12.1 14.0

5 16.7 19.5

10 18.7 23.4*

* The criteria for a 10 year return period is not provided in ISO and has been extrapolated

Figure 7 - Long-term settlement curve for elastic shortening, creep

and shrinkage as well as the total shortening of a typical column

Figure 8 - Settlement of a typical tower column (TC-3) and the core wall as

well as the differential settlement between the two typical column and core

The structural design of Almas Tower, Dubai, UAE 89

-

7/22/2019 Almas Tower Atkins

6/10

STRUCT

URES

70

Long term axial deformationand differential shortening

As with all tall buildings, it wasnecessary to estimate the long-termaxial deformation (see Figure 7) andthe differential shortening betweenthe core and the columns (see Figure8). This deformation has an impacton the design of connecting elementsand also requires adjustmentswhile casting the floors to ensurethat the floors are horizontal.

Two approaches were considered one using the Eurocode 23and another using the American

Concrete Institute 2091model.

The Eurocode method does nottake into account the relaxationof creep due to the presence ofreinforcement, whereas the ACImodel does. This was a significant

The actual material test results fromsite demonstrated that the values

of modulus of elasticity used wereabout 35% higher than the codifiedvalues and the compressive strengthof concrete was about 10% higherthan design strength. Consideringthese factors, the long-term deflectionat completion of the last floor wasestimated as 189mm (H/1470) at level+279m and 126mm (H/1900) at level+236m. These values are well withinthe acceptable range of H/1000.

Although the analysis indicatedthat in theory the sway wouldbe within acceptable limits, thecontractor monitored the verticalityof the building during constructionand made adjustments to accountfor this sway by casting floorslevel to the ground benchmark.Adjustments were relatively small

for the lower symmetrical partand relatively large for the upper

asymmetrical part of the building.Lateral sway recorded on siteimmediately upon completionof the last floor was 55mm(H/5070) at level +279m and53mm (H/4450) at level +236m.

The procedure demonstrated thatwith simple compensation techniqueson site, lateral dead load sway canbe controlled to a large extent. Otherfactors such as stiffening effects ofinternal block wall partitions andfaade elements might have also

contributed to the reduction in sway.

Figure 9 - Plan view of podium the largest of eight triangular-shaped petals radiating from the central core accommodates a diamond exchange centre

The structural design of Almas Tower, Dubai, UAE89

-

7/22/2019 Almas Tower Atkins

7/10

STRU

CTURES

71

factor in this building consideringthat the columns were compositeand contained significant amounts ofreinforcement and that the walls were

heavily reinforced at lower levels.

It was therefore decided to use theACI method for the assessment. Acomputer program was developed

based on the procedure outlined inthe ACI as well as that presented bythe Portland Cement Association6.

The program assessed the long-termaxial shortening of columns and wallsby considering elastic shortening,creep, shrinkage and by allowing forthe fact that floors would be castlevelled to the position indicated onthe drawings. The calculation wascarried out for the core walls andcolumns and the difference was

allowed for in the construction ofthe floors between the cores andthe columns. A typical differencebetween the core walls and onecolumn is shown in Figure 8.

Cladding

The building faade consists of aunitised cladding and curtain wallingsystem, which is manufacturedincorporating aluminium, glass andinsulation as a complete module.

The vertical spacing was based ona floor-to-floor height of 4m whilethe horizontal spacing was based ona combination of the structural gridand the widths of offices to achievea maximum number of vision bays.

A 10mm gap was provided betweeneach panel for thermal and seismicmovement as well as the long-termmovement of the concrete framedue to creep and shrinkage. Thefull depth of the mullions, includingthe glazing or cladding is 150mm,which left a tolerance of 25mm

either way in the 200mm structuraldepth allowance for cladding fixing.

Figure 10 - Elevation of diamond exchange centre overhanging cascading podium landscape

Figure 11 - Temporary device to suppress vortex shedding on the spire during

construction of the spire and installation of its tuned mass dampers

The structural design of Almas Tower, Dubai, UAE 89

-

7/22/2019 Almas Tower Atkins

8/10

STRUCT

URES

72

reinforced concrete upstand wall

over a length of 21m, such that thefree-standing length of the spire inone direction is approximately 60m.

The spire has two distinct sectionswith a step transition approximatelytwo thirds of the way up. The lowerportion is roughly elliptical in shapeand is constructed from a triangulatedsteel frame with aluminium cladding.The major and minor axis of theellipse is 7.4 and 3.4m at the baserespectively. The 23m high upperportion of the spire is of sheet steel

construction. The major and minoraxis of the upper portion is 4.3and 1.5m at its base respectively.

The spire structure was initiallyanalysed and designed for code-calculated static wind forces. However,due to the slender nature of the spire,it was realised early on in the designthat without additional damping,the spire would vibrate excessivelycausing unacceptable fatigue stressesthat could lead to structural failure.

A dynamic analysis was carried out

to assess the susceptibility of thespire to a number of wind-inducedexcitations, such as galloping, flutter,wind turbulence and vortex sheddingin accordance with provisions inEurocode 14. It was found that thecritical wind speed for vortex shedding

Podium

The design of the podium wasinspired by the inherent angulargeometry of a diamond. The podiumcomprises an array of eight triangularglass petals that radiate from thecentral core (Figure 9). The diamondexchange is accommodated within thenorth-eastern petal that juts out overa terraced water feature steppingdown to a lake. The three-storeypodium accommodates a varietyof retail spaces and food courts, abusiness centre, a health club and

the diamond exchange centre.

Each triangular retail petal consistsof a steel framed structure withcomposite metal deck floor slabs. Thediamond exchange centre comprisesprofiled metal-deck slabs supportedon a grid of steel beams. These are inturn supported by an exposed steeltruss and steel columns, which arestraight or raking (Figure 10). Thesteel frames are stabilised by portalaction and by the central core of thebuilding to which they are connected.

The ground floor slab is formed bya 140m diameter stepped floor,which radiates from the centraltower to the perimeter. Close to thetower, the podium is at ground level,gradually stepping to basement 1

level towards tower entrance and

basement 2 towards the rear side.The ground floor slab is a single unitof 750mm thick folded concreteplate. All the basement columnsoutside the tower terminate at groundfloor slab level. These columns forma regular grid of 17.5m x 8m toincorporate the clients requirementof a large column free basementparking area. The folded slabsupports the landscape loading andplanted columns from the retail unitsand diamond exchange centre.

A three-dimensional finite-elementmodel generated using the Robotpackage8was used for analysis anddesign of the slab. No expansionjoints were provided the slab isexposed externally and thereforedesigned for stresses due toseasonal temperature variationsof 20oC. All podium columns aswell as perimeter retaining wallswere designed for additional lateralloads due to thermal movements.

Spire structureThe top of the Almas Tower featuresan 81m tall spire, which forms the tipof the building reaching to a heightof 360m. The base of the spire isconnected to the tower through a

Table 3 - Dynamic performance of spire

The structural design of Almas Tower, Dubai, UAE89

-

7/22/2019 Almas Tower Atkins

9/10

STRU

CTURES

73

was below those expected on siteand hence did have the potentialto excite the spire. Significant

deflection amplitudes and fatiguestresses were estimated for the firsttwo modes in each direction (majorand minor) based on the codifiedintrinsic level of damping of 0.5%.

The calculations were re-run withincreasing levels of damping toestablish the minimum dampingvalues required in each modeand direction to produce anacceptable fatigue life.

The properties of tuned mass dampersnecessary to provide the required level

of damping were then determined.Four 2t dampers located close to thetop of the spire were installed. Table3 shows the mode shape, frequencyand required and achieved dampingvalues. The measured frequenciesshowed good agreement with thepredicted frequencies. The provideddamping of approximately 4% inthe first mode and more than 5%in the second mode was confirmedby site measurements when thedampers were fine tuned.

The design was then verifiedupon completion of the dynamicstudy with dynamic wind forcescorresponding to proposed damping.The Robot software was used toperform the static finite elementanalysis and for member design ofthe structure and an Etabs modelwas run in parallel to verify themodal properties of the spire.

The top part of the spire needed tobe installed in stages because of itsweight. The dampers were locked,

that is inactive, until the dampersupplier was allowed access tounlock and tune them. Unpredictablewinds during the installation couldhave led to an extended installationperiod until the dampers couldbe activated, which meant thatexcessive vibration could occur in thattime. Therefore a vortex sheddingsuppression device (see Figure 11)was attached around the spire untilthe dampers were activated. Thisdevice caused wind turbulence inthis area rather than alternate vortex

shedding and hence preventedexcessive movement of the spire.

Conclusion

The design of Almas Tower

evolved from meeting the clientshigh expectations and stringentrequirements. The solution adoptedby the design team proved to bemost effective in producing a floorusage of the highest efficiency.

Detailed studies were carried out toaddress issues arising from the swaydue to vertical asymmetry of mass.This was overcome by using simplecompensation techniques duringconstruction, thereby demonstratingthat a practical approach can be

successful in addressing such issues.Vortex shedding suppressiondevices based on simple principleswere used as temporary measuresduring the construction stage toprevent excessive wind inducedmovement of the spire.

Acknowledgements

The key members of the projectteam were: client - Dubai MultiCommodity Centre, architect, buildingservices engineer, fire, life and safety,

acoustics, structure - WS AtkinsDubai, dynamic analysis of spire WSAtkins Epsom, wind tunnel specialist RWDI, third party structural reviewer Halcrow Yolles, project management Faithful & Gould, contractor jointventure Taisei Corporation andArabian Contracting Company, tunedmass damper supplier Gerb.

The authors would also like to thankChander Shahdadpuri, lead structuralengineer of the project and ShapourMehrkar-Asl, former head of structural

engineering at WS Atkins in Dubai,who were the main contributors ofthe paper presented at the conferenceof International Federation forHighrise Structures in 2007. Theywould also like to acknowledge thatthe computer program to estimatelong-term axial deformation wasdeveloped by Dr. Mehrkar-Asl.

This paper was published inICE Proceedings 2010.

The structural design of Almas Tower, Dubai, UAE 89

-

7/22/2019 Almas Tower Atkins

10/10

STRUCT

URES

References

ACI Committee 209 (1997) Prediction of Creep, Shrinkage and Temperature Effects1.

in Concrete Structures. American Concrete Institute, Farmington Hills, MI.BSI (British Standards Institution) (1985) BS 8110 Part 2 Structural Use of Concrete.2.Code of practice for special circumstances. BSI, Milton Keynes.

BSI (2004) BS EN 1992-1-1 Design of Concrete Structures General Rules for Buildings. BSI, Milton Keynes.3.

BSI (2005) BS EN 1991-1-4 Action on Structures General Actions Wind Actions. BSI, Milton Keynes.4.

CSI (Computers and Structures Inc) (2005) ETABS nonlinear version 8.5,5.extended 3D analysis of building systems. CSI, CA, USA.

Fintel M, Ghosh SK and Lyengar H (1987) Column Shortening In Tall Structures 6.Predictions and Compensation. Portland Cement Association, Stokie IL, USA.

ICBO (International Conference of Building Officials) (1997) Uniform Building Code, UBC-97. Whittier, CA.7.

Robobat (2005) Robot Millenium Software Package. Robobat, USA.8.

RWDI (Rowan Williams Davies & Irwin Inc.) (2005) Wind-induced structural9. responses, DMCC Almas Tower, Dubai, UAE. RWDI, Ontario, Canada.

The structural design of Almas Tower, Dubai, UAE89