Aker Arctic Technology Inc Newsletter September 2016 … · 2021. 6. 1. · Polaris is equipped...

Transcript of Aker Arctic Technology Inc Newsletter September 2016 … · 2021. 6. 1. · Polaris is equipped...

September 2016

ArcticPassionNews

Aker Arctic Technology Inc Newsletter

2 / 2016 / 12

Bronze propeller testin heavy icePage 12

Safe cruising in the Polar areasPage 5

Heavy icebreaker for theUnited States Coast GuardPage 8

LNG-powered offshorepatrol vessel in full-scale ice trialsPage 13

Finland's LNG icebreaker readyPage 3

2

Reko-Antti Suojanen

Managing Director

Announcements

In this issue Dear Reader,

Jyrki Saari joinedAker Arctic in March2016 as a softwaredeveloper to work onthe Ice Simulatorproject. Beforecoming to Aker Arctic,he has worked in themobile phoneindustry as well as

with remote management and monitoringsystems and logistical systems.

Page 2 From the Managing Director

Page 3 LNG icebreaker Polariscompleted

Page 5 Safe cruising in Polar areas

Page 8 Icebreaker for theUS Coast Guard

Page 12 Ice trials withbronze propeller test

Page 14 Top class ice research atAalto University

Page 16 Winter navigationon the Baltic Sea

Page 17 New stern improvesice management

Page 18 Oil platform winterisationcheck

Page 19 News in brief

Page 20 11th Arctic Passion Seminar

Meet us here

Arctic Passion News No 12

The market situation in the shipping and

especially in the shipbuilding industry

has always been volatile. Newbuilding

orders have gone up and down and

different vessel types have reflected

shipping industry needs in different

ways. The cargo vessel market is

currently at one of its lowest points, with

order intakes at a record low. However,

at the same time cruise vessels have

been ordered in big numbers, and other

passenger vessels also show signs of

increased activity. Also, it seems that

other special vessel types such as

icebreakers and special ice capable

fleets need to be rebuilt.

This summer has been remarkable in

many ways, but one specific issue is to

be noted that is of interest to people

working with arctic and ice issues. NOAA

announced that average global

temperatures reached an all-time record

high in the previous July. Also, variations

in weather conditions have increased,

and the temperature increase in the

arctic region has been at least twice as

high as global averages. This naturally

has a significant effect on the ice cover

and may be one reason for increased

interest in arctic tourism. Is this the last

time we will be able to see the polar ice

cap? Scientists, marine operators and

engineers like us have been familiar with

arctic ice and extreme cold temperatures

for a long time and can confirm the

significant changes in ice conditions.

Unpredictably increases, and what used

to be normal is something else today,

with conditions becoming increasingly

varied. Creating the design basis for

technical engineering and solid practices

for safe operations are becoming even

more challenging. Therefore, familiarity

with and knowhow of this experience-

based technology is even more valued

today.

We have always emphasised reliability

and safety, as is demonstrated by the

ships in operation. A careful, professional

approach has to be taken in regards to

the increased shipping activity in the

polar regions, whether we are talking

about a cruise vessel with large numbers

of passengers or a vessel transporting

cargo or performing special operations.

We have written in this magazine about

the polar cruises, and we have also

detailed the US icebreaker challenges

and have given an overview of other

activities occurring in the arctic and cold

climate projects, where we are working

together with our clients to deliver safe,

reliable vessels and operations for you.

Front cover:MSV Nordica, a Finnish multipurposeicebreaker ploughing through theNorthwest Passage in November 2015.Two Aker Arctic experts were on boardthe vessel for the journey.

September 2016

Alexey Dudaljoined Aker Arcticas a StructuralNaval Architect towork in ship designand engineering.Alexey graduatedfrom the StateMarine TechnicalUniversity of Saint

Petersburg, Russia in 2007 and holds anM. Sc. Degree in Shipbuilding and OceanTechnologies. In his previous work,Alexey was involved in projects related tothe design of offshore units and ice-goingvessels for the Arctic. This included theassessment of ice loads and design of theappropriate ice reinforcement. His mainactivities at Aker Arctic are related to thedesign of the hull structure of ice-goingvessels and icebreakers.

Kauno Sarkkinen in Memoriam

Our dear colleague and friend Kauno Sarkkinen has passed away.

Kauno began his work at Masa-Yards Arctic Research Centre

(MARC) in 1990, where he took care of the centre as well as

prepared and performed ice model tests. He also took part in ice

expeditions and full-scale tests. In 2001 he transferred to the

Helsinki Shipyard, but when Aker Arctic was founded in 2005,

Kauno's old colleagues persuaded him to join them in Vuosaari,

where the new third generation ice model testing facility was being

set up.

In addition to preparing and participating in ice model testing,

Kauno's responsibilities included taking care of the entire building. He knew all the

equipment and machinery by heart, and whenever there was a technical issue, Kauno

always came up with a solution. His multi-talented personality will be greatly missed.

Topi Leiviskä

33

Polaris is an exceptional icebreaker, asshe can exceed the performance of eventhe highly regarded Finnish icebreakersUrho Sisuand built in the 1970s, whichhave been widely recognised as themost capable icebreakers in northernBaltic conditions. The main purpose ofPolaris is icebreaking and assisting othervessels in difficult ice conditions in thenorthern Gulf of Bothnia, where iceridges can grow to over ten metres thickdue to strong winds. It is common thatridge formations are deeper than thedraft of the icebreakers.

Towing needs will increaseDuring the design phase, two propulsionconcepts were compared: a moretraditional twin-azimuth concept and atriple-azimuth concept with twopropulsion units in the stern and one inthe bow. The triple-azimuth concept waschosen as it turned out to be only slightlymore expensive, but significantlyimproved the icebreaking performanceand lowered operational costs.

"The Energy Efficiency Design Index(EEDI) is expected to change

commercial vessels sailing on the BalticSea in terms of size and engine power,"project manager Mika Hovilainen says."Most likely, vessels will become longerand slimmer and be equipped withsmaller engines. In difficult iceconditions, these vessels will need moreassistance and towing needs willincrease in the future."

In the most challenging ice conditionssuch as heavy ridges, contact towing isusually needed. The benefit of thechosen concept with a bow propulsionunit is that will have exceptionalPolarissteering capability and performance inridge fields, even when she is attachedto the vessel she is towing.

She is also able to perform oil spillresponse operations, emergency towingand rescue operations on the open seaall year round.

Fifty years of serviceHer planned service life is fifty years–twice that of typical commercial vessels– and this long service life has beentaken into account in the design. By wayof comparison, her predecessors Urho

and are now forty years of age.SisuThe ice belt is made of compound steel

with a stainless steel outer lining. Itrequires less service and saves fuel dueto reduced corrosion when compared tonormal steel coated with abrasion-resistant paint. All the basic work inmanufacturing the hull has been donewith the long service life in mind andeverything is made in accordance withthe highest quality standards. Spaces formachinery and equipment areadditionally planned so that it will beeasy to upgrade and make changeswhen it becomes necessary.

Polaris is equipped with Wärtsilä 34DFseries dual fuel engines. They areequivalent of typical diesel engines, butcan also use LNG as fuel withsignificantly reduced emissions as aresult.

³"The two 400 m LNG tanks carryenough fuel for ten days independentoperations in demanding ice conditions.Apart from LNG, low-sulphur marinediesel can also be used to continue theautonomy time," Hovilainen adds.

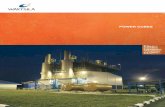

First LNG icebreaker Polaris

The construction of Finland’s new icebreaker has beencompleted at Arctech Helsinki Shipyard. Th vessel wille , ,Polarisbe owned and operated by Arctia Ltd., a Finnish state ownedcompany providing icebreaking services. is the world's firstSheLNG-fuelled icebreaker, which also makes her the mostenvironmentally friendly icebreaker ever built. is basedPolarison the Aker ARC 130 concept developed by Aker Arctic incooperation with ILS and the Finnish Transport Agency.

Polaris in sea trials in spring2016 outside Helsinki.

September 2016Arctic Passion News No 12

Main tasks and features:� Icebreaking and escort operations in

all prevailing ice conditions in theBaltic Sea

� Oil spill response with Lamor's built-inmechanical recovery system and

³1 200 m tanks for recovered oil� High bollard pull and emergency

towing capability also in heavy seas� “No compromise” approach to

icebreaking operations; performancesuperior to all existing Finnishicebreakers

4

September 2016Arctic Passion News No 12

Tonnage: 3,000 DWTLength: 110 m (360 ft)Beam: 24 m (79 ft)Draft: 8 m (26 ft) (design)

9 m (30 ft) (max)Ice class: PC 4 Icebreaker(+)Installed power: 2 × Wärtsilä 9L34DF(2 × 4,500 kW), 2 × Wärtsilä 12V34DF(2 × 6,000 kW), 1 × Wärtsilä 8L20DF(1,408 kW)Propulsion: Diesel-electric; three ABB

Azipod units, 1 × 6 MW(bow), 2 × 6.5 MW (stern)

Speed: 17 knots (31 km/h; 20 mph)(open water), 4 knots(7.4 km/h; 4.6 mph) in 1.8 m(6 ft) ice

Endurance: 10 days on LNG20 days on fuel oil

Crew: 16Builder: Arctech Helsinki Shipyard, 2016

General characteristics

Mika Hovilainen is convinced that thenew vessel will shine.

" is the world's mostPolarisenvironmentally friendly icebreaker, shecan use LNG and she has enoughpower and manoeuvrability for all hertasks. Her special hull form andpropulsion arrangement will minimiseice resistance and maximise theicebreaking capacity of the vessel.I believe she will become the best andmost efficient icebreaker in the Finnishfleet!"

“Extensive full-scale testinghas been done during seatrials,” states Jarkko Toivola,Head of Winter NavigationUnit at the Finnish TransportAgency. “Course stability ofPolaris going ahead andespecially going astern isbetter than in previousicebreakers with azimuthpropulsion units, but stillmanoeuvrability isexceptional. Open waterspeed and bollard pull in bothdirections exceed specifiedrequirements. Also responseof the power plant is quickregardless of used fuel type;LNG or MDO.”

Aker Arctic's design responsibilities:� Concept design including technical

documentation for shipbuildingcontract

� Hull form and propulsion systemdevelopment

� Model tests in open water and ice� Initial design of hull structure and

machinery� In co-operation with ILS Oy and The

Finnish Transport Agency� Technical support in procurement

process

The ice belt is made of compoundsteel covered with a stainless steellayer to reduce ice resistance andmaintenance costs.

The main engines are installed on themain deck level. The vertical LNG tanks inthe background can hold enough gas fuelfor 10 days of independent operation.

Polaris has three Azipod propulsionunits, one of which is in the bow of theicebreaker

Arctech Helsinki Shipyard

Arctech Helsinki ShipyardArctech Helsinki Shipyard

5

Safe cruising in thePolar areasIn November 2007, the sinking of MVExplorer in Antarctic shocked the world.She was ice-strengthened, butmisjudgement and operational mistakescombined with a low ice class vessel couldnot match the prevailing ice conditions.Today, an increasing amount of cruiseships are bringing passengers to explorethe Polar waters. Few of these vessels areactually designed to operate in Polar areasand to manage the various challenges thatthese high latitudes present.

September 2016Arctic Passion News No 12

In 2007 the sinking of MV Explorer in Antarctic shocked theworld. Luckily, all passengers and crew were saved.

photo: Reinhard Jahn/CC BY-SA 3.0

The Arctic and Antarctic differ from eachother, primarily because of their differentgeographical locations. Arctic ice is notas mobile as the ice in Antarctic becausethe Arctic is almost completelysurrounded by land forming a semi-enclosed ocean. Therefore, ice ridgespile up more easily and become thickerthan in Antarctic. Antarctic , on the otherahand, is a land mass surrounded by anocean. Ice floes can drift more freely andmix with snow, underwater ice, bergy bitsand growlers, forming large underwaterrams posing great danger to vessels.

"The Arctic and Antarctic areoften referred to with only oneword and still we are talkingabout an area, which is biggerthan Europe," says sales andmarketing director ArtoUuskallio.

Polar Code and Polar Classare not the sameThe newly introduced IMO Polar Codewill require additional crew training,enhanced operational practices andvessels to fulfil the criteria, which matchthe conditions in the intended area ofoperation. The intention of the PolarCode is to improve safety for thepassengers, the crew and also theenvironment.

"However, complying with the PolarCode is not a guarantee that a vesselcan manage all kinds of harsh iceconditions and freezing temperatures,”Uuskallio says.

A ship intended for Polar areas needs tohave the appropriate ice class. Theowners, designers and administratorsneed to select an appropriate ice class tomatch the requirements for the ship withits intended voyage or service.

"It is important to understand, that thePolar Class focuses on structuralintegrity," Uuskallio emphasises. "Movingaround is a completely different story.What if the vessel is stuck in ice for twoweeks because the Captain made anincorrect interpretation of the ice field?What if the wind packed the ice so thickthat the vessel cannot go through? Willthe systems still work? What to do withwaste and wastewater, which cannot bedumped in these fragile areas? Willsomebody come to help?

Area, profile, seasonAker Arctic has been designing high iceclass vessels for decades. The startingpoint is always to decide on theoperational area, the operational profileand operational season before beginningto design a vessel.

“It is not sensible to order a vessel firstand then hope that the circumstanceswill be favourable," Uuskallio adds.

Once the operational area has beendefined the planning can start. If a vesselis only intended to sail nearby ice areas,but not actually designed to break thickerice, a low ice class vessel can bechosen, as it will be cheaper to build. Itcan be P 6 or 7 and use Aker Arctic'sCnew multi-draft bow, which can managewell in light ice and is economical to usein open water transits.

However, a high ice-class vessel,which can manage independently inthicker ice, is more complicated todesign, as the design has to be abalance between the open waterperformance and good icebreakingcharacteristics. When operating in Arcticor Antarctic waters, the safety aspect isalways crucial. Therefore, a goodunderstanding of the ice loads, effectivewinterisation to keep the cold out and theoperation of the ship's systems isessential when designing the vessel.

Crystal Cruises br passengers to the North for the first time. Anings west Passageicebreaker accompanie the ship during the entire trip for the safety of the passengers.s

photo: Crystal Cruises

6

September 2016Arctic Passion News No 12

Ice class is safetyFirst of all, from a safety point of view,the right ice class needs to be chosen.Secondly, the right performance in iceand open water has to be selected tokeep operating costs down.

"Ice class is a guarantee of safety, nota guarantee of performance," Uuskalliopoints out.

The choices in performance concernhow the vessel will manage operations inice and open water. Operation in difficultice conditions is of utmost importance,but also involves higher operation costs.When selecting icebreaking capabilities,it is essential to also include open waterperformance for cost efficiency in longopen water transits.

"Our aim is to always find the optimalsolution for our customers' needs, whichwill combine the icebreaking capabilitieswith hydrodynamics without at any pointcompromising safety," says Uuskallio.

Winterisation needsA third area of consideration iswinterisation. This means how well allthe machinery and equipment cansustain freezing temperatures and howto keep the accommodation andrecreational spaces comfortable.

"Winterisation is not something youcan add as a warm jacket when you arefeeling cold. It has to be part of thedesign from the beginning. At the sametime, it makes the vessel energyefficient," Uuskallio adds.

Winterisation guarantees that thevessel can function in freezingtemperatures. If, for some reasonsomething would happen, the big vesselis usually the safest place to stay. Smalllifeboats are cold to sit in and help canbe days away.

There are different types of cruiseships and passengers. Expedition-cruises usually take more adventurouspassengers, who are prepared tomanage also uncomfortable situations.Luxury cruises usually carry passengerswho like to dress up nicely and admirethe scenery from the restaurant window.Nevertheless, safety should not be aquestion in either case.

That November night in 2007 wasfortunate. The seas around MV Explorerwere calm and there was enough timefor the passengers to board the lifeboatsand RIBs in the darkness, while theircruise vessel was taking in more andmore water. Help came after only a fewhours and all the passengers and crewwere saved by another vessel. The nexttime might not be as lucky, so pleasecontact Aker Arctic before starting to planyour Arctic cruise liner, we would bemore than happy to assist you indesigning a safe cruise ship.

B

PolarClass

Ice descriptions (based on WMO Sea Ice Nomenclature)

PC 1 Year-round operation in all polar waters

PC 2 Year-round operation in moderate multi-year ice conditions

PC 3 Year-round operation in second-year ice, which may include multi- yearice inclusions.

PC 4 Year-round operation in thick first-year ice which may include old iceinclusions

PC 5 Year-round operation in medium first-year ice which may include old iceinclusions

PC 6 Summer/autumn operation in medium first-year ice which may include oldice inclusions

PC 7 Summer/autumn operation in thin first-year ice which may include old iceinclusions

The Polar Class notation is used throughout the Unified Requirements for PolarClass ships to convey the differences between classes with respect to operationalcapability and strength. It is the responsibility of the Owner to select an appropriatePolar Class. Source www.iacs.org.uk

The Double-Acting shipconcept Aker Arctic hasdeveloped can also be usedfor cruise vessels. The vesseladvances bow first in openwater or light ice conditionsand stern first in heavy iceconditions. The vessel on theright is Norilskiy Nickel, anArctic container ship designedby Aker Arctic and built byAker Finnyards in 2006.She has been operatingsuccessfully in the RussianArctic for ten years and doesnot require icebreakerassistance even in thehardest ice conditions.

Aker Arctic has designed strong ice vessels for decades. The starting point is alwaysto decide the operational area, the operational profile and operational season beforebeginning to design a vessel. The concept drawing is for the International MarineAssociation’s annual conference held in 1989 in Helsinki.

Bow ahead

Stern first

7

The Aker Arctic designed module carriersare equipped with propellers we havecustom-designed for them.

September 2016Arctic Passion News No 12

Aker Arctic designed anAntarctic cruise ship in 2008,which was planned to be asafe cruise ship for iceconditions. Most other cruiseships sailing to the Arctic andAntarctic are convertedpassenger ships and actuallynot designed for the cold andice.

The Arctic/Antarctic cruise ship wasplanned for the actual operationalconditions: to bring passengers to theArctic in summer and to Antarctic inwinter.

The PC 5 class ship was designediceas a luxury modern ice-strengthenedexpedition cruise vessel for one to threeweeks of worldwide itineraries with about200 passengers.

It has a double-acting stern and canbreak 1 metre thick ice at a speed of twoknots.

The bow is optimised for open wateroperations but allows breaking 0.5 metrethick ice.

It is also equipped with rib boats forexpeditions to take passengers toexperience the Polar nature.

The vessel was not constructed due tolack of financing, but the design isavailable to be used as a basis for new,interested parties.

Since 2008, there have beenmany inventions andinnovations. If the ship wouldbe built today, the optimal hullwould be the new multi-drafthull concept, which providesexcellent open waterperformance at design draught

and good ice performancewhen the bow is trimmeddown. It would also need to beupdated to meet the new PolarCode rules.

“Before beginning the process to acquirean Antarctic cruise vessel, the mostimportant thing is to decide what it will beused for," project manager MaximilianVocke points out. "What is theoperational area and what is theoperational profile? Does the vesselneed to break ice or will it only stay closeto ice areas? What ice class does it needto be and what is the icebreakingcapability needed?"

We are now working with high intereston real Polar class cruise vesselprojects, which could provide the arcticexperience for passengers in a safe way.

12 12,5 13 13,5 14 14,5 15 15,5 16 16,5 17 17,5 18

Pb [kW]

Speed [knots]

Open Water Speed Power CurveTrial Condition

Aker Arctic Concept (kW)

Open water reference vessel 1

Open water reference vessel 2

A safe Arctic/Antarctic cruise ship

Aker Arctic has developed a new hull concept, which isoptimised for both ice and open water. The bow form is acombination of a bulbous bow and an icebreaking bow. Atdesign draught, the vessel uses the bulbous bow, which isoptimal for open water. In ice conditions, the bow is trimmeddown and then works like an icebreaking bow.

"This invention is optimal for cruise ships as they have astable draught," says Tom Mattsson, senior specialist in iceperformance at Aker Arctic.

"It offers excellent comfort for passengers with its goodseakeeping characteristics. Safety is another essentialfeature as the vessel can manage to get away from evensevere ice conditions on its own by using her excellenticebreaking capability."

Multi draft bow cruise vesselsbenefits ice classed

At ice draft the bow shapeworks like an icebreaker

The hull of the vessel sioptimized to use lowengine power at servicespeed.At this draft the bowshape works just like anopen water design

8

Pola

r R

ese

arc

h Inst

itute

of C

hin

a

September 2016Arctic Passion News No 12

An extraordinary icebreakerfor the United States CoastGuardThe United States Coast Guard (USCG) has launched aPolar Icebreaker Acquisition Program to replace twoexisting heavy icebreakers built in the 1970s with a newvessel. Aker Arctic is committed to help the USCG to findthe best solution to their needs.

Since the 1950s, heavy polar icebreakershave been used to support OperationDeep Freeze, the annual resupplymission to Antarctica, where theicebreakers open a channel through theRoss Sea ice pack and escort tankersand freighters to the world's southernmostharbor at the McMurdo Station. Duringthis month-long voyage that begins andends in Seattle, the icebreaker willexperience extreme temperatures fromtropical heat at the equator to the freezingpolar climate, strong winds and heavyseas, and finally ice up to eight feet thick.The vessel required for this task has to bean extraordinarily versatile, heavy-dutyicebreaker with excellent seakeeping andopen water features.

In addition to the resupply mission toAntarctica, the new polar icebreaker willalso be used to support science missionsin the Arctic and will feature an extensivescientific outfit and laboratories. Due toincreasing activity in the Arctic, it will alsoremain in constant stand-by fordemanding search-and-rescue andmarine environment protection operationsin the ice-covered seas.

"There is neither existing nor plannedvessels in the world that fulfill all thedemanding mission objectives andrequirements set by the USCG," NavalArchitect Tuomas Romu at Aker Arcticemphasizes.

"Most icebreakers that work in northernlatitudes are not designed for long transitsin open water and heavy seas, and mostAntarctic vessels are primarily scientificresearch and supply vessels with lowericebreaking capability. None of them canfirst manage rough seas with waves up to45 ft high in tropical heat and then breakthick multi-year ice in freezingtemperatures."

The optimal vesselAker Arctic has already started drafting anicebreaker concept to find out what kindof vessel could meet the objectiverequirements defined by the UnitedStates Coast Guard in the recentlypublished Polar Icebreaker

Industry Data Package. "We are lookinginto a relatively compact vessel which canfulfill all the objectives, but still beaffordable to build and economical to useand maintain," says Romu. “A largervessel would require more powerfulengines and bigger fuel tanks. Aiming fora vessel that is not larger than it needs tobe to complete its mission successfullykeeps the construction and operationalcosts at bay.”

Based on Aker Arctic's preliminaryestimates, the new heavy polaricebreaker would have a displacement ofabout 20,000 metric tons, making itslightly larger than the existing US-flagged icebreakers. It would feature ahighly redundant diesel-electric powerplant, which is the current standardworldwide in icebreakers, and apropulsion system with electrically drivenfixed-pitch propellers. Possible propulsionalternatives include a conventional tripleshaft arrangement as well as azimuththruster/shaftline hybrids.

"The end result will most likely be aheavy icebreaker that may looksomewhat conventional from the outside,but inside has modern technology whichhas proven to be efficient and reliableover the years," Romu adds. "Icebreakingtechnology has made a huge leap in thepast forty years since the USCGC PolarSea Polar Starand USCGC were built."

Since the heavy icebreaker is expectedto encounter extremely hard multi-yearpolar ice, it will be designed to break iceprimarily bow-first. The hull form needs tohave the right balance betweenicebreaking and open water operations inorder to efficiently fulfill all the operationalrequirements set by the United StatesCoast Guard."In addition to giving an accurateperformance prediction, our in-housemodel testing facility gives the benefit ofevaluating different hull form andpropulsion concepts before making anyfinal decisions," says Romu.

The ice strengthening in the hull needsto be sufficient to withstand collision with

Aker Arctic provided extensiveconceptual development and designsupport, including hull form developmentand propulsion line engineering for themedium icebreaker USCGC Healy.

The highly advanced polar researchicebreaker for China is soon ready forconstruction. Its main tasks will beresearch operations in the Antarctic.Aker Arctic provided the concept andbasic design of the vessel.

Taymyr and Vaygach are the onlynuclear-powered icebreakers builtoutside the Soviet Union or Russia. AkerArctic employees were involved in thedevelopment of these highly capableshallow-draft icebreakers.

Aker Arctic was part of the design teamfor the new icebreaker for theCanadian Coast Guard, CCGS John G.Diefenbaker. We developed the hullform and performed the model tests forthis advanced polar icebreaker.

9

September 2016Arctic Passion News No 12

thick ice floes at high speeds withoutrisking structural damage. For thisreason, cold-resistant high-strength steelwill be extensively used in the ice belt.On deck, all exposed equipment must bewinterized against cold ambienttemperatures. The crew should also beprotected from sea spray and icing.

Other features include accommodationfor a crew of 100-150 as well as 50additional personnel such as scientists, ahelicopter hangar for two helicopters,and large onboard stores. Therequirement is that the polar icebreakerhas to be able to sail 21,500 nauticalmiles at a speed of 12 knots in openwater. In addition, it has to be able tomanage up to three months withoutrefueling or stocking up on supplies.

Tailor made for the best resultWhile there are many icebreakingvessels and icebreaker designs on themarket, they are all designed withspecific missions, operating areas andice conditions in mind. The best endresult is always achieved when a vesselis designed for its intended use.

According to Romu, trying to modify anexisting design for this project does notmake sense. “The result would likely bea compromise where the designer triesto balance between keeping featuresfrom the parent vessel in order to savetime and making small modifications toadapt the vessel to a new role.Regardless of the end result, most of theclassification and production designwould have to be re-made, so neithermoney nor time would be saved at theend.”

"For us, being specialized in designingicebreakers, the time required to designa new icebreaking vessel concept ismeasured in months, not years. In thetotal acquisition process, which lastsmany years, this is no time at all. Thecost of a new concept design is also afraction of the total investment and theend result is a tailor made vessel thatfully meets all requirements and isperfect for its intended use."

"To acquire a new icebreaker is a hugeinvestment both in terms of money andtime: it is not worth a compromise,"Romu adds.

Time frame for icebreakerAcquisition processes can takeeverything from two to ten years. It alldepends on the efficiency of the processand the ability to make decisions. TheUnited States Coast Guard hasaccelerated its timetable for therecapitalization of the icebreaker fleetunder President Barack Obama, andaims to begin production activities in2020. This is two years earlier than whatwas initially proposed.

CCG

photo: / P A SUnited States Coast Guard ublic ffairs pecialist 2nd Class NyxoLyno Cangemi

10

Photo

: Sovco

mflo

t OA

O

September 2016Arctic Passion News No 12

“This kind of the timetable is clearlyachievable, for example The PC 3/Arc7iceclass arctic module carriers took 28months from start of concept design todelivery of the first vessel, even thoughthere was no preceding design and theChinese shipyard had never builticebreaking vessels before," says Romu.

"Working with us makes the processvery straightforward as this is oureveryday work. We know what needs tobe done and in which order," Romuunderlines.

Two previous joint projectsAker Arctic and its predecessors havehad a strong involvement in the previousUSCG icebreaker projects."We provided extensive conceptualdevelopment and design support,including hull form development andpropulsion line engineering for themedium icebreaker USCGC ," saysHealyManaging Director Reko-Antti Suojanen.

"We also developed the vessel conceptfor the Great Lakes icebreaker USCGCMackinaw in cooperation with the USCoast Guard. It is one of the first vesselsusing the "double acting" ship principle,

we have developed and the poddedpropulsion system, invented in Finland.In both projects, model testing was usedin the concept evaluations and to supportthe final work as well."

Aker Arctic has a long historyof successful icebreakerdesigns, including the mostadvanced and innovativeicebreakers designed withinthe past few years.

Support for shipyardsAker Arctic always works in closecooperation with its customers, in orderto make sure that the final vessel meetsthe customers' wishes and demands.Another close cooperation partner is theshipyard that will build the vessel.

"There are capable shipyards in the USso there is no doubt that, with assistancein specific matters related to operationsin ice and cold environment, they couldconstruct a heavy polar icebreaker,"Romu says. "This is where ourconstruction-time support for shipyardscomes in handy. We are, for instance,

currently assisting the French shipyardPiriou, which is constructing the newFrench polar supply vessel, in ice relatedmatters. We also supported Guangzhoushipyard in China during the constructionof the arctic module carriers, delivered atthe beginning of this year."

Successful icebreakersAker Arctic has designed one successfulicebreaker class after another and hasalso gained valuable feedback from theoperators as well as trials over the pastfew decades."We know what is needed for efficienticebreaking and especially what isneeded in extreme conditions. In full-scale ice trials, our icebreakinginnovations continue to outperform otherdesigns," Romu highlights.

"Based on this we know that we candesign a polar icebreaker, which meetsall the USCG requirements withoutbecoming the most expensive icebreakerin the world. A compact vessel, which iseconomical to build, use, and maintainhas many benefits."

Severe winters at the Great Lakes stops vesselsThe past winters in the GreatLakes area in North Americahave been exceptionally hard.Local industries have reportedhuge financial losses aftercargo ships became frozen inthe ice and commercialshipping all but stopped duringthe winter months. Thequestion has now been raisedof investing in a newicebreaker in order to avoidsimilar situations in the future.

Among other smaller icebreakers andtug boats assisting commercial vesselsin the Great Lakes, there is USCGCMackinaw, which Aker Arctic designed incooperation with the US Coast Guard in2005. is based on the doubleMackinawacting ship principle, sailing bow first inopen water and stern first in heavy ice.Its twin Azipod concept and design werecreated jointly by USCG, Kvaerner MasaMarine and Aker Arctic.

The oblique icebreaker is able toproceed sideways in ice and create awide channel for tankers or commercialvessels. The first vessel built, , isBaltikacurrently working in 1.5 meter thick ice inthe Gulf of Ob. She surpassed allexpectations in full-scale tests in 2015.

Aker Arctic developed the concept for the Great Lakes icebreaker, USCGCMackinaw, together with the United States Coast Guard.

11

The port icebreaker Aker ARC 124 willassist large LNG carriers inapproaching and berthing in Sabetta.

September 2016Arctic Passion News No 12

Meet Tuomas RomuTuomas Romu started his career at Aker Arctic in 2011.Before joining the company as a full-time naval architect, he

studied shipbuilding at Aalto University in Finland and arctic

technology at the University Centre in Svalbard in Norway.

Tuomas has worked as the project engineer in two recent

icebreaker projects, Aker ARC 130 A and Aker ARC 124. In

addition, he participated in the full-scale ice trials of the oblique

icebreaker last year.BaltikaWhen he is not designing icebreakers or travelling in the High

Arctic, Tuomas enjoys relaxing at his family's summer cabin.

He is also a voluntary SAR boat crewman in the Finnish

Lifeboat Institution.

“The new Great Lakes icebreaker wouldhave to be capable of assisting even thebiggest lake freighters or 'lakers', butunlike them, be compact enough not tobe confined to inland waters,” saysTuomas Romu. “Having participated inthe recent full scale ice trials and seenwhat such a vessel is capable of, Ibelieve the best solution for the GreatLakes would be our oblique icebreakerconcept. It could break a wide channel inthe Great Lakes during the wintermonths and then leave for other tasksthrough the St. Lawrence Seaway. Theicebreaker could also utilize some of thetechnologies featured in the new Finnishicebreaker .”Polaris

The first LNG-poweredicebreaker ever built wascompleted in August 2016 inFinland. features allPolaristhe latest technologyavailable for icebreakers.

Hybrid DAS propulsion adds cost efficiencyOne of the latest icebreakingtechnologies in Aker Arctic’s portfolio isthe Hybrid DAS, which combines thesuperiority of the azimuth thrusterpropulsion in ice conditions with the costefficiency of a conventional shaftline inlong open water transits. This is one ofthe propulsion system alternativesproposed for the new United StatesCoast Guard heavy icebreaker.

"The design with a powerful shaftpropeller at the centerline and twoazimuth thrusters on the sides addsbenefits in varying situations," says TomMattsson, senior specialist in ice

performance at Aker Arctic.“In ridges and difficult ice conditions, thevessel can move stern first and use thethrusters for maximum effect. In longopen water transits, the shaftlinepropeller is used for cost efficiency."

Maneuverability in ice will be muchbetter with this solution compared to aconventional icebreaker.

Additionally, the power balancebetween the thrusters and centerpropeller can be varied to maximize theefficiency in different operationalsituations.

Arctech Helsinki Shipyard

Arctech Helsinki Shipyard

12

The bronze propeller for ice has beendeveloped in cooperation with TEVO Oyand the Technical Research Center ofFinland, VTT Oy. Although not as stronga material as stainless steel, bronze hassome benefits compared to a stainlesssteel propeller: better corrosionresistance, easier to manufacture andmaintain, not to mention cheaper. Bronzeis a widely used marine propellermaterial in open water and TEVO Oywanted to find out if it would be feasibleto use also in ice .-going vessels

Bronze propeller test on LouhiThe bronze propeller was fitted on theFinnish Navy's multipurpose vesselLouhi. She is designed specially as an oiland chemical spill response vessel andis owned by the Finnish EnvironmentInstitute (SYKE), but manned by the

Finnish Navy. is equipped with twoLouhiazimuthing thrusters with stainless steelpropellers, but for this test one propellerwas changed to the bronze propeller.

bothThe tests were performed inahead and astern direction in 60 and 85cm thick level ice, 6 m thick ice ridges,and ice channels.

"The conditions for extreme iceconditions were excellent," says KariLaukia, head for ship design andengineering. "We wanted to test thepropellers in as heavy conditions aspossible and succeeded in findingdifferent suitable for it."conditions

"In addition to strength measurements,we also took underwater videos in orderto see how the ice and propellerinteraction took place. After the testing,Louhi returned back to drydock and the

test propeller was remounted and sent toTEVO for inspection."

The conclusions based on the testresults are that the bronze propeller canbe suitable for vessels in 1A Super iceconditions. The testing conditions gavereliable results and input for the propellerdesign for 1A and 1A Super classicevessels.

FNS was built by Uki WorkboatLouhiLtd. in 2011. She is a multi-purposeresponse vessel designed to operate inall Baltic Sea ice conditions and fittedwith extensive mechanical oil spillresponse outfit, including equipmentdesigned specifically for collecting spilledoil in ice conditions.

Full-scale ice trials withbronze propellerIn March 2016, two full-scaleice trials were performed in theBay of Bothnia between Ouluand Kemi, where iceconditions are extremely hardduring cold winters. The firsttrial was to perform ice trialsfor the Finnish Border Guard'soffshore patrol vessel Turva.The second trial was to testthe newly developed bronzepropeller in heavy ice.

Technical details:Displacement 3,450 ton

Length 71.4 metres

Beam 14.5 metres

4 x Wärtsilä 9L20 diesel engines

2 x 2.7 MW Rolls-Royce Z-drive thrusters

FNS Louhi was fitted with the bronzepropeller. The level ice tests wereperformed in 60 to 85 cm thick level ice,both ahead and astern operation modewas used.

Only one quarter of the ice ridgeis visible on the surface andthree quarters of it is below thesurface If the visible ice ridge.measures two metres, thismeans that there are six metresof ice under water.

September 2016Arctic Passion News No 12

13

September 2016Arctic Passion News No 12

Technical details:Length 95.9 m

Beam 17.4 m

Draught 5.0 m

Wärtsilä 12V34DF dual fuel engine

2 x Wärtsilä 6L34DF dual fuelgenerating sets

2 x Rolls-Royce Azipull Z-drive thrusters

Controllable pitch propeller at centerline

The trials focused on testing basicperformance in ice to ensure that targetsare fulfilled. She was tested ahead andastern in level ice 60 to 85 centimetresthick, ahead and astern in ice ridges 6 to8 metres thick, in ice channels as well asin manoeuvring tests. According to thetests, the vessel fulfils all requirements.

Dual-fuel in ice"It was especially interesting to followhow the duel-fuelled machineryperformed in ice conditions," says KariLaukia. "We now have seen theoperation in heavy ice, which can beused for further developing thecombination of marine diesel and LNG-fuel."

Aker Arctic was involved in the conceptdevelopment of the vessel and alsoperformed the ice model tests. She wasbuilt by STX Rauma Shipyard anddelivered in 2014 to the Finnish BorderGuard. is mainly intended forTurvaborder control, but is also a highlycapable multipurpose vessel fitted withmechanical oil recovery systems. Shehas an extensive command and control

outfit including the Cassidian TRS-3Dradar and a helideck capable of receivingand refuelling Super Puma helicoptersboth on deck and while hovering.Despite having a bulbous bow, canTurvaalso operate in ice-covered waters.

You can watch the tests on theAker Arctic YouTube channel(www. )youtube.com/akerarctic

LNG-powered in full-Turvascale ice trialsOPV , owned by theTurvaFinnish Border Guard, is oneof the world's first LNG-powered offshore patrolvessels. The official full-scaleice trials were carried out inthe Bay of Bothnia in March2016.

The ice cores were collectedduring the day and then testedon Turva's aft deck.

14

”Our cooperation with Aalto Universitytakes place on many levels," says TopiLeiviskä, head of research and testingservices at Aker Arctic.

"Basic research on ice behaviour is animportant area for both of us, thereforewe want to be involved and support theresearch as much as we can. Weregularly employ graduates for thesisprojects and many of them havecontinued to work at Aker Arctic aftergraduation. We also offer part-time workfor students at our ice model testinglaboratory."

Unique squared basinAalto University in Otaniemi has its ownice model testing facility, which hasrecently been undergoing renovation andshould be ready for use by the end of2016. The basin is square in shape andmeasures forty times forty metres, beingthe only one in the world of this size.

"The university focuses on researchprojects. We can now rent their basin forcommercial projects, where the squareshape is beneficial, as there is plenty ofspace on all sides," Leiviskä says.

It is excellent, for instance, for turningtests, operational tests and manoeuvringtests as well as for tests related tooffshore and ice management such asice movement and ice flowing direction.

"Before the renovation began, we built,for instance, an island in the basin inorder to see how ice piles up against theshore," Leiviskä adds.

Current research projectsAker Arctic supports research projects atAalto University through various Tekes(the Finnish Funding Agency forinnovation) -funded joint projects.

Read Assistant Professor ArttuPolojärvi's description of two importantresearch projects, ICESCALE andARAJÄÄ, on the next page.

September 2016Arctic Passion News No 12

Top class ice researchat Aalto UniversityAker Arctic and Aalto University have a long history ofcooperation, not least because many of Aker Arctic'semployees have graduated as Naval Architects from theUniversity. Arctic marine and ice technology research is strongat Aalto and through various Tekes (the Finnish FundingAgency for innovation) -funded joint projects Aker Arctic helpssupporting the research.

A research seminar was held at Aker Arctic in March 2016, where professors and researchersfrom Aalto University gave presentations on on-going ice research activities.The topics were:� Overview on research on ship-ice interaction (Pentti Kujala)� Stochasticity in full-scale ice load measurements of a ship's hull (Mikko Suominen)� Risk management of Baltic winter navigation systems (Osiris Valdez)� Ice load dependency on the conditions the ship is in (Mikko Kotilainen)� Numerical modelling of model ice failure (Rudiger von Bock und Polach)� Risk analysis of ice management (Risto Haimelin)� Overview on research on ice-structure interaction in Aalto (Jukka Tuhkuri/Arttu Polojärvi)� Statistics of peak loads in the ice-structure interaction process (Janne Ranta)� Ice-structure interaction in shallow water (Sonja Schneider)

Ice research seminar

The Aalto Ice Tank is under renovationand will be upgraded significantly forfuture research.

The Aalto Ice Tank is a multipurposebasin, which is mainly used for ice modelscale tests, but can also be employed fortests in open water. The tank is 40 mwide and 40 m long with a depth of2.8 m. The facility has a rail-boundbridge (orange, see photo) andunderneath the towing carriage (blue).

A 40 m wide segmented wedge typewave maker, which can generate bothregular and irregular waves, is installedon one side of the basin.

Photo: Aalto University

15

September 2016Arctic Passion News No 12

Numerical modelling of the ice-structure interaction process in shallow water. Theseare performed in ARAJÄÄ together with model scale experiments on the same topic.

Comprehensive understanding of Arcticmarine technology is of crucialimportance as operations in the northernseas keep on increasing. Finland as anArctic country and Finnish Arctictechnology companies are activelyparticipating in these operations. Thesafety and efficiency of the offshorestructures in the Arctic environment is atopic commonly discussed within theArctic technology community and even inthe public media. The ice loads are amajor factor on the safety of thesestructures, yet predicting these loadsaccurately remains challenging.

ICESCALEIt is well known that the ice loads onstructures are related to the failure andfracture of sea ice, but the detailedphysics of the fracture processes are notwell understood. This makes the fractureof sea ice an important research area.We know that the results from thefracture experiments on sea ice dependon scale: small sea ice samples appearto be stronger than large ones. TheICESCALE-project studies the fracture offresh water ice and model ice byconducting unique fracture experimentsin the Aalto Ice Tank. The work alsoincludes modelling efforts.

To ensure the success of ourexperiments, Aalto University has invitedProfessor John Dempsey as a FiDiPro-professor between 2015 and 2018 towork on ICESCALE. He is very wellknown for his research on the fractureand constitutive behaviour of sea ice.Professor Dempsey has exceptionallyvast experience in high qualityexperimentation on sea ice. Forexample, he has been the leadinvestigator on six field projects in theArctic and five in the Antarctic,conducting in-situ cyclic, creep-recovery,fracture and tension experiments onfloating freshwater and sea ice.

ARAJÄÄProject ARAJÄÄ concentrates on avariety of topics closely related to designof Arctic offshore structures. The work isbased on both numerical modelling andmodel scale experiments. The goals ofthe project are closely related to fractureof ice similarly to ICESCALE. On ageneral scale, ARAJÄÄ wants toimprove the reliability and applicability ofmodel scale tests. This should lead tomore efficient and streamlined designprocesses for Arctic offshore structures.The work requires interaction betweenthe Arctic Technology industry andresearchers, and ARAJÄÄ increases thisinteraction through informal meetingsdiscussing central topics in icemechanics.

In addition, ARAJÄÄ studies ice loads onshallow water structure using numericalmodelling and model scale experiments.This work aims to improve understandingof the fundamental mechanisms behindice behaviour and the causes for iceloads. Numerical modelling helps us toobtain detailed knowledge of theproblem, while the model scaleexperiments give reliable data forvalidation. We also look into icemanagement related model scale testswith an aim to understand how toincrease the efficiency of icemanagement operations. We also aim togain understanding for theimplementation of an ice load portal,which, once in operation, could be usedeffectively in designs of offshore windturbines for ice-covered seas.

Ice research cooperation projects

Arttu Polojärvi is the Assistant Professorin Ice Mechanics at Aalto UniversitySchool of Engineering, Department ofMechanical Engineering.Photo: Johanna Ketola

16

Safeguardingwinter navigationon the Baltic SeaThere are around two thousand vessels in the Baltic Seaarea at any given time, carrying 750,000,000 tonnes of cargoevery year. During wintertime, large parts of the sea surfaceare covered by ice. A two-year EU-funded project calledWINMOS was set in place in 2014 to develop maritime winternavigation and safeguard the future needs of icebreakingresources in the Baltic Sea.

Meet Ilkka SaistoIlkka joined Aker Arctic in 2014 and is a specialist inhydrodynamics. Open water characteristics are animportant feature in icebreakers and Ilkka isinvolved in most design projects within his area ofspecialisation. He worked previously at VTTTechnical Research Centre of Finland in shiphydrodynamic research and arctic research.Ilkka enjoys ships and hydrodynamics also in hisfree time. He has spent his summer vacations onthe same sailing boat since he was a child.Nowadays his wife and two teenage daughtersaccompany him.

The objectives of the project were toensure sustainable efficient maritimetransports round the year and mitigatethe barrier effect caused by sea ice by:� Foreseeing possible changes in the

future and analysing the impact onthe winter navigation system and therequirements for icebreaking capacity.� Working out proposals for different

concepts and designs of icebreakersand composition of the icebreakerfleet that meet industrial andenvironmental demands on maritimetransport.� Reducing emissions from

existing icebreakers.� Modernising the existing Finnish-

Swedish Icebreaking ManagementSystem, IBNet, and improving theaccessibility to the information for allrelevant stakeholders within maritimeshipping.� Developing training methods for

navigation in sea ice.� Ensuring sufficient icebreaking

resources.

The long-term vision is a joint Baltic SeaIcebreaking Service where the EuropeanUnion and Russia cooperate within ajoint winter navigation system.

Aker Arctic's roleThere were a total of seven activities inthe project, of which Aker Arcticparticipated in three.

1. Future demand in icebreakingThe predicted impact on the present andfuture merchant fleet's independent icegoing capacity was estimated, especiallywith reference to new regulationsconcerning sulphur emissions and theEnergy Efficiency Design Index, EEDI.Based on findings from the studies, aholistic simulation model of the winternavigation system performance wasworked out. The result of this Activity isof utmost importance for decisionsconcerning the icebreaking strategy forthe period 2020-2030."As EEDI limits the engine sizes of futurevessels, these will need more assistancein ice than previously," says Ilkka Saisto,

hydrodynamics specialist and Aker Arcticcoordinator for the WINMOS-project."This increased demand needs to beplanned for."

2. Next generation icebreakersThe objective was to assess the optimalcomposition of the Baltic Seaicebreaking fleet. A study on the requiredperformance (size, design and enginepower) of icebreakers for different areasin the Baltic Sea was performed.Available icebreaker concepts fordifferent icebreaker categories in theBaltic Sea system were assessed. Theselection of concepts for furtherevaluation was based on the results ofthe study together with findings of knownperformance factors of existingicebreakers and the results fromActivity 1.

"The icebreaking Trimaran concept, theOblique icebreaker, the new Finnishicebreaker and an add-onPolarisicebreaking bow developed by ILS werecompared to URHO/ATLE classicebreakers," Saisto explains.

A study on fuelling possibilities forselected icebreaker types wasperformed. The study covered the effectof alternative fuels on bunker capacity,as well as their environmental impact,lifetime costs and operational propulsionefficiency. The pros and cons of variouspropulsion types were also considered inthis study. Based on results from thestudy, the relative overall efficiency fordifferent selected icebreaker conceptswas performed.

Existing model-basin-data (test result inartificial ice) and models was utilised.During the project time, adjustments onpower and size of the models werecarried out in order to assess theirsuitability for operations in intendedareas.Studies on commercial and legal aspectsand experiences of different ownership,chartering and operating arrangementspros and cons were performed. Thestudy covered several aspects of variousarrangements including long-term totalcosts, risks, control functions andliabilities.

A plan was developed on nextgeneration icebreaker, which will supportdecisions for new buildings during 2020-2030.

5. The human element andtraining facilities

Well-trained officers on board ships willreduce the risk of accidents and maintaina high ice navigation performance. Theobjective of Activity 5 was to facilitatewinter navigation training for shipofficers. Simulator facilities and asimulator training programme for shipofficers were developed. The programmewill be adapted to winter navigationconditions in the Baltic Sea.

Relevant skills and their componentsfor ship officers operating vessels in iceconditions was assessed and defined. ABaltic Sea standard simulator trainingprogram related to these skills waselaborated. Specific criteria for simulatorfacilities and individual ship model qualitywere defined. Specific shortcomings inpresent simulators and their modellingand presentation technologies wereevaluated and listed.The most critical simulationshortcomings for ice-training simulatorswere selected for development andimprovement in co-operation withsimulator manufacturers.

The WINMOS partnership involvedpublic, private and academic entitiesfrom Finland, Sweden and Estonia. Theproject was appointed as a flagshipaction within the European UnionStrategy for the Baltic Sea Region. Themain coordinator from Finland was TheFinnish Transport Agency. Ilkka Saistocoordinated the project work on behalf ofAker Arctic Technology Inc.

September 2016Arctic Passion News No 12

17

September 2016Arctic Passion News No 12

Icebreakers and ice managementvessels are required to have efficienticebreaking and ice clearing capabilities.Their normal tasks are to clear ice frompiers, clear and enlarge ice channelsand clear ice ridges, etc. so that othervessels can move and berth withoutproblems.

In a typical arrangement of azimuthingpulling type thrusters, the propellers arelocated very close to each other whenthey are turned inwards for the flushingoperation. The amount of water theyneed in order to create the maximumflushing effect might be limited, whichcauses them to cavitate, vibrate andcreate noise. The flushing operation istherefore not very efficient if thethrusters cannot be used with full poweror they have large forbidden sectors.

"We have now invented a solution tothis," Project Manager Riku Kiilihighlights. "By changing the sterndesign to an asymmetrical form, thethrusters can be installed lengthwiseaway from each other. There is morespace in between the pods and whenturning them sideways for ice flushing,they get enough water and can blow theice away using full power."

Model testing resultsAn extensive model testing series wascarried out, lasting totally about tendays. Two different designs of the sternwere manufactured and both of themwere tested with the same tests:

- level icebreaking capability in twodifferent thicknesses

- breaking out from an ice channel sternfirst, both directions

- breaking through an ice ridge- clearing capability of brash ice

The model used to compare the testresults was one of the icebreakingsupply and stand-by vessels we havedesigned.

The results from the tests showed thatthe level ice breaking capability and thebreaking out from an ice channelremained, but brash ice and ridgeclearing capability was improved withthe new design.

Many benefits for icemanagement vesselsRegarding the open watercharacteristics of the new stern design,excellent manoeuvrability will remainand directional stability will not be aproblem. Movements in waves will beslightly asymmetrical and slamming stillneeds to be studied, but the new sternform can be designed also to manageand break waves more efficiently astern.

In addition to ice managementadvantages and improved flushingcapabilities, this design showedimproved DP potential in somesituations. There are smaller limitedsectors for propulsors and full thrust withboth propulsors can be directedsideways in the same direction.

The asymmetrical icebreaking processis similar to the icebreaking Trimaran,where ice is broken and bentdownwards in phases. Theasymmetrical shape can be designed toallow small oblique icebreaking anglesfor the vessel, similar to the obliqueicebreaker .Baltika

The asymmetrical stern will haveimpacts on the ship size compared to atraditional design. At the samedeadweight, the ship length increases,meaning more cargo deck. The cargodeck can be designed to be symmetricalor asymmetrical. On the other hand, ifthe length of the vessel is kept thesame, the deadweight decreases. If thesize of the propulsion units determinesthe breadth of the vessel, with thisdesign the vessel can be narrower, withthe benefit of smaller ice resistance. Allchoices, detailed design and shape ofthe stern depend on the intended use ofthe vessel.

"The benefits of an asymmetrical sternfor icebreaking ice management vesselsare obvious," says Kiili. "Especially forharbour icebreakers, supply vessels oreven drillships that need to manageindependently in ice."

"Because the propulsion units are notpositioned side by side, there is alsoless risk that a piece of ice will getjammed between the propellers."

New asymmetrical sternimproves ice management

Aker Arctic has developed a new stern design speciallyintended for ice management vessels. Among many otherbenefits, the design will improve the flushing effect of thepropulsion units compared to a traditional propulsionarrangement. The flushing effect of water flow is typically usedin ice management operations to clear ice away to achieveopen water areas.

18

September 2016Arctic Passion News No 12

Oil platform winterisation check

Ilkka Rantanen and Sami Saarinen visitedLukoil's new Filanovsky oil platform in theCaspian Sea in July 2016 and performed an oilplatform winterisation check.

This winterisation check included evaluation of ice

resistance, evaluation of the ability to function in extreme

cold weather as well as an environmental and oil spill check.

Based on the results, we can make recommendations on

how to improve certain aspects," Ilkka Rantanen explains.

"All major things are in good order, but winterisation can

always be improved in terms of safety. For instance, how to

keep walkways and helideck ice free at all times, installation

of heating systems for evacuation routes or wind protection

for walkways to mention but a few.”

The Caspian Sea is a challenging area, especially due to

its shallow waters. The area around the Filanovsky platform

is about 6.5 m deep, but in other areas the water depth can

be as little as 3 m. An additional challenge is that the level

varies throughout the year. The air temperature can range

from -30 degrees Celsius to +35 degrees Celsius.

"Only about ten per cent of the year is extremely cold, but

when this occurs with strong, freezing winds, the ice piles up

against the structures," Rantanen adds. "This ice is often a

brash type of ice, which is difficult to remove and also does

not support walking on. Therefore, it is essential to plan the

ability for machines and people to function during this time,

how to service the platform and how to evacuate in case of

an accident."

The Vladimir Filanovsky oil field is one of the largest oil

fields discovered in Russia in the past 25 years. It is located

in the northern part of the Caspian Sea. Lukoil's Filanovsky

platform is expected to begin production this year.

Aker Arctic has earlier experience from Caspian Sea

operations. Among other projects, we designed the five

Mangustay shallow draught icebreaking tugs for Caspian

Offshore Construction in 2009. These tugs have an

exceptional draught of only 2.5 m.

Winter is a challenging time in the Caspian Sea withfreezing temperatures and strong winds.In1998, Aker Arctic designed and Kvaerner Masa- Yardsbuilt two icebreaking supply vessels for WagenborgKazakhstan B.V.

Aker Arctic designed five shallow draught icebreaking tugsfor Caspian Offshore Construction in 2009.

ZP

MC

-Red B

ox E

nerg

y Service

s

September 2016Arctic Passion News No 12

United States CoastGuard visits Aker ArcticV of theice CommandantUnited States Coast Guard,Admiral Charles Michelvisited Aker Arctic with hisdelegation in March 2016.The purpose of his visit toFinland was to learn aboutthe Finnish Border Guard's

Arctic operations and otherFinnish Arctic stakeholders.The visit was hosted by theFinnish Border Guard andsupported by other FinnishArctic stakeholders andpartners.

Aker Arctic receivesMaritime achievement awardAker Arctic Technologyreceived the Finnish MaritimeSociety's MaritimeAchievement - HonoraryAward in April 2016, for itswork in keeping icebreakingknowhow on a high level andfor continuously developingnew innovative technologicalsolutions for the globalmarket.

The Finnish MaritimeSociety works for the benefitof the Finnish maritimeculture and promotesactivities related to the sea.The Maritime Society haslong concentrated its activitieson the Finnish sea cluster, thecompanies and associations

operating in the maritimesectors.

Since 1986, The FinnishMaritime Society has grantedits ”Maritime Achievement-Honorary Award” asrecognition of majorachievements for increasingknowledge and appreciationof maritime culture. Thisrespected award has so farbeen granted seven times.

As a marine cooperationforum, the Society enhancesthe importance of shippingand other marine operationsto our country, and its target isto increase the interest in andknowledge and appreciationof the maritime sectors.

State-of-the-art Port ice-breaker ready for construction

Basic design includingclassification documentationfor the most advanced porticebreaker in the world, AkerARC 124, is almostcompleted. The vessel will beused to support LNG-carriers'operability in Sabetta harbourin the Russian Arctic.

Construction will soonbegin at Vyborg ShipyardPJSC. The vessel, ordered byFSUE Atomflot, is planned tobe ready in 2018.

The state-of-the-arttechnical for thisfeatures

vessel include a four thrusterpropulsion solution, two in thestern and two in the bow,which will takemanoeuvrability to a newlevel. It will also be competentin thick brash ice in Sabettaharbour. Further technicaldetails is a completely newOnboard DC Grid, developedby ABB, and Wärtsilä's new31 series main engines,recently acknowledged as theworld's most efficient four-stroke engine type.

Gas condensatetanker designsoon readyAker Arctic is designing an Arcticcondensate tanker, which will be usedto transport gas condensate from theLNG-plant under construction on thecoast of the Ob Bay, Yamal peninsula.Gas condensate is a valuable by-product, which is separated from thenatural gas before its liquefactionprocess.

"The basic design of the tanker is inits final stages," says Project ManagerRiku Kiili. “GSI Shipyard continues thedetail and production design. Steelcutting and production in Guangzhou isplanned to begin at the end of 2016."

The hull of a vessel needs aprotective coating to preventcorrosion and to minimisefriction. New improved paintsare regularly entering themarket and Aker Arcticcontinues to test their durabilityand friction protection.

“About 20-30% of a vessel'sresistance in ice comes fromfriction between the hull andthe ice. The smoother the hull,the less friction there is, this isevident. Reducing frictionsaves money and isecologically important as fuelconsumption is highly relatedto friction," says StructuralEngineer Ville Valtonen.

Paint testingcontinues

Arctic module carriers busy at workThe two Aker Arctic designed PC 3/ARC7 Arctic Module Carriers, andAudaxPugnax, are now busy transportingconstruction modules to the arctic LNGplant being built in Sabetta.

The two carriers were delivered at thebeginning of 2016. The developmentwork was carried out in closecooperation with the owners, ZPMC-Red

Box Energy Services, and the vesselswere constructed at GuangzhouShipyard International in China.

We additionally took responsibility fordesigning and delivering the specialpropellers suitable for extremelydemanding use in heavy ice conditionsfor the two carriers.

Mr Mikko NiinipresentedMr Reko-AnttiSuojanen with theFinnish MaritimeSociety's HonoraryAward in April2016.

20

Aker Arctic Technology Inc’s newsletterISSN 2342-7965, ISSN 2342-7973Publisher: Aker Arctic Technology IncMerenkulkijankatu 600980 Helsinki, FinlandTel. +358 10 323 6300Fax +358 10 323 [email protected]

ditor in chiefE Reko-Antti Suojanen:Texts by CS Communications Oy:

ay-out Kari SelonenL :rinted in byP September 2016 Grano

Meet us here!

We will participate in the following events:

FastScoop was a newgame for many of us.

September 2016Arctic Passion News No 12

SMM Hamburg6 - 9 Sept 2016

Arctic Shipping Forum North America, Montreal4 - 6 Oct 2016

ATC 2016, St. Johns24 - 26 October 2016

The 11th Arctic PassionSeminar was held at AkerArctic on 3 March 2016.Nearly one hundred Arcticspecialists and othershipbuilding, shipping andoffshore professionals fromaround the world gathered inHelsinki, Finland, to discussthe latest developments in theArctic, as well as on-going andupcoming projects, new ice-going vessel concepts andadvances in technology.The opening speech was given by theMinister of Economic Affairs of Finland,Olli Rehn, who talked about the Finnishexperience and perspectives for Arcticdevelopment.

Mr Reko-Antti Suojanen gave anoverview of the current situation withinAker Arctic and the markets. He alsobriefly presented the new Arctic Aframaxvessel design and new developments foroperational services, such as the IceLoad Monitoring System, which will helpship owners in challenging iceoperations.

Mr Mikhail Grigoryev, GECON, gave anupdate on oil and gas developmentprojects in the Russian Arctic in the

current condition of low oil prices andalso talked about how it will influence thedevelopment of Arctic navigation.

rcThe world's first PC 3/A 7 arcticmodule carriers were delivered at thebeginning of this year. Mr Zhou Xuhuifrom Guangzhou Shipyard Internationalpresented the construction project.

Aker Arctic is supporting theconstruction of the new French PolarLogistics Vessel at Piriou Shipyard inFrance. Mr Pierre-Alan Michel, Piriou,and Mr Heikki Sipilä, Aker Arctic, gave apresentation on the vessel and anupdate on progress made in itsconstruction.

In addition to the seminarpresentations, the Arctic PassionSeminar included an ice model test inAker Arctic's ice laboratory. This year, wedemonstrated the operation of adynamically positioned icebreakingoffshore vessel in floe ice using a realDP system adapted to model scale. Thetest was part of an on-going R&D projectbetween Aker Arctic and NavisEngineering with the aim to developimproved DP-capabilities in iceoperations.

After lunch, Mr Evan Martin and MrArno Keinonen from Aker Arctic Canada(AKAC) talked about utilising pastoperational experience to benefit thefuture. Mr Mikhail Belkin, FSUE Atomflot,followed with an interesting speechabout icebreaking assistance to major

national Arctic hydrocarbon projects.ICEYE is quick response radar

imagery from small satellites. Mr TuomasKorpela, Iceye Oy, explained how itworks.

Vyborg Shipyard has recently beenawarded construction of modern,innovative icebreakers designed by AkerArctic, such as the two Aker ARC 130 Aicebreakers and the advanced porticebreaker design Aker ARC 124 for theFSUE Atomflot. Mr Alexander Solovyevtalked about their experiences. MrAndrey Knyazevskiy, Gazprom Neft NovyPort, then explained what the Aker ARC130 A will be used for and how the NovyPort development project is movingforward.

ARDMr Andrew Kendrick, V Marine,held a presentation on how they havebenefited from Aker Arctic's experiencein the design co-operation.

Mr Mika Hovilainen, Aker Arctic,concluded the day with a presentation onthe extraordinary sideways movingicebreaker and the experiencesBaltikafrom the full-scale tests held in 2015 inthe Gulf of Ob, where she surpassed allexpectations and finally he gave histhoughts on the future potential of thisunique vessel concept.

We would like to thank all guestspeakers and participants of thisyear's successful and interestingArctic Passion Seminar!

11th Arctic Passion Seminar

The highlight of this year’s seminar was demonstratingdynamic positioning in ice using a real DP software adapted tomodel scale.

Mr Zhou Xuhui presented the world's firstPC-3/ARC-7 module carriers.

Mr Valtonen, Mr Sipilä and Mr Micheldiscussing the new French Polar LogisticsVessel.