Advanced Planning from Standard MPS/MRP

-

Upload

insync-conference -

Category

Education

-

view

1.390 -

download

4

description

Transcript of Advanced Planning from Standard MPS/MRP

Advanced Planning from Standard MPS/MRP

Darren SwindellsHills Industries Limited

16 August 2010

The most comprehensive Oracle applications & technology content under one roof

The Situation

• JDE (rel. 8.10)being implemented as ERP solution across Hills Group • Orrcon had unique requirement and was next!

• Product manufactured in Cycles at Orrcon

• Budget and time-frame would not allow an off-the-shelf ‘APS’ solution

About Orrcon – Racing Team

• .. Oh, and on the side we make steel pipe & tube as well …

About Orrcon – Tube Mills

• Manufacturers of steel Pipe & Tube Large division of Hills Industries Limited Local manufacturing in Brisbane, Adelaide & Wollongong

About Orrcon – Make in Cycles

• Set-up time is significant– Each change of profile incurs set-up

• To reduce downtime – roll groups of products once every 4 weeks

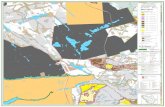

About Orrcon – Changeovers

Full-Changeover

1/4-Changeover

1/2-Changeover

Problem with Standard MPS/MRP

• R3483 (Master Planning Schedule-Multi-Plant)

• Plans Work Orders for Date of Need (& Demand is dated daily)

• Orrcon groups Planned WOs into pre-published Rolling Cycles for each Product Family– Only make each product once per Cycle

The Solution – Create MPS/MRP Cycles – Step 1 (Buyer Number)

• Link each Item Number to a Cycle using the ‘Buyer Number’

• Buyer 201 = Cycle 1

• Buyer 202 = Cycle 2

• Buyer 203 = Cycle 3

• Buyer 204 = Cycle 4

The Solution – Create MPS/MRP Cycles – Step 2 (Cycle B/Ps)

• Create ‘Branch Plants’ for each Cycle

• B/P 241=Cycle 1• B/P 242=Cycle 2• B/P 243=Cycle 3• B/P 244=Cycle 4

The Solution – Create MPS/MRP Cycles – Step 3 (Cycle Calendars)

• Create ‘Shop Floor Calendars’ for each Cycle

• B/P 241=Cycle 1• B/P 242=Cycle 2• B/P 243=Cycle 3• B/P 244=Cycle 4

• ‘W’ Working Day - only in one week from Cycle

The Solution – Create MPS/MRP Cycles – Step 4 (Create MPS Versions)

• Create versions of MPS that are linked with ‘Branch Plant’ Shop-floor Calendars for each Cycle– One version for each Cycle

• Continued …

The Solution – Create MPS/MRP Cycles – Step 4 (Create MPS Versions)

• Data Selections (only select items that belong to the Cycle)• MCU = Cycle SFC

(to get records)• BUYR = Cycle

group from

Item Branch

• Continued …

The Solution – Create MPS/MRP Cycles – Step 4 (Create MPS Versions)

• Processing Options (call Shop-Floor Calendar for Cycle)

• Multi-Facility Tab• 1. Date Branch = Cycle Branch Plant• MPS then uses the Shop Floor Calendar from this Branch

Plant

• This is what makes the Cycles possible!

• Continued …

1. Date Branch

This was actually designed to reduce processing time when Multi-Facility MPS/MRP was generated – however it also achieves Cycle Planning when used for this Work-Around

The Solution – Create MPS/MRP Cycles – Step 5 (Generate MPS)

• Generate MPS (R3483)

• Note: ALL Cycles are generated each week – to create correct projected requirements for components

The Solution – Create MPS/MRP Cycles – Step 6 (Detailed Message Review)

• Planned Order Messages now group so each product is only made once per week in Detailed Message Review

• Note: Request Date

Changes from 30/08/10

to 29/09/10 – jump of

4 weeks

Summary• Work-around: using R3483 ‘Date Branch’ feature designed

to save Processing Time to achieve some ‘APS’ functionality of grouping Item production into correct weekly buckets

• Requires set-up of Branch Plants, Shop-Floor Calendars and one MPS/MRP version for each Cycle

• Can also be used for Manufacturing AND Purchasing

• ACHIEVES OBJECTIVE = one setup for each product family every 4 weeks

Questions?

Tell us what you think…

• http://feedback.insync10.com.au