Solar Street Lighting LED by Adithya Solar Energy Systems Hyderabad

Adithya Cement Corparation of India

-

Upload

adithyan88 -

Category

Documents

-

view

214 -

download

0

Transcript of Adithya Cement Corparation of India

A PROJECT REPORT

ON

“FINANCIAL ACCOUNTING

REAL LIFE STUDY

ON

COST ACCOUNTING”

BY

RATKAL SHIVAKANTH

PGP/FW/09-11/ISBE/1209

1

CEMENT CORPARATION OF INDIA LIMITED

TANDUR CEMENT FACTORY

R.R. DIST. A.P. - 501 158

“Practice makes more perfect”

In the field of management every time there is a requirement of understanding or practical aspect

of the organization with managerial mind. There is requirement to go for practical training of any

subject supplement to the theoretical knowledge and clarified concept.

It is more applicable in the field of the management especially a professional course like M.B.A.

Moreover IIPM Business School, has prescribed two month project report training during the II

Sem. as a part of M.B.A programmers my training at the CEMENT CORPORATION OF INDIA

LIMITED to comply with this requirements also.

The project report includes various aspects like cost audit report , balance sheet ,& cash flow

statement of the company and which provide perfect direction of production made during the

year . The data collections were by annual cost audit report of the company, web related to the

cement association and discussion with concerned employees and experts.

At the end findings and suggestions are reported.

I hope this serves the Purpose.

2

Words are indeed inadequate to convey my deep sense of gratitude to all those who have helped me in

completing this summer project to the best of my ability. Being a part of this project has certainly been a

unique and a very productive experience on my part.

I am really thankful to, Mr. I.C JAIN ACA Sr.Manager (Fin), CCI Ltd, Tandur Cement

Factory for making all kinds of arrangements to carry the project successfully and for guiding and

helping me to solve all kinds of quarries regarding the project work. His systematic way of working and

incomparable guidance has inspired the pace of the project to a great extent.

I would also like to thank my mentor and project – coordinator, Ms. R. Raghunatham,

Officer(Accounts) for assigning me a project of such a great learning experience and acquainting me

with real life project financing and appraisal.

I am very grateful to Mr.Pankaj (Training & Placement Officer) IIPM Business School,

Hyderabad Who has given me the opportunity to do this project in the cement Corporation of India

Ltd. and very thankful to all lecturers of IIPM Business School, Hyderabad for their useful guidance

and advise.

This project would not have been successful without the help of Dr .N.C.G.NAIR Deputy

General Manager (persona & Administration Department) of CCI.

Last but not least I would like to thank all the employees of Cement Corporation of India Ltd.

who have directly or indirectly helped me with their moral support for the completion of my project.

RATKAL SHIVAKANTH

3

CH.

NO.

PARTICULARS PAGE

NO.

1 INTRODUCTION OF CEMENT INDUSTRY 1

Cement industry in India

Sector structure/market size

Key points

7

8

2 INTRODUCTION OF CCI

History & Company profile

Plants of Cement Production

Working units

Product profile

Objectives

Awards & Achievements

9

10

11

3 COST ACCOUNTING:

Objectives

Advantages

Limitations

11

12

4

4 Analasis

COST AUDIT REPORT

Overall financial position

Capacity utilization

Non-cost items & abnormal cost & income

Cost of production

Net sales realization

System of allocation expences

Current year profit

Break even point

Capacity utilization

Non-moving stores &spares

Budget preparation

Default in payment

14

5 ANNEXURE TO THE COST AUDIT REPORT

GENERAL

COST ACCOUNTING SYSTEM

MANUFACTURING PROCESS OF CEMENT

QUANTITATIVE DETAILS

MAJOR INPUT MATERIAL

BREAK-UP OF COST OF INPUT MATERIAL

POWER, FUEL AND UTILITIES

SALIRIES &WAGES

REPAIRS&MAINTENANCE

FIXED ASSETS REGISTER &DEPRECIATION

GROSS BLOCK,DEPRECIATION&LEASE RENT

OVERHEADS

22

5

RESEARCH AND DEVELOPMENT EXP

ROYALITY&TECH KNOW HOW CHARGES

QUALITY CONTROL EXPENCES

POLLUTION CONTROL EXP

ABNORMAL NON-RECURRING COSTS

NON-MOVING STOCK

WRITTEN OFF STOCK

INVENTORY VALUATION

SALES OF PRODUCT UNDER REFERANCE

MARGIN PER UNIT OF OUTPUT

COMPETITIVE MARGIN AGAINST IMPORT

VALUE ADDITION & DISTRIBUTION OF EARNINGS

FINANCIAL POSITION &RATIO ANALYSIS

CAPITALISATION OF REVENU EXPENDITURE

CENTRAL EXCISE RECONCILATION

PROFIT RECONCILATION

BALANCE SHEET FOR THE YEAR 2008-09

BASICS OF ACCOUNTINCOST ACCOUNTING SYSTEM

PRODUCTION FLOW CHART

CASH FLOW STATEMENT

CHARTS

6

1.CEMENT INDUSTRY IN INDIA

Cement is a key infrastructure industry. It has been decontrolled from price and

distribution on 1st March, 1989 and delicensed on 25th July, 1991. However, the performance of

the industry and prices of cement are monitored regularly. The constraints faced by the industry

are reviewed in the Infrastructure Coordination Committee meetings held in the Cabinet

Secretariat under the Chairmanship of Secretary (Coordination). Its performance is also reviewed

by the Cabinet Committee on Infrastructure. Fast rising Government Expenditure on

Infrastructure sector in India has resulted in a higher demand of cement in the country. In the

same direction, participation of larger companies in the sector has increased.

Sector structure/Market size

India is the second largest cement producer in the world after China. The cement industry in

India is dominated by around 20 companies, which account for almost 70% of the total cement

production in India. In the present year, the Indian cement companies have produced 11 MT

cement during April-September 2009. It took the total cement production in FY09 to 231 MT.

With the boost given by the government to various infrastructure projects, road networks and

housing facilities, growth in the cement consumption is anticipated in the coming years.

According to Jyotiraditya Scindia, Minister of State, Ministry of Commerce and Industry,

cement production could rise to 236.16 MT in FY11 and touch 262.61 MT in FY12.

7

With almost total capacity utilization levels in the industry, cement dispatches have maintained a

10 per cent growth rate. Total dispatches grew to 170 MT during 2007–08 as against 155 MT in

2006–07.

Key Points

Supply The demand-supply situation is tightly balanced with the latter being

marginally higher than the former.

Demand Housing sector acts as the principal growth driver for cement. However, in

recent times, industrial and infrastructure sector have also emerged as demand

drivers for cement.

Barriers to

entry

High capital costs and long gestation periods. Access to limestone reserves

(principal raw material for the manufacture of cement) also acts as a significant

entry barrier.

Bargaining

power of

suppliers

Licensing of coal and limestone reserves, supply of power from the state grid

and availability of railways for transport are all controlled by a single entity,

which is the government. However, nowadays producers are relying more on

captive power, but the shortage of coal and volatile fuel prices remain a

concern.

Bargaining

power of

customers

Cement is a commodity business and sales volumes mostly depend upon the

distribution reach of the company. However, things are changing and few

brands have started commanding a premium on account of better quality

perception.

Competition Due to large number of players in the industry and very little brand

differentiation to speak of, the competition is intense with players resorting to

8

expanding reach and achieving pan India presence.

2. CEMENT CORPORATION OF INDIA

CCI or the Cement Corporation of India is a leading manufacturer of cement in India. The high

class products matched with the professional approach of the company makes it one of the

leading business houses in this segment in the country. The CCI Cement Plants make use of the

best facilities and services for the production of high quality brands and products. More and

more firms and organizations across the country are opting for the products of the Cement

Corporation of India.

Cement plants of CCI

The different cement plants of CCI are located in a number of locations across

the country. Presently there are 10 units which produce a total capacity of around 38.48 lakh

tones of cement on a yearly basis. To cater to the different market segments across the country,

the CCI Cement Plants are located in various states from Assam in the east to Karnataka in the

south. There is also a high class grinding unit that is located in the capital city of Delhi. The chart

provided below gives an ideal of the idea of the location of the cement plants of CCI or Cement

Corporation of India.

The high class cement plants of CCI use sophisticated gadgets and other facilities of high

standard which comply with the international standards. The equipments that are used are fully

equipped with environment friendly facilities which make the cement manufacturing process

9

fully free from pollution. The company has also put emphasis on water conversation and

recycling of the waste produced in the cement production process.

Working units

1)Tandur cement corporation of India

2)bokajan cement corporation of India

3)rajban cement corporation of India

Tandur unit was started in 1st july 1987.Its production capacity is in lakh tones. It is one of the

largest of all units. It is high position in profits. It is India’s largest income getting unit

PRODUCT PROFILE OF CCI CEMENT

i. Poorna shakti-33 grade

ii. Maha shakti-43 grade

iii. Param shakti-53 grade

iv. Railway sleeper grade-53s grade

v. Jal shakti - portland pozzolona cement

OBJECTIVES OF CCI:

To emerge resultants as the largest seller of cement in the country and to continue to

perpetuate and improve upon the same position by constant increase in the production

capabilities

10

To emerge as a growing and important leader in the production of cement in the country

by creating additional capacity either by expansion or by improved technology or by

setting up new cement plants.

To achieve a pioneering and leading position in the exploration prospecting and proving

cement grade limestone reserves and deposits to sustain ambitious growth plans of the

corporation in particular and of the cement industry in general

AWARDS OF TANDUR UNIT:

It is given by IBM

1. mine and coal 2nd prize (2007-08)

2. Topsoil water 2nd prize (2007-08)

3 .Air quality management 1st prize (2006-07)

3.COST ACCOUNTING

OBJECTIVES OF COST ACCOUNTING:

The objectives of cost accounting are:

To ascertain and analyze costs: the primary objective of cost accounting is to ascertain and

analyze costs incurred on the production of various products, jobs and services, etc.

To control costs: cost accounting has developed various techniques such as standard costing and

budgetary control for controlling costs.

To fix the selling price: cost accounting provides reliable data on the basis of which selling price

can be fixed.

11

To reduce costs: of late, the objectives of cost accounting have been extended to reducing costs.

Value analysis, time and motion study, standardization, simplification, etc. are important

techniques of cost reduction.

To prepare monthly or quarterly cost statements for periodic review of operating results.

To provide useful information for planning and control and for taking various decisions

regarding increase in production, installation or replacement of machine, the making or buying

of a component, continuing or closing down of business, etc

ADVANTAGES OF COST ACCOUNTING:

The following are the advantages of cost accounting:

Cost accounting is very helpful in controlling expenditure and economizing in the manufacture

of products.

Cost accounting relates various expenses to their functions and provides an effective instrument

for control over such expenses.

Cost accounting provides useful data not only about product costs but also about production

efficiency and performance.

It helps the management to initiate action to rectify delays, inefficiencies and wastage.

Centralization of purchasing is facilitated by the use of cost accounting.

Maintenance of time and jobs records for workers reveals losses incurred due to idle time. Such

records assist in taking steps to minimize these losses.

A cost accounting system provides information about availability of materials, labor, and

machine capacity. In the absence of such information, proper production plans cannot be drawn

up.

Cost accounting entails identifying normal and abnormal losses and gains. This task becomes

simpler when standards are set up.

Cost accounting lays the basis for the system of standard costing and budgetary control. These

two are instrumental in the control of expenditure. Variance analyses and comparison of actual

performance with budgets pinpoint areas where economies can be affected.

12

Cost accounting data are very useful for the management for planning carious activities. A wise

manager takes a decision only after he has carefully studied the cost implications of carious

alternatives.

LIMITATIONS OF COST ACCOUNTING:

In spite of so many advantages, some people feel that cost accounting is an unnecessary

luxury for business establishments. This is not true. Perhaps they feel so because of a few

limitations of cost accounting such as:

Cost accounting is not an exact and foolproof science. Classification of cost into its elements,

pricing of material issues on the basis of average or standard costs, etc., appointment and

allocation of joint costs and overheads to joint/by-products and cost centres, division of

overheads into fixed and variable, division of costs into normal and abnormaln, controllable and

uncontrollable, etc., are based on conventions, estimation and arbitrariness. The information

provided by a cost accountant, therefore, may not be necessarily being absolutely true.

It may be noted that such limitations are also found in any other

system of accounting. Principles and practice of cost accounting are based on sound reasoning

and keen common sense.

4.ANALYSIS

COST AUDIT REPORT

13

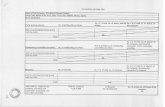

I A. Ramachandra Rao, having been appointed as Cost Auditor under Section 233B of the Companies Act, 1956 (1 of 1956) of M/s. Cement Corporation of India Limited, Tandur Cement Unit having its registered office at Core 5, Scope Complex, 7 Lodhi Road, New Delhi – 110 003, (hereinafter referred to as the company), have examined the books of account prescribed under clause (d) of sub-section (1) of section 209 of the said Act, and other relevant records in respect of the unit Tandur Cement Factory, Karankote, RR Dist – 501 158, A.P, for the financial year 1st April 2008 to 31st March 2009, relating to CEMENT maintained by the company and report, in addition to my comments in para 3 relating to auditor’s observations and suggestions, that-

1. OVERALL FINANCIAL POSITION:

The capacity utilization and profits, ahieved by the Tandur Cement Factory, a Unit of Cement Corporation of India Limited, for the current year and previous two years are as follows:

14

2. CAPACITY UTILISATION:

It can be seen that the capacity utilization has been 61.50% in 2007-08 and it has increased to 68.34% in 2008-09. There is an increase of 6.84% of capacity utilisation during current year compared to previous year. However, after considering the present favourable market condition. the capacit utilisation needs to improve further.

3. NON-COST ITEMS AND ABNORMAL COSTS AND INCOME:

During 2008-09 all the costs and income have been looked into and abnormal costs, non-cost items and other income have been specifically identified and excluded from the costs. The items excluded relate to prior period expenses (Rs. 37.07 lakhs), non cost items (Rs. 163.12 lacs), E/D adjustments (Rs 24.62 lacs), abnormal cost relating to captive power generation (Rs.98.51 lakhs), excess provision written back (Rs.147.63 lakhs), FBT. (Rs.8.80 lakhs), Prior period Income( Rs.19.27 lakhs), ACR/DEC in stocks (Rs.21.70 lakhs), Provision for doubtful debts (Rs 8.15 lakhs) etc. The rest of the expenditures have been taken in costs.

4. COST OF PRODUCTION: (upto packing stage):

The cost of production of cement (upto packing stage) has increased in 2008-09 by Rs.25.91 per MT i.e. from Rs.1553.35 per MT in 2007-08 to Rs.1579.26 per MT in 2008-09. This is due to increase in input costs like Iron ore and Gypsum, packing material cost, cost of coal, Salaries, cost of stores and spares etc.

15

4.1. LIMESTONE & SHALE:

Limestone and shale overburden cost DRE is being absorbed to limestone cost and shale cost on the basis of fixed percentage of quantity raised every year i.e. 10% in case of limestone raised and 20% in case of shale raised. This system need to be reveiwed since huge amount of overburden cost is lying unadjusted in the books of account since long. As on 31.03.2009, the unabsorbed overburden cost still stands at Rs.201.89 lakhs against opening balance of Rs.220.12 lakhs. Presently as the unit is earning profits, it is now the time to review for quick recovery of this expenditure.

4.2. POWER:

1. The power consumption has decreased from 134.98 units in 2007-08 to 129.73 units in 2008-09 i.e. decrease by 5.25 units per MT of cement. There is decrease in the average Power cost from Rs.2.60 per Kwh in 2007-08 to Rs.2.24 per Kwh in 2008-09. There is enough scope to bring down power consumption further. If consumption rate comesdown to 120 units per MT of cement, which is the internal norm, there will be a saving Rs.21.80 per MT of cement and this is a direct substantial saving amounting to Rs.1.49 Crores. Every effort should be made to reduce power consumption at least to achieve internal norm which itself is very high compared to present industrial norm.

2. The total purchased power during 2008-09 is 89636980 units. The transit losess included in the purchased units, which worksout to 2563410 units i.e. 2.86% of the total units purchased. This loss is higher side and efforts may be made to minimise the transit losess.

4.3. CAPTIVE POWER:

There are seven DG sets in the unit includes three HT and four LT as per records. There is no generation of power from DG sets during the year 2008-09 as there is adequate power available from state grid which is of lower cost than DG power generation cost.

16

An investment of Rs.13.66 crores was made in March 1999 in installation of one DG set for Captive Power Generation. But this is not put to regular use due to the reason that the cost of purchase of electricity has been found to be cheaper than the cost of captive power generation. An expenditure of around Rs.93.93 lakhs relating DG cost centre has therefore been treated as abnormal during 2006-07 and taken to reconciliation in Para 28. Similar expenditure amounting to Rs.92.84 lakhs in 2007-08 and Rs.93.93 lakhs in 2006-07 have been shwon as non-cost items. This asset requires review for better utilisation at the time of expansion or during non-availability of power from state grid.

4.4. COAL:

The consumption of coal has been around 232.25 Kg per MT of clinker in 2008-09 as compared to 239.40 Kg in 2007-08 and 224 Kg in 2006-2007. It is informed, that this decrease in coal consumption by 7.15 Kg per MT in current year is due to less stoppages in kiln operation. Measures must be taken to bring down coal consumption while taking care of quality. A norm of 200 Kg coal consumption per MT of clinker is a reasonable figure which should be aimed and achieved.

4.5. STORES AND SPARES:

Stores and space consumption for 2008-09 per MT of cement is Rs 130.98 as against previous year consumption of Rs.131.05.The reason for decrease is due to higher production of cement during current year compared to previous year

4.6. INTEREST CHARGES:

During 2008-09, The unit earned an income of Rs 1506.20lacs and Zonal office Rs 11.90 lacs as interest income on FDR investments. Against this, the interest charge for the unit is Rs 379.34 lacs and Zonal office charge is Rs 221.80 lacs. The net income is Rs 16.98 lacs. This has been

17

considered in Proforma "K" to arrive at th total cost of cment sold. This positio has reduced the cost of cement by Rs 134.12 per MT in 28-09 compared to reduction of Rs 35.16 per MT in 2007-09.

4.7. FACTORY OVERHEADS:

Compared to 2007-08 there has been increase of over heads by 6.12% in 2007-2008 i.e. from Rs.273.59 lakhs in 2007-08 to Rs.176.77 lakhs in 2008-09 (Para - 12A). There is increase in salary & wages under factory overheads compared to previous year.

4.8. ADMINISTRATION OVERHEADS:

During 2008-09 there has been reduction by Rs.96.82 lakhs (ie 35.39%) compared to 2007-08 i.e. Rs.273.59 lakhs in 2007-08 decreased to Rs.176.77 lakhs in 2008-09 (Para 12-B). However there is increase in controlable revenue heads like Salaries & Wages by Rs 41.94 lakhs, increase in advertisement expenses by Rs 7.75 lakhs, increse in stores and spares by Rs 4.30 lacs, increase in repairs by Rs 4.15 lacs, increase in T.A expenses by Rs 3.31 lacs, increase in office expenses by Rs 6.75 lacs and increase in C.O expenses by Rs 58.44 lacs. Management stated that the increase in slaries & wages and C.O expense is due to implementation of 6th pay commision pay to CDA, IDA employees in 2008-09, increase in advertisement is due to increase in advertisement tariffs and increase in office expenses, stores and spares, repairs and T.A expenses is due general increase in price index. However, these areas are to be kept under watch.

4.9. SOCIAL OVERHEADS:

During 2008-09 there has been increase by Rs.18.45 lakhs compared to 2007-08 i.e. Rs.141.94 lakhs in 2007-08 increased to Rs.160.39 lakhs in 2008-09. This increase is mainly due to increase in salaries and medical expeses, repairs , canteen, other welfare expenses, stores & spares and G.H expenses. (Para 12-C).

18

4.10. SELLING OVERHEADS:

During 2008-09 there has been a decrease by Rs.18.45 lakhs compared to 2007-08 i.e. Rs.104.47 lakhs in 2007-08 decreased to Rs.87.99 lakhs in 2008-09 (Para 12-D). This decrease is due to reduction in railway siding expenses in 2008-09.

4.11. DISTRIBUTION OVERHEADS:

During 2008-09 there has been decrease by Rs.198.11 lakhs compared to 2007-08 i.e. Rs.2353.42 lakhs in 2007-08 decreased to Rs.2155.31 lakhs in 2008-09 (Para - 12D). The decrease is mainly due to more rail dispatches in 2008-09 compared to previous year instead of despatches by road.

4.12. ZONAL OFFICE EXPENSES:

The net Zonal office expensesexcluding interest. Provision for doubtful debts and accretion in stocks has been decreased by Rs 55.68 lacs compared to previous year . However, the major head (i.e.) Salaries and wages of Zonal office has increased by Rs 25.11 lacs (i.e) from Rs 121.33 lacs in 2007-08 to 137.44 lacs in 2008-09 due to implementation of 6th pay commision pay for CDA, IDA employees in 2008-09 to Zonal staffs.

5. NET SALES REALISATION:

During 2008-2009, the net sales realisation, excluding excise duty, has increased from Rs. 3116.26 per MT of cement in 2007-2008 to Rs.3252.76 per MT in 2008-09. Thus, the average increase worksout to Rs.136.80 per MT of cement, i.e. 4.38 % increase over 2007-2008. The sales prices have picked-up from January 2006 onwards, which is still contunuing.

6. SYSTEM OF ALLOCATION EXPENSES:

19

The work shop service department cost are distributed on the basis of original value of plant & machinery installed in different cost centers. This system is not correct as the work shop expenses has no relationship with original cost of plant & machinery. In this connection, it is suggested to control this through job costing with due codification of all the jobs executed in the plant. This work can be done in computer with proper program.

7. CURRENT YEAR PROFIT

The current year profit of this unit as on 31st March 2009 has been Rs.9920.46 lakhs resulted in wiping off of cumulative loss and accumulation of Reserves and surplus by 524.61 lacs as per audited financial accounts. In the case of working capital, the net positon is Rs.8.91 Crores as against 2007-08 Rs.(-) 8.73 crores due to investment of surplus funds in FDRs during 2008-09.

8. ACHIEVING 100% CAPACITY UTILISATION:

This is very high time that the unit achieves 100% utilisation in the present market scenerio. In addition, further expension also can be looked into as the current market can absorb any level of production.

From the analysis of Machinery Report, the following is noted.

It is seen that stoppage hours have decreased in all machines and therefore the production as well as sales have gone up in current year compared to previous year. However, improvement to achieve ful utilisation of the plant is required.

In the light of above, the following areas need attention:

(i) Taking care of working capital requirement

(ii) Increase in capacity utilization; by reducing stoppage hours

(iii) Further reduction in power consumption per MT of cement;

(iv) Further reduction in coal consumption per MT of cement;

20

(v) Further reduction in overhead expenditure

9. NON-MOVING STORES & SPARES:

The value of non-moving stock of stores and spares has been Rs.1142.33 lakhs for a period of twenty-four months and above. In the total inventory of stores and spares of Rs.1967.14 lakhs as on 31st March 2009, the value of non-moving stock works out of 58.07%. This needs to be reviewed by the management, and action to be taken for disposal of surplus stores and spares.

12. DEFAULTS IN PAYMENTS:

Regarding defaults in respect of payments due to Govt., Financial Institutions and Banks and penal interest levied thereon;

Reply: In case of Hyderabad Z.O. Sales tax demand for Rs.1570.05 lakhs has been received from Sales Tax Authorities. Appeals against their demands have been filed and stay orders obtained.

(f) steps required to strengthen the company under the competitive environment especially with regard to need for protection from cheaper imports, if any;

(g) export commitments of the company vis-à-vis actual exports for the year under review. Also comment on comparative profitability and pricing policy of the company for domestic and export sales. Give impact of exports benefits / incentives offered by the Government on export profitability;

21

(h) the scope and performance of Internal audit of cost records, if any, and comment on its adequacy or otehrwise.

4. The Cost Auditor shall suggest measures for making further improvements in the performance in respect of cost control and cost reduction.

5. The Cost Auditor may also give his other observations and suggestions, if any, relevant to the cost audit.

ANNEXURE TO THE COST AUDIT

REPORT

1. GENERAL: 1. (a) Name and address of the registered office of the company whose accounts are audited.

Cement Corporation of India Limited, Core-5, Scope Complex, 7, Lodhi Road, New Delhi – 110 003.

(b) Name and address of the place where the cost accounting records are maintained viz. registered office, head office or factory.

Cement Corporation of India Limited, Tandur Cement Factory, Tandur, Karankote, Ranga Reddy Dist – 501 158. A.P.

2. Name of the product and location of the unit to which the Annexure pertains.

Cement, Tandur Unit, A.P.

3. The Company’s financial year to which the Cost Audit Report relates.

2007-2008 i.e. 1st April 2008 to 31st March 2009

4. Date of first commencement of commercial production of the product under reference.

1st July, 1987

5. Location of other sites manufacturing or producing or processing or mining the product or carrying out the activity under reference.

Factories Date of commencement

Units of comml. Production ---------- ------------------------ a. Mandhar 19th July, 1970

b. Kurkunta 01st Oct, 1972

c. Bokajan 01st Apr, 1977

d. Rajban 01st Apr, 1980

22

e. Akaltara 01st Apr, 1981

f. Charkhidadri 01st Oct, 1981

(sick unit taken over by CCI) g. Nayagaon 01st Mar, 1982

h. Adilabad 01st Apr, 1984

i. Nayagaon Exp. 01st May, 1990

k. Delhi Grinding 01st May, 1990

Unit 6. Name and address of the Cost Auditor. Mr. A. Ramachandra Rao, Cost

Accountant, 6-3-1086/1/2, Rajbhavan Road,

Somajiguda, Gulmohar Avenue, Hyderabad – 500 082. A.P.

7. Membership number of the Cost Accountant. In case of firm of Cost Accountants, name and membership number of all the partners.

M-428

8. Reference number and date of Government Order under which the Audit is conducted.

9. Reference number and date of Government letter approving the appointment of the Cost Auditor.

52/327/CAB-89 dated 2.07.2009

10. Date of Board of Directors’ meeting wherein the Annexure and Proforma to the cost audit report were approved.

Report approved in - Boarding meeting held on

11. The number of Audit Committee meetings held by the company, and attended by the Cost Auditor during the year under reference.

Number of meetings held: Attended by the Cost Auditor: NIL

12. Name, qualification and designation of the officer heading the cost accounting section or department of the company.

Mr. I.C.Jain, ACA. Sr. Manager (Fin), CCI Ltd, Tandur Cement Factory, A.P.

13. In case of loan license / job work arrangement by the company, mention the name of the third party and location of the factory, where the product has been produced / manufactured.

Not applicable

14. If there is any foreign technical collaboration for the product under reference, the following details shall be given;

NIL

(a) name and address of the foreign collaborators;

23

(b) main terms of agreement: (c) amount of royalty, lump-sum payment, technical aid fee payable and the basis of calculating the same;

(d) whether the technical collaborator has contributed to the share capital. If so, the paid up share capital so held. 15. If the company is engaged in other activities besides the manufacture of the product under reference, the following details in respect of each such product or activity shall be given;

NIL

(a) list of the products or activities; (b) list of the products or activities for which Cost Accounting Records Rules have been prescribed under section 209(1)(d) of the Act.; (c) whether Cost Audit Order has been issued by the Government in respect of any of the products or activities. If so, number and date of the order.

16. A printed copy of the Annual Report, containing audited Profit and Loss Account, Balance Sheet and Auditor’s Report in respect of the company’s financial year for which the report is rendered, shall be enclosed with the Cost Audit Report.

A copy of the audited financial accounts of Tandur Cement Factory, containing audited Profit and Loss Account, Balance Sheet and Auditor’s Report for the Financial year 1st April 2007 to 31st March 2008 is enclosed. Copy of Company’s Annual Report for 2007-2008 will be sent separately when it is made ready. In respect of Annexure to the Cost Audit Report figures relating to previous two years (2006-07 and 2005-06) have been taken by the Management from relevant years Cost Audit Reports to the extent available and balance information have been compiled and incorporated by the Management.

2. COST ACCOUNTING SYSTEM: Cost Accounting System existing in the

factory is given below: 1. Briefly describe the cost accounting system existing in the company, keeping in view the requirements of the Cost Accounting Records Rules applicable to the class of companies manufacturing product under reference and also its adequacy or otherwise to determine correctly the cost of production, cost of sales, sales

The unit follows mercantile method of accounting based on double entry system. The accounts are codified for the Company as a whole to maintain uniformity of accounting. Receipts and expenditure are classified according to the nature of each item in accordance with the

24

realization and margin of the product under reference.

Accounting Manual. For costing of the product, process-costing system is adopted. For collection of costs, the factory is divided into production cost centers, service cost centers and overhead cost centers. There is also a non-cost center to collect expenses of non-cost nature. Voucher-wise details are analysed from the financial books allocated and apportioned to these cost centers as detailed below:

1. RAW MATERIALS: The main Raw

materials used are limestone, shale, laterite and Gypsum. For all Raw materials, separate quantity records are maintained by production department, while priced stores ledgers are maintained for all items except for limestone and shale kept in the Accounts Department. The consumption of various raw materials are valued on the weighted average basis, including Coal & Packing Materials (yearly). Excise Duty on modvatable inputs is not considered while computing the weighted average cost of inputs.

Limestone, shale and laterite are obtained

from the Corporation's own mines. On date there are four Mining Lease Areas, two for limestone and one each for shale and laterite. The mines of limestone are adjacent to factory, while the mine for shale is within one Km. distance from Factory & Laterite mine is at a distance of more than 45 Kms which is given on a contract for mining and transportation and paid a fixed rate per tonne of the material delivered at the factory. Limestone and shale are transported by departmental dumpers as well as through Private Contractors Dumpers to crusher and laterite is transported by the contractor to factory. Laterite is weighted in factory weighbridge on its receipt while the quantity of limestone and shale is determined on the basis of capacityof Dumper, and on the number of trips made either to crusher or to stockpile. The valuation of limestone and shale is made on the basisof actual expenditure incurred after apportioning and charging off the Quarry Development expenditure in accordance with the Accounting Policy of

25

Corporation. All other Raw materials are normally received by Rail and unloaded through wagon trippler, which has got the automatic recording of the wight.

In case of road receipts, the quantity is

accepted on actual weight through road weighbridge installed in the factory. Issues are accounted from the monthly reports prepared by the Production Department, issues are priced at only weighted average rate. Physical verification is also undertaken every month and year. Stock adjustments are made for any discrepancies found on physical verification through consumption.

2. STORES & SPARES: Stores receipt

note is prepared for all stores material received. Receipts are valued at landed cost, which is calculated on the basis of invoice value excluding Modvat wherever is applicable plus freight, where directly identifiable. Weighted average price is used for valuing the issues. Bin cards are kept in stores while Price Stores Ledger is maintained in Accounts Department. Physical Verification of stores is made by the management as per perpetual inventory system.

3. VALUATION OF SEMI-FINISHED AND

FINISHED GOODS: Finished and Semi finished goods are valued at lower of weighted average cost or net realisable value in financial accounts. In cost accounts, as per cost at the relevant stage.

4. LABOUR: Payroll is computerised and

the monthly wages/salary are computed based on the attendance by the system of card punching. The payroll are maintained cost-center-wise. Summary of the payrolls is used for allocation to the cost centers.

5. OVERHEADS: For the purpose of cost

allocation, the following cost centers have been adopted.

A) Main Production Cost Centers: 1. Limestone raising & Shale raising 2. Crusher 3. Raw Mill

26

4. Kiln 5. Cement Mill 6. Packing house B) Service Cost Centers: Basis of

allocation 1. Power, including DG set - Units

consumed 2. Workshop - Depreciation

of Plant & Machinery 3. Civil Maintenance -

Depreciation of plant bldgs. 4. Material handling - Quantity

handled 5. Laboratory - Technical

Assessment 6. Water supply - Technical

Assessment 7. Railway siding and Loco - Quantity

handled 8. Coal Mill - Kiln (100%) C) OVERHEADS COST CENTERS: 1. Administration Overheads - Conversion Cost for clinker,

Cement grinding & packing 2. Social Overheads - Direct employees in the Kiln,

Cement mill and Packinghouse. 3. Selling & Distribution - Quantity of cement sold. Overhead expenses incurred in the

Production centers and the overheads apportioned to factory from service and utility cost centers constitute factory, manufacturing overheads.

6. DEPRECIATION: The Company adopts

the straight-line method of depreciation. The rates of depreciation is as per schedule XIV of the Companies Act as amended by Govt. of India, Department of Company Affairs, letter dt.16th December 1993. Depreciation on common assets are allocated along with overheads.

7) ACCOUNTING FOR ROYALTY:

Royalty is paid on limestone & shale raised on the rates prescribed by the State Government. This is treated as a part of limestone cost.

27

8) Accounting for Research and Development: For research and development activities separate account code is maintained and expenditure is collected. This is treated as a part of overheads.

9) Accounting for packing cost including

cost of packing materials and packing overheads: Separate account codes for the above expenditures are there. These are collected and shown as a part of packing cost.

10) Accounting for interest and Financial

Charges: Separate account codes are there for these expenditures. The company’s Corporate Office apportions, this expenditure once in a year to each of its units. Such expenditure is shown separately for each unit and taken into account for charging to each account code.

In the cost statement these expenditures

are taken as provided in the Cost Audit guidelines.

11) Accounting for Inter-unit Transfers:

These are adopted at actuals and accounted accordingly.

12) Accounting for expenses incurred for

Pollution Control: Separate account code is maintained for collection of expenditure incurred for Pollution Control. This is taken as a part of overheads.

13) Accounting for Sales Realisation and

Excise Duty, Taxes: The Sales Realisation and Excise Duty are accounted on the basis of actuals/accruals based on invoices raised.

14) Inventory Valuation: Raw Material : Valued on actual

cost basis; Work-in-progress } Explained in para 3

above. And Finished Goods } 2. Briefly specify the changes, if any, made in the costing system; basis of inventory valuation;

NIL

28

method of overhead allocation; appointment to cost centers / departments and final absorption to the product under reference etc; during the current financial year as compared to the previous financial year. 3. PROCESS OF MANUFACTURE: PROCESS TECHNOLOGY: 1. A brief note regarding the process manufacture along with flow chart covering, production, utility and service departments of the product:

The Tandur Cement Factory of Cement Corporation of India Limited is a 3000 TPD Dry Process, precalcinator based plant incorporating some of the modern concepts and equipments, which require minimum energy and ensure sustained operation. These modern concepts among others include single stage crushing system. Preblending stockpiles for limestone, shale and coal to smoothen out quality variation, grinding of raw meal and coal by vertical roller mill for energy conservation, high degree of environmental control by installing electrostatic precipitators in major units, latest pyro-processing technology by use of precalcinator automatic quality and production control of raw meal and most modern and efficient control and monitoring system adopting data supervisory computers for on line process programming, data logging and simultaneous display of process flow diagram.

2. The raw material i.e. limestone is

received from the quarry which is usually less than 1 cubic meter size. It is crushed in the single stage impacter to a size of 75mm. It is then preblended in preblending stockpile. The crushed limestone along with the additives like laterite etc, is ground to the size 12-14 mm retained on 90 micron sieve, in a vertical roller mill. The powdered mill product i.e. raw meal is taken to the continuous blending silo for blending before feeding it to the preheater precalcinator system. About 80-90% of calcinations is achieved in the preheater precalcinator. The calcined (80-90%) material is fed to a coal-fired kiln, where it is burnt upto a temperature of 1350 C and clinker is formed. The clinker is passed through a grate cooler where it is cooled upto a temperature of 60 degree centigrade above ambient. The size of clinker is 85%

29

less than 25mm. The clinker can be stocked in the clinker silo and can be fed to the cement mill hoppers for grinding. The clinker is ground along with gypsum (upto 5%) to make Ordinary Portland Pozzolana cement.

The clinker is also ground with Fly Ash

(upto 19%) and Gypsum (upto 5%) to make Portland Pozzolana Cement. The cement is stocked in the cement silos from where it is transported to the packing plant for packing into the bags. There is also provision for bulk loading of cement. The bagged cement is transported by road or by rail.

Encl: Manufacturing Process Flow Chart

4 QUANTITATIVE DETAILS :

Particulars 2008-2009 2007-2008 2006-2005

1. Installed capacity * (in MT)

Multiple shift 1000000 1000000 1000000 2. Capacity enhanced during the year

0 0 0

by leasing arrangement etc. 3. Total available capacity (in MT)

1000000 1000000 1000000

30

4. Production during the year: (in MT)

683415.000

615000.000 696730.000

(a) self manufactured 683415.000

615000.000 696730.000

(b)third party on job work etc.

(c) loan license basis

5. Total production quantity (in MT)

683415.000

615000.000 696730.000

6. Production as per Excise Records (in MT)

683415.000

615000.000 696730.000

7. Capacity utilisation percentage

68.340 61.500 69.673

8. Opening stock (finished quantity) (in MT)

15954.560 12000.232 7776.007

9. Total available quantity (in MT)

699369.560

627000.232 704506.007

10. Quantity captively consumed (in MT) – Factory

30.314 18.102 4.610

- Inter unit 5.000 7.000 12.000

11. Shortages 11.250 105.600 67.900 12.Quantity sold: (in MT)

(a) domestic at controlled price (b) domestic at market price

683715.555

610914.970 692421.265

(c) export under advance license

(d) export under other obligation

(e) export at market price

0.000 0.000 0.000

(f) total 683715.555

610914.970 692421.265

13. Closing stock (finished quantity) (in MT)

15607.441 15954.560 12000.232

Notes :

1. It should be clarified whether the installed capacity is on single shift or multiple shift basis.- MULTIPLE SHIFT 2. In order to have a meaningful comparisons of production

31

and installed capacity, wherever necessary these details should also be expressed in appropriate units, e.g. standard hours or equipment/ plant/ vessel occupancy hours, crushing hours, spindle/ loom shifts, equivalent production, production in terms of standard hours etc.COMPLIED

5(A). MAJOR INPUT MATERIALS / COMPONENTS CONSUMED:

2008-2009 2007-2008 2006-2007

Qty. Rate Amount Qty. Rate Amount Qty. Rate Amount

(MT) (RS) (RS) (MT) (RS) (RS) (MT) (RS) (RS)

1. Indigenous:

(a) lime stone

950283.000

108.50

103105049

846000.000

102.51

86721738

929050.000

101.12

93940950

(b) Iron Ore

25882.000

2998.57

77608901

25058.000

2075.62

52010763

24358.000

1626.30

39613398

(c) Laterite

7480.000

178.33

1333884

6489.000

169.47

1099664

5806.000

165.54

961133

(d) Shale 98945.00

67.46 6674824

80228.00

60.44 4849312

99746.00

5876.00

5861154

(e) Fly-Ash Dry

0.000 0.00 0 0.000 0.00 0 0.000 0.00 0

(f) Gypsum

10711.000

1896.13

20309441

9713.000

1735.54

16857289

14167.000

1390.64

19701222

(g) Packing Material

13738145

6.02 82636692

12187630

5.67 69163688

13891747

5.59 77698620

(Nos)

2.Self manufactured:

3. Imported:

32

4. Total 291668791

230702454

237776477

Note : Details should be furnished in respect of major input materials each constituting at least 2% of the total raw material cost.COMPLIEDComments: The increase in cement production over previous year comes to 11.12%, whereas the incresae in Raw material consumption cost including packing materials works to 26.43% due to mainly increase in input cost per MT of Iron ore by 44.47% and gypsum by 9.25% over prev.year and packing material by 6.17%

5(B). STANDARD/ ACTUAL CONSUMPTION OF INPUT MATERIALS PER UNIT:

Particulars Unit Standard / Actuals Norm

Clinker stage 2008-

20092007-2008

2006-2007

(a) Iron Ore Ton / Ton of Clinker 0.04 0.04 0.04 0.04 (b) Laterite Ton / Ton of Clinker 0.04 0.01 0.01 0.02 (c) Crushed Limestone Ton / Ton of Clinker 1.31 1.39 1.40 1.39 (d) Crushed shale Ton / Ton of Clinker 0.21 0.15 0.13 0.15 Cement Stage (F) Gypsum Ton / Ton of Cement 0.04 0.02 0.02 0.02

Note : Details should be furnished in respect of major input materials each constituting at least 2% of the total raw material cost for each major type/ variety/ size etc. of product under reference.COMPLIED

Comments: There is increas in Crushed shale consumption per MT of clinker by over 0.02 over prev year. However, there is a decrease in crushed lime stone consumption at clinker stage since both the products are interlinked products..

6. BREAK-UP OF COST OF INPUT MATERIALS IMPORTED DURING THE YEAR :

Particulars 2008-2009 2007-2008

2006-2007

1. FOB Price in foreign currency/ rupees

Nil Nil Nil

2. Insurance & freight Nil Nil Nil

33

3. Customs duty Nil Nil Nil

4. Clearing charges Nil Nil Nil

5. Inland freight Nil Nil Nil

6. Other expenses Nil Nil Nil

7. Total Nil Nil Nil

Note : Details should be furnished in respect of major input materials each constituting at least 2% of the total material cost - NIL

7 (A). POWER, FUEL AND UTILITIES :

Particulars 2008-2009 2007-2008 2006-2007 Qty. Rate Amount Qty. Rate Amount Qty. Rate Amount RS RS RS RS RS RS1. Indigenous (purchased) :

coal (MT) 158523.000

2343.37

371478173

145401.000

2168.88

315357062

149921.000

1913.86

286928007

(a) APTRANSCO (KWH)

89636980

2.24 200873775

83141800

2.60 216099873

89984500

2.27 204468580

(b)power overhead

5284943 5372213 6243690

2. Self generated/ produced:

(KWH) 3. Imported:

4. Total power

206158718

221472086

210712270

34

Note : Details should be furnished in respect of major items each constituting at least 2% of the total material cost:COMPLIEDComments: The coal cost per MT has increased by 8.05% compared to pervious year due to increase insale price by supplier i.e. by M/s . SCCL & M/s. WCL. The power cost has decreased to Rs.2.24 per KWH in current year compared to Rs 2.60 per KWH in previous year. This is on account of credits due to revision of rates passed on by APGPCL in 2008-09.

Rs.2.27 per KWH in previous year.

7 (B). STANDARD/ ACTUAL CONSUMPTION OF POWER, FUEL AND UTILITIES IN TERMS OF QUANTITY PER UNIT OF PRODUCTION :

Particulars Unit Standa

rdActuals

(Budget)

2008-09 2007-08 2006-07

(a) Diesel unit power

produced

--- 0.00 0.00 0.00

(b) Coal Kgs./ Ton of clinker

232.25 239.40 224.00

(c) Power consumption

Units/ Ton of

Cement

120.00 129.73 134.98 130.80

35

Note : Details should be furnished in respect of each major type/ variety/ size etc. of product under reference:NOT APPLICABLEComments : There is still scope in achieving power reduction to the level of 120 units taken as standard. If the unit can achieve the standard internally fixed, there will be a saving Rs.21.80 per MT of cement and per bag the reduction will be Re.1.09 in cost which is

substantial amount working to Rs.149 Crores.

36

8. SALARIES AND WAGES:

Particulars 2008-09 2007-08 2006-07 A. Quantitative Details : 1. Direct Workers: a. Average number during the year 287 306 310 b. Man days available 104572 95472 96962 c. Mandays actually worked for: (i) own production 76324 85268 83510 (ii job work d. Reason-wise analysis of idle man-days (a-b)

i) absenteeism 28248 10204 13392 ii) shortage of raw materials iii) power shortage/ failures iv) Others (specify) 2. Indirect Workers : a. Average number during the year 531 553 557 b. Man days available 165672 172405 177840 c. Mandays actually worked for: (i) own production 141265 172066 173951 (ii) job work d. Reason-wise analysis of idle man-days (a-b) i) absenteeism 24407 339 3889 ii) shortage of raw materials iii) power shortage/ failures iv) Others (specify)

Comments: There is considerable increase in absenteeism of permanent works. This requires looking into.

B. Cost Detail : Particulars 2008-

20092007-2008

2006-2007

Rs. in Lakhs1. Direct labour cost on production

304.94 251.89 235.56

2. Indirect employee costs on production

306.17 234.35 218.69

3. Employee costs on administration and

234.30 188.62 181.97

social overheads

4. Employee costs on selling and distribution

179.51 142.82 109.28

zonal office : Rs.112.33

Factory : Rs. 30.49

5. Other employees costs, if any

0.00 0.00 0.00

6. Total employee costs 1024.92 817.68 745.50

7.a.Payments under any VRS scheme

0.00 2.90 0.00

7.b.Amount provided during the year

1024.92 820.58 745.50

Comments: The increase in total cost salaries & wages and benefits charged to cost of cement works out to 24.90% due to implementation of 6th pay commission Pay for CDA & IDA employees with arrears from 1.1.06 & 1.1.07 respectively. Arrears payment pertainig to previous years has been taken into non-cost in reconciliation.

9. REPAIRS AND MAINTENANCE:Particulars 2008-

20092007-2008

2006-2007

RS RS RS

1. Land and Building 12699998

963015 714039

2. Plant and machinery 24768838

10620058 9572124

3. Staff quarters and colony 879968 493563 372474

4. Others (to be specified asset category-wise)

Railway Siding 1545535 1324082 1162188

37

Leased Apartments 0 0 0

Others 5031966 6256470 4567533

Cars/Jeeps 602361 539916 604872

5. Total amount 34098666

20197104 16993230

6. Amount capitalized/ deferred during the year

0 0 0

7. Net amount (5-6) 34098666

20197104 16993230

8. Deferred amount of earlier years, if any

9. Total amount provided in the cost records (7+8)

34098666

20197104 16993230

NOTE:Stores and spares not included above as it is taken separately as stores and spares consumption

in cost statementsComments: The total Repairs & Maintainance cost increased by 68.83% compared to previous year whereas the decrease in cement production is on 11.12% over previous year. Major repair works done like Thermal insulation, repairs of motors,etc, and increase in wages of contract labourers are reasons. the age factor of the plant which is more than 20 years is also the reason for increase in repair costs.

10. FIXED ASSETS REGISTER AND DEPRECIATION:

+Particulars 2008-

20092007-2008 2006-2007

RS RS RS

1.Whether fixed Yes Yes Yes

38

assets register maintained cost centre-wise2. Method of providing depreciation

SLM SLM SLM

3.Amount of depreciation under section 205(2) of the Companies Act, 1956 or any other relevant Act, as the case may be

19529238

17675086 26914596

4. Amount of depreciation provided in the financial records #

19529238

17675086 26914596

5. Amount of depreciation absorbed in the cost records *

19529238

17675086 26914596

6. Shortfall / Excess, if any (3 and 5)

0 0 0

Note : The impact of re-valuation of assets, if any, shall not be included.-Reply:No revaluation done. (1) Factory only considered. Selling Zone depreciation Rs.45039.72 is included in selling overheads. The depreciation excludes the quarry (Limestone raising) I.e. Rs.673057.00 included in lime stone cost (2) For 2007-2008, the above figures are for factory only. It excludes Rs.49464.44 relating to Zonal Office included in selling overheads and Rs.102860.00 relating to quarry included in limestone cost.

11. GROSS BLOCK, DEPRECIATION AND LEASE RENT:

2008-20092007-2008

2006-2007

Particulars Gross Block Depreciation Lease Rent paid, if any

Total (b+c) RS RS RS RS RS RSName of major cost centers/ products:

a b c d

LIME STONE RAISING 74739821 673057 0 673057 102860 106921 LIME STONE 0

39

TRANSPORTATION LIME STONE CRUSHING 150801034 847420 0 847420 830078 830077

RAW MILL 354782728 1243830 0 1243830 1243830 1243830

COAL MILL 79773299 321196 0 321196 321196 321196

KILN 278765229 2446550 0 2446550 1727305 6322907

CEMENT MILL 160284727 1080696 0 1080696 1080696 1080696

PACKING PLANT 72595110 861678 0 861678 861678 1723356

ELECTRICAL MAINTENANCE 0 0 0 INSTRUMENTATION MAINTENANCE

0 0 0

CIVIL MAINTENANCE 0 0 0

MINES-HEAVY EQUIPMENT 0 0 0 MECHANICAL MAINTENANCE WORKSHOP

4372225 43114 0 43114 54863 26875

A C PLANT MAINTENANCE 0 0 0

WATER SUPPLY 19259289 58028 0 58028 28998 586443

COMPRESSED AIR 0 0 0

LABORATORY 18255626 27073 0 27073 9560 0

RAILWAY SIDING 87454734 1201427 0 1201427 704845 3179967

MATERIAL HANDLING 112344635 946611 0 946611 652607 641848

MARKETING 0 0 0 0 0 0

ADMINISTRATION & SOCIAL 89204822 1140525 0 1140525 957489 985725

POWER DISTRIBUTION 87193457 1809211 0 1809211 1707820 3224082

OWN GENERATION 200687530 7494724 0 7494724 7494121 7609271 Total 179051426

6 20202295 0 2020229

5 1777794

6 2702151

6 Note : Excluding gross block of assets given on lease, if any REPLY: No assets have been given on lease. (2) The Zonal Office depreciation of Rs.45039.72 is not included in above. This has been taken in selling and distribution overheads. (3) The depreciation increase by Rs 24.24 lacs compared to previous year is due to additions(net) amounting to Rs 136.92 lacs in current year.

12. OVERHEADS:

Particulars Break up enclosed

2008-2009 2007-2008 2006-2007

in appendix

RS RS Rs.

for the factory as a

whole&for the factory as a

whole&for the factory as a

whole&

product under

referenceproduct under

referenceproduct under

reference1. Factory 12(a)

66648431 62803597 58421154

2. Administration 12(b)

17677026 27356873 32532325

3. Social 12(c)

16038801 14193723 12357402

4. Selling 8798720 10446540 7154567

40

12(d)

5. Distribution 12(d)

215530601 235341965 244526188

TOTAL 324693579 350142698 354991636

Note :(1)The break-up under each head should be furnished in respect of major items constituting at-least 80% of the overhead cost under each head.COMPLIED (2) Sl.5 includes zonal office expenses (3) There is a decrease of overall overheads cost by Rs 254.49 lacs during 08-09 compared to prev year.

13. RESEARCH AND DEVELOPMENT EXPENSES:

Particulars 2008-2009 2007-2008 2006-2007

RS RS RS

1. Process development and improvement

2. Existing product development 0 0 435284

3. New product development

4. Others, if any

5. Total amount 0 0 435284

6. Amount capitalized/ deferred during the year

7. Net amount (5-6) 0 0 435284

8. Deferred amount of earlier years, if any

9. Total amount provided in the 0 0 435284

41

cost records (7+8)

10. Amount paid to related parties NIL NIL NIL

CEMENT CORPORATIO

N OF INDIALIMITED

TANDUR CEMENT

FACTORY APPENDIX-

12(a)

ELEMENT WISE BREAK-UP OF FACTORY OVERHEADS (VIDE PARA.12 OF ANNEXURETO THE COST AUDIT REPORT) FOR THE YER 2008-2009

Particulars 2008-2009 2007-2008 2006-2007

Amount Amount Amount

(Rs.) (Rs.) (Rs.)

Employees remuneration & benefits 23740941.54 18196220.05 16975062.31

Stores & Spares 7029243.42 8359050.35 11851851.00

Depreciation 2156243.98 1990281.95 3675079.00

Other Expenses 33722002.51 34258044.62 25919162.00

TOTAL 66648431.45 62803596.97 58421154.31NOTE:- There is an increase of Factory Over heads to the tune of Rs 38.45 laks (I.e) 6.12% compared to previous year.This is in employees cost and depreciation.

CEMENT CORPORATIO

N OF INDIALIMITED

TANDUR CEMENT

42

FACTORY APPENDIX-

12(b)

ELEMENT WISE BREAK-UP OF ADMINISTRATION OVERHEADS (VIDE PARA.12 OF ANNEXURE TO THE COST AUDIT REPORT) FOR THE YEAR 2008-2009

Particulars of A/C Heads 2008-2009 2007-2008 2006-2007

Amount Amount Amount

(Rs.) (Rs.) (Rs.)

Salaries, Wages & benefits 20838115.52 16644297.48 16193126.45

Stores & Spares / Repairs 522961.48 92682.24 716986.60

Depreciation 680930.52 415493.95 562637.53

Repairs & Maintenance 1060519.00 645203.00 556115.80

Direct Expenses :

Travelling Expenses 1540458.00 1208728.50 1180212.00

Conveyance Charges 128281.00 126976.00 134122.50

Travelling Expenses - Recruit 0.00 0.00 0.00

Advt. for invtg Tenders 1758560.00 983892.00 773553.00

Insurance (P&M) allocated 0.00 5722.00 5722.00

Office Expenses 1673828.00 999143.40 839061.60

Running Expenses of Vehicles 1321745.97 1336602.35 1217157.13

Other Expenses : 1261561.46 4119916.98 4013692.72

Other Sundry Expenses 6479125.45 6494449.76 5302030.16

Insurance 275275.00 399628.00 343442.93Corporate Office & R&D Expenses 2844180.00 -3000000.00 1500000.00

Expenses on Pros. & Boring 0.00 0.00 101537.00

Other Expenses 2272419.00 2340989.00 2597305.00

SUB TOTAL 42657960.40 32813724.66 36036702.42

Apportioned Expenses

Civil Expenses allocated 130624.76 317121.10 193200.91

Power 1782491.19 1944695.60 1739242.92

Water Supply 528158.63 558763.09 681482.91

Power Overhead 47036.83 48521.42 53237.84

SUB TOTAL 2488311.41 2869101.21 2667164.58

CEMENT CORPORATIO

N OF INDIALIMITED

TANDUR

43

CEMENT FACTORY

APPENDIX-12(b)

ELEMENT WISE BREAK-UP OF ADMINISTRATION OVERHEADS (VIDE PARA.12 OF ANNEXURE TO THE COST AUDIT REPORT) FOR THE YEAR 2007-2008

Particulars of A/C Heads 2008-2009 2007-2008 2006-2007

Amount Amount Amount

(Rs.) (Rs.) (Rs.)

LESS: Scrap Sales / Other Misc. Income 8858594.00 432837.00 3627184.08

Sundry Receipts 3984792.39 7848028.93 2417377.49

Hire Charges of Equipment 14622129.70 18372.00 15713.00

Hire Charges of Vehicles 3730.00 20993.00 9730.00

SUB TOTAL 27469246.09 8320230.93 6070004.57

NET AMOUNT 17677025.72 27362594.94 32633862.43

Note: There has been decrease in total Administrative overheads in 2008-09 by Rs.96.82 lakhs which works to reduction of 35.39% compared to previous year i.e. 2007-2008 due to increase in revenue like scrap sales & hire charges of equipments. it is to be noted that there has been increase in Salaries & wages, Stores & spares, repairs, T.A expenses, Advertisement and ofice expns However, there is substantial reduction in Corporate Office expenditure compared to last year. The increased heads are to be noted for watch and control.

CEMENT CORPORATIO

N OF INDIALIMITED

TANDUR CEMENT

FACTORYAPPENDIX-

12(c)

ELEMENT WISE BREAK-UP OF SOCIAL.OVER HEADS (VIDE PARA.12 OF ANNEXURE TO THE COST AUDIT REPORT) FOR THE YEAR 2007-2008

44

Particulars of A/C Heads 2008-2009 2007-2008 2006-2007

Amount Amount Amount

(Rs.) (Rs.) (Rs.)

Salaries, Wages & benefits 2591452.19 2217358.62 2003987.29

Stores & Spares 202268.62 80318.51 337059.76Medical & Other benefits to employees 2668686.00 60625.00 476393.60

Medical Expenses 4386935.01 4230675.00 3133433.01

Subsidy to employee welfare 272258.00 61890.00 68800.00

Expenses on canteen 1019579.00 724847.00 497273.00Other Welfare Expenses (canteen) 334266.00 1493340.00 607697.90

Repairs & Maintenance 880937.92 601707.00 405642.00

Leveries to Staff 561734.20 633625.70 383268.37

Guest House Expenses 236975.00 104295.00 207394.00

Depreciation 459594.40 541994.62 423687.37

Insurance - Others 0.00 0.00 1488.00

Coal Consumption - (Others) 0.00 0.00 0.00

Apportioned Expenses:

Civil 271823.91 385123.72 234630.41

Power 1824863.35 261541.72 2662541.82

Water Supply 1277803.15 1351846.18 1648748.98

Power Over Heads 48154.95 65249.49 81499.81

SUB TOTAL 17037331.70 12814437.56 13173545.32

LESS:

House Rent 401529.00 408355.50 319876.80

Electricity Charges 426126.50 390989.60 351874.15

Subsidised Transport 159675.00 165149.00 136653.00

Guest House Receipts 11200.00 9820.00 7140.00

SUB TOTAL 998530.50 974314.10 815543.95

NET AMOUNT 16038801.20 11840123.46 12358001.37Note: There is increase in Salary & Wages, stores & Spares,medical expns & other benefits to employees madical charges reimbursement, expenses on canteen, other welfare expenses, repairs and maintenance and guest house exps, etc., in 2008-09 (i.e) increase by Rs 18.45 lacs (13.00%) over prev. year. These are to bekept under watch.

CEMENT CORPORATIO

N OF INDIA LIMITEDTANDUR CEMENT

FACTORY

45

APPENDIX-12(d)

ELEMENT WISE BREAK-UP OF SELLING AND DISTRIBUTION OVERHEADS (VIDE PARA.12OF ANNEXURE TO THE COST AUDIT REPORT) FOR THE YEAR 2007-2008

Particulars of A/C Heads 2008-2009 2007-2008 2006-2007

Amount Amount Amount

(Rs.) (Rs.) (Rs.)

SELLING OVERHEADS:

A) Direct Expenses Salaries & Wages and benefits 4206672.38 3048686.66 2938394.96

Other Expenses 11888.00 13103.00 399504.00

SUB TOTAL (A) 4218560.38 3061789.66 3337898.96

B) Siding Charges Apportioned Salaries & Wages and benefits 364392.45 287760.00 279067.00

Stores & Spares 2313202.00 5624485.00 373868.00

Depreciation 822157.75 507605.00 2316953.00

Other Expenses 1080406.98 964900.73 846780.00

SUB TOTAL (B) 4580159.18 7384750.73 3816668.01

SUB TOTAL (A+B) 8798719.56 10446540.39 7154566.97

DISTRIBUTION OVERHEADS:

Zonal Office Expenses 235341965.10 244526187.88 165621679.91

Note: (a) During 2008-09 , there is increase by Rs 11.57 lacs in selling expenses when compared to previous year. (b) During 2008-09, there has been substantial decrase in Railway sdg. expenses by Rs 248.05 lacs. (c) In Zonal Office exepenses, there has been decrease by Rs.19.11 lakhs compared to prev year. This is mainly due to increase dspathches by rai instead of road.

14. ROYALTY AND

46

TECHNICAL KNOW HOW CHARGES:

Particulars 2008-2009

2007-2008

2006-2007

RS RS RS

1. Royalty

1.a Royalty paid on Production -Limestone

43425000

38625000

41940000

1.b Royalty paid on production- shale

494000 316000 408000

2. Lump sum payment of royalty, if any

3. Technical know how charges

4. Others if any : cess 3860000 3380000 3728000

5. Total amount 47779000

41721000

46076000

6. Amount capitalized/ deferred during the year

7. Net amount (5-6) 47779000

41721000

46076000

8. Deferred amount of earlier years, if any

317944

9. Amount provided in the financial accounts (7+8)

48096914

41721000

46076000

10. Amount absorbed in the cost records

47779000

41721000

46076000

11. Shortfall/ Excess, if any 317944 0 0

12. Amount paid to related parties

NIL NIL NIL

Note : The details should be furnished in respect of each agreement separately. Not applicableas above relate to statutory paymentsProvision made in Financial books towards liability of difference of royalty on shale relating to 2004-05 to 2007-08. This amount shown under Reconcialation - head "cost not considered.

47

48

15. QUALITY CONTROL EXPENSES:

Particulars 2008-2009 2007-2008 2006-2007 RS RS RS1. ISO number, if any ---- ---- ---- 2. Name of certifying agency ---- ---- ---- 3. Salaries & Wages 0 0 0 4. Others, if any (specify)(I) bureau of Indian standards)

1539370 1372407 1764551

(II) NCBM/VIMTA 71663 75504 6285 5. Total amount 1611033 1447911 1770836

16. POLLUTION CONTROL EXPENSES:

Particulars 2008-2009 2007-2008 2006-2007 RS RS RS1. Effluent treatment 0 0 0 2. Control of air pollution APPCB 1800119 272600 81000 3. Control of ash pound/ ash mound 4. Penalty, if any 0 0 0 5. Others if any : water cess 0 0 0 6. Total amount 1800119 272600 81000

17. ABNORMAL NON-RECURRING COSTS:

Particulars 2008-2009 2007-2008 2006-2007 RS

RS RS

1. DG MAINT. COST 9850719 9284408 9393184 2 VRS DRE CHARGED OFF 0 290483 0 3. IDA/WB SALARY ARREARS 0 0 0 4. Provision for Doubt Debts 814706 14744023 0 Total 10665425 24318914 9393184

*(a) The unabsorbed cost on DG set due to non operation for all three years

18.(A) NON-MOVING STOCK (at the end of the year) :

Rs. in lakhsParticulars 2008-2009 2007-2008 2006-2007

a1.Total direct material consumption 2916.69 2307.02 2377.76 a2.Closing stock of direct material 236.45 132.39 141.42 a3. Value of non-moving stock 0.00 0.00 0.00 a4. Percentage of a3 to a2 0.00 0.00 0.00 b1.Total indirect material consumption (coal + stores 4612.32 3959.60 3538.42 & spares) b2.Closing stock of indirect material (including 2250.32 1837.77 1826.82 coal lakhs) b3.Value of non-moving stock 1142.33 1025.33 986.47 b4. Percentage of b3 to b2 50.76 55.79 54.00 c1.Work-in-progress ------ ------ ------c2.Closing stock 265.99 120.32 89.64 c3.Value of non-moving stock 0.00 0.00 0.00

49

c4.Percentage of c3 to c2 0.00 0.00 0.00 d1.Finished Goods ---------- ---------- ----------d2.Closing stock 327.26 342.16 218.42 d3.Value of non-moving stock 0.00 0.00 0.00 d4.Percentage of d3 to d2 NA NA NAe1.Total : (Consumption) 7529.01 6266.62 5916.18 e2.Closing stock 3080.02 2432.64 2276.30 e3.Value of non-moving stock 1142.33 1025.33 1026.80 e4.Percentage of e3 to e2 37.09 42.15 45.11

18.(B) WRITTEN OFF STOCK (during the year) : Rs. in lakhs Particulars 2008-2009 2007-2008 2006-2007

1. Direct Materials (Raw Material & Components etc) NIL NIL NIL2. Indirect Materials NIL NIL NIL3. WIP NIL NIL NIL4. Finished Goods NIL NIL NIL5. Total NIL NIL NIL

19.(A) INVENTORY VALUATION (at the end of the year) :Particular

sBasis 2008-2009 2007-2008 2006-2007

of valuation

Quantity

Rate Amount Quantity

Rate Amount Quantity

Rate Amount

(MT) (Rs) (Rs.) (MT) (Rs) (Rs.) (MT) (Rs) (Rs.)

1. Input material:

(i) Purchased

- Indigenous

(a) Iron Ore

AT COST

4175.075

3006.25

125510309.02

2752.825

2075.62

5713805.15

3298.775

1626.30

5364795.42

(b) Laterite " 1232. 195. 241586. 3531. 169. 598476.8 2073. 165. 343326.

50

902 95 97 547 47 8 962 54 27 (c) Gypsum

" 3906.405

1529.67

5975514.13

836.995

1398.02

1170133.25

3517.958

1136.30

3976363.39

(d) Raw material in transit

'

0.00 0.00 0.00 0.000 0.00 0.00 - Imported " 0.00 NIL NIL(ii)Self manufactured

"

0.00 NIL NIL2. Chemicals, additives

"

0.00 NIL NIL3.(a) Stores and spares

"

1967143

62.18 1671811

04.29 1511159

83.33 including consumables

3(b) Coal 6999.

5672344

.89 1641322

7.71 3716.

3172168

.88 8060238.

99 8628.

1871913

.86 1651315

3.57 3© Coal in Tansit

0.000 0.00 0.000 0.00 0.00 0.000 0.00

7047868.00

4. Packing materials (NOs)

"98783

1 4.94 4876701

.81 80318

9 4.56 3659861.

71 92174

8 4.66 4298017

.78 5. Tools and implements and Jigs, Dies and Fixtures.

" 390.00 1861.00 6531.00

6. Work-in-progress:

(a) CRUSHED LIME STONE

AT COST

30544.453

108.50

3314047.93

15827.415

102.51

1622436.10

16827.415

101.12

1701505.14

(b) CRUSHED SHALE

AT COST 3858.

990 67.4

6 260327.

26 4003.

990 60.4

4 242017.7

1 5231.

990 58.7

6 307435.

17 (c) RAW MEAL

AT COST

6425.000

249.32

1601868.50

2248.000

243.59

547583.57

4062.000

208.34

846289.63

(d) CLINKER

AT COST

18103.550

1215.79

22010057.11

8267.550

1210.72

10009720.88

6219.550

1030.41

6408702.17

7. Finished goods:

(a) Finished Goods - Silo

AT COST

6455.441

1391.98

8985844.41

10200.560

1374.31

4018740.01

5201.032 0.00 0.00

(b) Finished Goods -Transit/Branches

9152.000

1579.26

14453345.71

5754.200

1553.30

8937974.19

6799.20

1889.72

12848584.22

8. Scrap 1190414 8533528. 8004524

51

0.00 00 .35 9. Others, if any

10.Total value of inventory as per cost accounts

299302722.74

230297481.73

225005833.57

11. Total value as per Financial accounts

3080025

21.88 2432641

71.06 2337792

81.45 Difference (10 - 11)

(8699799.14)

(12966689.33)

(8773447.88)

12. Reasons for major differences, if any, Valuation of Finished Goods in Fin books with Excise Duty and freight Main Reasons: 1) Excise Duty included in valuation of stocks in financial books. 2) In financial accounts finished goods and work in progress valued at cost or market price which ever is lower. In cost accounts actual costs are taken.Note:

(1)In respect of item at Sr. No. 1 and 6 details be furnished in respect of each major input material constituting at least 2% of the total material cost.COMPLIED(2) In respect of items at Sr. No. 2 to 5, total amount be given without any quantitative details.NOTED AND COMPLIED(3) Give in brief the method of inventory valuation system indicating the elements of cost included therein and the extent thereof. - indicated above.

(4)Capital work-in-progress to be shown separately. NIL Inventory valuation done on Weighted average method for raw material,stores,packing material and coal in financial books Inventory valuation done on material cost plus appropriate overheads at respective stages for work in progress and finished goods stocked at silo in cost sheet.

19.(B) PHYSICAL VERIFICATION OF INVENTORY :

2008-2009 2007-2008 2006-2007Sr. No.

Particulars Periodicity of

Shortage Value

(Rs.)

Excess

Value

Net (Rs.

)

Shortage Value

(Rs.)

Excess

Value

Net (Rs.

)

Shortage Value

(Rs.)

Excess

Value

Net (Rs.

) verification (Rs.) (Rs.) (Rs.)

1 Raw material

month/yearly

0 0 0 0 0 0 0 0 0

2 Chemicals, additives,

_

52

consumable3 Stores &

Sparesperpetual 0 0 0 0 0 0 0 0 0

4 Packing Materials

month/yearly

0 0 0 0 0 0 0 0 0

5 Tools & Implements

yearly 0 0 0 0 0 0 0 0 0

6 WIP month/yearly

0 0 0 0 0 0 0 0 0

7 Finished Goods

month/yearly

0 0 0 0 0 0 0 0 0

8 Scrap, Wastage

yearly 0 0 0 0 0 0 0 0 0

9 Total 0 0 0 0 0 0 0 0 0 0

20. SALES OF THE PRODUCT UNDER REFERENCE: Particulars 2008-2009 2007-2008 2006-2007

Qty. Rate Amount Qty. Rate Amount Qty. Rate Amount Rs.Pe

r MTRs. Rs.Pe

r MTRs. Rs.Pe

r MTRs.

1. Purchased goods :

a) TRADING

NIL NIL NIL NIL NIL NIL NIL NIL NIL

2. Loan NIL NIL NIL NIL NIL NIL NIL NIL NIL

53

license basis:3. Own manufactured:

4. Total sale of Cement

683715.555

3252.76

2223961162

610914.970

3116.26

1903772092

692421.265

2652.23

1817765045

5.Export sales

0.000 0.00 0 0.000 0.00 0 0.000 0.00 0

TOTAL SALE OF CEMENT &

CLINKER 683715.555

3252.76

2223961162

610914.970

2975.48

1817765045

692421.265

2625.23

1817765045

1) Above details shall be furnished for major product groups/ varieties. NOT APPLICABLE(2)Separate details shall be furnished for indigenous sales and export sales. REPLY: No explorts during 2006-07 and 2007-08 (3)2006-2007and 2007-08: Sales amount excludes self consumption and stock transfer to other units of CCI and related excise duty.

21. MARGIN PER UNIT OF OUTPUT: (Rupees per MT)

Particulars 2008-2009 2007-2008 2006-2007 Cost of

SalesNet

SalesMargin Cost of

SalesNet

SalesMargin Cost of

SalesNet

SalesMargin

54

(Rs.) Reals.

(Rs.)(Rs.) (Rs.) Reals.

(Rs.)(Rs.) (Rs.) Reals.

(Rs.)(Rs.)

1.Purchased goods :

NIL NIL NIL NIL NIL NIL NIL NIL NIL

2.Loan license basis :

NIL NIL NIL NIL NIL NIL NIL NIL NIL

3.Own manufactured:

a) OPC Cement

1773.27 3252.76

1479.49 1920.79 3116.26 1195.47 1771.99 2625.23 853.24

Notes :

(1) Above details shall be furnished for major product groups/ varieties. NOT APPLICABLE(2) Separate details shall be furnished for margin on indigenous sales and export sales. Where the product (such as sugar, bulk drugs, formulations, etc.) is sold at different prices in accordance with government policy, sales realisation and margin on such product at different prices shall be shown separately alongwith quantity and value. NOT APPLICABLE.

22. COMPETITIVE MARGIN AGAINST IMPORTS:Particulars 2008-2009 2007-2008 2006-2007

55

1. Name of product Cement Cement Cement

2. Estimated demand of the product in the country * information not

information not

information not

readily available

readily available

readily available

3. Total production in the country * information not

information not

information not

readily available

readily available

readily available

4. Quantities imported in the country ** information not

information not

information not

readily available

readily available

readily available

5. Total production by the company (Tandur Unit) MT

683415.000 615000.000

696730.000

6. %age share of the company in total inland production (item 5/ item 3)

--- --- ---

7. a. Cost of production per Unit (Inland sale) 1391.98 1374.31 1165.73

(Up to naked stage)

b. Cost of Sale per Unit (Inland sale) 1773.27 1920.79 1771.99

c. Cost of production per Unit (Export sale) 0.00 0.00 0.00

d. Cost of Sale per Unit (Export sale) 0.00 0.00 0.00

8. Quantity of the product imported by the company NIL

NA NA NA

9.FOB value of quantity imported by the company NIL

NA NA NA

56

10. Weighted average FOB rate for quantities imported by the company (item 9/ item8) ** NIL

NA NA NA

11. FOB value of quantity imported in the country ** NA NA NA

12. Weighted average FOB rate of quantities imported in the country (item 11/ item4) **

NA NA NA

13. Competitive margin (item 12 less item 7(A)) ** NA NA NA

14. Major exporting countries (other than those NA NA NA

listed in item 4 above)

15.(A) Total import duty paid by the company NA NA NA

(net of CENVAT)

(B) Weighted average rate of import duty paid by the company (net of CENVAT) (item 15(A)/ item 8)

NA NA NA

16. Bound rate of duty under WTO agreement. NA NA NA

Notes : N.A. - NOT APPLICABLE / ** Not Available.

(1)* Indicate the source of information.

(2) ** Country-wise details should be furnished in respect of major countries covering at-least 75% of the total and balance should be shown under the head “Others”.