Accurate Measurement of Pasting Temperature by the Rapid Visco Analyser a Case Study Using Rice

-

Upload

carlos-arias -

Category

Documents

-

view

256 -

download

1

Transcript of Accurate Measurement of Pasting Temperature by the Rapid Visco Analyser a Case Study Using Rice

Rice Science, 2008, 15(1): 69–72Copyright © 2008, China National Rice Research Institute. Published by Elsevier BV. All rights reserved

Accurate Measurement of Pasting Temperature by the Rapid Visco-Analyser: a Case Study Using Rice Flour

BAO Jin-song (Institute of Nuclear-Agricultural Sciences/Key Laboratory of Chinese Ministry of Agriculture for Nuclear-Agricultural Sciences,

College of Agriculture and Biotechnology, Zhejiang University, Hangzhou 310029, China)

Abstract: Pasting properties are among the most important characteristics of starch, determining its applications in food

processing and other industries. Pasting temperature derived from the Rapid Visco-analyser (RVA) (Newport Scientific), in

most cases, is overestimated by the Thermocline for Windows software program. Here, two methods facilitating accurate

measurement of pasting temperature by RVA were described. One is to change parameter setting to ‘screen’ the true point

where the pasting viscosity begins to increase, the other is to manually record the time (T1) when the pasting viscosity begins

to increase and calculate the pasting temperature with the formula of (45/3.8)×(T1–1)+50 for rice flour. The latter method

gave a manually determined pasting temperature which was significantly correlated with the gelatinization temperature

measured by differential scanning calorimetry.

Key words: rice; starch; gelatinization temperature; pasting temperature; methodology

In addition to amylose content, pasting and gelatinization

properties are among the most important physicochemical

properties of starch that determine its applications in food industry

and other uses [1]. Among rice grain quality, amylose content is

believed to be the most important parameter in determining the

eating and cooking quality of cooked rice [1-3], and it is agreed

that pasting viscosity properties and gelatinization temperature

(GT) also contribute to differences in cooked rice quality [4-5].

Pasting viscosity properties have been used to predict the

end-use quality of various products, e.g. cooked rice texture [4,6]

and noodles [7]. In many food industries, analysis of pasting

viscosity and gelatinization temperature is still necessary for

samples at different stages of processing.

Pasting properties of starches are measured by using

various instruments such as Rapid Visco Analyser (RVA,

Newport Scientific, Warriewood, Australia), Micro Visco-

Amylograph (Brabender, Duisberg, Germany), etc [8]. GT is the

critical temperature at which starch granules irreversibly lose

their birefringence and crystalline order during heating. GT can

be directly measured under a polarized light microscopy with a

heating stage to record the temperature when the birefringence

is lost. GT can also be measured by differential scanning

calorimetry (DSC) [9], or indirectly by the alkali spreading

value test for rice grains [10]. Some studies also measured the

pasting temperature (PT) of starch from RVA analysis [3, 6, 8, 11].

If the PT obtained from RVA were equivalent to the GT from

DSC, information on pasting viscosity and gelatinization temperature

Received: 2 August 2007; Accepted: 9 October 2007Corresponding author: BAO Jin-song ([email protected]) This is an English version of the paper published in Chinese in ChineseJournal of Rice Science, Vol. 21. No. 5, 2007, Pages 543–546.

could be simultaneously obtained from a single test on the RVA,

thus saving time and resources. Unfortunately, the PT measured

from RVA is always overestimated, being much higher than the

GT derived from DSC. In some cases, the RVA derived PT of

rice samples was higher than 90°C [3, 6]. Hence, the PT from

RVA will be misleading if it is not interpreted properly. In the

present paper, we report how to accurately estimate the

gelatinization temperature using RVA.

MATERIALS AND METHODS

Rice materials

A total of 15 rice varieties (or breeding lines) representing

a wide range of amylose content (2% to 30%) and gelatinization

temperature were used in this study. The rice was grown in

Hainan Province, China from November 2003 to April 2004.

Rough rice grains were dehulled, and milled to white rice with

a Satake mill (Satake Corp. Japan) and then ground to flour

with a Cyclone sample mill (UDY Corp., Fort Collins, CO).

The flour was further passed through a 100-mesh sieve prior to

analysis.

RVA measurement

Rice flour pasting properties were determined using a

Rapid Visco-Analyzer model 3D (RVA) (Newport Scientific,

Warriewood, Australia) with the software program Thermocline

for Windows (TCW) according to AACC method 61-02 [12].

Each rice sample (3 g, 12% m.b.) was mixed with 25 g of

distilled water in an RVA sample canister. The idle temperature

was set at 50°C, and the following 12.5-minute test profile was

run: (1) held at 50°C for 1.0 min, (2) linearly ramped up to

70 Rice Science, Vol. 15, No. 1, 2008

95°C in 3.8 min, (3) held at 95°C for 2.5 min, (4) linearly

ramped down to 50°C in 3.8 min and (5) held at 50°C for 1.4

min. The peak viscosity, holding viscosity, final viscosity, and

pasting temperature were determined by the analysis window

of TCW. In the program, the formula to measure pasting

temperature is TempAtViscRate (T1,T2,.Tinc,Vinc), which

means that the temperature (°C) when the rate of change in

viscosity (Vinc/Tinc) is first achieved between T1 (min) and T2

(min) of the curves. The viscosity is either in RVA arbitrary

unit (RVU) or centiPoise (cP). For rice flour, the recommended

total test time is generally 12.5 min (AACC 2000), thereby the

first two parameters (T1 and T2) of the formula are generally

set as (2, 7), whereas the latter two parameters (Tinc and Vinc)

can be changed.

DSC analysis

The gelatinization temperatures of the rice flour samples

were measured with a DSC 2920 Modulated DSC thermal

analyser (TA Instruments, Newcastle, DE) equipped with DSC

standard and dual sample cells. Rice flour (2.0 mg) was weighed

into an aluminum pan, 6 µL distilled water was added, and the

pan was sealed hermetically with a lid. After equilibration at

room temperature for 1 h, the sample was heated at a rate of

10°C/min from 30°C to 110 °C. A sealed empty pan was used

as a reference. Onset (To), peak (Tp), and completion (Tc)

temperatures of gelatinization were calculated by a Universal

Analysis Program, Version 1.9D (TA Instruments, Newcastle, DE).

Statistical analysis

Student’s t-test for comparing the means of the paired data

and analysis of correlation coefficient were carried out in

Microsoft Excel (Microsoft Corp, Seattle, WA).

RESULTS AND DISCUSSION

According to the software formula setting, the pasting

temperature (PT) was recorded when the rate of change viscosity

above the set point was first achieved. In many cases, the

viscosity increased rapidly after initial rise, so the formula given

by the software, such as TempAtViscRate (2,7,.2,24), accurately

measured the PT (Fig. 1-A). For example, the software gave the

samples BP003, BP004 and BP095 the PTs with less than 2°C

deviation when different parameters were tried (Table 1). In

some cases, wide deviations in the PTs were found when

different formulas were tried. For example, the formula

TempAtViscRate (2,7,.1,36) gave BP530 and BP547 the PTs

higher than 88°C (Table 1), whereas the TempAtViscRate

(2,7,.1,10) formula gave them around 73oC (Table 1). The

reason was that the pasting viscosity was increasing at a low

rate, even lower than the set point for a long time (Fig. 1-B to

F). For example, if a sample’s pasting viscosity increased at a

constant rate of 18 cP/s between the time 2 min to 7 min during

test, no PT would be recorded with formula TempAtViscRate

(2,7,.1,36) or TempAtViscRate (2,7,.1,24) because the actual

rate was always less than 36 or 24 cP/s. Thus, the recorded PT

would gradually decline as the set rate declined as shown in Fig.

1-B to F. However, too small a change rate setting would also

result in incorrect PT, such as TempAtViscRate(2,7,.1,10) gave

BP005 66°C, much lower than the true value (Table 1).

Because of genotypic differences in pasting behavior, accurate

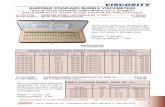

Fig. 1. Typical pasting profile of rice flour tested on a Rapid Visco-analyser. A, PT derived from the program formulae of TempAtViscRate (2,7,.2,24) for rice BP003; B to F, PT derived from various program formula of

rice BP025; B, TempAtViscRate (2,7,.1,36); C, TempAtViscRate (2,7,.1,24); D, TempAtViscRate (2,7,.1,18); E, TempAtViscRate (2,7,.1,12); F,TempAtViscRate (2,7,.1,10). Peak, Peak viscosity; Hold, Holding viscosity; Final, Final viscosity; PT, Pasting temperature.

Vis

cosi

ty

(cP

)

V

isco

sity

(cP

)

Tem

pera

ture

(°C

)

T

empe

ratu

re (

°C)

Vis

cosi

ty (

cP)

Time (min) Time (min)

Temperature

Temperature

Viscosity

Viscosity

BAO Jin-song. Accurate Measurement of Pasting Temperature by the Rapid Visco-Analyser: a Case Study Using Rice Flour 71

automatic measurement of PT by a single formula was

impossible. To analyze with different formulae and check

whether the PT was determined at the proper point would help

to obtain a correct result for a specific pasting profile. Two

inferences could be drawn. One is that an accurate PT is easier

to be obtained for higher viscosity samples because of a

generally rapid increase in viscosity for these samples. The

other is that measurement of PT will be affected by starch or

flour concentrations. Lower concentration of a sample results in

higher PT when measured by the software formula though it is

actually low in gelatinization temperature, whereas higher

concentration leads to more accurate measurement of the PT

because of the rapid increase in viscosity. Varavinit et al [3] used

1.5 g rice flours instead of 3.0 g to test pasting properties, so

the high PTs (>90°C) might result from the low concentration.

PT could be measured by inspection of individual curves

to determine the point at which the pasting viscosity began to

increase (Fig. 1-B). Since the temperature was increased

linearly from 50°C to 95°C in 3.8 min during pasting and was

held at 50°C for 1.0 min before increasing the temperature, the

PT could be calculated by the formula, PTm = (45/3.8)×

(T1–1)+50, where T1 is the time when the pasting viscosity

began to rise (Table 1). In the TCW software, the time at the

point when the mouse arrow lies in the curve will be displayed

when the ‘Show Cursor Coordinates’ is chosen in the ‘Options’.

This method was very accurate, because in TCW, one can

enlarge the profile so as to locate the point at a right place. We

recorded the time for all 15 samples and calculated the PT

(Table 1). As a result, the manually calculated PTs (PTm) were

significantly correlated with those from DSC measurements,

whereas all other software formula derivatives gave poor

correlation with DSC parameters (Table 2). TempAtViscRate

(2,7,.2,24), TempAtViscRate (2,7,.1,12) and TempAtViscRate

(2,7,.1,10) gave relatively more accurate PT because of their

higher correlation with DSC parameters (Table 2).

Under the assumption that the two paired data had the

same mean, the Student’s t-test indicated that PTm was

significantly different from To (P<0.0001), Tp (P<0.01) and Tc

Table 1. Pasting temperatures of rice flours derived from different methods.�

PT a (˚C)� PTm b� � DSC c (˚C)�

Sample�(2,4) d (2,24) (2,36) (1,36) (1,24) (1,18) (1,12) (1,10)

Time(min)

PT (˚C)

To Tp Tc

BP003 77.7� 76.7� 77.7� 78.4� 77.7� 77.7� 77.7� 76.7� 3.17 75.7� 71.2� 75.2 81.0

BP004 77.6� 76.8� 77.6� 78.4� 77.6� 77.6� 76.8� 76.8� 3.28 77.0� 72.4� 75.8 81.2

BP005 79.9� 79.2� 79.2� 79.9� 79.9� 79.2� 75.2� 66.0� 3.47 79.2� 74.4� 78.9 83.7

BP010 85.4� 72.9� 72.9� 86.1� 73.5� 73.5� 70.6� 67.4� 2.50 67.8� 58.3� 67.0 76.1

BP011 79.1� 78.3� 79.1� 79.9� 79.9� 79.1� 78.3� 75.8� 3.43 78.8� 74.8� 79.4 84.6

BP025 83.8� 71.9� 76.0� 87.9� 79.1� 72.9� 71.9� 70.6� 2.73 70.5� 63.0� 69.2 76.1

BP026 73.6� 70.5� 71.3� 74.5� 74.5� 71.3� 70.5� 70.5� 2.75 70.7� 62.9� 69.6 78.0

BP086 83.0� 69.1� 81.6� 87.2� 82.3� 81.6� 69.8� 68.2� 2.42 66.8� 58.1� 65.2 72.6

BP095 76.8� 76.0� 76.8� 77.6� 77.6� 76.8� 76.8� 76.0� 3.20 76.1� 70.6� 75.3 81.2

BP133 79.9� 66.8� 78.3� 82.9� 79.1� 66.8� 66.8� 66.0� 2.38 66.4� 56.3� 63.4 70.9

BP225 69.7� 69.0� 69.0� 71.4� 69.7� 69.7� 69.0� 68.2� 2.55 68.4� 62.5� 70.3 77.3

BP420 85.4� 80.7� 84.0� 86.2� 84.6� 81.5� 80.7� 70.5� 2.48 67.6� 58.7� 65.6 72.9

BP530 87.8� 77.4� 83.8� 88.6� 87.2� 83.0� 78.3� 73.6� 2.75 70.7� 62.9� 69.2 76.1

Bp547 87.2� 84.0� 85.4� 89.5� 86.1� 84.6� 72.9� 72.9� 2.77 70.9� 62.7� 68.9 75.8

Bp551 82.2� 70.5� 77.6� 84.5� 81.5� 72.9� 69.7� 69.7� 2.63 69.3� 59.2� 66.0 73.1a PT was pasting temperature derived from program software formula, TempAtViscRate (2,7,.Tinc,Vinc); b PTm was pasting temperature derived from manual location of the time when the viscosity began to rise; c Differential scanning calorimetry: To, Onset temperature; Tp, Peak temperature; Tc, Completion temperature; d This was set in the RVU mode, whereas others were in cP mode.

Table 2. Correlation coefficients for pasting temperatures derived from different methods with DSC values a.

Parameter (2,4) b (2,24) (2,36) (1,36) (1,24) (1,18) (1,12) (1,10) PTm

To� -0.35� 0.49� -0.02� -0.46� -0.11� 0.28� 0.59*� 0.60*� 0.99**�

Tp� -0.38� 0.47� -0.09� -0.49� -0.18� 0.25� 0.56*� 0.54*� 0.97**�

Tc� -0.40� 0.44� -0.18� -0.52*� -0.26� 0.20� 0.52*� 0.52*� 0.94**�

* and ** are significant at P<0.05 and P<0.01, respectively; a Differential scanning calorimetry: To, Onset temperature; Tp, Peak temperature; Tc, Completion temperature; b This was set in the RVU mode, whereas others were in cP mode.

72 Rice Science, Vol. 15, No. 1, 2008

(P<0.0001). However, when the difference between two paired

data was set to 1°C, the PTm was not significantly different

from Tp (P = 0.71), but it was still significantly different from

To and Tc (P<0.0001), indicating that the mean PTm (71.7°C)

was only 1°C higher than the mean Tp of DSC (70.6°C).

Our analysis only focused on the measurement of PT of

rice flour tested according to the AACC method 61-02; whether

other samples or other methods will encounter the same

problem is not known. The manually obtained PT should

always resolve the problem, but the formula to calculate the PT

could be reestablished for that specific method.

CONCLUSIONS

Pasting temperature measured by RVA does not reflect the

true gelatinization temperature, such as measured by DSC.

Changing parameters in the analysis program could increase

the measurement accuracy but still gave great deviation for

some samples. Inspecting the curves to record the time (T1)

when the pasting viscosity began to rise and calculating the

pasting temperature by a specific formula, such as

(45/3.8)×(T1–1)+50 for rice flour can measure the pasting

temperature (estimate gelatinization temperature) very accurately.

The results also indicated that the pasting temperature from

RVA was 1°C higher than peak temperature of DSC.

ACKNOWLEDGEMENTS

This research was financially supported in part by the

National High Technology Development Project of China

(Grant No. 2006AA10Z193), the National Natural Science

Foundation of China (Grant No. 30300227), and the Science

and Technology Department of Zhejiang Province (Grant No.

2007C32014).

REFERENCES

1 Bao J, Bergman C J. The functionality of rice starch. In: Eliasson A C. Starch in Food: Structure, function and applications. Cambridge: Woodhead Publishing Ltd., 2004: 258–294.

2 Juliano B O. Criteria and tests for rice grain quality. In: Juliano B O. Rice: Chemistry and Technology. 2nd ed. St Paul, MN: AACC, 1985: 443–524.

3 Varavinit S, Shobsngob S, Varanyanond W, Chinachoti P, Naivikul O. Effect of amylose content on gelatinization, retrogradation and pasting properties of flours from different cultivars of Thai rice. Starch, 2003, 55: 410–415.

4 Shu Q Y, Wu D X, Xia Y W, Gao M W, McClung A. Relationship between RVA profile character and eating quality in Oryza sativaL. Sci Agric Sin, 1998, 31 (3): 25–29. (in Chinese with English abstract)

5 Bao J S, Shu Q Y, Wu D X, Xia Y W. Comparative study on the RVA profiles from the milled and brown rice flour. Chinese J Rice Sci, 2001, 15(2): 145–146. (in Chinese with English abstract)

6 Limpisut P, Jindal V. Comparison of rice flour pasting properties using brabender viscoamylograph and rapid visco analyzer for evaluating cooked rice texture. Starch, 2002, 54: 350–357

7 Bhattacharya M, Zee S Y, Corke H. Physicochemical properties related to quality of rice noodles. Cereal Chem, 1999, 76:861–867.

8 Suh D S, Jane J L. Comparison of starch pasting properties at various cooking conditions using the micro amylograph and the rapid visco analyzer. Cereal Chem, 2003, 80: 745–749.

9 Normand F L, Marshall W E. Differential scanning calorimetry of whole grain milled rice and milled rice flour. Cereal Chem, 1989, 66: 317–320.

10 Little R R, Hilder G B, Dawson E H, Elsie H. Differential effect of dilute alkali on 25 varieties of milled white rice. Cereal Chem,1958, 35: 111–126.

11 Liang X M, King J M, Shih F F. Pasting property differences of commercial and isolated rice starch with added lipids and β-cyclodextrin. Cereal Chem, 2002, 79: 812–818.

12 American Association of Cereal Chemists (AACC). Methods 61-02 for RVA. In: Approved Methods of the AACC. 10th ed. St. Paul, MN: AACC, 2000.

![TLE ANALYSER · TLE ANALYSER User Manual v2.8 TLE analysis ... TLE ANALYSER Version 2.8 - 2013 TLE ANALYSER - User Manual [4] 2. TLE Analyser Setup and Options TLE Updater allow to](https://static.fdocuments.us/doc/165x107/5aa68a5c7f8b9a517d8ea13c/tle-analyser-analyser-user-manual-v28-tle-analysis-tle-analyser-version-28.jpg)