A Proposal for Developing Competency -Based, Dimensional ... · Analog and digital calipers, analog...

Transcript of A Proposal for Developing Competency -Based, Dimensional ... · Analog and digital calipers, analog...

NCSL International Workshop & Symposium | Metrology in Motion August 26 – 29, 2019 | Cleveland, Ohio

2019 NCSL International Workshop & Symposium: Metrology in Motion Huntington Convention Center, Cleveland, OH, August 24 – 29, 2019

A Proposal for Developing Competency-Based, Dimensional Certification

Speaker/Author: Joseph P. Fuehne, Ph.D., P.E. Director and Maha Associate Professor Mechanical Engineering Technology

Purdue Polytechnic Institute Advanced Manufacturing Center of Excellence

4444 Kelly Street Columbus, IN 47203-1749 Telephone: (812)348-2040

Fax: (812)348-2016 [email protected]

Abstract

The Purdue Polytechnic Institute in Columbus, working together with corporate partner Cummins Inc., has developed a metrology training program that includes competency-based credentialing based on hands-on activities rather than a written test. This work includes specific details of the training program with activities required for competency-based credentialing. Many training programs include only a lecture/discussion format that usually include some written examination to demonstrate competency. In this plan, the Purdue Polytechnic Institute in Columbus utilizes metrology tools with targeted measurement artifacts, which may be 3-D printed or machined, to facilitate learning and provide opportunities to demonstrate competency, leading to badges awarded by Purdue Polytechnic Institute for satisfactory performance. An initial activity presents an assembly line with different methods for ensuring fit and quality of the final product. Participants will see how the properly chosen tools can greatly facilitate production operations. Digital measurement tools are utilized as well as 3D printed go-no go gauges that demonstrate their tremendous value in an efficient manufacturing production line. Analog and digital calipers, analog and digital micrometers, Pi tapes, bore micrometers, and dial indicators are all demonstrated and employed during the training. Trainees are required to complete measurement forms that are developed using a spreadsheet program and submit those completed forms for assessment. Sufficient exercises are required with different instruments to award competency badges to individuals who successfully complete the measurements. The proposal is that badges can then be stacked to award successful individuals a certification for dimensional measurement. Most training materials are 3D printed and measurement tools are common. The total equipment package is designed to be portable and available to NCSLI local section meetings for testing and use. Potentially, a kit could be developed which would be available for check out through the NCSLI.

Learning Objectives The learning objectives for this paper are summarized below:

1. To evaluate measurement tools, measurement artifacts and measurement methods for potential to be used in creating a dimensional measurement certification.

NCSL International Workshop & Symposium | Metrology in Motion August 26 – 29, 2019 | Cleveland, Ohio

2019 NCSL International Workshop & Symposium: Metrology in Motion Huntington Convention Center, Cleveland, OH, August 24 – 29, 2019

2. To inspect 3D printed measurement artifacts for their use, portability, and manufacturing repeatability for other organizations

3. To discuss competency-based learning activities with significant hands-on exercises that are developed into measurement tool badges and, ultimately, a dimensional measurement certification.

1. Introduction Several years ago, the Purdue Polytechnic (formerly the College of Technology) desired to upgrade its teaching and learning methods to a more modern, active, and student-centered style. While the Polytechnic always had emphasized applied learning more than theory learning and included many hands-on activities in the classes, some improvements were needed to transform the educational experience to the 21st century. There are 10 elements to this transformation:

1. Theory-based Applied Learning 2. Team Project-based Learning 3. Modernized Lecture Methods 4. Integrated Learning-in-Context Curriculum 5. Integrated Humanities Studies 6. Competency Credentialing 7. Senior Capstone Projects 8. Internships 9. Global/Cultural Immersions 10. Faculty-to-Student Mentorship

These 10 elements are being integrated into 4-yr Bachelor of Science degree programs throughout the Purdue Polytechnic but, clearly, utilizing all 10 in a short-term training program is not possible. However, two of these elements – Modernized Lecture Methods and Competency Credentialing – are incorporated into this dimensional measurement training program.

• Modernized Lecture Methods – these methods focus on creating more interactive lectures that utilize online tools like Kahoot! that allow the students to participate using their own phones in a game-like activity that keeps everyone involved. Additionally, the lectures are organized in a modular format where each module is not more than 15-20 minutes in length. This limited length plus the interactive tools aim to keep participants engaged for the entire lecture. PowerPoint files and selected videos are also employed to enhance student learning.

• Competency Credentialing – In a classroom setting, students are encouraged to complete the tasks at their own pace over the course of a semester or two but that approach does not really apply to a short training session. However, competency badges are earned by participants who successfully complete measurement activities, which are all hands-on measurement activities. As this training is intended as a multi-day training session, each session includes time for practice with each tool and opportunities to earn the appropriate badges.

NCSL International Workshop & Symposium | Metrology in Motion August 26 – 29, 2019 | Cleveland, Ohio

2019 NCSL International Workshop & Symposium: Metrology in Motion Huntington Convention Center, Cleveland, OH, August 24 – 29, 2019

NCSL International Workshop & Symposium | Metrology in Motion August 26 – 29, 2019 | Cleveland, Ohio

2019 NCSL International Workshop & Symposium: Metrology in Motion Huntington Convention Center, Cleveland, OH, August 24 – 29, 2019

2. Dimensional Tools and Competency Badges

Instruction during the training focuses on dimensional tools like micrometers, calipers, bore micrometers, pi tapes, rulers, and dial indicators in both English and metric versions. There are short, modular lectures associated with each tool and then plenty of practice time to learn the operation of each tool. Competency badges are also earned for each tool. Participants complete measurements independently on each tool without assistance from colleagues or instructors. Measurements are recorded on supplied sheets that identify the particular measurement required and the associated resolution for each tool. A minimum score of 80% is required to earn the competency badge for each tool. 3. Calipers

Calipers are popular dimensional measurement tools whether they are Vernier, dial or digital. For obvious reasons, digital calipers are popular because little operator skill is required to

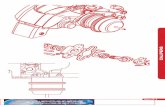

Figure 1. Verner Calipers utilized in the measurement activities.

NCSL International Workshop & Symposium | Metrology in Motion August 26 – 29, 2019 | Cleveland, Ohio

2019 NCSL International Workshop & Symposium: Metrology in Motion Huntington Convention Center, Cleveland, OH, August 24 – 29, 2019

properly read the instrument. Dial calipers require more skill to read while Vernier calipers certainly demand more training, skill and patience to read correctly.

All three caliper types are used in the training which includes a measurement effort that highlights the advantages and disadvantages of each one and ultimately compares the capability of calipers to micrometers (depth, outside, and bore) and to dial indicators. The objective is to not only assist participants in learning how to use the various measurement tools but also provide some understanding of which tool is preferred for the assortment of measurements required for a successful manufacturing activity.

4. Three-Point Bore Micrometers

NCSL International Workshop & Symposium | Metrology in Motion August 26 – 29, 2019 | Cleveland, Ohio

2019 NCSL International Workshop & Symposium: Metrology in Motion Huntington Convention Center, Cleveland, OH, August 24 – 29, 2019

The differences in diameter measurements between two-point caliper measurements and three-point micrometer measurements are significant. The Vernier caliper utilized is shown in Figure 1 while Figure 2 shows the bore micrometers. The three-point micrometer allows for consistent contact between the instrument and the workpiece while the two-point caliper instruments suffer from a plethora of maladies including inconsistent contact even with a single operator, alignment

with the hole axis, inability to account for out-of-roundness, and others. A short exercise which exposes the flaws with two-point measurements as compared to three-point measurements is also included. Figure 3 exhibits the worksheet developed for measurements performed with the bore micrometers and with digital calipers as a comparison. Figure 4 is a drawing of a 3-D printed part employed in this part of the training class. The holes represent a range of diameters to allow the participant an opportunity to use all five of the bore micrometers illustrated in Figure 2. The side-by-side comparison of measurement results from these tools provides the participant an opportunity to consider measurement science in a different way – it’s not just about making measurements with any tool available but promotes the idea that there might be a better or more appropriate tool for the task. This type of consideration represents critical thinking and gives the employee an occasion to improve the process and hopefully leads to the company manufacturing higher quality parts.

Figure 3. A drawing of one of the measureable artifacts used to practice three-point bore micrometers.

Figure 2. Three-point micrometers with inch units.

NCSL International Workshop & Symposium | Metrology in Motion August 26 – 29, 2019 | Cleveland, Ohio

2019 NCSL International Workshop & Symposium: Metrology in Motion Huntington Convention Center, Cleveland, OH, August 24 – 29, 2019

Table 1 and Figure 4 display results of the inside diameter measurements made with varying tools. Figure 4, in particular, highlights the difference between the 2-point calipers and the three-point bore micrometers, which are much closer to values determined using a coordinate measuring machine (Zeiss Duramax). The CMM is able to scan the around the entire hole, collecting many points that are used to determine the diameter.

5. Outside Micrometers

Outside micrometers are very similar to operate as the bore micrometers previously discussed. Typically, outside micrometers are also limited to certain ranges of measurements. In Figure 2, it might be apparent that the bore micrometers are valid only within certain ranges; for example, the five bore micrometers cover a diameter range of 0.5 inches to 1.2 inches.

NCSL International Workshop & Symposium | Metrology in Motion August 26 – 29, 2019 | Cleveland, Ohio

2019 NCSL International Workshop & Symposium: Metrology in Motion Huntington Convention Center, Cleveland, OH, August 24 – 29, 2019

Two sets of outside micrometers – English and metric units – are exercised during the training

Table 1. Table of results comparing a three-point micrometer to a Vernier caliper for measuring hole diameters

Nominal Hole Diameter (inches)

CMM (inches)

Digital Caliper (inches)

Minimum Mic Value = 0.6000 inchSleeve/Barrel Reading = 0.0000 inch Zero-Line Reading = 0.56250 inchThimble Scale Reading = 0.0142 inch Vernier Scale Reading = 0.03125 inch

Total Measurement = 0.6142 inch Total Measurement = 0.59375 inchMinimum Mic Value = 0.6000 inch

Sleeve/Barrel Reading = 0.0250 inch Zero-Line Reading = 0.5625 inchThimble Scale Reading = 0.0172 inch Vernier Scale Reading = 0.0625 inch

Total Measurement = 0.6422 inch Total Measurement = 0.6250 inchMinimum Mic Value = 0.6000 inch

Sleeve/Barrel Reading = 0.0500 inch Zero-Line Reading = 0.625000 inchThimble Scale Reading = 0.0090 inch Vernier Scale Reading = 0.015625 inch

Total Measurement = 0.6590 inch Total Measurement = 0.640625 inchMinimum Mic Value = 0.6000 inch

Sleeve/Barrel Reading = 0.0750 inch Zero-Line Reading = 0.6250000 inchThimble Scale Reading = 0.0044 inch Vernier Scale Reading = 0.0390625 inch

Total Measurement = 0.6794 inch Total Measurement = 0.6640625 inchMinimum Mic Value = 0.7000 inch

Sleeve/Barrel Reading = 0.0000 inch Zero-Line Reading = 0.68750 inchThimble Scale Reading = 0.0172 inch Vernier Scale Reading = 0.00000 inch

Total Measurement = 0.7172 inch Total Measurement = 0.68750 inchMinimum Mic Value = 0.7000 inch

Sleeve/Barrel Reading = 0.0250 inch Zero-Line Reading = 0.6875000 inchThimble Scale Reading = 0.0164 inch Vernier Scale Reading = 0.0234375 inch

Total Measurement = 0.7414 inch Total Measurement = 0.7109375 inchMinimum Mic Value = 0.7000 inch

Sleeve/Barrel Reading = 0.0500 inch Zero-Line Reading = 0.6875000 inchThimble Scale Reading = 0.0094 inch Vernier Scale Reading = 0.0546875 inch

Total Measurement = 0.7594 inch Total Measurement = 0.7421875 inchMinimum Mic Value = 0.7000 inch

Sleeve/Barrel Reading = 0.0750 inch Zero-Line Reading = 0.7500000 inchThimble Scale Reading = 0.0164 inch Vernier Scale Reading = 0.0000000 inch

Total Measurement = 0.7914 inch Total Measurement = 0.7500000 inch

0.73

0.75

Hole Measurement in English Units (inches)

0.67

0.61248

0.64399

0.65327

Three-Point Micrometer Vernier Caliper

0.62

0.65

0.77

0.79

0.69

0.604

0.635

0.64

0.6815

0.716

0.725

0.7475

0.77

0.72104

0.74015

0.76624

0.79074

0.69196

NCSL International Workshop & Symposium | Metrology in Motion August 26 – 29, 2019 | Cleveland, Ohio

2019 NCSL International Workshop & Symposium: Metrology in Motion Huntington Convention Center, Cleveland, OH, August 24 – 29, 2019

depending on the length of the artifact being measured. Both English and metric units are considered as well given the current bi-unit standard configuration of manufacturing in the country. Digital micrometers are also utilized to provide experience and practice with these tools, which may find more use in today’s manufacturing environment. Figure 6 provides an example the worksheet employed to assist participants in learning to read outside micrometers.

An important aspect of any measuring instrument is the contact pressure between the instrument and the artifact. An advantage of most micrometers – outside, inside, bore, and depth – is a ratchet mechanism that allows for consistent and repeatable contact pressure between the instrument and artifact. Calipers typically don’t have this feature, requiring the user to establish their own feel for that pressure. The result is inconsistent results. The training also emphasizes this aspect of using the instruments.

Figure 5 displays a spreadsheet used to make the same measurement – length of small wooden cylinders shown in Figure 6 – with a dial indicator, analog micrometer and a digital micrometer.

Figure 4. A bar graph showing inadequacy of 2 point calipers for diameter measurements.

NCSL International Workshop & Symposium | Metrology in Motion August 26 – 29, 2019 | Cleveland, Ohio

2019 NCSL International Workshop & Symposium: Metrology in Motion Huntington Convention Center, Cleveland, OH, August 24 – 29, 2019

Like the previous worksheets, the individual measurements are broken down to emphasize the various parts of each measurement. For example, participants record the minimum value on the micrometer, the value of the sleeve, the value of the thimble and, finally, the value of the Vernier scale if one exists. Recognizing and recording the individual components of the measurement to achieve the final measurement encourages understanding of the instrument and lessens the anxiety involved in reading a complex instrument.

With dial indicators, an indirect measurement approach is used to illustrate how dial indicators are most often employed. Typically, gauge blocks are used to set the “zero” of the dial indicator to the nominal value of the dimension and then the indicator will provide the difference between the measurement and the nominal dimension. For example, if a block is placed under the instrument and the indicator is on “zero” then the dimension is equivalent to the nominal value. Any value other than zero on the indicator is simply added or subtracted from the nominal dimension. Dial indicators are very useful in situations when they are practically treated as go/no-go gauges. A range is established on the indicator with red arrows and the user is instructed that any indicator reading between those arrows specifies a “good” part and any reading outside of the arrows designates a “bad” part. This technique is not quite as simple as a go/no-go gauge but is very functional under certain conditions.

The spreadsheet shown in Figure 5 breaks down the dial indicator and analog micrometer readings into their various parts, again assisting the user in the task. Participants will be asked to

measure 10 different cylinders and record the numbers on the cylinders in addition to the measurements.

Measuring the same feature with different tools begins the development of basic measurement understanding. Different tools have varying resolution, different precision, and require the user to recognize those differences when choosing a tool for measurement.

Figure 5. Worksheet displaying exercises for measuring with dial indicators, analog micrometers and digital micrometers.

Digital Micrometer Measurements -

English Units

Item Number

Gauge Block

Setting

Length Variance (inches)

Length (inches)

Item Number

MinimumMic

Value

Sleeve/Barrel Reading

Thimble Scale

Reading

Total Length

Item Number Digital Reading

1 1 12 2 23 3 34 4 45 5 56 6 67 7 78 8 89 9 9

10 10 10

Micrometer Measurements - English Units

Dial Indicator MeasurementsEnglish Units

NCSL International Workshop & Symposium | Metrology in Motion August 26 – 29, 2019 | Cleveland, Ohio

2019 NCSL International Workshop & Symposium: Metrology in Motion Huntington Convention Center, Cleveland, OH, August 24 – 29, 2019

6. Competency Testing

Figure 7 shows the artifact used for the primary competency testing. The part is adopted from a similar part used for demonstration purposes on the Zeiss CMM. It has been manufactured from several different materials – ABS plastic used with 3D printing, and aluminum and steel that has been machined. All three are shown in the photo. Figure 8 is a dimensioned drawing of the artifact with all dimensions in millimeters.

Figure 6. Small, numbered cylinders used to make and compare measurements with dial indicators and analog and digital micrometers.

Figure 7. CMM artifact manufactured with 3 different materials employed for the dimensional measurement competency testing

NCSL International Workshop & Symposium | Metrology in Motion August 26 – 29, 2019 | Cleveland, Ohio

2019 NCSL International Workshop & Symposium: Metrology in Motion Huntington Convention Center, Cleveland, OH, August 24 – 29, 2019

Participants are required to complete the dimensions in Table 2 first using analog tools - Vernier calipers and metric micrometers. Additionally, they’ll need to complete the table a second time using digital calipers and digital micrometers. Both tables will be assessed for accuracy compared to an answer key – basically, the work will be graded – and competency based on the performance of the participants.

The differing materials of the blocks allow participants to experience the different “feel” between the blocks and the measuring instrument. It’s difficult to properly describe the differences between materials so the best way is to simply provide artifacts for the participants to recognize this themselves. Again, this is a hands-on activity for our participants to demonstrate competency in using basic measurement tools.

The measurement tools utilized in the assessment are not specified – participants will have several tools to choose from and will be selecting the tools for the measurements. This is an attempt to assess if participants are able to choose the best tool for the desired measurement and that choice will be noted as participants complete the assessment. Correctly measuring 80% of the required measurements is required to earn the competency badge for the CMM artifact.

Figure 8. A fully dimensioned drawing of the CMM artifact used for the dimensional measurement competency testing.

NCSL International Workshop & Symposium | Metrology in Motion August 26 – 29, 2019 | Cleveland, Ohio

2019 NCSL International Workshop & Symposium: Metrology in Motion Huntington Convention Center, Cleveland, OH, August 24 – 29, 2019

Figure 9. A similar drawing of the CMM artifact with letters to designate the dimensions to be measured by the participants.

NCSL International Workshop & Symposium | Metrology in Motion August 26 – 29, 2019 | Cleveland, Ohio

2019 NCSL International Workshop & Symposium: Metrology in Motion Huntington Convention Center, Cleveland, OH, August 24 – 29, 2019

Dimension Aluminum ABS Plastic Steel

A

B

C

C Depth

D

D Depth

E

E Depth

F

F Depth

G

H

I

J

K

L

M

N

P

Q

R

S

T

Stepped Block Dimensions

Table 2. Table of dimensions to be completed by participants.

NCSL International Workshop & Symposium | Metrology in Motion August 26 – 29, 2019 | Cleveland, Ohio

2019 NCSL International Workshop & Symposium: Metrology in Motion Huntington Convention Center, Cleveland, OH, August 24 – 29, 2019

7. Competency Testing – Dial Indicators & Micrometers

The next assessment is to challenge the participants to properly organize a measurement using dial indicators with gauge blocks. Each participant is given 10 wooden blocks to measure. The format for performing and recording the measurements is identical to Figure 5 – the measurements are performed with a dial indicator, a micrometer, and a digital micrometer. Multiple out-of-service gauge block sets are provided, along with gloves, for training participants to utilize for setting the dial indicator correctly. Limited assistance is provided to allow the trainees to demonstrate competency. The worksheet in Figure 5 is completed by the trainees for each of the 10 blocks assigned. Assessments of the worksheets are performed for determining competency.

8. Conclusions

The objective of this work is to provide very specific details about a measurement training program developed jointly between Purdue Polytechnic Columbus and Cummins, Inc. in Columbus, Indiana. Various measurement tools are employed for dimensional measurements and 3-D printed parts are often utilized as measurement artifacts. Not only does the training program focus on teaching the skills to properly use the tools but also emphasizes the idea that one tool may be more appropriate for a certain type of measurement than the others. This is the beginning of understanding more about measurement and how it affects the quality of manufactured products. Other training classes are being planned which will address issues of uncertainty, calibration, and overall lab operation.