6 COMBINATION ROTARY TABLE - Grizzlycdn0.grizzly.com/manuals/g1049_m.pdf · Some dust created by...

Transcript of 6 COMBINATION ROTARY TABLE - Grizzlycdn0.grizzly.com/manuals/g1049_m.pdf · Some dust created by...

6" COMBINATION ROTARYTABLE

MODEL G1049

INSTRUCTION MANUAL

COPYRIGHT © DECEMBER 2003 BY GRIZZLY INDUSTRIAL, INC.WARNING: NO PORTION OF THIS MANUAL MAY BE REPRODUCED IN ANY SHAPE

OR FORM WITHOUT THE WRITTEN APPROVAL OF GRIZZLY INDUSTRIAL, INC.#5824 PRINTED IN TAIWAN

WARNINGSome dust created by power sanding, sawing, grind-ing, drilling, and other construction activities containschemicals known to the State of California to causecancer, birth defects or other reproductive harm.Some examples of these chemicals are:

• Lead from lead-based paints.• Crystalline silica from bricks, cement, and

other masonry products.• Arsenic and chromium from chemically treated

lumber.

Your risk from these exposures varies, depending onhow often you do this type of work. To reduce yourexposure to these chemicals: work in a well ventilatedarea, and work with approved safety equipment, suchas those dust masks that are specially designed to fil-ter out microscopic particles.

SECTION 1: SAFETY

Safety Instructions For Metalworking Machines5. KEEP CHILDREN AND VISITORS

AWAY. All children and visitors should bekept at a safe distance from work area.

6. MAKE WORK SHOP CHILD PROOF withpadlocks, master switches, or by removingstarter keys.

7. DO NOT FORCE TOOL. It will do the jobbetter and safer at the rate for which it wasdesigned.

8. USE RIGHT TOOL. DO NOT force tool orattachment to do a job for which it was notdesigned.

1. READ AND UNDERSTAND MACHINEOWNERS MANUAL FOR THIS EQUIP-MENT.

2. REMOVE ADJUSTING KEYS ANDWRENCHES. Form a habit of checking tosee that keys and adjusting wrenches areremoved from tool before turning on.

3. KEEP WORK AREA CLEAN. Clutteredareas and benches invite accidents.

4. DO NOT USE IN DANGEROUS ENVI-RONMENT. DO NOT use power tools indamp or wet locations, or where any flam-mable or noxious fumes may exist. Keepwork area well lighted.

For Your Own Safety Read InstructionManual Before Operating This Equipment

Indicates an imminently hazardous situation which, if not avoided,WILL result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided,COULD result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided,MAY result in minor or moderate injury.

This symbol is used to alert the user to useful information aboutproper operation of the equipment or property damage hazards.

The purpose of safety symbols is to attract your attention to possible hazardous conditions. Thismanual uses a series of symbols and signal words which are intended to convey the level ofimportance of the safety messages. The progression of symbols is described below. Rememberthat safety messages by themselves do not eliminate danger and are not a substitute for properaccident prevention measures.

NOTICE

G1049 6" Combination Rotary Table -1-

-2- G1049 6" Combination Rotary Table

9. USE PROPER EXTENSION CORD. Makesure your extension cord is in good condi-tion. Conductor size should be in accor-dance with the chart below. The amperagerating should be listed on the motor or toolnameplate. An undersized cord will causea drop in line voltage resulting in loss ofpower and overheating. Your extensioncord must also contain a ground wire andplug pin. Always repair or replace exten-sion cords if they become damaged.

Minimum Gauge for Extension Cords

10. WEAR PROPER APPAREL. DO NOTwear loose clothing, gloves, neckties,rings, bracelets, or other jewelry whichmay get caught in moving parts. Non-slipfootwear is recommended. Wear protec-tive hair covering to contain long hair.

11. ALWAYS USE SAFETY GLASSES.Everyday eyeglasses only have impact resis-tant lenses, they are NOT safety glasses.

12. SECURE WORK. Use properly securedclamps or vises to hold work while per-forming the machining operation.

13. DO NOT OVER-REACH. Keep properfooting and balance at all times.

14. MAINTAIN TOOLS AND MACHINERYWITH CARE. Keep tools sharp and cleanfor best and safest performance. Followinstructions for lubricating and changingaccessories.

15. USE RECOMMENDED ACCESSORIES.Consult the owner’s manual for recom-mended accessories. The use of improperaccessories may cause risk of injury.

LENGTHAMP RATING 25ft 50ft 100ft

0-6 16 16 167-10 16 16 1411-12 16 16 1413-16 14 12 1217-20 12 12 1021-30 10 10 No

Safety Instructions For Metalworking Tools16. REDUCE THE RISK OF UNINTENTION-

AL STARTING. On machines with mag-netic contact starting switches there is arisk of starting if the machine is bumped orjarred. Always disconnect from powersource before adjusting or servicing equip-ment. Make sure switch is in OFF positionbefore reconnecting.

17. CHECK DAMAGED PARTS. Before fur-ther use of the tool, a guard or other partthat is damaged should be carefullychecked to determine that it will operateproperly and perform its intended function.Check for alignment of moving parts, bind-ing of moving parts, breakage of parts,mounting, and any other conditions thatmay affect its operation. A guard or otherpart that is damaged should be properlyrepaired or replaced.

18. NEVER LEAVE MACHINE RUNNINGUNATTENDED. TURN POWER OFF. DONOT leave machine until it comes to acomplete stop.

19. SOME COOLANTS USED FOR MACHIN-ING MAY CONTAIN HAZARDOUS CHEMI-CALS. Read and understand all user infor-mation on the coolant container and pro-tect yourself accordingly.

20. NEVER OPERATE A MACHINE WHENTIRED, OR UNDER THE INFLUENCE OFDRUGS OR ALCOHOL. Full mental alert-ness is required at all times when runninga machine.

No list of safety guidelines can be com-plete. Every shop environment is different.Always consider safety first, as it applies toyour individual working conditions. Usethis and other machinery with caution andrespect. Failure to do so could result inserious personal injury, damage to equip-ment or poor work results.

G1049 6" Combination Rotary Table -3-

Grizzly Industrial, Inc. is proud to offer the ModelG1049 6" Combination Rotary Table. This rotarytable is part of Grizzly’s growing family of finemetalworking equipment. When used accordingto the guidelines stated in this manual, you canexpect years of trouble-free, enjoyable operation,and proof of Grizzly’s commitment to customersatisfaction.

We are also pleased to provide this manual forthe Model G1049 6" Combination Rotary Table. Itwas written to guide you through assembly,review safety considerations, and cover generaloperating procedures. It represents our latesteffort to produce the best documentation possi-ble.

If you have any comments or criticisms that youfeel we should address in our next printing,please write to us at:

Grizzly Industrial, Inc.C⁄O Technical Documentation

P.O. Box 2069Bellingham, WA 98227

Most important, we stand behind our machines.We have excellent regional service departmentsat your disposal should the need arise.

If you have any service questions or partsrequests, please call or write to us at the locationlisted below.

Grizzly Industrial, Inc1203 Lycoming Mall Circle

Muncy, PA 17756Phone:(570) 546-9663

Fax:(800) 438-5901E-Mail: [email protected] Site: http://www.grizzly.com

The specifications, drawings, and photographsillustrated in this manual represent the ModelG1049 as supplied when the manual was pre-pared. However, owing to Grizzly’s policy of con-tinuous improvement, changes may be made atany time with no obligation on the part of Grizzly.For your convenience, we always keep currentGrizzly manuals available on our website atwww.grizzly.com. Any updates to your machinewill be reflected in these manuals as soon as theyare complete.

If you DO NOT read thisentire manual beforeoperating the machine,you will greatly increaseyour chances of seriouspersonal injury. To pro-tect yourself, read andunderstand this entiremanual!

Commentary

SECTION 2: GENERAL INFORMATION

-4- G1049 6" Combination Rotary Table

After all the parts have been removed fromthe box, you should have:

• 6" Combination Rotary Table• Handwheel Crank Handle• Handwheel

In the event that any non-proprietary parts aremissing (e.g. nuts or washers), we would be gladto replace them, or for the sake of expediency,replacements can be obtained at your local hard-ware store.

The Model G1049 6" Combination Rotary Tablewas carefully packed when it left our warehouse.If you discover the machine is damaged after youhave signed for delivery, please immediately callCustomer Service at (570) 546-9663 for advice.

Save the containers and all packing materials forpossible inspection by the carrier or its agent.Otherwise, filing a freight claim can be difficult.

When you are completely satisfied with the con-dition of your shipment, you should inventory itsparts.

The purpose of this section is to guide youthrough the required steps to get your machineout of its packaging and into operating condition.

Wear safety glasses dur-ing the entire setupprocess!

This equipment pre-sents serious injury haz-ards to untrained users.Read through this entiremanual to become famil-iar with the controls andoperations before usingthe equipment

Piece Inventory

Unpacking

About this Section

SECTION 3: SET UP

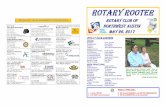

Figure 1. Piece inventory from packing box.

G1049 6" Combination Rotary Table -5-

To install your Model G1049 onto your milltable:

1. Disconnect power to the milling machinebefore installing the rotary table.

2. Position the 1/2" T-bolt slots on the rotarytable over the T-slots in the milling table.

3. Insert the T-slot nuts into the milling tablegrooves.

4. Secure the rotary table in place. It is impor-tant to secure the rotary table to the mill tablein a very strong and solid set up. This willhelp with accuracy, efficiency and generalsafety.

Note—The T-slots for the rotary table are 2"between centers. You will need to have thesame distance between centers on yourmilling table to be able to use T-nuts andbolts. If your milling table has different T-slotcenters, you will need to incorporate stepblocks or clamps to secure the rotary table.

Installation

Make sure the rotary table is secured tothe milling table. Check the T-slot clampsbefore each cutting operation. If rotarytable is not secured, serious personalinjury and damage to your mill and rotarytable could result.

Before installing the Model G1049 6"Combination Rotary Table, make sure that yourmill table and spindle are aligned correctly asdescribed in your milling machine instructionmanual.

NOTICEMake sure the rotary table handle is free ofany obstruction. Depending on your setupin the vertical or horizontal positions, therotary table may have to be blocked up ormounted so the handle is hanging over theedge of the milling table. Once making asetup, check for any possible obstructionsthat may interfere with rotary table handle.

-6- G1049 6" Combination Rotary Table

Aligning the center of the rotary table to the spin-dle is essential for achieving quality results.

There are many ways to align the Model G1049to a vertical mill spindle. It is up to the machinistand his capabilities to decide which approach isbest.

Here are a couple of ways to align the spindleaccurately to the center of the rotary table:

1. Using a test indicator, (see Models G9610,G9611 & G9612 in the current Grizzly cata-log) indicate the inside or the outside of therotary table. Position the spindle over centerof the rotary table and touch all four sides(inside or outside) until all sides read “0” onthe indicator (remember to rotate the spindleand not the rotary table). Using this proce-dure of indicating, no measuring tools areneeded.

Alignment

Figure 2. Locations for edge finding.

2. Use an edge finder, like the Model H2939, tolocate the center of the rotary table by con-tacting two outside edges (Figure 2) andthen moving the mill table half of the rotarytable diameter in both directions. Note—Make sure to account for radius of the edgefinder and use a precision measuring instru-ment when determining the diameter of therotary table.

Wear safety glasses dur-ing the entire setupprocess!

G1049 6" Combination Rotary Table -7-

NOTICEThe following section was designed to giveinstructions on the basic operations of thisequipment. However, it is in no way com-prehensive of all of the equipment applica-tions. WE STRONGLY RECOMMEND thatyou read books, trade magazines, or get for-mal training to maximize the potential ofyour equipment.

Loose hair and clothingcould get caught inmachinery and causeserious personal injury.Keep loose clothingrolled up and long hairtied up and away frommoving machinery.

Your safety is important! Please follow thewarnings below:

Table MovementOperation Safety

SECTION 4: OPERATIONS

The rotary table moves by turning the handwheelwhich engages a precision worm gear. The wormgear ratio is 1:90. One complete turn of the hand-wheel moves the table 4 degrees. The micro col-lar is graduated in steps of 1 minute and thevernier scale can be set to indicate to 20 sec-onds.

Basic Example:

You are making a flange and you need to indexsix holes for the bolt pattern:

Crank turns = 90⁄N

N = the desired division number (6).90/6 = 15 full crank turns

1. Turn the handwheel before making the firsthole to take up any play in the worm gears.

2. Make your first hole then turn the crank 15times. Note—When you are cranking to adesired number and crank too far, do not justimmediately back up to the number. Youmust back up one revolution then dial back todesired number, Then lock the table in placeto locate the second hole. This procedureeliminates backlash in the worm gear.

3. Repeat step 2 for the remaining holes.

Damage to your eyes, lungs, and ears couldresult from failure to wear safety glasses, arespirator and hearing protection whileusing this equipment. Make sure proper fil-ter is worn while wearing respirator.

Rotary TableMaintenance

Keep oiled to prevent rust. Do not use air to blowoff chips. A few drops of oil before each use willprevent excessive wear. The worm gear isgreased at the factory.

-8- G1049 6" Combination Rotary Table

1. MT#2—Used for quick setups by placing adead center into the taper and aligning cen-ters, picking up hole centers, ect and justgeneral machining operations.

2. Rotary Table Lock—Used during millingoperations to lock the table solid. This fea-ture keeps the stresses of the milling opera-tions off of the wormgear to extend the life ofthe rotary table and ensure that accuracy isnot compromised. Simply tighten the handlesto lock the table.

3. Free Wheeling—This is a convience featurewhich allows the operator to rotate the tableby hand and not having to turn the crankhandle. just loosen the lock handle (#3) androtate the adjustment ring (#6) C.W. By rotat-ing the adjustment ring, this disengages thewormgear and allows the table to rotate.

4. Vernier Scale—Allows precise rotary move-ments. The vernier scale allows graduationsof 20" seconds.

5. Gross Scale—This scale will allow youkeep track of where the rotary table is goingand where its been. The scale reads from 0˚-360˚ in one degree graduations.

Figure 3. Main view of rotary table features .

3

2

5

4

2

1

Main Features

FEATURES & CONTROLS

-9-G1049 6" Combination Rotary Table

The model G1049 comes supplied with a directreading scale marked in whole degrees along theedge of the table as well as the handwheel dialmarked with whole degrees with divisions in min-utes. Graduations of 20 seconds can be extract-ed using the vernier scale.

When the handwheel is rotated clockwise thosemarkers to the left of the “0” on the vernier scaleare used. When the handwheel is rotated coun-terclockwise those on the right hand side areused.

We will be setting the table to 16˚ 42' 20" in theexample below. This exercise assumes the tableposition starts at 0˚, as read along the edge of thetable and the “0” on the handwheel dial and the“0” on the stationary verier scale are aligned.

1. Rotate the handwheel 4 times in the clock-wise direction. Watch for the “0” marker onthe dial and slow down the rotation as the “0”comes into view the 4th time.

2. Rotate the dial clockwise 2 graduations pastthe second “10” (42˚) and align with the “0”.Be careful not to let the handwheel turn anyfurther!

It is important to understand that the graduations-between each degree on the handwheel dial aremarked in 10’s of minutes and marked as 10, 20,30, 10, 20 and then the next whole degree. To get42 minutes in our example we simply added 12to the 30 minute marker.

3. Finally, rotate the handle until the next near-est mark aligns with the 20 second mark onthe left hand side of the zero on the vernierscale. It is important the handwheel is notrotated past this point. If it is you must rotateit counterclockwise one full turn and “sneak”up on the mark again. Once satisfied with thetable postion lock it in place with the tablelocks.

Figure 4. This dial reads 0˚ 42 minutes and 20seconds.

Vernier Scale

20 sec.

42 min.

-10- G1049 6" Combination Rotary Table

Figure 9. Adjustment hex bolts

3. Align the dead center of the tailstock by loos-ening the hex bolts located on the side of thetailstock. With a precision level or indicator(depending on tolerance of work being per-formed), make the dead center parallel to thehorizontal plane and on center with rotarytable center.

Figure 7. Key placement.

Figure 8. Indicating surface.

TailstockGrizzly offers the Model G1763 Tailstock for theG1049 Rotary Table. This tailstock allows theoperator to support larger workpieces that nor-mally cannot be supported while maintaining ahigh level of accuracy. The tailstock is manage-able, easy to use and can be found in the Grizzlycatalog or at Grizzly’s website,www.grizzly.com.

To install the Model G1763 Tailstock to yourmilling table:

1. Secure the Model G1049 Rotary Table in thevertical position on the milling table.

2. Install the tailstock onto the milling table sothe dead center of the tailstock is inline withthe center of the rotary table. Slots are pro-vided for keys to help with alignment of cen-ters. The alignment of the Y and Z axes areshown in Figures 5 & 6.

Figure 6. Alignment of Z axis.

Figure 5. Alignment of Y axis.

-11- G1049 6" Combination Rotary Table

Dividing Plates

Grizzly offers the Model G1760 Dividing Platesfor this rotary table. These dividing plates can beinstalled to achieve a higher precision of holeplacement, spot facing and gear making. Thesedividing plates can be found in the Grizzly catalogor at Grizzly’s website, www.grizzly.com.

This dividing plate assembly is extremely easy touse and setup, but we recommend that you referto the Index table in the instruction sheet thatcomes with the G1760 to index complex patterns.

Piece inventory

1. 3 Dividing Plates2. Crank Handle & Index Pin3. 2 Piece Sector Arm Assembly w/Set Screw4. Sector Spring5. Allen Wrench

Figure 10. Dividing plate parts.

5

1

3

2 4

Loose hair and clothingcould get caught inmachinery and causeserious personal injury.Keep loose clothingrolled up and long hairtied up and away frommoving machinery.

Damage to your eyes, lungs, and ears couldresult from failure to wear safety glasses, arespirator and hearing protection whileusing this equipment. Make sure proper fil-ter is worn while wearing respirator.

-12- G1049 6" Combination Rotary Table

To install the Model G1760 Dividing Plate:

1. Remove the crank handle cap screw asshown in Figures 11 & 12.

2. Gently tap the crank handle off the shaft witha rubber mallet.

3. Insert the dividing plate with the holes facingout and secure it with the provided screw.

4. Place the sector arm assembly over theshaft, followed by the sector spring.

5. Install the crank handle with the indexing pinand secure it with the cap screw removed instep 1.

Figure 11. Crank handle cap screw.

Figure 12. Completed assembly with dividingplates.

G1049 6" Combination Rotary Table -13-

15

2

3

2616

17 22

18

1

23

19

27

18

17

16

2821

29

20

425

24

5

2430

6

30

13

35

12

11

14

10

349

33 8

3231

7

26

36

G1049 6" Rotary TableParts Breakdown

G1049 6" Combination Rotary Table -14-

REF PART # DESCRIPTION

1 P1049001 MAIN BODY2 P1049002 TABLE3 P1049003 WORM GEAR4 P1049004 WORM SHAFT5 P1049005 ECCENTRIC HOUSING6 P1049006 LOCK COLLAR7 P1049007 HOLDING COVER8 P1049008 ADJUSTMENT RING9 P1049009 VERNIER RING10 P1049010 MICRO COLLAR11 P1049011 HANDWHEEL12 P1049012 SMALL HANDLE13 P1049013 HANDLE14 P1049014 SPACER15 P1049015 BUSHING16 P1049016 CLAMP BOLT17 P1049017 CLAMP HANDLE18 P1049018 CLAMP

REF PART # DESCRIPTION

19 P1049019 LOCK NUT20 P1049020 LOCK HANDLE21 P1049021 POINTER22 P1049022 BEARING 30 X 45 X 20T23 P1049023 BEARING 25 X 42 X 4T24 P1049024 SPACER25 PK65M KEY 4 X 4 X 7MM 26 PSB15M CAP SCREW M5-.8 X 2027 PSB18M CAP SCREW M4-.7 X 828 P4000809 RIVET 2 X 529 PSS50M SET SCREW M4-.7 X 2030 PSS08M SET SCREW M4-.7 X 531 PSS08M SET SCREW M4-.7 X 532 PSB08M CAP SCREW M4-.7 X 1334 PSS07M SET SCREW M5-.8 X 535 PSB27M CAP SCREW M6-1. X 1436 PSS07M SET SCREW M5-.8 X 5

G1049 6" Rotary TableParts List

G1049 6" Combination Rotary Table -15-

Grizzly Industrial, Inc. warrants every product it sells for a period of 1 year to the original purchaser fromthe date of purchase. This warranty does not apply to defects due directly or indirectly to misuse, abuse,negligence, accidents, repairs or alterations or lack of maintenance. This is Grizzly’s sole written warrantyand any and all warranties that may be implied by law, including any merchantability or fitness, for any par-ticular purpose, are hereby limited to the duration of this written warranty. We do not warrant or representthat the merchandise complies with the provisions of any law or acts unless the manufacturer so warrants.In no event shall Grizzly’s liability under this warranty exceed the purchase price paid for the product andany legal actions brought against Grizzly shall be tried in the State of Washington, County of Whatcom.

We shall in no event be liable for death, injuries to persons or property or for incidental, contingent, spe-cial, or consequential damages arising from the use of our products.

To take advantage of this warranty, contact us by mail or phone and give us all the details. We will thenissue you a “Return Number,’’ which must be clearly posted on the outside as well as the inside of the car-ton. We will not accept any item back without this number. Proof of purchase must accompany the mer-chandise.

The manufacturers reserve the right to change specifications at any time because they constantly strive toachieve better quality equipment. We make every effort to ensure that our products meet high quality anddurability standards and we hope you never need to use this warranty.

Please feel free to write or call us if you have any questions about the machine or the manual.

Thank you again for your business and continued support. We hope to serve you again soon.

WARRANTY AND RETURNS

CU

T A

LON

G D

OT

TE

D L

INE

___Other__________________________________________________9. How many of your woodworking machines are Grizzly? _____________

10. Which benchtop tools do you own? Check all that apply.

___1" x 42" Belt Sander ___6" - 8" Grinder___5" - 8" Drill Press ___Mini Lathe___8" Table Saw ___10" - 12" Thickness Planer ___8" - 10" Bandsaw ___Scroll Saw___Disc⁄Belt Sander ___Spindle⁄Belt Sander___Mini Jointer___Other__________________________________________________

11. How many of the machines checked above are Grizzly? ____________

12. Which portable⁄hand held power tools do you own? Check all that apply.

___________________________________________________________

___________________________________________________________

___________________________________________________________

13. What machines⁄supplies would you like Grizzly Industrial to carry?

___________________________________________________________

___________________________________________________________

___________________________________________________________

14. What new accessories would you like Grizzly Industrial to carry?

___Builders Hardware ___Hand Tools___Fasteners ___Wood Components___Other__________________________________________________

15. What other companies do you purchase your tools and supplies from?____________________________________________________________________________________________________________________

16. Do you think your purchase represents good value?

___Yes ___No

17. Would you recommend Grizzly Industrial to a friend?

___Yes ___No

18. Would you allow us to use your name as a reference for Grizzly customersin your area? Note: We never use names more than three times.

___Yes ___No

19. Comments:__________________________________________________

__________________________________________________________

___________________________________________________________

___________________________________________________________

1. How did you learn about us?

___Advertisement ___Friend___Catalog ___Card Deck___World Wide Web

___Other__________________________________________________

2. Which of the following magazines do you subscribe to.

___American Woodworker ___Practical Homeowner___Cabinetmaker ___Shop Notes___Family Handyman ___Today’s Homeowner___Fine Homebuilding ___WOOD___Fine Woodworking ___Wooden Boat___Home Handyman ___Woodshop News___Journal of Light Construction ___Woodsmith___Old House Journal ___Woodwork___Popular Mechanics ___Woodworker___Popular Science ___Woodworker’s Journal___Popular Woodworking ___Workbench___Other__________________________________________________

3. Which of the following woodworking⁄remodeling shows do you watch?

___Backyard America ___The New Yankee Workshop___Home Time ___This Old House___The American Woodworker ___Woodwright’s Shop___Other__________________________________________________

4. What is your annual household income?

___$20,000-$29,999 ___$60,000-$69,999___$30,000-$39,999 ___$70,000-$79,999___$40,000-$49,999 ___$80,000-$89,999___$50,000-$59,999 ___$90,000 +

5. What is your age group?

___20-29 ___50-59___30-39 ___60-69___40-49 ___70 +

6. How long have you been a woodworker?

___0 - 2 Years ___8 - 20 Years___2 - 8 Years ___20+ Years

7. How would you rank your woodworking skills?

___Simple ___Advanced___Intermediate ___Master Craftsman

8. What stationary woodworking tools do you own? Check all that apply.

___Air Compressor ___Panel Saw___Band Saw ___Planer___Drill Press ___Power Feeder___Drum Sander ___Radial Arm Saw___Dust Collector ___Shaper___Horizontal Boring Machine ___Spindle Sander___Jointer ___Table Saw___Lathe ___Vacuum Veneer Press___Mortiser ___Wide Belt Sander

Name ____________________________________________________________________________________Street ____________________________________________________________________________________City ______________________________________________________________State________Zip_________Phone Number_______________________E-Mail_______________________FAX________________________MODEL: ________________________ Serial #______________________ Order _______________________

The following information is given on a voluntary basis. It will be used for marketing purposes to help us develop better products and services. Ofcourse, all information is strictly confidential.

WARRANTY CARD

TAPE ALONG EDGES--PLEASE DO NOT STAPLE

FOLD ALONG DOTTED LINE

FOLD ALONG DOTTED LINE

GRIZZLY INDUSTRIAL, INC.P.O. BOX 2069BELLINGHAM, WA 98227-2069

PlaceStampHere

Name_______________________________

Street_______________________________

City______________State______Zip______

Send a Grizzly Catalog to a friend:

Buy Direct and Save with Grizzly® – Trusted, Proven and a Great Value!

-OR-

• SECURE ORDERING

• ORDERS SHIPPED WITHIN 24 HOURS

• E-MAIL RESPONSE WITHIN ONE HOUR

Visit Our Website Today And Discover WhyGrizzly® Is The Industry Leader!

Call Today For A FREEFull Color Catalog