2291B1 3500 33 16

Transcript of 2291B1 3500 33 16

-

8/18/2019 2291B1 3500 33 16

1/52

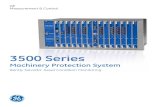

Operation and Maintenance Manual

3500/33 16-Channel Relay Module

Part Number 162291-01Rev. B (02/08)

-

8/18/2019 2291B1 3500 33 16

2/52

3500/33 16 Channel Relay Module Operation and Maintenance Manual

Copyright 2002. Bently Nevada LLC.

All rights reserved.

The information contained in this document is subject to change without notice.

The following are trademarks of General Electric Company in the United States and othercountries:

Bently Nevada

The following are trademarks of the legal entities cited:

Velostat is a trademark of 3M Company.

Contact Information

The following contact information is provided for those times when you cannot contactyour local representative:

Mailing Address 1631 Bently Parkway South

Minden, Nevada USA 89423

USATelephone 1.775.782.3611

1.800.227.5514

Fax 1.775.215.2873

Internet www.ge-energy.com/bently

ii

http://www.ge-energy.com/bentlyhttp://www.ge-energy.com/bently

-

8/18/2019 2291B1 3500 33 16

3/52

Additional Information

Notice:

This manual does not contain all the information required to operate and maintain

the product. Refer to the following manuals for other required information.

3500 Monitoring System Rack Installation and Maintenance Manual (PartNumber 129766-01)

• General description of a standard system.

• Instructions for installing and removing the module from a 3500 rack.

• Drawings for all cables used in the 3500 Monitoring System.

3500 Monitoring System Rack Configuration and Utilities Guide (PartNumber 129777-01)

• Guidelines for using the 3500 Rack Configuration software for setting theoperating parameters of the module.

• Guidelines for using the 3500 test utilities to verify that the input and outputterminals on the module are operating properly.

3500 Monitoring System Computer Hardware and Software Manual (PartNumber 128158-01)

• Instructions for connecting the rack to 3500 host computer.

• Procedures for verifying communication.

• Procedures for installing software.

• Guidelines for using Data Acquisition / DDE Server and Operator Display Software.

• Procedures and diagrams for setting up network and remote communications.

3500 Field Wiring Diagram Package (Part Number 130432-01)

• Diagrams that show how to hook up a particular transducer.

• Lists of recommended wiring.

iii

-

8/18/2019 2291B1 3500 33 16

4/52

3500/33 16 Channel Relay Module Operation and Maintenance Manual

Product Disposal Statement

Customers and third parties, who are not member states of the European Union, who arein control of the product at the end of its life or at the end of its use, are solelyresponsible for the proper disposal of the product. No person, firm, corporation,association or agency that is in control of product shall dispose of it in a manner that is

in violation of any applicable federal, state, local or international law. Bently Nevada LLCis not responsible for the disposal of the product at the end of its life or at the end of itsuse.

iv

-

8/18/2019 2291B1 3500 33 16

5/52

Contents

1. Receiving and Handling Instructions ..................................................... 1 1.1

Receiving Inspection........................................................................................................................1

1.2

Handling and Storing Considerations......................................................................................1

2. General Information.................................................................................. 3 2.1

The 16-Channel Relay Module .................................................................................................... 3

2.2

Statuses................................................................................................................................................. 7

2.2.1

Module Statuses ...................................................................................................................... 7

2.2.2

Channel Status ......................................................................................................................... 8

2.3

LED Descriptions................................................................................................................................9

3. Configuration Information ..................................................................... 11 3.1

Hardware Considerations ...........................................................................................................11

3.2

Entering Alarm Drive Logic..........................................................................................................11

3.2.1

Relay Module Configuration Considerations ............................................................12

3.2.2

Relay Module Configuration Options............................................................................12

3.3

Software Switches ..........................................................................................................................14

3.3.1

Configuration Mode .............................................................................................................15

3.3.2

Bypass........................................................................................................................................15

4. Output Module Description.................................................................... 17 4.1

16-Channel Relay Output Module............................................................................................17

4.2

Wiring Euro Style Connectors ....................................................................................................19

5. Maintenance ............................................................................................. 21 5.1

Verifying a 3500 Rack - Relay Module ...................................................................................21

5.1.1

Choosing a Maintenance Interval..................................................................................21

5.1.2

Required Test Equipment...................................................................................................22

5.1.3

Typical Verification test setup .........................................................................................22

5.1.4

Using the Rack Configuration Software......................................................................23

5.1.5

Standard Relay Channels ..................................................................................................24

5.1.6

If a Channel Fails a Verification Test.............................................................................26

5.2

16-Channel Relay Firmware Upgrade Procedure ............................................................26

6. Troubleshooting ....................................................................................... 28

v

-

8/18/2019 2291B1 3500 33 16

6/52

3500/33 16 Channel Relay Module Operation and Maintenance Manual

6.1 Self-test................................................................................................................................................28 6.2

LED Fault Conditions......................................................................................................................29

6.3 System Event List Messages ......................................................................................................30 6.4 Alarm Event List Messages .........................................................................................................41

7. Ordering Information...............................................................................42

7.1

16-Channel Relay Module ...........................................................................................................42

7.2

Spares...................................................................................................................................................42

8. Specifications.............................................................................................43 8.1

Relays ...................................................................................................................................................43

8.2

Environmental Limits.....................................................................................................................44

8.3

Mechanical.........................................................................................................................................44

8.4

Electromagnetic Compatibility..................................................................................................44

8.5

Approvals ............................................................................................................................................45

8.6

Physical ................................................................................................................................................46

8.6.1

Main Module............................................................................................................................46

8.6.2

Output Module........................................................................................................................46 8.7

Rack Space Requirements ..........................................................................................................46

vi

-

8/18/2019 2291B1 3500 33 16

7/52

Section 1 - Receiving and Handling Instructions

1. Receiving and Handling Instructions

1.1 Receiving Inspection

Visually inspect the module for obvious shipping damage. If shipping damage isapparent, file a claim with the carrier and submit a copy to Bently Nevada LLC.

1.2 Handling and Storing Considerations

Circuit boards contain devices that are susceptible to damage when exposed toelectrostatic charges. Damage caused by obvious mishandling of the board willvoid the warranty. To avoid damage, observe the following precautions in theorder given.

Application Advisory

Machinery protection will be lost whenthis module is removed from the rack.

• Do not discharge static electricity onto the circuit board. Avoid tools orprocedures that would subject the circuit board to static damage. Somepossible causes include ungrounded soldering irons, nonconductiveplastics, and similar materials.

• Personnel must be grounded with a suitable grounding strap (such as 3M

Velostat®

No. 2060) before handling or maintaining a printed circuit board.• Transport and store circuit boards in electrically conductive bags or foil.

• Use extra caution during dry weather. Relative humidity less than 30%tends to multiply the accumulation of static charges on any surface.

• When performed properly, you may install this module into or remove itfrom the rack while power is applied to the rack. Refer to the RackInstallation and Maintenance Manual (part number 129766-01) for theproper procedure.

1

-

8/18/2019 2291B1 3500 33 16

8/52

-

8/18/2019 2291B1 3500 33 16

9/52

Section 2 - General Information

2. General InformationYou can use the 16-Channel Relay Module for most monitoring applications. Themodule uses a single relay to drive the output for each channel. See Section 2.1

for additional information on the 16-Channel Relay Module.

4

5

6

7

1 2 3

NE

NDE

RELAY MODE

NDE NE

1. Relay module

2. I/O module (front view)

3. I/O module (left side view)

4. LEDs indicating the module status.

5. LEDs indicating the status of the Relay Channels.

6. Terminals for connecting relay contacts to external devices.

7. Switches that control how the relay contacts work.

Figure 2-1: Views of 16-Channel Relay Module

2.1 The 16-Channel Relay Module

The 3500/33 16-Channel Relay Module is a full-height module that provides 16

relay outputs. You can place any number of these relay modules in any of theslots to the right of the Rack Interface Module (RIM).

You can use AND and OR voting to fully program each relay output. The AlarmDrive Logic for each relay channel can use alarming inputs (Alert, Danger, Not OK,and individual channel parameters) from any monitor channel in the rack. Youprogram this Alarm Drive Logic using the Rack Configuration Software.

3

-

8/18/2019 2291B1 3500 33 16

10/52

3500/33 16 Channel Relay Module Operation and Maintenance Manual

The three common configuration types of Alarm Drive Logic are:

1) Bussed relays. Bussed relays use an Alarm Drive Logic that ORs theAlerts or Dangers for all channels in the rack to drive a single relay.

2) Individual relays. Individual relays use Alarm Drive Logic that ORs theAlerts or Dangers for channel pairs (channel 1 and channel 2 or channel

3 and channel 4) in a monitor to drive a single relay.

3) Independent relays. Independent relays use Alarm Drive Logic thatcause each alarm level (Alert and Danger) from a channel to drive aseparate relay channel.

The following examples show the drive logic for these three types of logic .

S = Monitor Slot A1 = Alert/Alarm 1

C = Channel A2 = Danger/Alarm 2

Example 1: Bussed Relays (Alert and Danger)

##A1 = Any Active Alert ##A2 = Any Active Danger

((S02C##A1) OR (S03C##A1) OR ... OR (S15C##A1)) Trip Relay Channel 1

((S02C##A2) OR (S03C##A2) OR … OR (S15C##A2)) Trip Relay Channel 2

Figure 2-2: Bussed Relays Example

4

-

8/18/2019 2291B1 3500 33 16

11/52

Section 2 - General Information

Example 2: Individual Relays (Alert and Danger)

(S02C01A1) OR (S02C02A1) Trip Relay Channel 1 (Alert Relay)

(S02C01A2) OR (S02C02A2) Trip Relay Channel 2 (Danger Relay)

(S02C03A1) OR (S02C04A1) Trip Relay Channel 3 (Alert Relay)

(S02C03A2) OR (S02C04A2) Trip Relay Channel 4 (Danger Relay)

Figure 2-3: Individual Relays Example

5

-

8/18/2019 2291B1 3500 33 16

12/52

3500/33 16 Channel Relay Module Operation and Maintenance Manual

Example 3: Independent Relays (Alert and Danger)

(S02C01A1) Trip Relay Module in slot 2 Channel 1 (Alert Relay)

(S02C02A1) Trip Relay Module in slot 2 Channel 2 (Alert Relay)

(S02C03A1) Trip Relay Module in slot 2 Channel 3 (Alert Relay)

(S02C04A1) Trip Relay Module in slot 2 Channel 4 (Alert Relay)

(S02C01A2) Trip Relay Module in slot 2 Channel 5 (Danger Relay)

(S02C02A2) Trip Relay Module in slot 2 Channel 6 (Danger Relay)

(S02C03A2) Trip Relay Module in slot 2 Channel 7 (Danger Relay)

(S02C04A2) Trip Relay Module in slot 2 Channel 8 (Danger Relay)

Independent relays require one 16-Channel Relay Modules for each monitormodule.

Figure 2-4: Independent Relays Example

6

-

8/18/2019 2291B1 3500 33 16

13/52

Section 2 - General Information

2.2 Statuses

The 16-Channel Relay Module will return both module and channel statuses. Thissection describes the available statuses and where you can find them.

2.2.1 Module Statuses

OK

This indicates if the 16-Channel Relay Module is functioning correctly. Themodule returns a Not OK status under any of the following conditions:

• Hardware Failure in the module

• Node Voltage Failure

• Configuration Failure

• Slot ID Failure

If the Module OK status goes Not OK, then the module will drive the system OKRelay on the Rack Interface I/O Module to a Not OK state.

Configuration Fault

This indicates if the 16-Channel Relay Module configuration is invalid.

Bypass

This indicates if some condition has caused the system to bypass any channelin the 16-Channel Relay Module. Any of the following conditions can cause

the system to bypass the Relay Module:• A channel has never been configured

• The Relay Module is in configuration mode

• A Fatal error was found during self-test

• Rack Alarm Inhibit has occurred

• A channel has an invalid configuration

• Any active channel is bypassed

Alarm 1 Active

This indicates that one or more channels of the 16-Channel Relay Module is inalarm.

Table 2-1 shows where the you can find the module statuses.

7

-

8/18/2019 2291B1 3500 33 16

14/52

3500/33 16 Channel Relay Module Operation and Maintenance Manual

Table 2-1: Location of Module Statuses

StatusesComm.

GatewayModule

RackConfiguration

Software

OperatorDisplay

Software

3500/94 VGADisplay

Module OK X X X

Module Configuration Fault X

Module Bypass X

Module Alert/Alarm 1 Active X X X

2.2.2 Channel Status

OK

This indicates that the associated channel of the 16-Channel Relay Modulehas detected no fault. If the Channel OK status goes not OK, then the modulewill drive the system OK Relay on the Rack Interface I/O Module to a Not OKstate.

Bypass

This indicates if some condition has caused the system to bypass theassociated 16-Channel Relay Module channel. Any of the following conditionscan cause the system to bypass the channel:

• The channel has never been configured

• The Relay Module is in configuration mode

• A Fatal error was found during self-test

• Rack Alarm Inhibit has occurred

• The channel has an invalid configuration

• The channel is bypassed using a software switch

Channel Off

This indicates if the associated 16-Channel Relay Module channel has beenturned off (not Active). You may turn off the Relay channels (inactivated) usingthe Rack Configuration Software.

Alarm 1 Active

This indicates if the associated 16-Channel Relay Module channel is in alarm.

Table 2-2 shows where the you can find the channel statuses.

8

-

8/18/2019 2291B1 3500 33 16

15/52

Section 2 - General Information

Table 2-2: Location of Channel Statuses

StatusesComm.

GatewayModule

RackConfiguration

Software

OperatorDisplay

Software

3500/94 VGADisplay

Channel OK X X X X

Channel Bypass X X X X

Channel Off X X X

Channel Alert/Alarm 1 Active X X X

2.3 LED Descriptions

The LEDs on the front panel of the 16-Channel Relay Module indicate theoperating status of the module as shown in Figure 2-5. Refer to Section 6.2 for allof the available LED conditions.

1. OK LED: Indicates that the 16-Channel Relay Module and the 16-Channel Relay Output Module are operatingcorrectly.

2. TX/RX LED: Flashes at the rate that messages are received.3. Channel Alarm LED: Indicates that an alarm condition has occurred with this relay.

Figure 2-5: 3500/33 Front Panel LEDs

9

-

8/18/2019 2291B1 3500 33 16

16/52

-

8/18/2019 2291B1 3500 33 16

17/52

Section 3 - Configuration Information

3. Configuration InformationYou configure 3500 relay modules through the 3500 Rack Configuration Software,by using the Relay Association screen to enter alarm drive logic for each relay

channel and the Software Switches screen to set software switches. This sectiondefines the options on these configuration screens. The Rack Configuration andUtilities Guide (part number 129777-01) shows how to operate those screens.

3.1 Hardware Considerations

The slots in the 3500 rack are numbered from 0 to 15, counting from left to right.The power supplies go into slot 0 and the RIM goes into slot 1. Slots 2 through 15are called “monitoring positions”. You can install the 3500/33 module into any ofthe monitoring positions. However, if you will use the 3500/20 Rack InterfaceModule and Data Manager I/O to interface to DDIX, TDIX or TDXnet, refer to the

3500/20 manual for slot restrictions that this may place on your configuration.

3.2 Entering Alarm Drive Logic

Use the Relay Association screen to define the alarm logic that will determinewhich alarms will cause the channels in the relay to drive the output.

Figure 3-1:Relay Association Screen for a 16-Channel Relay Module

11

-

8/18/2019 2291B1 3500 33 16

18/52

3500/33 16 Channel Relay Module Operation and Maintenance Manual

3.2.1 Relay Module Configuration Considerations

• Add monitor modules to the rack configuration before configuring the RelayModule.

• Activate only the Relay Module channels that will be used.

• Note that only monitor modules may be used in the alarm drive logic.

• Plan ahead to determine if you will configure any channels as channel pairs(DPDT).

• Determine whether your application will need True AND or Normal AND votinglogic.

• Consider using the Copy function if you configure several channels withsimilar logic or conditions.

• Note that prior to downloading, the configuration software will determine if

the number of instructions exceeds the limit of your relay module. Thesoftware limits the 16-Channel Relay module to 100 logical operations perchannel for each of the 16 channels.

• Note that prior to exiting the Relay Association screen, the configurationsoftware will determine if there are errors in any channel alarm drive logic.The cursor will be placed at the location of the syntax error.

3.2.2 Relay Module Configuration Options

Available Monitors

This field shows the monitors in the rack.

Rack Type

This specifies the type of RIM installed in the rack (Standard or TMR).

Config ID

This is a unique 6-character identifier that the software enters whendownloading a configuration to the 3500 rack.

Relay Slot

This indicates the location in the 3500 rack of the relay module you areconfiguring.

Active

This check box applies to the selected channel in the Channel Associationgroup. The relay channel drives the output only when this box is enabled (⌧)and the alarm drive logic for the channel is TRUE.

12

-

8/18/2019 2291B1 3500 33 16

19/52

Section 3 - Configuration Information

Latching Relays

When you select this option, the corresponding relay alarm channel will holdthe alarm state until it receives a rack reset or the relay is reconfigured.

Relay Channel Pair (DPDT)

Selecting this option will group the current channel with its channel pair, thusallowing both channels to have identical configurations and alarm logic.

Standard Relay Channel Association

This is a group for you to select the channel, or channel pair, you wish toconfigure and activate.

Relay NE/NDE Switch Status

This indicates the the relay hardware switch settings on the Relay OutputModule. This status is available only after you have uploaded the relay.

Available Monitor Channels/Alarms

When you select a monitor, this area shows all the alarms that are availablefor the relay module.

Alarm Drive Logic

This is the area in which you build the alarm drive logic using the availablemonitor alarms.

AND Voting Setup

This option determines the type of AND voting for a standard rack type.

Figure 3-2: AND Voting Setup Screen

13

-

8/18/2019 2291B1 3500 33 16

20/52

3500/33 16 Channel Relay Module Operation and Maintenance Manual

Normal AND Voting (Default)

With you select this option, if an alarming parameter is Not OK or bypassed(due to either user selection or monitor failure), then the software will removethe parameter from the relay logic. Please note that the software will notremove a “Not-OK” alarming parameter (a parameter intended to alarm on aNot-OK condition) from the alarm logic equation.

True AND Voting

True AND logic causes alarming parameters that are Not OK or bypassed toremain in the relay logic. True AND logic will not drive an alarm if an alarmingparameter being ANDed is

• Not OK (parameters are not intended to alarm on a Not-OKcondition), or

• in bypass.

Application Advisory

Take care when selecting the AND voting to be used. Youshould consider the configuration settings for the channel youintend to use as an alarm parameter. Not OK Channel Defeat(single channel measurements), Not OK Channel Pair Defeat(paired channel measurements), Timed OK Channel Defeatand Latching vs. Non-Latching Not OK modes all affect the

circumstances that cause a channel to be "Not OK" orbypassed.

Note in particular that the following channel types have special scenarios thatyou must consider:

Thrust Position: Monitor reports an Alarm (not a "Not OK" condition) to the relaymodule for a transducer not OK.

Overspeed, Zero-Speed, Rotor Speed:

These channel types have optional "OK Voltage Checks" that willdetermine if the monitor will or will not report a Not OK status tothe relay module due to a transducer voltage error.

Eccentricity: "Direct Channel Above 600 RPM" affects bypass and Not OKstatus.

3.3 Software Switches

Software switches for relay modules let you temporarily bypass or inhibit therelay module and channel functions. Set these switches on the SoftwareSwitches screen under the Utilities Option on the main screen of the Rack

14

-

8/18/2019 2291B1 3500 33 16

21/52

Section 3 - Configuration Information

Configuration Software. Switch settings take affect only after you press the Set button.

3.3.1 Configuration Mode

This module software switch allows you to configure the 16-Channel RelayModule (see Figure 3-3).

Module Switch Number Switch Name

1 Configuration Mode

Figure 3-3: Module Software Switches Screen

To configure a relay module, enable (⌧) this switch and set the key switch on thefront of the RIM to the PROGRAM position. When downloading a configurationfrom the Rack Configuration Software, this switch will automatically be enabledand disabled by the Rack Configuration Software. If the connection to the rack islost during the configuration process, use this switch to remove the module fromConfiguration Mode.

The module switch number is used in the Communication Gateway Module.

3.3.2 Bypass

When enabled (⌧), the channel will be turned off and not allow alarming (seeFigure 3-4).

Channel Switch Number Switch Name

4 Bypass

15

-

8/18/2019 2291B1 3500 33 16

22/52

3500/33 16 Channel Relay Module Operation and Maintenance Manual

Figure 3-4: Channel Software Switches Screen

The channel switch number is used in the Communication Gateway Module.

16

-

8/18/2019 2291B1 3500 33 16

23/52

Section 4 - Output Module Description

4. Output Module Description

This section describes the output module that is associated with the 16-ChannelRelay Module. This section also describes how to use the connectors on the Relay

Output Module and describes where to install each Output module.

4.1 16-Channel Relay Output Module

The 16-Channel Relay Output Module contains 16 sets of relay contacts (1 set foreach channel). You can set up the module so that each channel (in groups of 4channels) is Normally Energized or Normally De-energized. You must install the16-Channel Relay Output Module behind the 16-Channel Relay Module (in a RackMount or a Panel Mount rack) or above the 16-Channel Relay Module (in aBulkhead rack).

NE

NDE

RELAY MODE

NDE NE

3

4

1 2

1. I/O module (front view)2. I/O module (left side view)

3. Terminals for connecting to the single-pole, double-throw (SPDT) relays.

4. DIP switches for configuring the relays for Normally Energized (NE) or Normally De-Energized (NDE) operation. Thenumbers refer to relay channel groups. For example, CH1-4 corresponds to relay channels 1 through 4.

Figure 4-1: 16-Channel Relay Output Module

17

-

8/18/2019 2291B1 3500 33 16

24/52

3500/33 16 Channel Relay Module Operation and Maintenance Manual

1

2

3

1. Screwdriver

2. Module cover

3. DIP Switch

Figure 4-2: Configuring the Normally Energized and Normally De-Energized Relays

CAUTION

The output module can carry high voltageswhile installed in the rack with power applied to

the rack. High voltages can shock or burnservice personnel and damage the output

module during the relay configuration process.Remove power from the rack and remove theoutput module from rack before attempting to

configure the relays.

NOTE

Relay contacts are marked NC (Normally

Closed), NO (Normally Open), and ARM(Armature). NC and NO define the stateof the relay contacts with no power

applied to the relay coil (de-energized,non-alarm state).

18

-

8/18/2019 2291B1 3500 33 16

25/52

Section 4 - Output Module Description

1

2

3

1. No Power/ No Alarm (shelf state)

2. With Power/ No Alarm

3. With Power/ In Alarm

Figure 4-3: Normally Energized (NE) Relay States

2

3

1

1. No Power/ No Alarm (shelf state)

2. With Power/ No Alarm 3. With Power/ In Alarm

Figure 4-4: Normally De-Energized (NDE) Relay States

4.2 Wiring Euro Style Connectors

To remove a terminal block from its base, loosen the screws attaching theterminal block to the base, grip the block firmly and pull, as shown in Figure 4-5. Do not pull the block out by its wires because this could loosen or damage thewires or connector.

19

-

8/18/2019 2291B1 3500 33 16

26/52

3500/33 16 Channel Relay Module Operation and Maintenance Manual

Figure 4-5: Removing Terminal Block From a Typical 3500 Output Module

DANGER

High voltage may be present on the relaycontacts or relay wiring. High voltage

can result in shock, burns, or death. Useproper isolation techniques and removeall power when working with the relays.

Refer to the 3500 Field Wiring Diagram Package for the recommended wiring.

Do not remove more than 6 mm (0.25 in) of insulation from the wires.

Figure 4-6: Connnecting Wire to Relay Terminal Block

20

-

8/18/2019 2291B1 3500 33 16

27/52

Section 5 - Maintenance

5. MaintenanceYou cannot repair the boards and components inside of 3500 modules in the field.3500 rack maintenance consists of testing module channels to verify that they

are operating correctly. You should replace modules that are not operatingcorrectly with a spare.

When performed properly, you may install the main module into or remove themodoule from the rack while power is applied to the rack. You should install orremove the relay output module only after removing the power to the rack. Referto the Rack Installation and Maintenance Manual (part number 129766-01) for theproper procedure.

This section shows how to verify the operation of the 3500/33 16-Channel RelayModule.

5.1 Verifying a 3500 Rack - Relay ModuleThe 3500 Monitoring System is a high precision instrument that requires nocalibration. You must, however, verify the functions of Relay Module channels atregular intervals. At each maintenance interval, we recommend that you use theprocedures in this section to verify the operation of all active channels in theRelay Module.

Section

Number

Topic Page

Number

5.1.1 Choosing a Maintenance Interval 21

5.1.2 Required Test Equipment 22

5.1.3 Typical Verification Test Setup 22

5.1.4 Using the Rack Configuration Software 23

5.1.5 Standard Relay Channels 24

5.1.1 Choosing a Maintenance Interval

Use the following approach to choose a maintenance interval:

• Start with an interval of one year and then shorten the interval if either ofthe following conditions apply:

- The monitored machine is classified as critical.

21

-

8/18/2019 2291B1 3500 33 16

28/52

3500/33 16 Channel Relay Module Operation and Maintenance Manual

- The 3500 rack is operating in a harsh environment, such as inextreme temperature, high humidity, or in a corrosive atmosphere.

• At each interval, use the results of the previous verifications and ISOProcedure 10012-1 1992(E) to adjust the interval.

5.1.2 Required Test Equipment

The test equipment you will need to simulate the inputs for the relay channel willdepend on the type of monitor providing inputs to the Relay Alarm Drive Logic.You can identify this equipment under “Required Test Equipment” in theMaintenance section of the specific monitor manual.

5.1.3 Typical Verification test setup

The following figure shows the typical test setup for verifying a Relay Module. Thetest equipment is used to simulate the transducer signal to selected monitors andthe laptop computer is used to observe the output from the rack.

1. 3500 Rack

2. Test Equipment

3. RS-232 communications

4. Laptop Computer

Figure 5-1: Typical Test Setup

You can connect transducers to a 3500 rack in a number of ways. Depending onthe wiring option for the I/O module of your monitor, connect the test equipmentto the Monitor Module and Relay Module using one of the following methods:

22

-

8/18/2019 2291B1 3500 33 16

29/52

Section 5 - Maintenance

1. Connect test equipment here.

2. Inputs

3. Monitor I/O Module (Internal Termination)

4. External Termination Block (Euro Style Connectors)

5. External Termination Block (Terminal Strip Connectors)

Figure 5-2: Test Setup Wiring Methods

1. Outputs

Figure 5-3: 16-Channel Relay Output Module

5.1.4 Using the Rack Configuration Software

The laptop computer that is part of the test setup uses the Rack ConfigurationSoftware to display output from the rack and to reset certain operating

23

-

8/18/2019 2291B1 3500 33 16

30/52

3500/33 16 Channel Relay Module Operation and Maintenance Manual

parameters in the rack. To perform the test procedures in this section you mustbe familiar with the following features of the Rack Configuration Software to

• upload and save configuration files

• display the Verification screen

The Rack Configuration and Test Utilities Guide (part number 129777-01) explainshow to perform these operations.

NOTE

Save the original rack configurationbefore doing any maintenance or

troubleshooting procedures.

The Verification screen displays relay channel output from a 3500 rack as shownin Figure 5-4. Information such as Alarm Drive Logic, Channel Alarm State andChannel OK State are used to verify relay channels.

Figure 5-4: 3500 Rack Configuration Software Verification Screen

5.1.5 Standard Relay Channels

Verify relay channels by forcing alarms from the monitors that provide inputs forthe Relay Alarm Drive Logic. When the logic is true, the Channel Alarm State willchange to Alarm on the Verification screen and the alarm relay and front panelLED for that channel will change state. Verify only those channels that are activeand configured.

To verify that a 16-Channel Relay channel is working correctly.

24

-

8/18/2019 2291B1 3500 33 16

31/52

Section 5 - Maintenance

1. Run the Rack Configuration Software on the test computer.

2. Choose Verification from the Utilities menu. A screen prompting for theslot and channel number of the relay to be tested will appear.

3. Choose the proper Slot number and Channel number and then click on theVerify button. The Verification screen will appear.

4. Verify that the Channel OK State status on the Relay Verification screenreads OK.

5. Use the Relay Verification screen to determine what inputs must besimulated.

6. Simulate the required Alarm Drive Logic inputs to cause the relay tochange states.

For example, for a 3500 Rack with the following configuration:

Slot Number Module Type

1 Rack Interface Module

2 3500/42 – 4 Channel Monitor

3 3500/42 – 4 Channel Monitor

4 3500/42 - 4 Channel Monitor

5 3500/33 - 16-Channel Relay

and a relay channel with the following Alarm Drive Logic:

( S02C01A1 * S03C01A1 ) + S04C01A2send test signals to the monitors in the rack to cause Slot 2 Channel 1 ANDSlot 3 Channel 1 to be in Alert OR cause Slot 4 Channel 1 to be in Danger.

7. Verify that the Channel Alarm State status on the Relay Verification screenchanges to Alarm. Verify that the relay contacts change state and thefront panel LED illuminates.

8. If the Relay channel does not respond correctly, check the inputs to ensurethey meet the Alarm Drive Logic requirements. If the module still does notmeet specifications, go to Section 5.1.6 (If a Channel Fails a Verification

Test).

9. Select the next channel to be tested by using the Channel drop down liston the Verification screen. Repeat steps 4 through 8 to test the next relaychannel.

25

-

8/18/2019 2291B1 3500 33 16

32/52

3500/33 16 Channel Relay Module Operation and Maintenance Manual

5.1.6 If a Channel Fails a Verification Test

When handling or replacing circuit boards always be sure to adequately protectagainst damage from Electrostatic Discharge (ESD). Always wear a proper wriststrap and work on a grounded, conductive work surface.

1. Use the Rack Configuration Software to save the configuration for the

module.

2. Replace the module with a spare. Refer to the installation section in the3500 Monitoring System Rack Installation and Maintenance Manual (partnumber 129766-01).

3. Return the faulty module to Bently Nevada LLC for repair.

4. Use the Rack Configuration Software to download the configuration forthe spare module.

5. Verify the operation of the spare.

5.2 16-Channel Relay Firmware Upgrade Procedure

Occasionally you may need to upgrade the original firmware that ships with the3500/33 16-Channel Relay Module. The following instructions describe how toupgrade the existing firmware using the 3500 Configuration software. You mustuse the 3500 Rack Configuration Software to reconfigure the module afterupgrading its firmware.

Application Advisory

During the following procedure youmust not not interrupt power to the rack

or remove the monitor that you areupgrading from the rack. Either of thse

events may cause the monitor tobecome inoperable.

1. Start the 3500 Configuration software and connect to the rack.

2. Upload and save the current configuration of the monitor, the upgradeprocess will erase any configuration in the monitor.

3. Under the Utilities menu option select Upgrade Firmware.

26

-

8/18/2019 2291B1 3500 33 16

33/52

Section 5 - Maintenance

4. Select the module you wish to update and click on the OK button.

5. The software will request you to download the file. Select the file and clickon the Open button.

6. The software will now download the file.

7. After the download completes, reload the configuration to the monitor. Ifthe process fails (simultaneous flashing alarm LEDs), depending on thefailure mode, the module may revert to its old code. See Section 6.2, “LEDFault Conditions” for an explanation of the failure mode. Under no

circumstances should you remove the module until it the downloadprocess finishes.

27

-

8/18/2019 2291B1 3500 33 16

34/52

3500/33 16 Channel Relay Module Operation and Maintenance Manual

6. TroubleshootingThis section describes how to use the module self-test, the LEDs, and SystemEvent List to troubleshoot a problem with the 16-Channel Relay Module or the

Output module.

6.1 Self-test

To perform a self-test:

1. Connect a computer running the Rack Configuration Software to the 3500rack (if needed).

2. Select Utilities from the main screen of the Rack Configuration Software.

3. Select System Events/Module Self-test from the Utilities menu.

4. Press the Module Self-test button on the System Events screen.

Application Advisory

Machinery protection will be lost whilethe module performs its self-test.

5. Select the slot that contains the relay module and press the OK button.The relay module will perform a full self-test and the software will displaythe System Events screen. Note that the list will not contain the results ofthe self-test.

6. Wait 30 seconds for the module to run a full self-test.

7. Press the Latest Events button. The software will update the SystemEvents screen to include results of the self-test.

8. Verify if the relay module passed self-test. If the module failed the self test,

refer to Section 6.3.

28

-

8/18/2019 2291B1 3500 33 16

35/52

Section 6 - Troubleshooting

6.2 LED Fault Conditions

The following table shows how to use the LEDs to diagnose and correct problemswith the 16-Channel Relay Module.

Table 6-1: OK and TX/RX LED Fault Condition Diagnostics

OK LED TX/RX Condition Solution

1 Hz 1 Hz Relay Module is not configured. Reconfigure the Relay Module.

5 HzNot

applicable

Relay Module or the Relay OutputModule has detected an internalfault and are not OK.

Check the System Event List.

ON FlashingRelay Module and the Relay OutputModule are operating correctly.

No action is required.

OFFNot

applicableRelay Module is not operatingcorrectly.

Replace the Relay Module.

Notapplicable

Notflashing

Relay Module is not

communicating correctly or theRelay Module is not associated withany monitors in the rack that arecommunicating.

Check the System Event List orconfigure the alarm logic of at leastone active relay channel.

Table 6-2: Alarm LED Fault Condition Diagnostics

Alarm LED Condition Solution

ON Channel is in Alarm. No action is required.

OFF Channel is not in Alarm. No action is required.

All LEDs Flashing (5flashes in 3 seconds) Failed firmware download dueto a recoverable error. Re-attempt firmware download.

All LEDs Flashing at (5flashes in 5 seconds)

Failed firmware download dueto a non-recoverable error.

Replace the relay module with a spare.Return the relay module to a BentlyNevada service center for repair.

29

-

8/18/2019 2291B1 3500 33 16

36/52

3500/33 16 Channel Relay Module Operation and Maintenance Manual

6.3 System Event List Messages

This section describes the System Event List Messages that are entered by the16-Channel Relay Module. Table 6-3 is an example of a System Event ListMessage.

Table 6-3: Example of a System Event List Message

SequenceNumber

EventInformation

EventNumber

ClassEvent Date(DDMMYY)

Event TimeEvent

SpecificSlot

0000000123EEPROM Memory

Failure13 1 02/01/90 12:24:31:99 5

Sequence Number: This is the number of the event in the System Event List (forexample 123).

Event Information: This provides the name of the event (for example EEPROMMemory Failure).

Event Number: This identifies the specific event that occurred.

Class: This indicates the severity of the event. The followingclasses are available:

Table 6-4: System Event List Classes

Class Value Classification

0 Severe/fatal event

1 Potential problem event

2 Typical logged event

3 Reserved

Event Date: This specifies the date that the event occurred.

Event Time: This specifies the time that the event occurred.

Event Specific: Provides additional information for the events that use thisfield.

Slot: This identifies the module with which the event isassociated. If the module is a half-height module in theupper slot or a full-height module, this field will be 0 to 15. Ifthe module is a half-height module in the lower slot thenthis field will be 0L to 15L. For example, this field wouldidentify a half-height module in the lower position of slot 5as 5L.

30

-

8/18/2019 2291B1 3500 33 16

37/52

Section 6 - Troubleshooting

The 16-Channel Relay module may place following System Event List Messages,which are listed in numerical order. Events marked with a star (*)will not driverelays on the 16-Channel Relay Output Module. If you are unable to solve anyproblems contact your nearest Bently Nevada LLC office.

Flash Memory Failure

Event Number: 11

Event Classification: Potential Problem

Action: Replace the Relay Module as soon as possible.

* Internal Network Failure

Event Number: 30

Event Classification: Severe/Fatal Event

Action: Replace the Relay Module immediately.

Resync Internal Network

Event Number: 31

Event Classification: Severe/Fatal Event

Action: Replace the Relay Module immediately.

Device Not Communicating

Event Number: 32

Event Classification: Potential ProblemAction: Determine whether one of the following components is faulty:

• the Relay Module

• the rack backplane

Device Is Communicating

Event Number: 33

Event Classification: Potential Problem

Action: Determine whether one of the following components is faulty:

• the Relay Module

• the rack backplane

31

-

8/18/2019 2291B1 3500 33 16

38/52

3500/33 16 Channel Relay Module Operation and Maintenance Manual

Fail Relay Coil Sense

Event Number: 55

Event Classification: Potential Problem

Action: Verify that the Relay Output Module is installed. If installed,

determine whether one of the following components is faulty:• the Relay Module

• the Relay Output Module

Pass Relay Coil Sense

Event Number: 56

Event Classification: Potential Problem

Action: Determine whether one of the following components is faulty:

• the Relay Module

• the Relay Output Module

I/O Module Mismatch

Event Number: 62

Event Classification: Potential Problem

Action: Determine whether one of the following components is faulty:

• the Relay Module

• the Relay Output Module

I/O Module Compatible

Event Number: 63

Event Classification: Potential Problem

Action: Determine whether one of the following components is faulty:

• the Relay Module

• the Relay Output Module

Fail I/O Jumper Check (Fail read I/O module ID)

Event Number: 64

32

-

8/18/2019 2291B1 3500 33 16

39/52

Section 6 - Troubleshooting

Event Classification: Potential Problem

Action: Determine whether one of the following components is faulty:

• the Relay Module

• the Relay Output Module

Pass I/O Jumper Check (Pass read I/O module ID)

Event Number: 65

Event Classification: Potential Problem

Action: Determine whether one of the following components is faulty:

• the Relay Module

• the Relay Output Module

Fail Main Board +5V-A (Fail Main Board +5V - upper Power Supply)

Event Number: 100

Event Classification: Potential Problem

Action: Verify that noise from the power source is not causing the problem.If the problem is not caused by noise, Determine whether one ofthe following components is faulty:

• the Relay Module

• the Power Supply installed in the upper slot

Pass Main Board +5V-A (Pass Main Board +5V - upper Power Supply)

Event Number: 101

Event Classification: Potential Problem

Action: Verify that noise from the power source is not causing the problem.If the problem is not caused by noise, determine whether one of thefollowing components is faulty:

• the Relay Module

• the Power Supply installed in the upper slot

Fail Main Board +5V-B (Fail Main Board +5V - lower Power Supply)

Event Number: 102

33

-

8/18/2019 2291B1 3500 33 16

40/52

3500/33 16 Channel Relay Module Operation and Maintenance Manual

Event Classification: Potential Problem

Action: Verify that noise from the power source is not causing the problem.If the problem is not caused by noise, determine whether one of thefollowing components is faulty:

• the Relay Module

• the Power Supply installed in the lower slot

Pass Main Board +5V-B (Pass Main Board +5V - lower Power Supply)

Event Number: 103

Event Classification: Potential Problem

Action: Verify that noise from the power source is not causing the problem.If the problem is not caused by noise, determine whether one of thefollowing components is faulty:

• the Relay Module

• the Power Supply installed in the lower slot

* Fail Main Board +5V-AB (Fail Main Board +5V - upper and lower PowerSupplies)

Event Number: 104

Event Classification: Severe / Fatal Event

Action: Verify that noise from the power source is not causing the problem.If the problem is not caused by noise, determine whether one of thefollowing components is faulty:

• the Relay Module

• the Power Supply installed in the lower slot

• the Power Supply installed in the upper slot

Pass Main Board +5V-AB (Pass Man Board +5V - upper and lower PowerSupplies)

Event Number: 105

Event Classification: Severe / Fatal Event

Action: Verify that noise from the power source is not causing the problem.If the problem is not caused by noise, determine whether one of thefollowing components is faulty:

34

-

8/18/2019 2291B1 3500 33 16

41/52

Section 6 - Troubleshooting

• the Relay Module

• the Power Supply installed in the lower slot

• the Power Supply installed in the upper slot

* Fail Main Board +3.3V (Fail Main Board +3.3V Supply)

Event Number: 162

Event Classification: Severe / Fatal Event

Action: Verify that noise from the power source is not causing theproblem. If the problem is not caused by noise, determine whetherone of the following components is faulty:

• the Relay Module

• the Power Supply installed in the lower slot

• the Power Supply installed in the upper slot

Pass Main Board +3.3V (Pass Man Board +3.3V Supply)

Event Number: 163

Event Classification: Severe / Fatal Event

Action: Verify that noise from the power source is not causing the problem.If the problem is not caused by noise, determine whether one of thefollowing components is faulty:

• the Relay Module

• the Power Supply installed in the lower slot

• the Power Supply installed in the upper slot

Device Configured

Event Number: 300

Event Classification: Typical logged event

Action: No action required.

* Configuration Failure

Event Number: 301

Event Classification: Severe/Fatal Event

35

-

8/18/2019 2291B1 3500 33 16

42/52

3500/33 16 Channel Relay Module Operation and Maintenance Manual

Action: Replace the Relay Module immediately.

Configuration Failure

Event Number: 301

Event Classification: Potential Problem

Action: Download a new configuration to the Relay Module. If the problemstill exists, replace the Relay Module as soon as possible.

* Module Entered Cfig Mode

Event Number: 305

Event Classification: Typical logged event

Action: No action required.

Software Switches Reset

Event Number: 305

Event Classification: Potential Problem

Action: Download the software switches to the Relay Module. If thesoftware switches are not correct. replace the Relay Module assoon as possible.

Fail I/O Board +5V-AB (Fail OUTPUT Board +14V Supply)

Event Number: 390

Event Classification: Potential Problem

Action: Verify that noise from the power source is not causing the problem.If the problem is not caused by noise, determine whether one of thefollowing components is faulty:

• the Relay OUTPUT Module

• the Relay Module

• the Power Supply installed in the lower slot

• the Power Supply installed in the upper slot

Pass I/O Board +5V-AB (Pass OUTPUT Board +14V Supply)

Event Number: 391

Event Classification: Potential Problem

36

-

8/18/2019 2291B1 3500 33 16

43/52

Section 6 - Troubleshooting

Action: Verify that noise from the power source is not causing the problem.If the problem is not caused by noise, determine whether one of thefollowing components is faulty:

• the Relay Output Module

• the Relay Module

• the Power Supply installed in the lower slot

• the Power Supply installed in the upper slot

Fail I/O Board +14V-AB (Fail OUTPUT Board +14V Supply)

Event Number: 396

Event Classification: Potential Problem

Action: Verify that noise from the power source is not causing the problem.If the problem is not caused by noise, determine whether one of the

following components is faulty:

• the Relay OUTPUT Module

• the Relay Module

• the Power Supply installed in the lower slot

• the Power Supply installed in the upper slot

Pass I/O Board +14V-AB (Pass OUTPUT Board +14V Supply)

Event Number: 397

Event Classification: Potential Problem

Action: Verify that noise from the power source is not causing the problem.If the problem is not caused by noise, determine whether one of thefollowing components is faulty:

• the Relay Output Module

• the Relay Module

• the Power Supply installed in the lower slot

• the Power Supply installed in the upper slot

Fail I/O Module DIP Sw (Fail Output Module DIP switch)

Event Number: 398

37

-

8/18/2019 2291B1 3500 33 16

44/52

3500/33 16 Channel Relay Module Operation and Maintenance Manual

Event Classification: Potential Problem

Action: Verify that the Relay Output Module is installed. If the Relay OutputModule is installed, replace the Relay Output Module as soon aspossible.

I/O Module Detect Fault (Pass Output Module DIP switch – there was a

detected fault that is no longer present)

Event Number: 399

Event Classification: Potential Problem

Action: Verify that the Relay Output Module is installed. If the Relay OutputModule is installed, replace the Relay Output Module as soon aspossible.

Pass Module Self-test

Event Number: 410

Event Classification: Typical Logged Event

Action: No action required.

Enabled Ch Bypass (Enabled Channel Bypass)

Event Number: 416

Event Classification: Typical logged event

Event Specific: Ch x

Action: No action required.Disabled Ch Bypass (Disabled Channel Bypass)

Event Number: 417

Event Classification: Typical logged event

Event Specific: Ch x

Action: No action required.

Invalid Alm Drive Logic (Invalid Alarm Drive Logic)

Event Number: 451

Event Classification: Severe/Fatal Event

38

-

8/18/2019 2291B1 3500 33 16

45/52

Section 6 - Troubleshooting

Action: Download a new configuration to the Relay Module. If the problemstill exists, replace the Relay Module as soon as possible.

Fail Slot Id Test

Event Number: 461

Event Classification: Severe/Fatal EventAction: Verify that the Relay Module is fully inserted in the rack. If the Relay

Module is installed correctly, determine whether one of thefollowing components is faulty:

• the Relay Module

• the rack backplane

Pass Slot Id Test

Event Number: 462

Event Classification: Severe/Fatal Event

Action: Verify that the Relay Module is fully inserted in the rack. If the RelayModule is installed correctly, determine whether one of thefollowing components is faulty:

• the Relay Module

• the rack backplane

Fail I/O Board +15V-A (Fail Output Board +15V - upper Power Supply)

Event Number: 554

Event Classification: Potential Problem

Action: Verify that noise from the power source is not causing the problem.If the problem is not caused by noise, determine whether one of thefollowing components is faulty:

• the Relay Output Module

• the Relay Module

•

the Power Supply installed in the upper slotPass I/O Board +15V-A (Pass Output Board +15V - upper Power Supply)

Event Number: 555

Event Classification: Potential Problem

39

-

8/18/2019 2291B1 3500 33 16

46/52

3500/33 16 Channel Relay Module Operation and Maintenance Manual

Action: Verify that noise from the power source is not causing the problem.If the problem is not caused by noise, determine whether one of thefollowing components is faulty:

• the Relay Output Module

• the Relay Module

• the Power Supply installed in the upper slot

Fail I/O Board +15V-B (Fail Output Board +15V - lower Power Supply)

Event Number: 556

Event Classification: Potential Problem

Action: Verify that noise from the power source is not causing the problem.If the problem is not caused by noise, determine whether one of thefollowing components is faulty:

• the Relay Output Module

• the Relay Module

• the Power Supply installed in the lower slot

Pass I/O Board +15V-B (Pass OUTPUT Board +15V - lower Power Supply)

Event Number: 557

Event Classification: Potential Problem

Action: Verify that noise from the power source is not causing the problem.

If the problem is not caused by noise, determine whether one of thefollowing components is faulty:

• the Relay OUTPUT Module

• the Relay Module

• the Power Supply installed in the lower slot

Fail I/O Board +15V-AB (Fail OUTPUT Board +15V - upper and lower PowerSupplies)

Event Number: 558Event Classification: Potential Problem

40

-

8/18/2019 2291B1 3500 33 16

47/52

Section 6 - Troubleshooting

Action: Verify that noise from the power source is not causing the problem.If the problem is not caused by noise, determine whether one of thefollowing components is faulty:

• the Relay OUTPUT Module

• the Relay Module

• the Power Supply installed in the lower slot

• the Power Supply installed in the upper slot

Pass I/O Board +15V-AB (Pass Output Board +15V - upper and lower PowerSupplies)

Event Number: 559

Event Classification: Potential Problem

Action: Verify that noise from the power source is not causing the problem.

If the problem is not caused by noise determine whether one of thefollowing components is faulty:

• the Relay Output Module

• the Relay Module

• the Power Supply installed in the lower slot

• the Power Supply installed in the upper slot

6.4 Alarm Event List Messages

The 16-Channel Relay Module may place the following messages in the AlarmEvent List.

Table 6-5: Alarm Event List Messages and Their Causes

Alarm Event List Message When the message will occur

Entered Not OK Module went Not OK

Left Not OK Module returned to the OK state

Relay Activated Condition for driving the relay channel met

Relay Deactivated Condition for driving the relay channel no longer met

41

-

8/18/2019 2291B1 3500 33 16

48/52

3500/33 16 Channel Relay Module Operation and Maintenance Manual

7. Ordering InformationThis section contains the ordering information for the 3500/33 16-Channel RelayModule.

7.1 16-Channel Relay ModulePart number 3500/33- AXX - BXX

A: Output Module

0 1 16-Channel Relay Output Module

B: Agency Approval Option

0 0 None

0 1 CSA-NRTL/C

7.2 Spares

149968

16-Channel Relay Control Module

149992-01

16-Channel Relay Output Module

00580453

Connector Header, 16-position

162291-01

3500/33 Relay Module Manual

04425545

Grounding Wrist Strap (single use only)

42

-

8/18/2019 2291B1 3500 33 16

49/52

Section 8 - Specifications

8. SpecificationsThis section contains the specifications for the 3500/33 16-Channel Relay Module.

8.1 Relays

Type

Single-pole, double-throw (SPDT) relays

Environmental sealing

Epoxy-sealed

Arc suppressors

250 Vrms, installed as standard.

Contact Ratings(resistive load)

Max switched power

DC: 160 W

AC: 1500 VA

Min switchedcurrent

100 mA @ 12 Vdc

Max switchedcurrent

6 A

Max switchedvoltage

DC: 300 VdcAC: 400 Vac

Contact Life

100,000 @ 5 A, 24 Vdc or 250 Vac

43

-

8/18/2019 2291B1 3500 33 16

50/52

3500/33 16 Channel Relay Module Operation and Maintenance Manual

Operation

Groups of four channels are switch selectable forNormally De-energized or Normally Energized.

8.2 Environmental LimitsTemperature

-30 ºC to 65 ºC (-22 ºF to 150 ºF) operating

-40 ºC to 85 ºC (-40 ºC to 185 ºC) storage

Humidity

95% non-condensing

8.3 MechanicalImpact

10 g’s for 11 ms

Shipping

Per mil Std 81D – Category G Equipment

Vibration

Sinusoidal, 3 g at 5 to 100 Hz

8.4 Electromagnetic Compatibility

EN50081-2

Radiated Emissions

EN 55011, Class A

ConductedEmissions

EN 55011, Class A

44

-

8/18/2019 2291B1 3500 33 16

51/52

Section 8 - Specifications

EN50082-2

ElectrostaticDischarge

EN 61000-4-2, Criteria B

RadiatedSusceptibility

ENV 50140, Criteria A

ConductedSusceptibility

ENV 50141, Criteria A

Electrical FastTransient

EN 61000-4-4, Criteria B

Surge Capability

EN 61000-4-5, Criteria B

Magnetic Field

EN 61000-4-8, Criteria A

Power Supply Dip

EN 61000-4-11, Criteria B

Radio Telephone

ENV 50204, Criteria B

Low Voltage Directives

SafetyRequirements

EN61010-01

8.5 Approvals

CSA-NRTL/C

Class I, Division 2, Groups A through D

45

-

8/18/2019 2291B1 3500 33 16

52/52

3500/33 16 Channel Relay Module Operation and Maintenance Manual

LCIE

Zone 2

CE Mark

8.6 Physical

8.6.1 Main Module

Dimensions (Height xWidth x Depth)

241 mm x 24.4 mm x 242 mm

(9.50 in x 0.96 in x 9.52 in)

Weight

0.7 kg (1.6 lbs)

8.6.2 Output Module

Dimensions (Height xWidth x Depth)

241 mm x 24.4 mm x 99.1 mm.

(9.50 in x 0.96 in x 3.90 in)

Weight

0.4 kg (1.0 lbs)

8.7 Rack Space Requirements

Main Module

1 full-height front slot

Output Module

1 full-height rear slot