131400MANUAL - Lowe's

Transcript of 131400MANUAL - Lowe's

COMPANY

UNITED STATES STOVE

CSSU

HTBL STAOModel 1300/1400

OWNERS MANUAL

SOLID FUELWARM AIR FURNACE

CAUTION:READ ALL INSTRUCTIONS CARE-FULLY BEFORE STARTING THEINSTALLATION OR OPERATINGTHE FURNACE

IMPROPER INSTALLATION MAY VOIDYOUR WARRANTY

DO NOT USE THIS FURNACEIN A MOBILE HOME OR TRAILER

UNITED STATES STOVE COMPANY227 Industrial Park Road

P.O.Box 151South Pittsburg, TN 37380

(423) 837-2100851486 02/01

*FOR PARALLEL INSTALLATION WITH EXISTING FORCED AIR-GAS OR OIL FIRED FURNACE (U.S. ONLY)

*FOR INSTALLATION AS A CENTRAL FURNACE

*CERTIFIED UNDER ANSI/UL 391 & CAN/CSA-B366.1-M91

NOTE: YOUR UNIT MUST BE INSTALLED BY AQUALIFIED FURNACE INSTALLER.

You've purchased one of America's Finest Wood and CoalBurning Furnaces. By heating with wood and coal you'rehelping CONSERVE AMERICA'S ENERGY! Wood is ourRenewable Energy Resource. Please do your part topreserve our wood supply. Plant at least one tree each year.Future generations will thank you.

CONGRATULATIONS!

TOOLS

Pencil6 Foot Folding Rule or TapeTin SnipsDrill, Hand or ElectricDrill Bit- 1/8" Dia. (For Sheet Metal Screws)Screw Driver (Blade-Type)GlovesSabre Saw5/16" Nut Driver or 5/16" Socket w/Ratchet

MATERIAL

6" Pipe, 6" Elbow, Collar and Thimble; as required (24 gauge min.)1/2" Sheet Metal Screws6" Inside diameter Listed Residential Type or Building Heating Appliance Chimney or existing masonry chimneyElectrical Wiring6" Draft Regulator1/2" Conduit (Conduit Connectors)Furnace Cement (Manufacturer Recommends: Rutland Black-Code 78 or Equivalent)Plenum and Duct work as required.

TOOLS AND MATERIALS NEEDED

2

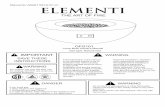

Caution LabelsYour Furnace has the following labels. Read and Obey all labels.

DANGER: RISK OF FIRE OR EXPLOSION.

DO NOT burn garbage, gasoline, drain oil, or other flammable liquids.

WARNING: FIRE HAZARD.

DO NOT operate with fire draft exceeding .06 inches w.c.

DO NOT operate with fuel loading or ash removal doors open.

DO NOT store fuels, paints, thinners, flammable liquids, or other highlyvolatile substances in the furnace room.

CAUTION: HOT SURFACES Keep children away. Do not touch during operation.

_______________________CAUTION!________________________INSPECT FLUE PIPES, FLUE PIPE JOINTS AND FLUE PIPE SEALSREGULARLY TO ENSURE THAT SMOKE AND FLUE GASES ARENOT DRAWN INTO, AND CIRCULATED BY, THE AIR CIRCULATION SYSTEM.

3

CAUTION!CLEANOUT OF THE HEAT EXCHANGER, FLUE PIPE, CHIMNEY,AND DRAFT INDUCER (IF USED), IS ESPECIALLY IMPORTANT ATTHE END OF THE HEATING SEASON TO MINIMIZE CORROSIONDURING THE SUMMER MONTHS, CAUSED BY ACCUMULATED ASH.

SAFETY NOTICE: If this heater is not properly installed, a housefire may result. For your safety, follow the installa-tion directions. Contact local building or fire offi-cials about restrictions and installation inspectionrequirements in your area.If not already installed, we recommend that smokedetectors be installed.

Rules for safe installation and operationRead these rules and the instructions carefully. Failure to follow them will cause a hazard thatcould result in death, serious bodily injury, and/or property damage.

4

Your Furnace is designed to be installed in a parallel air flow arrangement with a gas or oil-firedforced air upflow-type central furnace, or it may be installed as a central furnace.

1. Check your local codes. The installation must comply with their rulings.2. Do not install this furnace in a mobile home or trailer.

3. Always connect this furnace to a chimney and vent to the outside. Never vent to another roomor inside a building.

4. Do not connect this furnace to an aluminum Type B gas vent. This is not safe and is prohibitedby the National Fire Protection Association Code. This furnace requires a masonry or a UL/ULCListed Factory Built Chimney for residential type or Building Heating Appliance Chimney. Use a 6"diameter chimney or larger, that is high enough to give a good draft. (See page 7)

5. Be sure that if a masonry chimney is used, it is safely constructed and in good repair. Have thechimney inspected by the Fire Department or an inspector.

6. Inspect chimney connector and chimney before and frequently during the heating season for anydeposit of creosote or soot which must be removed (See Chimney Maintenance, page 18).

7. Provide air for combustion into the room where the furnace is located. If the intake is not in thesame room, air must have free access to the room.

8. CAST IRON PARTS MUST BE "SEASONED" TO AVOID CRACKING, BUILD ONLY SMALLFIRES ON FIRST USE.

9. To prevent injury, do not allow anyone to use this furnace who is unfamiliar with the correctoperation of the furnace.

10. For further information on using your furnace safely, obtain a copy of the National Fire ProtectionAssociation (NFPA) publication "Chimney's, Fireplaces and Solid Fuel Burning Appliances" NFPA211. The address of the NFPA is Batterymarch Park, Quincy, MA 02269. For more information onCanadian installation, obtain a copy of CAN/CSA-B365-M91 Installation Code for Solid-Fuel-Burning Appliances and Equipment.

11. Keep the ashpit section free of excess ashes. Do not allow ashes to stack higher than the sidesof the ash pan.

12. DISPOSAL OF ASHES- Place ashes in a metal container with a tight fitting lid. Keep the closedcontainer on a noncombustible floor or on the ground, well away from all combustible materials. Keepthe ashes in the closed container until all cinders have thoroughly cooled. The ashes may be buriedin the ground or picked up by a refuse collector.

13. CAUTION- The special paints used on your furnace may give off some smoke while they arecuring during first few fires., Build small fires at first. The metal used in construction of the furnaceand duct work has a light coating of oil. This could give off smoke and/or odor from registers whenfurnace is used for the first time. This should disappear after a short period of time. Once this burn-off has occurred, it should not reoccur.

14. CARING FOR PAINTED PARTS- This furnace has a painted outside jacket, which is durable,but it will not stand rough handling or abuse. When installing your furnace, use care in handling.Clean with soap and warm water when furnace in not hot. DO NOT use any acids or scouring soap,as these wear and dull the finish. DISCOLORATION WILL OCCUR IF THE FURNACE ISOVERHEATED. FOLLOW OPERATING INSTRUCTIONS CAREFULLY.15. Keep the feed and ash doors closed at all times except while tending the furnace.

Your HOTBLAST Furnace is designedto be a supplemental or central heating sourcefor your home. This Solid Fuel Furnace maybe installed in conjunction with a properlyoperating central furnace that is listed or cer-tified in accordance with nationally recog-nized safety standards and equipped with therequired controls and other safety featuresand which has been installed in accordancewith appropriate standards of the NationalFire Protection Association with installationclearances specified in the furnace name-plate marking. The installation must be ac-complished by a qualified agency (one who isengaged in, and is responsible for, or is thor-oughly familiar with the installation and op-eration of the gas, oil, and solid fuel burningheating appliances, who is experienced insuch work, familiar with all the requirements ofthe authority having jurisdiction.) The instal-lation shall be in strict accordance with themanufacturer's installation instructions fur-nished with the solid fuel furnace. The chimney connector of the furnace isto be installed to provide clearances to com-bustible material not less than specified in theindividual classifications and marked on thefurnace. The chimney connector must beconnected to a chimney suitable for use withresidential type or building heating applianceswhich burn solid fuel. The Furnace is designed to operate ineither parallel or series air flow arrangementwith the central furnace or as a central fur-nace.CENTRAL FURNACE INSTALLATION: Asa central furnace, the unit functions indepen-dently of any other system. The blower willcome on when the plenum temperaturereaches the setting on the blower control.

PARALLEL INSTALLATION: (U.S. ONLY)(See Optional Wiring Diagram, Page 16, Fig.15) The design is such that when the blowercomes on, the blower on the central systemalso comes on. The blower will only come onwhen the temperature in the plenum hasreached the setting on the blower control.This is to insure that there is sufficient warm airin the system to make it efficient for the unit tooperate. When the central system thermostatcalls for heat, the central system will operateby the burner igniting and the blower comingon. It is possible that both systems will operatesimultaneously. It is recommended that for themost efficient use of your HOTBLAST Fur-nace, that it be fired as much as possible inorder to reduce the demand on your existingcentral heating system. This unit has an op-tional forced draft kit that operates from a wallthermostat. When the temperature falls belowthe setting on the wall thermostat, the forceddraft will come on (U.S. Stove Option 11/DKU) The warm air supply outlet of theHOTBLAST Furnace shall not be connectedto the cold air return of the central furnace,because the possibility exists of componentsof the central furnace overheating and caus-ing the central furnace to operate other than isintended.SERIES INSTALLATION: (U.S. & CANADA)This type of installation uses only the blowersof the existing central furnace. The solid fuelfan/limit control must also control the functionsof the existing furnace. All electrical powermust come from a single branch circuit (SeeFig. 15).

HOW THE FURNACE FUNCTIONS

5

24-7/8" 1-3/4"

9"

33-7/8"

41"

21-1/32"

40-11/16"

32-1/8" 1-3/4"

9"

33-7/8"

49-1/8"

24-1/16"

40-11/16"

Figure 1A1300

Figure 1B1400/1500

DIMENSIONS OF FURNACE

6

Figure 1B1400

Figure 1A1300

Locating the Furnace

1.The furnace should be located in thesame room as the central systemand as close as possible, but notcloser than 9". There should be nowall between the furnace and thewarm air outlet duct that is connecteddirectly to the warm air outlet plenumof the central furnace. (See Fig. 2)

The unit will require installation withthe following clearances:Unit to sidewall............12"(305mm)Unit to backwall...........30"(760mm)Chimney connector pipe to sidewall.....................................18"(460mm)Chimney connector pipe to backwall.....................................18"(460mm)Hot air ducts to combustibles.......................................6"(150mm)

(Refer to Fig. 2 & 3)

Place the furnace on a noncombus-tible floor.

Check figures 2 and 3. Be sure youhave the clearances shown from thefurnace and the connector pipe tocombustible surfaces. If you have asolid brick or stone wall behind yourfurnace, you can place the furnaceas close as you wish to the wall. If thewall is only faced with brick or stone,treat it as a combustible wall.

2.

3.

4.

18"

18"

6" SOLID DAMPER

6" BAROMETRICDRAFT REGULATOR(OPTIONAL)

NON-COMBUSTIBLE FLOOR

12" 9"

48"

18"

CENTRALFURNACE

6" CHIMNEY

Figure 2

Figure 3

7

LISTED FACTORY BUILT CHIMNEYCarefully follow chimney manufacturer's instructions. Use only a Listed Residential Type orBuilding Heating Appliance Chimney. If your chimney starts at the ceiling (Fig. 5), you will needenough 6" pipe to reach the ceiling.

The top of the chimney must be at least 3 feet above the roof and be at least 2 feet higher than anypoint of the roof within 10 feet (Fig. 5).

8

10'

2' MIN.

3' MIN.

6" CHIMNEY CONNECTOR

6" ELBOW

6" SOLID DAMPER

6" BAROMETRICDRAFT REGULATOR(OPTIONAL)

REFER TO CHIMNEYMANUFACTURER'SINSTRUCTIONS ANDPARTS.

6" SOLID DAMPER

6" BAROMETRICDRAFT REGULATOR(OPTIONAL)

THIMBLE6" ELBOW

6" CHIMNEYCONNECTOR

6" ELBOW

NON-COMBUSTIBLEWALL

Chimney Connection Fig. 4MASONRY CHIMNEYBefore using an existing masonry chimney, clean the chimney and inspect the flue liner to be sureit is safe to use. Make repairs before attaching the furnace. See page 4, item 5. Look at Fig. 4.The connector pipe and fittings you will need to connect directly to a masonry chimney are shown.The chimney connection should be as short as possible.If the connector pipe must go through a combustible wall before entering the masonry chimney,consult a qualified mason or chimney dealer. The installation must conform to local fire codes, andN.F.P.A. 211.DO NOT CONNECT THIS FURNACE TO A CHIMNEY FLUE SERVING ANOTHER APPLI-ANCE.The chimney used for a furnace must not be used to ventilate the cellar or basement. If there isa cleanout opening at the base of the chimney, close it tightly.

Fig. 5

Rules for ConnectorPipe Installation1. The crimped end of the chimney connector fitsinside the furnace flue collar. Install additional chim-ney connectors and elbow with the CRIMPED ENDTOWARD THE FURNACE. This will allow anycondensation in the flue to run back into the furnace.Use 6" dia. steel pipe and elbows for connection tochimney. Never use less than 26 gauge and al-though blued steel is satisfactory, high temp paintedblack is much more desirable.2. Slope any horizontal pipe upward toward thechimney at least 1/4 inch for each foot of horizontalrun.3. You must have at least 18 inches of clearancebetween any horizontal piping and the ceiling.(See Fig. 3)4. The chimney connector must not extend into thechimney flue. (See Fig. 6)5. Seal each chimney connector pipe joint with fur-nace cement. Also seal the pipe at the chimney.6. Use 3 sheet metal screws at each chimney pipejoint to make the piping rigid.7. The chimney connector may include a section fora barometric draft regulator between the furnace andthe chimney (Fig. 4,5, &7). The barometric draftregulator must be installed in the same room (samepressure zone) as the furnace.8. Install the barometric draft regulator strictly inaccordance with the instructions that are providedwith the barometric draft regulator.9. A solid damper must be used in the chimneyconnecting pipes between the flue collar and thechimney. When used in conjunction with a baromet-ric draft regulator, the solid damper must be placedbetween the barometric and the chimney. (See Fig.4,5,7)

Adjusting the Barometric Draft Regula-tor1. Drill a hole in the chimney connector within 18" ofthe flue collar below the barometric draft regulatorjust large enough for the tube of the manometer.2. Build a fire after all chimney connections havebeen made.3. Use a manometer to measure the draft in the flue.4. Adjust the Barometric Draft Regulator to obtain adraft of 0.05 - 0.06" W.C. under stable fire conditions.

9

6" SOLID DAMPER

6" BAROMETRICDRAFT REGULATOR(OPTIONAL)

MEASURE FLUEDRAFT HERE

NON-COMBUSTIBLEINSTALLATION PERNFPA 211

Fig. 7

RIGHT WRONG WRONG

Fig. 6

NOTE:A flue pipe shall not pass through an attic,roof space, closet or similar concealed space,a floor or ceiling of combustible construc-tion. Where passage through a wall or parti-tion is desired, installation must conformwith UL standards.

CONNECTION OF CHIMNEY CONNECTOR TO A MASONRY CHIMNEY THROUGH A COMBUSTIBLE WALL

Figure 8 shows how to connect the chimney connector of a heater to a masonry chimney through a combustible wall.

There are five allowable ways that a chimney connector can be connected to a masonry chimney by passing througha combustible wall. NFPA Standard 211 allows the following wall pass-through systems.

FIGURE 8 -CONNECTION OF CHIMNEY CONNECTOR TO A MA-SONRY CHIMNEY THROUGH A COMBUSTIBLE WALL

MASONRY CHIMNEYCONSTRUCTED TONFPA 211

AIRTIGHTCLEANOUTDOOR

FLOORPROTECTOR

COMBUSTIBLE WALL

TOHEATER

CHIMNEY CONNECTOR

CEILING

SEE PARTS A, B,C, D, AND E OFTHIS FIGURE FOROPTIONS.

CH

IMN

EY

FLU

E

(FIGURE 8 CONTINUED ON NEXT PAGE)

10

MINIMUM 12 IN.TO COMBUSTIBLES

PART A, FIGURE 8(FIGURE 8 CONTINUED ON NEXT PAGE)

1. Use a minimum 3-1/2" thick brick masonry wall framed into the combustible wall. A fireclay liner (ASTM C315 orequivalent) having a 5/8" minimum wall thickness must be used and it must be at least 12" away from any materialthat could catch fire. The inside diameter of the fireclay liner shall be sized for the proper snug fit of a 6" diameterchimney connector pipe. The fireclay liner shall run from the outer surface of the brick wall to, but not beyond, theinner surface of the chimney flue and shall be firmly cemented in place. See Part A of Figure 8.

2. Use a solid insulated listed factory-built chimney length having an inside diameter of 6" and having 1" or more ofsolid insulation. There must be at least a 9" air space between the outer wall of the chimney length and anycombustible materials. The inner end of the chimney length shall be flush with the inside of the masonry chimneyflue shall be sealed to the flue and to the brick masonry penetration with nonwater-soluble refractory cement. Sheetsteel supports which are at least 24 gauge(0.024") in thickness shall be securely fastened to wallsurfaces on all sides. Fasteners between supports and the chimney length shall not penetrate the chimney liner.See Part B of Figure 8.

3. Use a 10" diameter ventilated thimble made of at least 24 gauge(0.024") steel having two 1" air channels. The venti-lated thimble must be separated from combustible materials by a minimum of 6" glass fiber insulation. The openingin the combustible wall shall be covered and the thimble supported with sheet steel supports which are at least 24gauge (0.024") in thickness. The sheet steel supports shall be securely fastened to wall surfaces on all sides andshall be sized to fit and hold the chimney section. Fasteners used to secure chimney sections shall not penetratechimney flue liner. See Part C of Figure 8.

4. Use an 8" inside diameter solid insulated listed factory-built chimney length which has 1" or more of solid insulation.The minimum length of this chimney section shall be 12" and will serve as a pass-through for the 6" diameterchimney connector. There must be at least a 12" air space between the outer wall of the chimney section and anycombustible materials. The chimney section shall be concentric with and spaced 1" away from the chimney connector by means of sheet steel support plates on both ends of the chimney section. The opening in the combustible wallshall be covered and the chimney section supported on both sides with sheet steel supports which are at least 24gauge (0.024") in thickness. The sheet steel supports shall be securely fastened to wall surfaces on all sides andshall be sized to fit and hold the chimney section. Fasteners used to secure chimney sections shall not penetratechimney flue liner. See Part C of Figure 8.

5. A listed factory-built wall pass-through system may be purchased and installed according to the instructions packaged with it to provide a safe method of passing the chimney connector through a combustible wall for connectionto a masonry chimney.

Additional requirements pertaining to Figure 8 and the above wall pass-through systems:

1. Insulation material used as part of wall pass-through system shall be of noncombustible material and shall have athermal conductivity of 1.0 Btu • in./ft.² • °F (4.88 kg • cal/hr • m² • °C) or less

2. All clearances and thicknesses are minimums: larger clearances and thickness are acceptable.3. A chimney thimble, as shown for 3" and 4" above (Parts C and D respectively of Figure 8) shall be for types "3" and

4" connections to facilitate removal of the chimney connector for cleaning. The chimney thimble shall be of ASTMC315 fireclay with 5/8" minimum wall thickness , or material or equivalent durability. The inside diameter of thethimble shall be sized for the proper snug fit of a 6" diameter chimney connector pipe. The thimble shall be installedwithout damage to the chimney flue. The thimble shall extend through the chimney wall to, but not beyond, theinner surface of the chimney flue and shall be permanently cemented in place with high temperature cement.

4. A chimney connector to a masonry chimney, except for 2" above (Part B of Figure 8), shall extend through the wallpass-through system to the inner face of the chimney flue, but not beyond. It does not have to be fastened in placeso long as it cannot accidently be pulled out of the chimney or shoved into the chimney flue. If fasteners are usedto secure the chimney connector to a masonry chimney, the fasteners shall not penetrate the chimney flue liner.

5. Any material used to close up any opening for the connector shall be noncombustible.

CH

IMN

EY

FLU

E

MINIMUM CHIMNEY CLEARANCE TOBRICK AND COMBUSTIBLES IS 2 IN.

MINIMUM CLEARANCES 12 IN.OF BRICK ALL AROUND

CHIMNEY CONNECTORTO HEATER

FIRE CLAY LINER(5/8" MIN. WALL THICKNESS)

MIN. 3-1/2" THICK BRICKMASONRY WALL

MASONRY CHIMNEYCONSTRUCTED TONFPA 211

11

PART BFIGURE 8 -(FIGURE 8 CONTINUED)

AIR SPACE9 IN. MINIMUM

FACTORY-BUILTCHIMNEY LENGTH

MINIMUM CHIMNEY CLEARANCES FROM MASONRY TOSHEET STEEL SUPPORTS AND COMBUSTIBLES 2 IN.

CHIMNEY LENGTHFLUSH WITH INSIDEOF FLUE

NONSOLUBLEREFACTORYCEMENT

MASONRY CHIMNEY CONSTRUCTEDTO NFPA 211

CHIMNEY CONNECTORTO HEATER

MINIMUM CLEARANCE9 IN. ALL AROUND

SHEET STEEL SUPPORTS(24 GAUGE MIN. THICKNESS)

CH

IMN

EY

FLU

E

SOLID INSULATED, LISTEDFACTORY-BUILT CHIMNEY LENGTH

USE CHIMNEY MFRS. PARTS TOATTACH CONNECTOR SECURELY

AIR

SPA

CE

TWO VENTILATED AIRCHANNELS EACH 1 INCH.CONSTRUCTED OFSHEET STEEL.

PART CFIGURE 8

MASONRY CHIMNEY CONSTRUCTEDTO NFPA 211

SHEET STEEL SUPPORTS(24 GAUGE MIN. THICKNESS)

MINIMUM CHIMNEY CLEARANCES FROM MASONRY TOSHEET STEEL SUPPORTS AND COMBUSTIBLES 2 IN.

MINIMUM 6 IN. GLASSFIBER INSULATION ALL AROUND

24 GAUGEVENTILATED THIMBLE WITHTWO 1 INCH AIR CHANNELSCHIMNEY THIMBLE

CH

IMN

EY

FLU

E

SHEET STEEL SUPPORTS

CHIMNEY SECTION

CHIMNEYCONNECTOR

AIR SPACE2 IN.

PART DFIGURE 8

MINIMUM CLEARANCE2 IN. ALL AROUND

CHIMNEY THIMBLE 1 IN. AIR SPACE TOCHIMNEY LENGTH

MASONRY CHIMNEY CONSTRUCTEDTO NFPA 211

SHEET STEEL SUPPORTS(24 GAUGE MIN. THICKNESS)

CH

IMN

EY

FLU

E

MINIMUM CHIMNEY CLEARANCES FROM MASONRY TOSHEET STEEL SUPPORTS AND COMBUSTIBLES 2 IN.

CONNECTION OF CHIMNEY CONNECTOR TO A MASONRY CHIMNEY WHEN CHIMNEY CONNECTORDOES NOT PASS THROUGH A COMBUSTIBLE WALL

PART E - (Figure 8)In addition to the methods shown by A, B, C, and D of Figure 8, a listed factory-built wall pass-through systemmay be purchased and installed according to the instructions packaged with it to provide a safe method ofpassing chimney connector through a combustible wall for a connection to a masonry chimney.

If the chimney connector does not have to pass through a combustible wall to get to a masonry chimney, simply connectthe chimney connector directly to the masonry chimney's chimney thimble as described and shown by parts C and D ofFigure 8. Remember, the chimney connector should extend into the chimney thimble to the innerface of the chimney fluebut not beyond; if the chimney connector is extended through the chimney thimble into the chimney flue, resistance to theflow of smoke and gases up the chimney will occur; that flow resistance will have an adverse affect on the operation andperformance of the heater and venting system.

12

CHIMNEY CONNECTORTO HEATER

SOLID INSULATED, LISTEDFACTORY-BUILT CHIMNEY LENGTH (12 IN. LONG MIN.)

CHIMNEY CONNECTORTO HEATER

Assembly of Furnace Your furnace requires the following itemsto be assembled or installed by the serviceperson:

Feed Door Pull HandleFeed Door Locking HandleBlower(s) and Blower ControlsElectrical Connections

Remove all parts from inside the furnaceand inspect for damage, including thefirebrick as some breakage could occurduring shipment.Assemble the feed door pull handle asshown in Figure 9. Install thermostatassembly and cover (complete withhandle) as illustrated in Figure 9.Align thermostat control knob with flat onthermostat control shaft and press ontoshaft. (See Fig. 9)Attach feed door locking handle as inFigure 10 with screws and nuts provided.Note: Slotted holes are for adjustment ofhandle. Adjust handle until some pres-sure is required to lock feed door duringfiring sequence.Install Honeywell Fan/Limit Control onrear of furnace cabinet as shown in Fig-ure 11.Remove blower(s) from carton(s). Re-move junction box cover. Attach clip nutsas in Figure 10. Install blower(s) andgasket(s) with 1/4"-20x3/4" bolts asshown.Wire right side blower first (See wiringdiagram, Fig. 12 & 13) and replace coveron junction box on blower.Wire left blower same as above andreplace cover.Check operation of shaker grates withgrate handle before operating furnace.

1.

2.

3.

4.

5.

6.

7.

8.

13

HoneywellFAN/LIMITCONTROL

4" ELECTRICALJUNCTION BOX

BLOWERASSEMBLY

GASKET

CLIP NUTS(DO NOT USE CLIP NUT ON UPPER CENTER HOLE)

Fig. 11

Fig. 10

Fig. 9

(MODEL 1300 - 1 BLOWER,

MODEL 1400 - 2 BLOWERS)

14

WIRE COLOR CODEG- GREEN- GROUNDB- BLACK- POWER SUPPLYW- WHITE- POWER SUPPLYR1- WHITE- FAN CONTROLR2- BLACK- FAN CONTROLM1- BLACK- BLOWER MOTORM2- WHITE- BLOWER MOTOR

Fig. 11

LOADFANLINE

LOADLIMITLINE

BREAK OFFJUMPER FOR

LOW VOLTAGE

FAN "OFF"INDICATOR

FAN "ON"INDICATOR

LIMITINDICATOR

HoneywellLIMIT SWITCH

R1R2

G

W110VAC,60 HZ.

GROUNDG

B

W

ELECTRICAL JUNCTION BOXM1M2

BLOWERMOTOR

B

WIRE NUTS

LOADFANLINE

LOADLIMITLINE

BREAK OFFJUMPER FOR

LOW VOLTAGE

FAN "OFF"INDICATOR

FAN "ON"INDICATOR

LIMITINDICATOR

HoneywellLIMIT SWITCH

R1R2

G

B

W

110VAC,60 HZ.

GROUNDG

B

W

ELECTRICAL JUNCTION BOXM1M2 M1 M2

BLOWERMOTOR

BLOWERMOTOR WIRE NUT

(7 PLACES)

IMPORTANT: POWER SUPPLY WIRING MUST NOT BE LESS THAN 90 CENTIGRADE.

WIRE COLOR CODEG- GREEN- GROUNDB- BLACK- POWER SUPPLYW- WHITE- POWER SUPPLYR1- WHITE- FAN CONTROLR2- BLACK- FAN CONTROLM1- BLACK- BLOWER MOTORM2- WHITE- BLOWER MOTOR

IMPORTANT: POWER SUPPLY WIRING MUST NOT BE LESS THAN 90 CENTIGRADE.

Fig. 12

Fig. 12

Fig. 13

WIRE COLOR CODEG - GREEN - GROUNDB - BLACK - POWER SUPPLYW - WHITE - POWER SUPPLYR1 - WHITE - FAN CONTROLR2 - BLACK - FAN CONTROLM1 - BLACK - BLOWER MOTORM2 - BLACK - BLOWER MOTOR

WIRE COLOR CODEG - GREEN - GROUNDB - BLACK - POWER SUPPLYW - WHITE - POWER SUPPLYR1 - WHITE - FAN CONTROLR2 - BLACK - FAN CONTROLM1 - BLACK - BLOWER MOTORM2 - BLACK - BLOWER MOTOR

InstallationPlease see all methods of Installation inAppendix at the rear of this booklet.

Pipe to combustible: Sides: 18"(460mm) Back: 18"(460mm)The installation must be made only on a noncom-bustible floor. d) Install the smoke pipe connector to the chim-ney with 26-gauge pipe and elbows (to be pur-chased separately), maintaining the proper clear-ances for the specific model. Seal the smoke pipein the chimney with furnace cement. (The chimneyconnector shall be securely supported, and jointsfastened with sheet metal screws or rivets.) e) Install 8" diameter heat pipe to plenum of thecentral hot air furnace. Use 26-gauge pipe andconnectors (to be purchased separately). (See Fig.14) If central air conditioning is installed in theplenum, install heat pipe above the air conditioningunit. Secure heat pipe connection with supportsand sheet metal screws. f) Connect electrical supply in the electrical junc-tion box that is mounted on the back of the Furnace.See Wiring Diagram (Fig. 12 or Fig. 13). Removethe cover from electrical junction box and connectpower supply wires to wires designated, using wirenuts. The power cord supplied may be used forinstallation, if permitted by local codes andregulations. If the power cord supplied cannot beused, the power supply wiring must be 90 degreescentigrade in a metal cable and should be completedby a qualified installer complying with NFPA StandardNo. 70 and local codes. g) Optional Plenum Fan Control Switch (Part No.11PCS) is available for installation on the plenum ofcentral hot air heating furnace. The purpose of thisswitch is to activate the circulating fan of the centralhot air heating furnace when the temperature in theplenum exceeds 120 degrees F., and shut off thefan when the temperature in the plenum is reducedto 100 degrees F. This avoids overheating theplenum. The electrical supply for operation of this fancontrol switch is to be obtained from the sameelectrical supply as the central hot air heating sys-tem. Follow the instructions of the wiring diagram(Fig. 12 or 13) Do not make connections acrossLimit Control in the furnace. Make electrical wire connections in accordancewith NFPA Standard No. 70 and local codes in thepower supply junction box (See Fig. 15). The wiringto complete the connections should be 18 AWGminimum copper and 90 degrees centigrade in acable.

15

This is a furnace, not a free standing stove.You must direct heated air from 8" outlets away fromthe furnace, or it will not function properly.

1. This installation must be done by a qualifiedheating equipment installer.2. The installation is to be done in compliance withNational Fire Protection Association installation stan-dards: No. 89M, 90B, 211, 70 (National ElectricalCode) and Uniform Mechanical Code 913, 6-4, in thestates where applicable. (Their code offers con-necting smoke pipe connectors into chimney withother fuel burning appliances.)3. Rooms large in comparison with size of theappliance: a)Wood or Coal Burning Furnace needs air forcombustion and circulation to house. b) Provision must be made to make up this airand not starve gas or oil furnace of combustion air. c) Have "Authority Having Jurisdiction" deter-mine that air is of adequate makeup. (ReferenceN.F.P.A. Nos. 30&54, Code for Installation of Gas &Oil Equipment).4. Have "Authority Having Jurisdiction" is to inspectall chimneys and installations for adequate ventingand for compliance with standard and local codesand regulations regarding installation of wood burn-ing appliances.5. Installation for Supplemental Heat Application toExisting Central System. (See Fig. 2 for typicalinstallation.) a) Place Wood or Coal Burning Furnace so thatthe chimney connector will be as short as practicaland avoiding unnecessary sharp turns in the smokepipe connector and the installation of devices thatwould create excessive resistance to the flow of fluegases. b) Locate the Wood or Coal Burning Furnace asclose as practical to the existing central hot airheating system, maintaining clearances as statedon the label on the fuel door. c) Clearance from combustible materials mustcomply with those stated on the label on the firedoor: Unit to combustible:

Front: 48"(900mm)Back: 30"(760mm)Sides: 12"(305mm)Plenum to Ceiling: 6"(150m)

2" MIN. AIR SPACEREQUIRED BY CODE

18" MIN.

CENTRALFURNACE

Figure 14

16

Power Failure Instructions:Operation after loss of power--1. Remove filter if provided2. Do not expect to keep home at normal temperatures.3. Do not load fuel above bottom of feed door.

TO GAS/OIL/ELECTRICTRANSFORMER AND

COMBUSTION FAN OFSOLID FUEL UNIT

H

N

POWERSUPPLY

FURNACEBLOWERMOTOR

FAN

LIMIT

COMBINATION CONTROL

GAS/OIL/ELECTRICPOWER SUPPLYJUNCTION BOX

JUMPER IN

CAUTION!DO NOT CONNECT

PLENUM FAN CONTROLSWITCH ACROSS FURNACE

LIMIT CONTROL.

Figure 15

PLENUM

TO

CEILING

6" MIN.

CAUTIONGASES THAT ARE DRIVEN FROM FRESHCOAL MUST BE BURNED OR THEY WILLACCUMULATE AND EXPLODE. NEVERSMOTHER A FIRE WHEN ADDING FRESHCOAL.

CAUTIONDO NOT OPERATE WITH THE FEED AND/ORASH DOOR OPEN. THIS FURNACE IS DE-SIGNED FOR THERMOSTATIC OPERATION.OPERATION WITH ANY OF THESE DOORSOPEN WILL OVERHEAT AND DAMAGE THEFURNACE.

CAUTIONNEVER USE GASOLINE, GASOLINE-TYPELANTERN FUEL, KEROSENE, CHARCOALLIGHTER FLUID, OR FLAMMABLE LIQUIDSTO START OR "FRESHEN UP" A FIRE IN THEFURNACE.

WARNINGNEVER STORE FLAMMABLE LIQUIDS, ES-PECIALLY GASOLINE, IN THE VICINITY OFTHE FURNACE.

ADJUSTING BLOWER LIMIT CONTROL SET-TINGS.The temperature in the plenum of the warm airfurnace at which the blower turns on or turns off,is controlled by the setting of the pointers in theblower limit control. These pointers may be ad-justed through their entire range of settings toachieve the desired warm air output from furnace.(See Fig. 16 below)

Operating InstructionsFUEL, Model 1300Egg size (1-3/16" or larger) bituminous coalfor residential furnaces, or any of the speciallypacked fireplace coals can be used. Coal with alow ash content (2% to 6%) is recommended.FUEL, Model 1400Hardwood, 18" to 26" should be split and air dried(seasoned) for 6 months.LIGHTING1.

2.

3.4.

5.

Set the thermostat on "HIGH" for maximumdraft.Open the feed door and place paper andkindling on the grate for starting the fire.Light the fire and close the feed door.Add wood or about 15 lbs. of coal (dependingon which model) after fire is burning briskly.Set thermostat for desired temperature."MEDIUM" setting is normally satisfactory.Set higher or lower for your comfort.

ADDING FUELWhen starting a fire, add small amounts of fuelinstead of adding large quantities of fuel. This willgive more complete combustion and less buildupof tars or soot in the chimney.

Set thermostat to HIGH before opening feeddoor.Wood fire - Model 1400.Add wood to a convenient level.Coal Fire - Model 1300.Never smother the fire when adding coal (SeeCaution). Gas accumulation and a mild smokyexplosion will occur. Add fresh kindling if thebed of coals has cooled.Add up to 20 lbs. of coal per loading. Never addcoal above the bottom of feed door opening.Stir the coal and watch the fire. Be sure thenew coal is burning briskly before you closethe doors and turn the thermostat down.Shake grates vigorously 1/2" left to right to spillashes into the ash pan. Do this at least onceevery 12 hours of operation. Empty ash panregularly. Do not allow ashes to buildup tograte as grate will warp and burnout, and youmight spill the ashes when removing the pan.Dispose of hot ashes properly (See note 12 onpage 4).Rotation of the handle (5 o'clock to 7 o'clock)position will agitate coals and spill ashes intoash pan.It is advisable for you to get familiar with theshaker grate operation before firing.

1.

2.

3. a.

b.

c.

d.

e.

f.

Move both pointers towards the right (counterclockwise) - this increases the temperaturesetting at which the blower will turn on and off.Move both pointers towards the left (clock-wise) - this decreases the temperature settingat which the blower will turn on and off.Move pointers away or apart from each other-this increases the time that the blower will runon each warm air cycle.

BLOWER FAN"OFF" POINTER

BLOWER FAN"ON" POINTER

BLOWER LIMITPOINTER & STOP

17

Fig. 16

18

Service HintsDo not expect a furnace to draw. It is thechimney that creates the draft. Smoke spillageinto the house or excessive buildup of water orcreosote in the chimney are warnings that thechimney is not functioning properly. Correct theproblem before using furnace. Possible causesare:

1. The connector pipe may be pushed into the chimney too far, stopping the draft (Fig. 6)

2. Do not connect two furnaces or a stove and furnace into the same chimney flue.

3. The chimney used for a furnace must not be used to ventilate the cellar or basement. If there is a cleanout opening at the base of the chimney, it must be closed tightly.

4. If the chimney is operating too cool, waterwill condense in the chimney and run backinto the furnace. Creosote formation will berapid and may block the chimney. Operatethe furnace at a high enough fire to keep thechimney warm, preventing this condensa-tion.

If the fire burns well, but sometimes smokesor burns slowly, it may be caused by thechimney top being lower than another partof the house or a nearby tree. The windblowing over a house or a tree, falls on topof the chimney like water over a dam, beat-ing down the smoke. The top of the chimneyshould be at least 3 feet above the roof andbe at least 2 feet higher than any point of theroof within 10 feet (Fig. 5).

See page 29 for list of trouble shooting tips.

5.

6.

A draft reading of .05 to .06 w.c. is suggested for proper burning of this unit when usingwood or bituminous coal as fuel. When using anthracite coal, this draft reading is a

minimum reading.

Chimney MaintenanceCreosote and Soot - Formation and Need for Removal

When wood is burned slowly, it produces tarand other organic vapors, which combine withexpelled moisture to form creosote. The creo-sote vapors condense in the relatively coolchimney flue of a slow-burning fire. As a result,creosote residue accumulates on the flue lin-ing. When ignited, this creosote makes anextremely hot fire.

When coal is burned, the products of combus-tion combine with moisture to form a soot resi-due which accumulates on the flue lining. Whenignited, this soot makes an extremely hot fire.

The chimney should be inspected at least twicemonthly during the heating season to deter-mine if a creosote or soot build up has occurred.

If creosote or soot has accumulated, it shouldbe removed to reduce the risk of a chimney fire.

Chimney fires burn very hot. If the chimneycatches fire, immediately call the fire depart-ment, then reduce the fire by closing the inlet aircontrol. Pour a large quantity of coarse salt,baking soda or cool ashes on top of the fire inthe firebox.

CAUTIONA chimney fire may cause ignition ofwall studs or rafters which you thoughtwere a safe distance from the chimney.If you have a chimney fire, have yourchimney inspected by a qualified per-son before using again.

19

Mo

del 1300

Rep

air Parts

9

11

7

8

3

1

223

24

2221

2017

18

35

33

32

31

29

28

27

26

19

25

34

6

30

10

4 5

30

14a

16

15

13

12

38

36

37

14

14c14b

PARTS LISTMODEL 1300

(SEE DIAGRAM, PAGE 19)

20

DESCRIPTIONCABINET LEFT SIDECABINET BACK PANELFORCED DRAFT RINGFLUE COLLAR GASKETFLUE COLLARFLUE COLLAR RINGBOLT (1/4-20 X 1)KEP NUT (1/4-20)CABINET TOP PANELCABINET RIGHT SIDEFEED DOOR HINGE BRACKETSMOKE CURTAINBOLT (5/16-18 X 1)LOCKNUT (5/16-18)ASH DOOR ASSEMBLYFEED DOOR ASSEMBLYTHERMOSTAT COVER ASSEMBLYTHERMOSTAT ASSEMBLYTHERMOSTAT CONTROL KNOBTHERMOSTAT DAMPER CHAINTHERMOSTAT DAMPER FLAP ASSEMBLYWOODEN HANDLEHANDLE BRACKETSCREW (#10-24 X 1/2")ASH DOOR HANDLEWASHER (3/32 THK)DOOR LATCHNUT (3/8-16)ASH PANCABINET BOTTOMFEED DOOR LOCKING MECHANISMBOLT (1/4-20 X 3/4")BLOWER MOTORBOLT (1/4-20 X 3/4")BLOWER CLIP NUT (1/4-20)BLOWER GASKETFAN CONTROL CORD ASSEMBLYBLOWER CONDUIT ASSEMBLYCORD STRAIN RELIEFBLOWER LIMIT CONTROLJUNCTION BOXPOWER SUPPLY CORDFLUE BAFFLESHAKER GRATESHAKER FRAMESHAKER HANDLEFRONT AND REAR LINERFIREBOX ASSEMBLYFIREBRICKBLOWER THERMOSTAT BRACKETRELAY BOX SUPPORT BRACKETDRAFT KNOBSMOKE DOOR CLIPKEP NUT (1/4-20)BOLT (1/4-20 X 1-1/4")

QTY.11111166111122111111112211111112155111111111111110111222

KEY123456

N/SN/S78910

N/SN/S1112131414a14b14c1516

N/S17181920212223

N/SN/SN/SN/SN/SN/SN/SN/S2425

N/S26272829303132333435363738

PART #2268422682227628803240246227618322783250226832268522662238008333783338682186821768733685988917586318687218952023425

83106S89354

83045A2344583274682382268689308833398023083339833408931968231682328015480145802318023223397402574025640260402646822589066682342214022824237878325083445

21

9

11

7

8

3

1

223

24

2221

2017

18

35

33

32

31

29

28

27 26

19

25

34

6

30

10

4 5

36

37

Mo

del 1400

Rep

air Parts

14a

16

15

13

12

14

14c14b

22

PARTS LISTMODEL 1400

(SEE DIAGRAM, PAGE 21)

DESCRIPTIONCABINET LEFT SIDECABINET BACK PANELFORCED DRAFT RINGFLUE COLLAR GASKETFLUE COLLARFLUE COLLAR RINGBOLT (1/4-20 X 1)KEP NUT (1/4-20)CABINET TOP PANELCABINET RIGHT SIDEFEED DOOR HINGE BRACKETSMOKE CURTAINASH DOOR ASSEMBLYFEED DOOR ASSEMBLYTHERMOSTAT COVER/PANEL ASSEMBLYTHERMOSTAT ASSEMBLYTHERMOSTAT CONTROL KNOBTHERMOSTAT DAMPER CHAINTHERMOSTAT DAMPER FLAP ASSEMBLYWOODEN HANDLEHANDLE BRACKETSCREW (#10-24 X 1/2")]ASH DOOR HANDLEDOOR LATCH WASHER (3/32 THK)DOOR LATCHDOOR LATCH NUT (3/8"-16)ASH PANCABINET BOTTOMFEED DOOR LOCKING MECHANISMBOLT (1/4-20 X 3/4")BLOWER LIMIT CONTROLJUNCTION BOXPOWER SUPPLY CORDFAN CONTROL CORD ASSEMBLYFLUE BAFFLEFURNACE GRATEFRONT LINERFIREBOX ASSEMBLYHALF FIREBRICKFIREBRICKBLOWER THERMOSTAT BRACKETRELAY BOX SUPPORT BRACKETDRAFT CONTROL KNOBBLOWER MOTOR ASSEMBLYMOUNTING BOLT (1/4-20 X 3/4")CLIP NUT (1/4-20)BLOWER GASKETCORD STRAIN RELIEFSMOKE CURTAIN CLIPBOLT (1/4-20 X 1-1/4")KEP NUT (1/4-20)

QTY.111111661111111111112211111112111323112121112101021222

KEY123456

N/SN/S789101112131414a14b14c1516

N/S17181920212223

N/S2425

N/SN/S262728293031323334

N/SN/SN/SN/SN/S353637

PART #234612345922762880324024622761832278325023457234612266223800682186821768733685988917586318687218952023425

83106S89354

83045A234458327468228234588930883339801458023180232682312339840263402586821523887890666823422140228246822983339833408931980154237878344583250

23

COLD AIR DUCT

6" PIPE

DAMPER

OPTIONAL11 RPT

90 ELBOW

FURNACE

PIPECONNECTOR

Central Installation

Fig. 16-1

(U.S. ONLY)

Add-On Installation

COLD AIR DUCT

6" PIPE

DAMPER

90 ELBOW

FURNACE

PIPECONNECTOR

EXISTING GAS/OIL/ELECTRIC FURNACE

8" PIPE

Fig. 16

(U.S. ONLY)

Fig. 17

Fig. 17-1

COLD AIRRETURN

TO EXISTINGDUCT WORK

WARM AIR

EXISTINGFURNACE

SOLID FUELFURNACE

FILTER BOX

APPENDIX

INSTALLATION A

24

(U.S. ONLY)

25

INSTALLATION B

INSTALLATION C

COLD AIRRETURN

TO EXISTINGDUCT WORK

WARM AIR

EXISTINGFURNACE

SOLID FUELFURNACE

FILTER BOX

PLENUMCOLLECTOR BOX

COLD AIRRETURN

TO EXISTINGDUCT WORK

WARM AIR

EXISTINGFURNACE

SOLID FUELFURNACE

FILTER BOX

PLENUM ELBOW

PLENUM TOP(OPTIONAL)

(U.S. ONLY)

(U.S. ONLY)

26

2" MINIMUMCLEARANCE

DUCTWORK

11 PCS(OPTIONAL PLENUM FAN CONTROL LOCATION)

FURNACE PLENUM

EXISTING FURNACE

ANTI-BACKDRAFTFLAPPER

SOLID FUELFURNACE

COLD AIRRETURN

INSTALLATION D

2" MINIMUMCLEARANCE

DUCTWORK

FURNACE PLENUM

EXISTING FURNACE

SOLID FUELFURNACE

COLD AIRRETURN

INSTALLATION E

BAFFLE

(U.S. ONLY)

(U.S. ONLY)

2" MINIMUMCLEARANCE

DUCTWORK

FURNACE PLENUM

EXISTING FURNACE

SOLID FUELFURNACE

COLD AIRRETURN

INSTALLATION F

2" MINIMUMCLEARANCE

DUCTWORK

SOLID FUELFURNACE

INSTALLATION G

COLD AIRRETURN TOFILTER BOX

CENTRALFURNACE

INSTALLATION

27

26

2" MINIMUMCLEARANCE

EXISTING OIL, ELECTRIC ORGAS FURNACE

SOLID FUELFURNACE

INSTALLATION H

EXISTING OIL, ELECTRIC ORGAS FURNACE

SOLID FUELFURNACE

(TOP VIEW)

(FRONT VIEW)

29

1. Smoking when feed door a) Insufficient Draft. a) Set Thermostat higher.is open. b) Clogged chimney or chimney b) Clean Chimney.

connector. c) Add raincap to chimney.c) Down draft in chimney.

2. Furnace does not heat. a) Wood not seasoned and dry. a) Allow wood to season in adry area for six months.

b) Blower control set too low. b) Set blower control to highertemperatures. (See P. 17)

c) Insufficient flue draft. c) Set flue draft. (See P. 9)

3. Blower Does not run. a) Improperly wired. a) Wire unit properly.b) Bad blower control. b) Replace blower control.c) Bad relay. c) Replace relay.d) Bad blower motor d) Replace blower.

4. No air from registers- a) Registers are closed. a) Open registers.fan running. b) Duct work improperly installed. b) Correct duct work install.

c) Improper wiring between central c) Wire unit properly.furnace and this unit.

5. Air from Registers is not hot a) Blower control is set too low. a) Adjust blower control tohigher setting. (See P. 17)

b) Bad blower control. b) Replace blower control.

6. Blower runs too long. Blower control cut off set Set blower control cut off totoo low. higher setting. (See P. 17)

7. Blower does not run long a) Blower control cut off set a) Set blower control cut off toenough. too high. lower setting. (See P. 17)

b) Bad blower motor. b) Replace Blower.

8. Smoke and/or odor from Oil from furnace and duct The metal used in constuc-registers when furnace work. tion of the furnace and ductis used for first time. work has a light coating of

oil. This should disappearafter a short period of time.Once this burnoff has occur-red, is should not reoccur.

9. Creosote build-up. a) Burning green wood (not a) Burn only seasoned wood.seasoned or dry).

b) Thermostat setting too low b) Set thermostat higher tofor type fuel. attain higher flue tempera-

tures. This will aid in pre-venting buildup of creosote.

10. Flame spillage when feed a) Insufficient draft. a) Set thermostat higher.door is open. b) Smothering fire when adding b) Add fuel so as not to

fresh fuel. smother fire.

LIST OF PROBLEMS POSSIBLE CAUSE SOLUTIONS

Trouble Shooting Tips for Warm Air Furnace

NOTES

30

NOTES

31

HOW TO ORDER REPAIR PARTS

THIS MANUAL WILL HELP YOU OBTAIN EFFICIENT, DEPENDABLE SERVICE FROMTHE HEATER, AND ENABLE YOU TO ORDER REPAIR PARTS CORRECTLY.

KEEP IN A SAFE PLACE FOR FUTURE REFERENCE.

WHEN WRITING, ALWAYS GIVE THE FULL MODEL NUMBER WHICH IS ON THENAMEPLATE ATTACHED TO THE BACK OF THE HEATER.

WHEN ORDERING REPAIR PARTS, ALWAYS GIVE THEFOLLOWING INFORMATION AS SHOWN IN THIS LIST:

1. The PART NUMBER

2. The PART DESCRIPTION

3. The MODEL NUMBER: 1300 1400

4. The SERIAL NUMBER:

UNITED STATES STOVE COMPANY227 Industrial Park Road

P.O. Box 151South Pittsburg, TN 37380

(423) 837-2100www.USSTOVE.com