Impulsive Force GUI Familiarity Level Required: Lower Estimated Time Required: 20 minutes

1 Forklift Estimated time required: 20 min GUI familiarity level required: Higher MSC.ADAMS 2005 r2.

-

Upload

april-simmons -

Category

Documents

-

view

220 -

download

1

description

Transcript of 1 Forklift Estimated time required: 20 min GUI familiarity level required: Higher MSC.ADAMS 2005 r2.

1

Forklift

Estimated time required: 20 min

GUI familiarity level required: Higher

MSC.ADAMS 2005 r2

2

Topics CoveredTopics Covered

You will need to download the file “FORKLIFT_model_start.zip“ to begin this tutorial

If you have any difficulties, import the “FORKLIFT_shortcut.cmd” file and proceed from pg 10

If you have any difficulties, import the “FORKLIFT_complete.cmd” file and proceed from pg 13

In this tutorial, you will learn how to:

1. Create a STEP function

2. Create contact

3

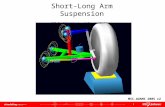

Forklift ProblemForklift Problem

Add contact forces and STEP function to delay movements of a forklift.

4

If you are successful, you should end up with a ADAMS model that illustrates contact forces and STEP function of

a forklift.

What You Should AccomplishWhat You Should Accomplish

5

Import ModelImport Modela. Download file FORKLIFT_model_start.zip

b. Unzip the files to C:\

c. Start ADAMS

d. Click Import a file radio button

e. Select C:\ as Start in text field

f. Click OK

File Import window will open

g. Right-click File To Read text field, select Browse

h. Locate saved file FORKLIFT_start.cmd

i. Click Open

j. Click OK

g

h

i

d

e

f

j

6

Add Translation JointAdd Translation Jointa. Select Translation Joint from Joint tool stack

b. Click ground PAR2 PAR2.MAR1 move cursor to the right, click MAR1.Z

c. Select Translation Joint

d. Click PAR2 PAR3 PAR2.lift2_22.V229 move cursor up, click lift2_22.V6

a

db

7

Add Translation Joint MotionAdd Translation Joint Motiona. Select Translational joint motion from Motion Driver tool stack

b. Click JOINT_1

c. Select Translational joint motion

d. Click JOINT_2

b

a

d

8

Create STEP funtionCreate STEP funtion

a. Right Click on JOINT_1, select Motion: MOTION_1 Modify

b. Click button

c. Enter STEP(time, 2.0, 0.0, 6.0, 150) in Define a runtime function text field

d. Click OK

e. Click OK

a

b

e

c

d

Note: the step function is a delayed movement function.

It works like: STEP(time, time, distance, time 2, distance 2)

9

Create STEP functionCreate STEP function

a. Right Click on JOINT_2, select Motion_1 Modify

b. Click button

c. Enter STEP(time, 0.5, 0.0, 4.0, +36) + STEP5(time, 6.0, 0.0, 8.5, -36)

d. Click OK

e. Click OK

10

Create ContactCreate Contact

a

bc d

a. Select Contact from Forces tool stack

b. Right-click in I Solid text field, select Contact_Solid Browse

c. Highlight BOX_42, BOX_43, BOX_44 Click OK

d. Repeat for J Solid except use PAR3 EXTRUSION_45, EXTRUSION_46

e. Choose Blue from Force Display pull down menu

f. Enter Stiffnees = (Stiff_Box_Fork) , Force Exponent = (Exp_box_fork) , Damping = (B_box_fork) , Penetration Depth = (Dmax_box_fork)

g. Choose Coulomb from Friction Force pull down menu

h. Enter Static Coefficient = 0.3, Dynamic Coefficient = 0.2, Striction Transition = 10.0, Friction Transition = 100.0

i. Click OK

e

f

g

h

i

11

Create ContactCreate Contact

a. I Solid = PAR3 BOX_42, BOX_43, BOX_44

b. J Solid = ground BOX_21

c. Choose Blue from Force Display pull down menu

d. Enter:

Stiffness =(Stiff_Box_Ground)

Force Exponent =(Exp_box_ground)

Damping =(B_box_ground)

Penetration Depth = (Dmax_box_ground)

e. Choose Coulomb from Friction Force pull down menu

f. Enter:

Static Coefficient = 0.62

Dynamic Coefficient = 0.6

Striction Transition = 10.0

Friction Transition = 100.0

g. Click OK

a

b

c

d

e

f

g

12

This is what your screen should look like whenyour model is complete

ModelModel

13

VerifyVerify

Verify the model

Run a Simulation: Duration = 10, Step Size = 0.1

14

In this tutorial you learned how to:

Topics CoveredTopics Covered

1. Create a STEP function

2. Create contact

15

Best PracticesBest Practices

• Check orientation and location of the translation joint

• Check direction of translation joint motion

• Check STEP function

• Check Contact forces are between the right bodies

• Check Contact values