1 - Cylinder Rings

description

Transcript of 1 - Cylinder Rings

All r

ight

s re

serv

ed -

Jona

than

Whi

te H

RPU

, Bra

dfor

d an

d G

. KIN

DL

Tra

inin

g C

ente

rH

OER

BIG

ER C

ompr

essi

on T

echn

olog

y–

Sep.

200

1

Trained forCompetenceTrained for

Competence

Cylinder RingsContents

Cylinder RingsContents

• Introduction� Sealing and Guidance of Pistons� Manufacturing of Rings at HRP

• Piston Rings� Basic Understanding� Standard Piston Ring Types

• Rider Rings� Basic Understanding� Standard Rider Ring Types

• Ring Mounting Instructions

6.0.2

All r

ight

s re

serv

ed -

Jona

than

Whi

te H

RPU

, Bra

dfor

d an

d G

. KIN

DL

Tra

inin

g C

ente

rH

OER

BIG

ER C

ompr

essi

on T

echn

olog

y–

Sep.

200

1

Trained forCompetenceTrained for

Competence

• Piston Rings– Seal the compression chamber

between the piston and the liner

• Rider Rings– Support the weight of the piston and

half of the rod weight, but should not seal gas pressure.

• Other designs:– Labyrinth Piston

Grooved piston with orwithout PTFE coating

Basic UnderstandingSealing and Guidance of Pistons

6.1.1

All r

ight

s re

serv

ed -

Jona

than

Whi

te H

RPU

, Bra

dfor

d an

d G

. KIN

DL

Tra

inin

g C

ente

rH

OER

BIG

ER C

ompr

essi

on T

echn

olog

y–

Sep.

200

1

Trained forCompetenceTrained for

Competence

Basic UnderstandingManufacturing of Rings at HRP

6.1.2

for differential pressures 0.1 to 400 bar for piston diameters 20 to 1400 mm made of metals cast iron, bronzeand non metallics filled PTFE, PEEK, PPS, Carbon

CylinderRings

All r

ight

s re

serv

ed -

Jona

than

Whi

te H

RPU

, Bra

dfor

d an

d G

. KIN

DL

Tra

inin

g C

ente

rH

OER

BIG

ER C

ompr

essi

on T

echn

olog

y–

Sep.

200

1

Trained forCompetenceTrained for

Competence

6.2

Piston Ringsfor Compressors

Piston Ringsfor Compressors

Basic UnderstandingBasic Understanding Ring TypesRing Types

All r

ight

s re

serv

ed -

Jona

than

Whi

te H

RPU

, Bra

dfor

d an

d G

. KIN

DL

Tra

inin

g C

ente

rH

OER

BIG

ER C

ompr

essi

on T

echn

olog

y–

Sep.

200

1

Trained forCompetenceTrained for

Competence• Design Criteria• Gliding Area for Rings• Ring Styles• Number of Rings

Basic UnderstandingContents

6.2.0

All r

ight

s re

serv

ed -

Jona

than

Whi

te H

RPU

, Bra

dfor

d an

d G

. KIN

DL

Tra

inin

g C

ente

rH

OER

BIG

ER C

ompr

essi

on T

echn

olog

y–

Sep.

200

1

Trained forCompetenceTrained for

Competence

Design pressure maximum differential pressure on the pistonForces on the ring - differential pressure,

- friction, - dynamic forces (acceleration),- piston movement, - forces exerted by the expander

Single acting rings Seal only in one direction Double acting rings Seal in both directions

Basic UnderstandingDesign Criteria

6.2.1

Rin

g cu

tLinerLiner

PistonPiston

All r

ight

s re

serv

ed -

Jona

than

Whi

te H

RPU

, Bra

dfor

d an

d G

. KIN

DL

Tra

inin

g C

ente

rH

OER

BIG

ER C

ompr

essi

on T

echn

olog

y–

Sep.

200

1

Trained forCompetenceTrained for

Competence

Basic UnderstandingGliding Area for Piston Rings

UCL = piston ring stack length + piston stroke - 2 x over-run

6.2.2< 3 mm

or < 25 % of ring width

Over-run:The piston ring stack

should never leavethe cylinder liner.

bearing surface

ring stack lenght

UCL“Uninterupted

Cylinder Length”

over-run

Uninterupted Cylinder Length

All r

ight

s re

serv

ed -

Jona

than

Whi

te H

RPU

, Bra

dfor

d an

d G

. KIN

DL

Tra

inin

g C

ente

rH

OER

BIG

ER C

ompr

essi

on T

echn

olog

y–

Sep.

200

1

Trained forCompetenceTrained for

Competence

Basic UnderstandingRing Styles

pressurebalanced

withexpander

withoutexpander

twinring

6.2.3

Cut

Ring Profiles

straight cut angle cut overlapped cutor step cut

All r

ight

s re

serv

ed -

Jona

than

Whi

te H

RPU

, Bra

dfor

d an

d G

. KIN

DL

Tra

inin

g C

ente

rH

OER

BIG

ER C

ompr

essi

on T

echn

olog

y–

Sep.

200

1

Trained forCompetenceTrained for

Competence

Basic UnderstandingIncreasing Sealing Ability

6.2.4

Cut Rings with expander

Twin Piston Ringsingle acting:

Cut rings, pegged together.

Rings for low pressure applications,large diameters

Sealing is improvedby springing the ring

to the liner.

Double Twin Piston Ring:

The smaller ring blocks the gap in the L-shaped ring in one direction

Double twin piston ringsseal in both directions.

All r

ight

s re

serv

ed -

Jona

than

Whi

te H

RPU

, Bra

dfor

d an

d G

. KIN

DL

Tra

inin

g C

ente

rH

OER

BIG

ER C

ompr

essi

on T

echn

olog

y–

Sep.

200

1

Trained forCompetenceTrained for

Competence

6.2.5

Basic UnderstandingPressure Compensation

Piston ring designs for high pressure application:without pressure balancing with pressure balancing

force profile torsionforce profile torsion

unbalancedforce

unbalancedforce

Piston rings without pressure balancing will wear quick at high differential pressures due to high contact pressure between the piston ring and the liner. Grooves and radial holes of pressure balanced rings allow a controlled leakage to the outer ring diameter; thereby reducing

the unbalanced force and torsion moment promoting reduced wear.

All r

ight

s re

serv

ed -

Jona

than

Whi

te H

RPU

, Bra

dfor

d an

d G

. KIN

DL

Tra

inin

g C

ente

rH

OER

BIG

ER C

ompr

essi

on T

echn

olog

y–

Sep.

200

1

Trained forCompetenceTrained for

Competence

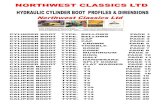

Basic UnderstandingNumber of Rings According to Experience

6.2.6

Differential Pressure Recommended Numberbar gauge psig of PTFE-Rings per Piston

0 - 10 0 - 150 210 - 15 150 - 225 315 - 25 225 - 375 425 - 30 375 - 450 530 - 50 450 - 750 650 - 100 750 - 1500 7

100 - 200 1500 - 3000 8200 - 320 3000 - 4725 9320 - 400 4725 - 6000 10

Differential pressure for single acting compressors : Outlet pressure minus atmospheric pressuredouble acting compressors: Outlet pressure minus inlet pressure

All r

ight

s re

serv

ed -

Jona

than

Whi

te H

RPU

, Bra

dfor

d an

d G

. KIN

DL

Tra

inin

g C

ente

rH

OER

BIG

ER C

ompr

essi

on T

echn

olog

y–

Sep.

200

1

Trained forCompetenceTrained for

Competence

• Ring - Type 0800

• Ring - Type 0801

• Ring - Type 0804

• Ring - Type 0808

• Ring - Type 0811

• Pressure Balanced Ring - Type 0803

• Pressure Balanced Ring - Type 0805

• Twin Ring - Type 0820

• T-Section Double Twin Ring - Type 0816

Standard Piston Ring TypesImportant Ring Types

6.3.0

All r

ight

s re

serv

ed -

Jona

than

Whi

te H

RPU

, Bra

dfor

d an

d G

. KIN

DL

Tra

inin

g C

ente

rH

OER

BIG

ER C

ompr

essi

on T

echn

olog

y–

Sep.

200

1

Trained forCompetenceTrained for

Competence

Description:Simplest ring with rectangular section and straight cut (gap).• Ring will not spin,

therefore preferred on soft aluminium piston

Application:Standard piston ring.

Standard Piston Ring TypesRing Type 0800

straight cut

6.3.1

All r

ight

s re

serv

ed -

Jona

than

Whi

te H

RPU

, Bra

dfor

d an

d G

. KIN

DL

Tra

inin

g C

ente

rH

OER

BIG

ER C

ompr

essi

on T

echn

olog

y–

Sep.

200

1

Trained forCompetenceTrained for

Competence

Description:Ring with rectangular section and angle cut. • Greater sealing efficiency

created by longer leakage path for gas due to angle cut.

• Ring gap will not form witness lines on the cylinder liner.

Application:Standard piston ring for non brittle materials.

Standard Piston Ring TypesRing Type 0801

angle cut

6.3.2

All r

ight

s re

serv

ed -

Jona

than

Whi

te H

RPU

, Bra

dfor

d an

d G

. KIN

DL

Tra

inin

g C

ente

rH

OER

BIG

ER C

ompr

essi

on T

echn

olog

y–

Sep.

200

1

Trained forCompetenceTrained for

Competence

Description:Ring with rectangular section and angle cut, 2 piece design.

Application:For smaller ring diameters and less flexible materials, to mount without warming up.

Standard Piston Ring TypesRing Type 0804

angle cut

6.3.3

All r

ight

s re

serv

ed -

Jona

than

Whi

te H

RPU

, Bra

dfor

d an

d G

. KIN

DL

Tra

inin

g C

ente

rH

OER

BIG

ER C

ompr

essi

on T

echn

olog

y–

Sep.

200

1

Trained forCompetenceTrained for

Competence

Description:Ring with rectangular section and step cut, greater sealing efficiency created by smaller gaps, more expensive.

Application:Piston ring for greater sealing efficiency.Not for brittle materials!

Standard Piston Ring TypesRing Type 0808

step cut,(overlapped gap)

6.3.4

All r

ight

s re

serv

ed -

Jona

than

Whi

te H

RPU

, Bra

dfor

d an

d G

. KIN

DL

Tra

inin

g C

ente

rH

OER

BIG

ER C

ompr

essi

on T

echn

olog

y–

Sep.

200

1

Trained forCompetenceTrained for

Competence

Description:Ring with rectangular section and step cut, 3 piece design, greater sealing efficiency created by smaller gaps, more expensive.

Application:For smaller ring diameters and less flexible materials, (especially metallic rings, e.g. Bronze).

Standard Piston Ring TypesRing Type 0811

step cut(overlapped gap)

6.3.5

All r

ight

s re

serv

ed -

Jona

than

Whi

te H

RPU

, Bra

dfor

d an

d G

. KIN

DL

Tra

inin

g C

ente

rH

OER

BIG

ER C

ompr

essi

on T

echn

olog

y–

Sep.

200

1

Trained forCompetenceTrained for

Competence

Description:Pressure balanced ring with rectangular section and angle cut.Less pressure load but approx. the same cross sectional area.

Application:For high differential pressure per ring. Longer life than plain rings.

Standard Piston Ring TypesPressure Balanced Ring Type 0803

6.3.6

angle cut

All r

ight

s re

serv

ed -

Jona

than

Whi

te H

RPU

, Bra

dfor

d an

d G

. KIN

DL

Tra

inin

g C

ente

rH

OER

BIG

ER C

ompr

essi

on T

echn

olog

y–

Sep.

200

1

Trained forCompetenceTrained for

Competence

Description:Pressure balanced ring with rectangular section and angle cut, 2-piece design. Less pressure load but approx. the same cross sectional area.

Application:For high differential pressure per ring, longer life than plain rings. For non-flexible materials.

Standard Piston Ring TypesPressure Balanced Ring Type 0805

6.3.7

angle cut

All r

ight

s re

serv

ed -

Jona

than

Whi

te H

RPU

, Bra

dfor

d an

d G

. KIN

DL

Tra

inin

g C

ente

rH

OER

BIG

ER C

ompr

essi

on T

echn

olog

y–

Sep.

200

1

Trained forCompetenceTrained for

Competence

Description:Twin ring consisting of an L-ring and a rectangular ring both straight cut and pegged together so that the gap of the rectangular ring is covered by the L-ring.

rectangular ring

L-ring

Application:The Twin Piston Ring is single acting and only seals against the small rectangular ring.For light gases.

Standard Piston Ring TypesTwin Piston Ring Type 0820

6.3.8

L-ring rectangular ringga

p

gap

All r

ight

s re

serv

ed -

Jona

than

Whi

te H

RPU

, Bra

dfor

d an

d G

. KIN

DL

Tra

inin

g C

ente

rH

OER

BIG

ER C

ompr

essi

on T

echn

olog

y–

Sep.

200

1

Trained forCompetenceTrained for

Competence

Description:Double Twin Ring consisting of a T-ring type 0816 and 2 rectangular rings all straight cut and pegged together so that the gaps of the rectangular rings are covered by the T-ring.

rectangular rings

T-ring type 0816

Application:Double Twin Rings seal in both directions.

Standard Piston Ring TypesT-Section Double Twin Ring Type 0816

6.3.9

T-ring T-ring Rectangular ringsRectangular rings

All r

ight

s re

serv

ed -

Jona

than

Whi

te H

RPU

, Bra

dfor

d an

d G

. KIN

DL

Tra

inin

g C

ente

rH

OER

BIG

ER C

ompr

essi

on T

echn

olog

y–

Sep.

200

1

Trained forCompetenceTrained for

Competence

Basic UnderstandingBasic Understanding Ring TypesRing Types

6.4

Rider RingsRider Ringsfor Compressors

All r

ight

s re

serv

ed -

Jona

than

Whi

te H

RPU

, Bra

dfor

d an

d G

. KIN

DL

Tra

inin

g C

ente

rH

OER

BIG

ER C

ompr

essi

on T

echn

olog

y–

Sep.

200

1

Trained forCompetenceTrained for

Competence

• Task - Calculation• Factors which influence wear• Axial Clearance

Basic UnderstandingContents

6.4.0

All r

ight

s re

serv

ed -

Jona

than

Whi

te H

RPU

, Bra

dfor

d an

d G

. KIN

DL

Tra

inin

g C

ente

rH

OER

BIG

ER C

ompr

essi

on T

echn

olog

y–

Sep.

200

1

Trained forCompetenceTrained for

Competence

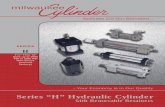

Task:– to prevent the piston from contacting the cylinder liner. – the rider ring should not seal the gas.

Design Criteria:– bearing load – piston and liner material – hardness of the liner – surface quality of the liner – lube or non lube – gas type

Specific load values:– lube 0,07 MPa– non lube 0,035 MPa

Calculation of load:

= weight of the piston* + half the rod weight*OD of rider ring x width of all rider rings

Basic UnderstandingTask - Calculation

width of rider ring

OD

6.4.1

* for V- and W-form compressors only the component of weight vertical to the liner

All r

ight

s re

serv

ed -

Jona

than

Whi

te H

RPU

, Bra

dfor

d an

d G

. KIN

DL

Tra

inin

g C

ente

rH

OER

BIG

ER C

ompr

essi

on T

echn

olog

y–

Sep.

200

1

Trained forCompetenceTrained for

Competence

piston

rider ring

liner

piston

rider ring

liner

• specific bearing load• ring projection• piston velocity• liner surface quality• liner cooling• gas type • gas condition• bedding in procedure

Basic UnderstandingFactors which Influence Wear

6.4.2

All r

ight

s re

serv

ed -

Jona

than

Whi

te H

RPU

, Bra

dfor

d an

d G

. KIN

DL

Tra

inin

g C

ente

rH

OER

BIG

ER C

ompr

essi

on T

echn

olog

y–

Sep.

200

1

Trained forCompetenceTrained for

Competence

Basic UnderstandingAxial Clearance

6.4.3

Correct design of axial clearance is important for good operation

The ring moves backwards and forwards in the piston groove hitting both groove side faces causing the ring and the groove side faces to be damaged.

Ring is deformed so that it bellows within the groove.

axial clearance is too great

axial clearance is too small

axial clearance

All r

ight

s re

serv

ed -

Jona

than

Whi

te H

RPU

, Bra

dfor

d an

d G

. KIN

DL

Tra

inin

g C

ente

rH

OER

BIG

ER C

ompr

essi

on T

echn

olog

y–

Sep.

200

1

Trained forCompetenceTrained for

Competence

Rider RingsImportant Ring Types

6.5.0

• Ring - Type 0841

• Ring - Type 0849

• Ring - Type 0854

• Ring - Type 0873

• Combination Ring -Type 0881

All r

ight

s re

serv

ed -

Jona

than

Whi

te H

RPU

, Bra

dfor

d an

d G

. KIN

DL

Tra

inin

g C

ente

rH

OER

BIG

ER C

ompr

essi

on T

echn

olog

y–

Sep.

200

1

Trained forCompetenceTrained for

Competence

Rider RingsRing Type 0841

Description:Solid Ring- without any gap or grooves

Function:Guides the piston in the liner.

Application:Rings mounted at the ends of the piston running over the valve port or over guidance.

6.5.1

All r

ight

s re

serv

ed -

Jona

than

Whi

te H

RPU

, Bra

dfor

d an

d G

. KIN

DL

Tra

inin

g C

ente

rH

OER

BIG

ER C

ompr

essi

on T

echn

olog

y–

Sep.

200

1

Trained forCompetenceTrained for

Competence

Rider RingsRing Type 0849

Description:Straight cut ring with side grooves

Function :Guide the piston in the liner. The grooves allow gas to pass across the ring, preventing the ring from becoming pressurised.

Application:Ring design where radial thickness is limited and small side grooves are sufficient to avoid pressure loading of the ring.

6.5.2

All r

ight

s re

serv

ed -

Jona

than

Whi

te H

RPU

, Bra

dfor

d an

d G

. KIN

DL

Tra

inin

g C

ente

rH

OER

BIG

ER C

ompr

essi

on T

echn

olog

y–

Sep.

200

1

Trained forCompetenceTrained for

Competence

Rider RingsRing Type 0854

6.5.3

cut

Description:Ring with angle cut, side and face grooves.Function:Ring guides the piston in the liner. The grooves allow gas to pass across the ring, preventing the ring from becoming pressurized. The grooves are arranged in alternatedirections to prevent the ring from turning in service. This will limit the velocity of the ring in relation to the cylinder liner.Application: Standard ring design

All r

ight

s re

serv

ed -

Jona

than

Whi

te H

RPU

, Bra

dfor

d an

d G

. KIN

DL

Tra

inin

g C

ente

rH

OER

BIG

ER C

ompr

essi

on T

echn

olog

y–

Sep.

200

1

Trained forCompetenceTrained for

Competence

Rider RingsRing Type 0873

Description:2 piece design, straight cuts, side and face pressure relief grooves.

Function:Guide the piston in the liner.The grooves prevent the ring from being pressure loaded.

Application:For smaller diameters and brittle materials.

6.5.4

All r

ight

s re

serv

ed -

Jona

than

Whi

te H

RPU

, Bra

dfor

d an

d G

. KIN

DL

Tra

inin

g C

ente

rH

OER

BIG

ER C

ompr

essi

on T

echn

olog

y–

Sep.

200

1

Trained forCompetenceTrained for

Competence

Combined Piston and Rider RingCombination Ring Type 0881

6.5.5

filler rings are piston rings

“T” shaped ring

Description:Rings with straight cut: T-shaped rider ring and two piston rings.Function:Rider ring guides the piston in the liner, piston rings seal. Application:For additional sealing. For retrofits, when the width of the rider ring has to be reduced, e.g. change from non lube to lube. For retrofit from cast iron to non metallic rings.

All r

ight

s re

serv

ed -

Jona

than

Whi

te H

RPU

, Bra

dfor

d an

d G

. KIN

DL

Tra

inin

g C

ente

rH

OER

BIG

ER C

ompr

essi

on T

echn

olog

y–

Sep.

200

1

Trained forCompetenceTrained for

Competence

Mounting Instructionsfor Piston and Rider Rings

Mounting InstructionsMounting Instructionsfor Piston and Rider Rings

• Nomenclature of Dimensions • Mounting of Piston Rings• Mounting of Solid Rider Rings

6.6.0

All rights reserved - Jonathan White HRPU, Bradford and G. KINDL Training Center HOERBIGER Compression Technology – Sep. 2001

Trained forC

ompetence

Trained forC

ompetence

Cylinder R

ingsN

omenclature of D

imensions

LinerLiner

Piston

Piston

axial clearance

axial clearance

axialring w

idth.

axial riderring w

idth

width of rider

ring groovew

idth of pistonring groove

cylinder DIA

outer DIAof piston

inner DIA of piston ring

piston ringgroove DIA

rider ring grooveDIA

inner DIA of rider ring

runningclearance

rider ringradial width

piston ringradial width

6.6.1

All r

ight

s re

serv

ed -

Jona

than

Whi

te H

RPU

, Bra

dfor

d an

d G

. KIN

DL

Tra

inin

g C

ente

rH

OER

BIG

ER C

ompr

essi

on T

echn

olog

y–

Sep.

200

1

Trained forCompetenceTrained for

Competence

Use thin sleeves for preventing rings jumping into grooves. For small cylinder diameters and/or brittle materials

heat rings up to 150°C.

Piston RingsMounting Instructions

6.6.2

sleevesleeve

piston ring

All r

ight

s re

serv

ed -

Jona

than

Whi

te H

RPU

, Bra

dfor

d an

d G

. KIN

DL

Tra

inin

g C

ente

rH

OER

BIG

ER C

ompr

essi

on T

echn

olog

y–

Sep.

200

1

Trained forCompetenceTrained for

Competence� � � � Heat rider ring up to 150°C

Cone angle 12°

Rings should be pushed down the coneby the pusher ring in a smooth continuous action. If possible, a press should be used.

� � � �

� � � �

Rider RingsMounting Instructions for Solid Rider Rings

6.6.3

Special information :

Pusher ring, with straight cut

Fitting cone

Solid rider ring

Rider ring groove

Piston diameter

Slipover diameter