ZED PURLIN SYSTEMS - · PDF fileZED PURLIN SYSTEMS Z and C - sections For secondary steel...

Transcript of ZED PURLIN SYSTEMS - · PDF fileZED PURLIN SYSTEMS Z and C - sections For secondary steel...

voestalpine PROFILFORM s.r.o.www.voestalpine.com/profilform-cz

ZED PURLIN SYSTEMS

Z and C - sectionsFor secondary steel structures

Design tables according to Eurocodes

Easy design in software MetSPEC 12

System solution

Purlins and side rails •

Eaves beams • Floor

beams • Framing

Large range of Z and C - sections

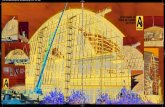

Structural systems METSEC – a name you can trust and which is a synonym for the efficient solution of secondary steel structures of hall constructions. Our existing results include thousands of successful deliveries of purlin systems for halls of various uses and with the size ranging from several hundred square meters to huge logistic and shopping centres.

There were photographs and material provided by the companies PKD, Warex and Ikon used in the catalogue.

Introduction and components 4Investment in the quality and services 4Anatomy of frame structure with METSEC systems 6–7Z - sections 8C - sections 9

Purlin systems 10Z - sections / purlins – structural systems 10–11Z - sections / purlin system Butt 12Z - sections / purlin system Sleeved 14–15Z - sections / purlin system H.E.B. 16–17Z - sections / purlin system Metlap 18–19Supports / wire diagonal ties and eaves braces For length of roof slope up to 20 m 20–21Supports / wire diagonal ties and eaves braces For length of roof slope up to more than 20 m 22–24Cantilever / overlap 25Cleader angle & frame struts 26

Eaves beam 28Eaves beams sizes and cross-section characteristic 28–29Eaves beams detail of eavesthrough 30Eaves beams column tie beams 31

Side rail systems 32Z a C - sections / side rails – structural systems 33C - sections / side rails system Butt 34Z - sections / side rails system Butt 35C - sections / side rails system Sleeved 36–37 Z - sections / side rails system Sleeved 38–39Systems of side rails support 40–43Attic frame 45Window trimmers 46Doorposts 47

Accessory components 48Gable posts 48Wind bracing components 49Cleats and trimmer cleats 50

Design tables 51Introduction 51Purlins / Z - sections – system Sleeved 51–54Purlins / Z - sections – system H.E.B. 55–58Purlins / Z - sections – system Metlap 59–62Purlins / Z - sections – system Butt 63–64Side rails / Z and C - sections – system Sleeved 65–66Side rails / Z and C - sections – system Butt 67–68Component weight 69

Floor beams 70 System for floor beams 70Sizes, punching and cross-section characteristic 71Frame design 72Version – inserted/oversail 73Accessory – cleats 74Accessory – bars 75Light version of the celling construction 76Heavy version of the celling construction 77Floor beams design – simply supported beam 78

Software 80Production detailing in programme TEKLA 80Advance Steel 81Design software MetSPEC 82

Contents

Introduction and components

Investment in quality and services

4

Company METSEC systems

Voestalpine PROFILFORM s.r.o., producer of the METSEC system is a part of Metal Forming division of the voestalpine corporation – the largest world producer of cold-rolled sections producing more than 800 000 tons of these section a year.

Voestalpine PROFILFORM s.r.o. belongs among the leading producers of thin-walled cold-rolled sections in the Czech Republic. It supplies the purlin systems METSEC on the markets in the Central Europe and Russia. These systems are used as secondary steel frames in the hall constructions.

We focus on the precise production with technical support and supplies "in time". Our objective is to provide an excellent service and quality product, which offers an efficient solution of hall frames to the customers.

- Purlin systems METSEC The system offers a wide range of Z - section design for the provision of optimum structural solutions of modern roof frames.

- Side rails systems METSEC The system offers a wide range of C or Z - sections designed for the provision of optimum structural solutions of modern wall frames.

- Floor beams METSEC The system offers a wide range of C - sections designed for easy and fast structural solution of hall ceiling buildings.

5

Anatomy of frame structure with METSEC systems

Attic pillar from C - section page 45

Cleader angle page 26

Eaves beam page 28

Floor beams page 70

Door posts from C - section page 47

6

Introduction and components

Upper attic side rail page 45

Tie beam of frame corner page 31

Wire diagonal tie / strut between purlins page 20

Side rails page 33

Side rails support page 40

Window trimmer cross bars from C - sections page 46

Trimmers from C - sections

Eaves brace page 30

Z - Purlin page 10

Introduction and components

Purlin systems 10–26

Eaves beams 28–31

Side rails systems 32–47

Accessory components 48–50

Design tables 51–69

Floor beams 70–79

METSEC systems are the most used systems for purlins and side rails in the Czech Republic.

7

8

All the METSEC Z and C - sections are made

of hot-dip galvanised steel S450GD + Z275

with the minimum strength at yield point

450 MPa.

X

Cx

X

E

Y

Y

HEI

GH

T

Lt

t

F

Cy

Lb

Reference of Z - Section

Reference of the height of Z - Section 232

mm and thickness 1.8 mm = 232 Z 18. First

three characters designate the section height

in millimetres (i.e. 232 is equal to height 232

mm). The fourth character designates the

section type (Z for Z - section). Last two

characters designate the section thickness

(18 is equal 1.8 mm).

Reference of sleeves

The designation of sleeves is the same as

of purlins with the following extension: S for

standard sleeves – S 232 Z 18, HS for sleeves

of next-to-last frames in the system H.E.B –

HS 232 Z 18.

Z - Sections / cross-section characteristic of the full cross section Section

referenceWeight kg/m

Area cm2

Height mm

Upper flange

Lower flange

tmm

Ixxcm4

Iyycm4

Wxxcm3

Wyycm3

Ixxcm

Iyycm

Cxcm

Cycm

McxkNm

McykNm

122 Z 13 2.59 3.30 122 60 55 1.3 82.9 27.2 13.41 4.65 4.93 2.83 6.18 5.53 5.097 2.093122 Z 14 2.78 3.55 122 60 55 1.4 88.9 29.1 14.39 4.98 4.93 2.82 6.18 5.52 5.743 2.243122 Z 15 2.97 3.79 122 60 55 1.5 95.0 31.0 15.36 5.31 4.92 2.81 6.18 5.52 6.394 2.390122 Z 16 3.16 4.04 122 60 55 1.6 100.9 32.9 16.33 5.64 4.92 2.81 6.18 5.51 7.043 2.536122 Z 18 3.54 4.52 122 60 55 1.8 112.8 36.5 18.25 6.27 4.91 2.79 6.18 5.50 8.307 2.824142 Z 13 2.84 3.62 142 60 55 1.3 117.4 27.2 16.34 4.65 5.66 2.72 7.19 5.52 6.007 2.091142 Z 14 3.05 3.89 142 60 55 1.4 126.1 29.1 17.54 4.98 5.66 2.72 7.19 5.52 6.776 2.240142 Z 15 3.26 4.16 142 60 55 1.5 134.6 31.0 18.74 5.31 5.65 2.71 7.19 5.51 7.554 2.388142 Z 16 3.47 4.42 142 60 55 1.6 143.2 32.9 19.93 5.63 5.65 2.71 7.19 5.51 8.330 2.534142 Z 18 3.89 4.95 142 60 55 1.8 160.1 36.5 22.28 6.27 5.64 2.69 7.19 5.49 9.850 2.821142 Z 20 4.30 5.48 142 60 55 2.0 176.8 40.1 24.60 6.89 5.63 2.68 7.19 5.48 11.302 3.101172 Z 13 3.25 4.14 172 65 60 1.3 192.6 33.9 22.17 5.33 6.79 2.85 8.69 6.01 7.497 2.397172 Z 14 3.49 4.45 172 65 60 1.4 206.9 36.3 23.81 5.71 6.78 2.84 8.69 6.01 8.498 2.569172 Z 15 3.73 4.76 172 65 60 1.5 221.1 38.6 25.44 6.09 6.78 2.83 8.69 6.00 9.517 2.739172 Z 16 3.98 5.06 172 65 60 1.6 235.2 41.0 27.07 6.46 6.77 2.83 8.69 6.00 10.547 2.908172 Z 18 4.45 5.67 172 65 60 1.8 263.1 45.6 30.29 7.20 6.76 2.81 8.69 5.99 12.603 3.239172 Z 20 4.93 6.28 172 65 60 2.0 290.8 50.1 33.47 7.92 6.75 2.80 8.69 5.98 14.606 3.564172 Z 23 5.63 7.17 172 65 60 2.3 331.7 56.6 38.18 8.97 6.74 2.78 8.69 5.96 17.460 4.038172 Z 25 6.09 7.76 172 65 60 2.5 358.6 60.8 41.28 9.66 6.73 2.77 8.69 5.95 19.271 4.346202 Z 14 3.82 4.87 202 65 60 1.4 301.0 36.3 29.53 5.70 7.82 2.71 10.19 6.00 10.072 2.567202 Z 15 4.09 5.21 202 65 60 1.5 321.7 38.6 31.56 6.08 7.82 2.71 10.19 6.00 11.310 2.737202 Z 16 4.35 5.54 202 65 60 1.6 342.4 41.0 33.58 6.46 7.81 2.70 10.19 5.99 12.559 2.905202 Z 18 4.88 6.21 202 65 60 1.8 383.3 45.6 37.60 7.19 7.80 2.69 10.19 5.98 15.051 3.236202 Z 20 5.40 6.88 202 65 60 2.0 423.8 50.1 41.57 7.91 7.79 2.68 10.19 5.97 17.486 3.560202 Z 23 6.17 7.86 202 65 60 2.3 483.8 56.6 47.45 8.96 7.78 2.66 10.19 5.96 20.984 4.034202 Z 27 7.19 9.16 202 65 60 2.7 562.3 64.9 55.16 10.32 7.76 2.64 10.19 5.94 25.403 4.642232 Z 15 4.44 5.66 232 65 60 1.5 446.1 38.6 38.14 6.08 8.84 2.60 11.70 5.99 13.022 2.734232 Z 16 4.73 6.02 232 65 60 1.6 474.8 41.0 40.59 6.45 8.83 2.59 11.70 5.99 14.500 2.903232 Z 18 5.30 6.75 232 65 60 1.8 531.7 45.6 45.45 7.19 8.82 2.58 11.70 5.98 17.450 3.234232 Z 20 5.87 7.48 232 65 60 2.0 588.1 50.1 50.27 7.91 8.81 2.57 11.70 5.97 20.342 3.558232 Z 23 6.71 8.55 232 65 60 2.3 671.8 56.6 57.42 8.96 8.79 2.55 11.70 5.95 24.526 4.031232 Z 25 7.27 9.26 232 65 60 2.5 726.8 60.8 62.13 9.64 8.78 2.54 11.70 5.94 27.221 4.338262 Z 16 5.11 6.50 262 65 60 1.6 634.6 41.0 48.07 6.45 9.83 2.50 13.20 5.98 16.333 2.901262 Z 18 5.73 7.29 262 65 60 1.8 710.9 45.6 53.85 7.18 9.82 2.49 13.20 5.97 19.763 3.231262 Z 20 6.34 8.08 262 65 60 2.0 786.6 50.1 59.58 7.90 9.81 2.47 13.20 5.96 23.138 3.555262 Z 23 7.26 9.24 262 65 60 2.3 898.9 56.6 68.08 8.95 9.79 2.46 13.20 5.95 28.051 4.028262 Z 25 7.86 10.01 262 65 60 2.5 972.9 60.8 73.69 9.63 9.78 2.45 13.20 5.94 31.236 4.335262 Z 29 9.06 11.54 262 65 60 2.9 1118.9 69.0 84.75 10.96 9.76 2.42 13.20 5.92 37.442 4.930302 Z 20 7.86 10.02 302 90 82 2.0 1355.9 132.9 88.70 15.15 11.57 3.62 15.29 8.23 30.362 6.819302 Z 23 9.01 11.47 302 90 82 2.3 1551.3 150.9 101.49 17.24 11.56 3.61 15.29 8.21 38.205 7.758302 Z 25 9.76 12.44 302 90 82 2.5 1680.5 162.7 109.94 18.60 11.55 3.59 15.29 8.20 43.417 8.372302 Z 29 11.27 14.35 302 90 82 2.9 1936.1 185.6 126.66 21.27 11.53 3.57 15.29 8.18 53.561 9.573342 Z 23 9.73 12.39 342 90 82 2.3 2085.0 151.0 120.56 17.22 12.90 3.47 17.29 8.20 43.380 7.750342 Z 25 10.55 13.44 342 90 82 2.5 2259.1 162.7 130.63 18.59 12.89 3.46 17.29 8.19 49.455 8.364342 Z 27 11.37 14.48 342 90 82 2.7 2432.1 174.3 140.63 19.93 12.88 3.45 17.29 8.18 55.447 8.968342 Z 30 12.58 16.03 342 90 82 3.0 2689.4 191.3 155.51 21.91 12.86 3.43 17.29 8.17 64.227 9.858402 Z 25 12.16 15.49 402 100 92 2.5 3549.3 222.9 174.86 22.84 15.06 3.77 20.3 9.19 60.38 8.909402 Z 27 13.01 16.69 402 100 92 2.7 3822.7 239.0 188.33 24.51 15.05 3.76 20.3 9.18 64.975 11.030402 Z 29 14.04 17.89 402 100 92 2.9 4094.4 254.8 201.72 26.15 15.04 3.75 20.3 9.17 76.37 10.200402 Z 30 14.41 18.49 402 100 92 3.0 4229.7 262.6 208.38 26.97 15.03 3.75 20.3 9.16 76.337 12.136402 Z 32 15.45 19.68 402 100 92 3.2 4499.1 277.9 221.65 28.58 15.02 3.73 20.3 9.15 88.10 11.146

Note: capacity moments Mcx, Mcy are specified for the efficient cross section.

Z - sectionsSizes and cross-section characteristic

Section height

Ltmm

Lbmm

Emm

Fmm

122–262 14 16 44 42

302–342 19 21 55 52

402 20 22 55 52

Introduction and components

Holes design

Holes in the web of 18 mm diameter are

transversely located on standard axes – see

figure. Holes in flanges of 14 mm diameter are

transversely located in the half of the flange

size. Longitudinal position of holes is carried

out in compliance with customer requirements.

9

All the METSEC Z and C - sections are made

of hot-dip galvanised steel S450GD + Z275

with the minimum strength at yield point

450 MPa.

Reference of C - sections

Reference of the height of C - Section 232

mm and thickness 1.8 mm = 232 C 18. First

three characters designate the section height

in millimetres (i.e. 232 is equal to height

232 mm). The fourth character designates

the section type (C for C - section). Last two

characters designate the section thickness

(18 is equal 1.8 mm).

Reference of sleeves

See pages 36–37, where the designation and

weights of C sleeves are mentioned.

HEI

GH

T

X

A

X

Y

L

L

t

A

Cx

B

YCy

D2

C - Sections / cross-section characteristic of the full cross sectionSection

referenceWeight kg/m

Area cm2

Height mm

Flangemm

tmm

Ixxcm4

Iyycm4

Wxxcm3

Wyycm3

Ixxcm

Iyycm

Cycm

McxkNm

McykNm

122 C 13 2.59 3.30 122 60 1.3 84.1 16.7 13.79 4.11 4.96 2.21 1.93 5.113 1.850122 C 14 2.78 3.55 122 60 1.4 90.3 17.9 14.80 4.40 4.96 2.21 1.93 5.758 1.981122 C 15 2.97 3.79 122 60 1.5 96.4 19.1 15.80 4.69 4.95 2.20 1.93 6.408 2.111122 C 16 3.16 4.04 122 60 1.6 102.5 20.3 16.80 4.98 4.95 2.20 1.93 7.057 2.240122 C 18 3.54 4.52 122 60 1.8 114.5 22.5 18.77 5.54 4.94 2.19 1.93 8.322 2.492142 C 13 2.84 3.62 142 60 1.3 119.0 17.6 16.76 4.18 5.69 2.19 1.80 6.022 1.882142 C 14 3.05 3.89 142 60 1.4 127.7 18.8 17.99 4.48 5.68 2.18 1.80 6.790 2.016142 C 15 3.26 4.16 142 60 1.5 136.4 20.1 19.22 4.77 5.68 2.18 1.80 7.566 2.148142 C 16 3.47 4.42 142 60 1.6 145.1 21.3 20.44 5.06 5.67 2.17 1.80 8.341 2.279142 C 18 3.89 4.95 142 60 1.8 162.2 23.7 22.85 5.63 5.67 2.16 1.80 9.862 2.535142 C 20 4.30 5.48 142 60 2.0 179.1 26.0 25.23 6.19 5.66 2.16 1.80 11.315 2.787172 C 13 3.25 4.14 172 65 1.3 194.7 22.7 22.64 4.83 6.81 2.32 1.81 7.507 2.174172 C 14 3.49 4.45 172 65 1.4 209.1 24.3 24.32 5.18 6.81 2.32 1.81 8.505 2.330172 C 15 3.73 4.76 172 65 1.5 223.5 25.9 25.98 5.52 6.80 2.31 1.81 9.523 2.484172 C 16 3.98 5.06 172 65 1.6 237.7 27.5 27.64 5.86 6.80 2.31 1.81 10.552 2.636172 C 18 4.45 5.67 172 65 1.8 266.0 30.6 30.93 6.52 6.79 2.30 1.81 12.607 2.935172 C 20 4.93 6.28 172 65 2.0 294.0 33.6 34.18 7.17 6.78 2.29 1.81 14.610 3.228172 C 23 5.63 7.17 172 65 2.3 335.3 38.1 38.99 8.13 6.76 2.28 1.81 17.466 3.656172 C 25 6.09 7.76 172 65 2.5 362.5 41.0 42.16 8.74 6.75 2.27 1.82 19.278 3.934202 C 14 3.82 4.87 202 65 1.4 303.9 25.4 30.09 5.26 7.85 2.27 1.66 10.076 2.367202 C 15 4.09 5.21 202 65 1.5 324.8 27.1 32.16 5.61 7.84 2.27 1.66 11.312 2.523202 C 16 4.35 5.54 202 65 1.6 345.6 28.8 34.22 5.95 7.84 2.26 1.66 12.560 2.678202 C 18 4.88 6.21 202 65 1.8 386.9 32.0 38.31 6.63 7.83 2.25 1.66 15.052 2.982202 C 20 5.40 6.88 202 65 2.0 427.8 35.2 42.36 7.29 7.82 2.24 1.67 17.487 3.280202 C 23 6.17 7.86 202 65 2.3 488.4 39.9 48.35 8.26 7.80 2.23 1.67 20.986 3.716202 C 27 7.19 9.16 202 65 2.7 567.7 45.9 56.20 9.50 7.78 2.21 1.67 25.405 4.274232 C 15 4.44 5.66 232 65 1.5 449.9 28.2 38.79 5.68 8.86 2.22 1.54 13.022 2.555232 C 16 4.73 6.02 232 65 1.6 478.8 29.9 41.28 6.03 8.86 2.21 1.54 14.499 2.711232 C 18 5.30 6.75 232 65 1.8 536.3 33.3 46.23 6.71 8.85 2.20 1.54 17.448 3.020232 C 20 5.87 7.48 232 65 2.0 593.1 36.6 51.13 7.38 8.83 2.19 1.54 20.340 3.322232 C 23 6.71 8.55 232 65 2.3 677.5 41.4 58.40 8.36 8.82 2.18 1.55 24.524 3.763232 C 25 7.27 9.26 232 65 2.5 733.0 44.6 63.19 9.00 8.81 2.17 1.55 27.220 4.049262 C 16 5.11 6.50 262 65 1.6 639.5 30.8 48.82 6.09 9.85 2.16 1.43 16.330 2.739262 C 18 5.73 7.29 262 65 1.8 716.4 34.3 54.69 6.78 9.84 2.15 1.43 19.760 3.050262 C 20 6.34 8.08 262 65 2.0 792.7 37.8 60.51 7.46 9.83 2.15 1.44 23.134 3.356262 C 23 7.26 9.24 262 65 2.3 905.8 42.7 69.15 8.45 9.82 2.13 1.44 28.047 3.801262 C 25 7.86 10.01 262 65 2.5 980.4 46.0 74.84 9.09 9.80 2.12 1.44 31.231 4.091262 C 29 9.06 11.54 262 65 2.9 1127.6 52.2 86.08 10.33 9.78 2.10 1.45 37.436 4.650302 C 20 7.86 10.02 302 88 2.0 1360.3 93.0 90.09 13.97 11.59 3.03 2.14 30.351 6.285302 C 23 9.01 11.47 302 88 2.3 1556.4 105.8 103.07 15.89 11.58 3.02 2.14 38.110 7.149302 C 25 9.76 12.44 302 88 2.5 1686.0 114.1 111.65 17.14 11.57 3.01 2.14 43.246 7.713302 C 29 11.27 14.35 302 88 2.9 1942.4 130.3 128.63 19.59 11.55 2.99 2.15 53.219 8.816342 C 23 9.73 12.39 342 88 2.3 2090.8 109.3 122.27 16.05 12.92 2.95 1.99 43.256 7.224342 C 25 10.55 13.44 342 88 2.5 2265.4 117.9 132.48 17.32 12.91 2.94 2.00 49.248 7.795342 C 27 11.37 14.48 342 88 2.7 2438.8 126.3 142.62 18.57 12.90 2.93 2.00 55.149 8.357342 C 30 12.58 16.03 342 88 3.0 2696.9 138.8 157.71 20.41 12.88 2.92 2.00 63.794 9.183

Note: capacity moments Mcx, Mcy are specified for the efficient cross section.

C - sectionsSizes and cross-section characteristic

Section height

Amm

Lmm

122–142 43 13

172, 202 43 13

232, 262 43 13

302 53.5 18

342 53.5 18

Introduction and components

Holes design

Holes in the web of 18 mm diameter are

transversely located on standard axes–see

figure. Holes in flanges of 14 mm diameter are

transversely located in the half of the flange

size. Longitudinal position of holes is carried

out in compliance with customer requirements.

System H.E.B. – single span lengths

System H.E.B – double span lengths

System Sleeved – single span lengths

Z - sections / purlinsStructural systems

Purlin systems

For the buildings with five or more

bays. The maximum purlin span is up

to 15.0 meters. Stronger purlins are

placed in outer bays and weaker ones

in inner bays. The purlin joints on the

next-to-last frames are reinforced

by the sleeves of the same section

as the purlins of outer bays and they

are longer than standard sleeves.

All the joints of inner purlins are

reinforced by standard sleeves of the

same section as the purlins of the

inner bay.

See – mentioned above: purlins

of inner bays are in double span

lengths in the maximum version of

length of 15 meters.

For the buildings with two or more

bays where it is not possible to use the

H.E.B. system. The maximum purlin

span is 15 meters. Standard sleeves

reinforce the purlin connections

on inner joints to frames and on each

joint on the next-to-last frame.

Figure 1: minimum of 5 bays, purlin span up to 15 m

Figure 2: minimum of 5 bays, purlin span up to 7.5 m

Figure 3: minimum of 2 bays, purlin span 15 m

10

CONTINUOUS BEAM

CONTINUOUS BEAM

CONTINUOUS BEAM

The production processes managed and controlled

electronically allow using the reference of individual

components according to the customer request.

(Maximum number of characters is 5).

Design tables 55–58

Details 16–17

Design tables 55–58

Details 16–17

Design tables 51–54

Details 14–15

System Sleeved – double span lengths

System Butt

System Metlap

Z - sections / purlinsStructural systems

Purlin systems

See System Sleeved but the standard

sleeves reinforce all the purlin

connections (at next-to-last frames and

inner frames also). Maximum length

can be up to 15 meters.

This system is used for single bays

and it can be used as inserted

between the frames or oversail above

the frames.

For the buildings with four or more

bays. The maximum purlin span is

up to 14.5 meters. Stronger purlins

are placed in outer bays and weaker

purlins in inner bays. The continuity

of purlins is secured by the section

overlap in the place where they are

connected to frames.

Figure 4: minimum of 4 bays, purlin span up to 7.5 m

Figure 6: minimum of 1 by, purlin span up to 12 m

Figure 5: minimum of 4 bays, purlin span up to 14.5 m

11

CONTINUOUS BEAM

CONTINUOUS BEAM

SIMPLY SUPPORTED BEAM

The production processes managed and controlled

electronically allow using the reference of individual

components according to the customer request.

(Maximum number of characters is 5).

Design tables 51–54

Details 14–15

Design tables 59–62

Details 18–19

Design tables 63–64

Details 12

12

Z - sections / purlin system ButtArrangement and details

Single span arrangement

Figure 8: typical single bay arrangement depicting the purlin placement

P2Figure 7: P1 and P1x (opposite side)

CAB

H

3270

3 3

32

CL CL CL

Total lengthTotal length

A B C H

142 42 56 50

172 42 86 50

202 42 116 50

232 42 146 50

262 42 176 50

302 52 195 60

342 52 235 60

402 52 295 60

Roof purlins designed as simply supported beams are

suitable for buildings with one or more bays up to 25° of

pitch (included).

The Butt system offers a simple connection to structural frames

and it is intended for smaller buildings, short or uneven spans

or for frames with small load. The Butt system is designed for

the span up to 12 meters depending on the load and type

of cladding securing the necessary reinforcement through its

connection to the purlin (according to producer’s requirements).

This system can be combined with other systems described

in this publication or as an independent system.

Design tables 63–64

The production processes managed

and controlled electronically allow

using the reference of individual

components according to the

customer request. (Maximum number

of characters is 5).

Holes in web are of 18 mm diameter.

* Alternatively executed holes for the placement of reinforcements.

Purlin systems

13

P2

Purlin systems

Z - sections / purlin system SleevedArrangement and details for 2 and more bays

14

Roof purlins designed as continuous beams are suitable

for buildings with two or more bays up to 25° of pitch

(included).

The Sleeved system optimises the use of beams by inserting

the sleeves in all the connections on the next-to-last frames

and alternate sleeves in inner frames. The Sleeved system

can be used for the purlin span up to 15 meters depending

on the load and on the precondition that the cladding secures

the sufficient stiffness of purlins by its connection (according

to producer’s instructions). The sleeve must be turned so as

to be able to insert it in the purlin. Information about the detail

of the connection is on the page 50.

More information about the connection detail is on the page 50.

Design tables 51–54

The production processes managed

and controlled electronically allow

using the reference of individual

components according to the

customer request. (Maximum number

of characters is 5).

Purlin systems

15

Single span arrangement

Figure 12: typical single span arrangement depicting the placement of purlins and sleeves

Figure 13: typical double span arrangement depicting the placement of purlins and sleeves

Double span arrangement

All the connections on the next-to-last frames are reinforced

by the sleeve. Connections on inner frames are reinforced

by alternate sleeves.

The purlins of end bays are single bay ones and the purlins

of inner bays are two bay ones. Maximum distance between the

frames is 7.5 meters. The maximum section length is 15 meters.

Please pay attention to the manipulation with longer lengths.

The sleeves must be placed in all the purlin connections.

32 32D D

3 3

C A

B

C A

EE

G

C

F

3 3

G

32 D3 3232 DD

GG

32 D3 3 3

70D D 2323

G

70

70

**

*

*

*

Total length

Axial distance of frames

Axial distance of frames

Axial distance of frames

Axial distance of frames

Axial distance of frames

Wide flange

Wide flange

Wide flange Wide flange

Wide flange

Narrow flange

Narrow flangeNarrow flange

Narrow flange Narrow flange

Wide flange

Variable overhang

Figure 9: P1 and P1x (opposite side)

Figure 11: P3

Figure 10: P2

P4 and P4x (opposite side)

A B C D E F G

142 42 56 240 44 50 614

172 42 86 290 44 50 714

202 42 116 350 44 50 834

232 42 146 410 44 50 954

262 42 176 460 44 50 1054

302 52 195 610 55 60 1354

342 52 235 760 55 60 1654

Design tables 51–54

General structural details

Holes in webs have a diameter 18 mm.

* Alternatively executed holes for the placement

of reinforcements.

Connection of sleeve

to beams:

- 8 screws for sections

232 and higher

- 6 screws for sections

142–202

Purlin systems

16

Arrangement of purlins and sleeves

The figures 14 and 15 (bellow) show that the purlins of end bays (P1 and P1x)

and sleeves in the next-to-last bays are of a same section – stronger than purlins

and sleeves in inner bays (P2, P3, P5, P5x, P6 and P6x). Single bay and two bay

arrangements are depicted in figures.

Note: Sleeves must reinforce all the mutual joints of purlins.

More information about the connection detail is on the page 50.

The purlin system of continuous beams H.E.B. provides,

in most cases, the most economic solution using the

advantages of sleeve systems highlighted by the use

of weaker purlins in inner bays.

This system uses the span of purlins up to 15 meter

depending on the load in effect on the precondition

that the cladding provides sufficient stiffness to purlins

(according to producer’s instruction) by its connection.

Z - sections / purlin system H.E.B.Arrangement and details for five and more bays

Figure 14: double span lengths – arrangement of purlins and sleeves

Pay attention to the manipulation with long sections.

The maximum length of one section is 15 meters.

Figure 15: single span lengths – arrangement of purlins

and sleeves

Návrhové tabulky 55–58

The production processes managed

and controlled electronically allow

using the reference of individual

components according to the

customer request. (Maximum

number of characters is 5).

Purlin systems

70 32 32H H

3 3

CA

B

CA

E

70J

70H H 2323

C

F

3232

3 3

E

G

70D D 2323

J

32 H

DD

703

*

*

*

*

*

*

*

3232

G

DD

G

G G

32 D 703 3232

G

DD

32 D 333

Total length

Axial distance of frames

Axial distance of frames

Axial distance of frames

Axial distance of frames

Axial distance of frames

Axial distance of frames

Axial distance of frames

Wide flange

Wide flange

Wide flange

Wide flange

Wide flange

Wide flange

Wide flange Wide flange

Wide flange

Wide flange

Wide flange

Narrow flangeNarrow flange

Narrow flange

Narrow flange

Narrow flange

Narrow flange

Narrow flange Narrow flange

Variable overhang

17

Figure 16: P1 and P1x (opposite side) P4 a P4x (opposite side)

A B C D E F G H J

142 42 56 240 44 50 614 308 750

172 42 86 290 44 50 714 390 914

202 42 116 350 44 50 834 470 1074

232 42 146 410 44 50 954 583 1300

262 42 176 460 44 50 1054 683 1500

302 52 195 610 55 60 1354 783 1700

342 52 235 760 55 60 1654 933 2000

General structural details

Design tables 55–58

Figure 17: P6 a P6x (opposite side)

Figure 18: P2

Figure 19: P3

Holes in webs have a diameter 18 mm.

* Alternatively executed holes for the placement of bracings.

Connection of the sleeve

to beams:

- 8 screws for sections

232 and higher

- 6 screws for sections

142–202

Purlin systems

18

Z - sections / purlin system MetlapArrangement and details for four and more bays

The purlin system of continuous beams Metlap provides

an efficient solution for purlins of large span (more than

10 meters) or in the case of heavy load. The system Metlap

uses the advantages of the continuous beam highlighted

by placing the stronger sections in outer bays and weaker

sections in inner bays.

The system Metlap is used up to the span of 14.5 meters

depending on the load in effect and on the precondition that

the cladding provides sufficient stiffness to purlins (according

to producer’s instruction, however, the maximum centres of the

connecting screw is 600 mm) by its connection. The purlins

must be alternatively turned in order to create the connections

with overlaps.

More information about the connection detail is on the page 50.

Single span arrangement

Figure 20 shows the structural arrangement of purlins in the Metlap system.

Stronger purlins with larger overlaps are placed in end bays; weaker purlins with

shorter overlaps are in inner bays.

Figure 20: single span lengths – arrangement

Design tables 59–62

The production processes managed

and controlled electronically allow

using the reference of individual

components according to the

customer request. (Maximum

number of characters is 5).

Purlin systems

19

METLAP System Sizes mm

A B C D G

172 86 44 42 50

202 116 44 42 50

232 146 44 42 50

262 176 44 42 50

302 195 55 52 60

342 235 55 52 60

402 295 55 52 60

Purlin span m

Overlap E mm

Overlap F mm

Up to 5 350 700

> 5–6 400 800

> 6–7 450 900

> 7–8 500 1 000

> 8–9 550 1 100

> 9–10 600 1 200

> 10–11 650 1 300

> 11–12 700 1 400

> 12–13 700 1 400

> 13–14 700 1 400

> 14–15 700 1 400

70 E E EF 32 32 32

B

C

A

D

70

B

G

B

C

A

D

32

7070 70

70

B

D

A

C

E E32 32

Total length Total length

Total length

Axial distance of frames Axial distance of framesAxial distance of frames

Wide flange Wide flange

Narrow flange Narrow flange

Variable overhang

Figure 21: position P2 and P2x

Figure 22: position P1, P1x and P3

General structural details

Holes in webs have a diameter 18 mm.

Purlin systems

20

Sag bars / sag rods and eaves bracesFor the pitch length up to 20 meters

A

28

B

28

28

28

28

25

25

A

28

B

28

28

28

28

25

25

A

28

B

28

28

28

28

Sag bars and sag rods METSEC are designed for securing

of purlins against twisting due to wind suction and

providing sufficient stiffness when installing the cladding.

Sag rods of 16 mm diameter are used for sections 122, 142,

172, 202, 232 and 262. Anti sag bars 45 × 45 × 2 mm are used

for sections 302 and 342. On roofs with pitch larger than 25°

or with the purlin span larger than 2.4 meters, the anti sag bars

45 × 45 × 2 mm must be always used for all the section lines.

If the bars or rods are not proposed, temporary reinforcements

can be required during the cladding installation.

For the roof with pitch larger than 25° use the program MetSPEC

for the design of purlins and reinforcement components.

Figure 27: apex angle from angle 45 × 45 × 2

Figure 25: purlin anti sag rods of 16 mm diameter for lines 142, 172, 202, 232, 262

A

28

B

28

28

28

28

Figure 24: version with sag rodsFigure 23: version without sag rods

Figure 26: apex tie of 16 mm diameter

Diameter 16 mm

Purlin center

At any time when wire diagonal ties are used, eaves angles shall

be used as it is shown in Figure 24.

Apex angles

Apex angle from the angle 45 × 45 × 2 mm must be used in the

case of sections 302 and 342 or at the roof with pitch larger

than 25°.

In all the other cases, in which the rods system is required, apex

ties of 16 mm diameter must be used – see Figure 25 and 26.

All the eaves bars are made from the angle 45 × 45 × 2 mm.

Purlin systems

21

25

25

A

28

B

28

28

28

28

A

28

B

28

28

28

28

All the holes have diameter 18 mm for screws M 16.

Static tables on pages 51–64 state minimum requirements

for reinforcement of individual systems.

However, it is recommended to always observe the principles

of minimum span without angles mentioned in tables on page 22.

Figure 28: eaves bar for sections of line 142, 172, 202, 232, 262

Figure 29a: anti sag bars for sections of line 302 and 342. For other section lines in the case that the non-restraint cladding is used.

Figure 29b: HCS bar for sections 402 and centres bigger than 2.4 m

Purlin span

Standard axes for the location of holes on purlins.

Section 142 172 202 232 262

A 28 43 58 73 88

B 56 86 116 146 176

Purlin systems

20 m max

20 m max

70 70

20 m max

20 m max

Anti-sags

70

20 m max

20 m max

70

22

Sag bars / sag rods and eaves bracesFor the slope length larger than 20 meters

Roof slope, length > 20 m

The recommended restraint version for the lengths of roof slope

larger than 20 meters is in the figures 30–32 (for the roof slope

length shorter than 20 meters, it is not necessary to use wire

diagonal ties). If it is not necessary to use supports or ties due

to stabilisation of purlins against wind suction loads, we always

recommend using the apex angles and eaves brace so that the

installation is easier. In some cases, it might be necessary to use

temporary ties or supports.

Figure 30: roof plan with one line of rods/bars

Section depth Purlin span m

142 6.1

172 6.6

202/232 7.2

262 7.6

302/342 8.1

402 8.5

Section depth Purlin span m

142 6.6

172 7.2

202/232 7.6

262 8.1

302/342 8.6

Anti sag rods 16 mm

Eaves brace

WDT wire diagonal ties

Eaves beamDetail 1Eaves brace

Eaves beam span

Maximum span of purlins without supports for the systems Sleeved, Metlap, Butt and end bays of the system H.E.B.

Maximum purlin span for inner bays of the system H.E.B.

20 m max

20 m max

70 70

20 m max

20 m max

Anti-sags

70

20 m max

20 m max

70

12

3

21

All the wire diagonal ties must be fastened to the bottom hole in the cleat connecting the purlin to the frame.

Upper rim of the purlin

Details mentioned on these pages assume that the adequate

reinforcement of purlins is secured by the cladding fastened

to purlins according to the requirements of the producer

of cladding and at the same time in such manner that

the maximum centres of connecting screws are 600 mm.

In the zones with high local wind load, additional fastening

components can be required.

Note: The mentioned reinforcements can be used even due

to static design of eaves beams.

Detail 1

Purlin systems

20 m max

20 m max

70 70

20 m max

20 m max

Anti-sags

70

20 m max

20 m max

70

Figure 32: roof plan – 3 lines of bars/rods

Anti sag rods∅ 16 mm

Eaves brace

WDT wire diagonal tie

Eaves beam

Eaves brace

Eaves beam span

23

Figure 31: roof plan – 2 lines of bars/rods

20 m max

20 m max

70 70

20 m max

20 m max

Anti-sags

70

20 m max

20 m max

70

Anti sag rods∅ 16 mm

Eaves brace

WDT wire diagonal tie

Eaves beam

Eaves brace

Eaves beam span

20 m max

20 m max

70 70

20 m max

20 m max

Anti-sags

70

20 m max

20 m max

70

12

3

21

Upper rim of the purlin

All the wire diagonal ties must be fastened to the bottom hole in the cleat connecting the purlin to the frame.

20 m max

20 m max

70 70

20 m max

20 m max

Anti-sags

70

20 m max

20 m max

70

12

3

21

Upper rim of the purlin

Detail 2 Detail 3

Detail 3Detail 2

Purlin systems

24

Sag bars / sag rods and eaves braces

Component Duo pitch roof ≤ 25°

Mono pitch roof ≤ 25°

Roof pitch > 25°

Non-restraint cladding

Slope length ≤ 20 m > 20 m

All roof pitches All roof pitches All roof pitches

WDT Every 20 m

Every 20 m

Eaves brace

Anti sag rod 16 mm * * *Apex angle of rod of 16 mm diameter

Anti sag bar 45 × 45 × 2 mm

Apex angle from angle 45 × 45 × 2 mm

Non-restraint cladding

If cladding, which is not fastened to purlins according to the

requirements on the pages 22–23, is used or if cladding,

which does not provide sufficient reinforcement of purlins

is used, it is necessary to design a reinforcement system,

which will secure the purlin stiffness against the deviation.

If you design purlins in the programme MetSPEC, you

will automatically get the number of supports necessary

for securing the purlin stiffness.

Roof pitch > 25°

The reinforcement effect of the cladding is considered

sufficient for the roof pitch up to 25°. The purlins with

the roof pitch larger than 25° are designed for the load

affecting in two directions. When designing the purlins in the

programme MetSPEC, you will simply define the required

amount of angles for each case.

Mono pitch roofs with pitch < 25°

When solving the mono pitch roofs, the eaves angles

with wire diagonal ties are always used as it is depicted

on pages 22–23 (Figure 30–31). If the purlin stiffness is

secured in another manner, it is of course possible to leave

the eaves angles and diagonal ties.

Support from angle 45 × 45 × 2 mm

Requirements for bracings

* They can be required due to the wind suction or installation – see recommendation on page 20.

Purlin systems

25

Cantilever / overlap

= =

28

CL

CL

CL

Roof purlin

Cleader angle

Frame rafter

Wall claddingPillar

Ceiling cladding

Roof cladding

Cleader angle

Execution

The figure 33 shows the recommended execution –

the purlin of the outer bay is overlapped across the gable

wall in necessary length. The sufficient cantilever stiffness

is secured by cladding or optional restraint.

Deflection criteria

The roof purlins designed in the compliance with this

technical manual must meet the minimum criterion for the

span deflection L/180. The final deflection of the cantilever

should be compatible with this criterion and therefore, we

recommend that the cantilever is maximum of 28 % of the

purlin span.

Cantilever restraint

It is recommended for cantilevers that their ends

are connected with reinforcement elements (for example

an angle 45 × 45 × 2 mm) because of the increase

of stiffness and stability at twisting. An example of such

detail in in Figure 33. The angle fastened to the upper and

bottom rim of the section provides sufficient reinforcement

and it also allows for the easy connection of the cladding.

These angles should be connected at the top due to the

prevention of the deflection on the roof pitch.

Mono pitch roofs and roofs with pitch > 25°

We recommend using diagonal ties in order to create

the restraint. Of course, you can use another manner

of reinforcement.

Figure 33: typical detail of cantilever

Purlin systems

26

Cleader angles & rafter stays

= =

28

CL

CL

CL

= =

28

CL

CL

CL

= =

28

CL

CL

CL

= =

28

CL

CL

CL

= =

28

CL

CL

CL

Cleader angles

Cleader angles are made of hot-dip galvanised steel.

They are used for the fixation of the cladding to purlins

(for example at gable wall or hipped end).

There are two cleat sections available

45 × 45 × 2 mm = 1.37 kg/m

100 × 120 × 2 mm = 4.30 kg/m

Max. length = 7.50 m

We recommend to use the angle 45 × 45 × 2 mm for purlin

centres up to 1.8 meters. There is an angle 100 × 120 ×

2 mm for larger spans. Figures 36–37 show the manner of

using and connecting cleader angles. With regards to the

angle thicknesses, we recommend to connect them by over-

laps of the length of minimum 28 mm (see Figure 36).

The angles can be fixed to the upper or bottom rim of the

section – see Figure 37.

Rafter stays

Where the static design of steel frames requires the use

of stays, it is possible to add holes to purlins according to

individual requirements. The ideal pitch of frame supports

is 45°.

Where it is possible, the holes for fixation of sleeves or purlin

overlaps can be used for the fixation of supports.

We supply stays made of an angle 45 × 45 × 2 mm. In the

case of higher sections of the frame rafter or truss tie

beams, a stronger section of the rafter stays must be used.

It is possible to define the support section through the

programme MetSPEC.

The size were designed so as the holes for sleeves can be used.

Figure 34: fixation of stays in the case of higher section of the frame rafter

Figure 35: fixation of stays into holes for sleeves

Figure 36: connecting of cleader angles

Figure 37: connecting the cleader angles

Purlin systems

27

Purlin systems

Eaves beams

D

B

C

Cy

F/2

F

L

L

t

A

EBS. 170EBS. 230EBS. 270EBS. 330

∅ 18 mm

35

30

30

70

35

30 86

= =

30

32

323

10

Eaves beamsSizes and cross-section characteristic

Eaves beams METSEC are sections designed so as they

can be used as an eaves purlin, eaves side rail or beam

bearing the gutter.

Design

Eaves beams are designed as simply supported up to the

span of 15 meters depending on the load in effect.

The design tables in this manual are intended for basic

designs only and they do not contain all the conditions.

We recommend using the programme MetSPEC for the

design of eaves beams.

Specification

Eaves beams are made of hot-dip galvanised steel

of S450GD + Z275 quality.

Load bearing capacity

It is specified for simply supported beam. The holes in

eaves beams can be in a standard or counterformed

version.

Note: The requirements for stiffening are on pages 20–24.

Diameter of holes is 18 mm.

Angle 0°–25° in 5° steps

All the holes have ∅ 18 mm for the use of screws M16

Height

Figure 38: options of holes executions

Nominal sizes and cross-section characteristic of the full cross section

Section reference

Weight kg/m

Surface cm2

Height mm

Flange F mm

Lmm

tmm

DimB mm

DimC mm

DimD mm

Ixxcm4

lyycm4

Wxxcm3

Wyycm3

Ixxcm

Iyycm

Cycm

Q McxkNm

McykNm

170 E 20 5.89 7.50 170 90 19 2.0 42 86 42 368.1 84.0 43.31 13.93 6.96 3.32 2.97 0.621 16.538 6.268

170 E 23 6.73 8.58 170 90 19 2.3 42 86 42 420.4 95.5 49.45 15.84 6.95 3.31 2.97 0.698 20.548 7.128

230 E 20 6.83 8.70 230 90 19 2.0 42 146 42 734.6 92.5 63.88 14.41 9.14 3.24 2.58 0.542 23.001 6.485

230 E 25 8.47 10.79 230 90 19 2.5 42 146 42 909.3 113.5 79.07 17.69 9.11 3.22 2.58 0.646 32.501 7.960

270 E 25 9.76 12.44 270 100 22 2.5 47 176 47 1429.2 162.0 105.87 22.55 10.65 3.59 2.81 0.582 40.623 10.147

270 E 29 11.27 14.35 270 100 22 2.9 47 176 47 1646.6 185.5 121.97 25.82 10.63 3.57 2.82 0.648 50.634 11.619

330 E 30 12.58 16.03 330 90 22 3.0 47 235 48 2558.9 156.2 155.09 22.99 12.54 3.10 2.20 0.597 63.283 10.347

Note: capacity moments Mcx and Mcy are specified for the efficient cross section.

28

Eaves beams

D

B

C

Cy

F/2

F

L

L

t

A

EBS. 170EBS. 230EBS. 270EBS. 330

∅ 18 mm

35

30

30

70

35

30 86

= =

30

32

323

10

D

B

C

Cy

65

F

L

L

t

A

EBS. 170EBS. 230EBS. 270EBS. 330

18 x 24 mm

35

30

30

70

35

30 86

= =

30

32

323

D

B

C

Cy

65

F

L

L

t

A

EBS. 170EBS. 230EBS. 270EBS. 330

18 x 24 mm

35

30

30

70

35

30 86

= =

30

32

323

D

B

C

Cy

F/2

F

L

L

t

A

EBS. 170EBS. 230EBS. 270EBS. 330

∅ 18 mm

35

30

30

70

35

30 86

= =

30

32

323

10

D

B

C

Cy

65

F

L

L

t

A

EBS. 170EBS. 230EBS. 270EBS. 330

18 x 24 mm

35

30

30

70

35

30 86

= =

30

32

323

D

B

C

Cy

65

F

L

L

t

A

EBS. 170EBS. 230EBS. 270EBS. 330

18 x 24 mm

35

30

30

70

35

30 86

= =

30

32

323

D

B

C

Cy

65

F

L

L

t

A

EBS. 170EBS. 230EBS. 270EBS. 330

18 x 24 mm

35

30

30

70

35

30 86

= =

30

32

323

Eaves beam

Eaves bracing

Packing plate

Reinforcement angle reference

Side rails supports

Details of connection

Eaves beams METSEC are designed so that they

can provide easy connection of the cladding by the

counterformed holes filled with screws M16 with

countersunk head. Due to these reasons, it is necessary

to use the packing plate as shown in the Figure 39.

Note: When using the eaves reinforcements, it is necessary

to shorten the reinforcement by 6 mm. The packing plate

is used at counterformed holes only.

Use of reinforcement angles

If you use side rail supports and hange them into the eaves

beam (see page 41), the connection must be reinforced

by so-called reinforcement angle and the length of the

eaves reinforcements must be shortened by another 6 mm

(thickness of the reinforcement angle).

Figure 39: view from the direction A

Figure 40: cladding fitting to the column rim Total length of the eaves beam = pillar centres Column width – 20 mm (10 mm from each end)

Figure 41: packing plate, material: galvanised steel plate 6 mm thick

Figure 42: oversail cladding Total length of the eaves beam = column centres – 6 mm (3 mm from each side)

Manners of fixating the eaves beams to frames

Holes of diameter 36 mm

Length = see table

Centres = see table

Cleat (not supplied by METSEC) is screwed to or welded to the column.

Reference number

Section depth

Centres mm

Length

PP 1 142 56 116

PP 2 172/170 86 146

PP 3 202 116 176

PP 4 232/230 146 206

PP 5 262/270 176 236

PP 6 302 195 255

PP 7 342/330 235 295

29

Figure 43: detail of fixation of gutter to the column

Figure 45: detail of fixation of eaves beam to the column

Eaves beamsGutter detail

Design of eaves beams and purlins will be made with the

help of design tables on the page 70 or by the design

programme MetSPEC. The use of eaves reinforcements

is necessary due to the fixation of the eaves beam when

there is a wind stress and twisting coming from the gutter

load. It is assumed that the upper pressed flange of the

eaves beam is stabilised by the cladding.

The examples of the eaves beam reinforcement are

in Figure 43–46. If necessary, non-standard eaves

reinforcement can be used so that it complies with

individual requirements. It is substantial to use the screwed

connections in the web for the fixation of the eaves beam

to columns.

Pillar tie beams

Figure 44: detail of eaves beam reinforcement

Figure 46: detail of eaves beam reinforcement

30

Eaves beams

Eaves beamsColumn tie beams

Column tie beams made of C - sections METSEC offer

an efficient solution starting with their purchase and ending

with the installation on site.

They are supplied as individual components and they are

connected into one component on the installation site. They

provide extreme performance due to their weight.

Design of column tie beams from C - sections can be made

in the programme MetSPEC.

Column tie beams

Figure 47: version of column tie beam at attic

Figure 49: details of fixation of column tie beamFigure 48: version of column tie beam at central gutter

31

Eaves beams

Side rails systems

Side rails systems

Side rails systems METSEC are designed so as to create

a reliable and efficient frame for various types of cladding

according to the requirements placed on them.

32

Side rails systems

Z and C - sections / side railsStructural systems

System Butt

System Sleeved – single span lengths

System Sleeved – double span lengths

This system can be used for a single

bay in the oversail or inserted version.

The sleeves reinforce every

connection on the next-to-last frames.

They are alternately placed on inner

frames – see figure.

The sleeves reinforce every

connection on the next-to-last frames.

They are alternately placed on inner

frames.

Figure 50: minimum 1 bay, maximum frame span is 15 m

Figure 52: minimum 4 bays, maximum frame span is 7.5 m

Figure 51: minimum 2 bays, maximum frame span is 15 m

SIMPLY SUPPORTED BEAM

CONTINUOUS BEAM

CONTINUOUS BEAM

Load tables 67–68

Details of C - sections 34

Details of Z - sections 35

Load tables 65–66

Details of C - sections 36–37

Details of Z - sections 38–39

Load tables 65–66

Details C - sections 36–37

Details Z - sections 38–39

33

C - sections / side rails systems ButtArrangement and details

The side rails system of simply supported beams Butt of C -

sections is suitable for buildings with one or more bays. This

system offers simple fixation to bearing frames by the cleats.

It is intended for smaller buildings, short or uneven spans or

for small loads.

This system can be used independently or in the

combination with other systems described in this

publication. This system can be used for the span up to

15 meters depending on the load in effect. It is assumed

that the cladding secures the stiffness of sections against

the deviation. Details of cleats – see page 50.

R1

R1

R1

R1

R1

R1

R1

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R1X

R1X

R1X

R1X

R1X

R1X

R1X

A C

B

70 32 32

3 3

CL CL CL

HR2

R1

R1

R1

R1

R1

R1

R1

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R1X

R1X

R1X

R1X

R1X

R1X

R1X

A C

B

70 32 32

3 3

CL CL CL

HR2

R1

R1

R1

R1

R1

R1

R1

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R1X

R1X

R1X

R1X

R1X

R1X

R1X

A C

B

70 32 32

3 3

CL CL CL

HR2

R1

R1

R1

R1

R1

R1

R1

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R1X

R1X

R1X

R1X

R1X

R1X

R1X

A C

B

70 32 32

3 3

CL CL CL

HR2

A B C H

142 43 56 50

172 43 86 50

202 43 116 50

232 43 146 50

262 43 176 50

302 53.5 195 60

342 53.5 235 60

Figure 53: R1 and R1X (opposite side) R2

Design tables 67–68

Single span arrangement

Total lengthTotal length

34

The production processes managed

and controlled electronically allow

using the reference of individual

components according to the

customer request. (Maximum

number of characters is 5).

Holes in web are

of 18 mm diameter.

Side rails systems

Z - sections / side rails system ButtArrangement and details

R1

R1

R1

R1

R1

R1

R1

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R1X

R1X

R1X

R1X

R1X

R1X

R1X

A C

B

70 32 32

3 3

CL CL CL

HR2

R1

R1

R1

R1

R1

R1

R1

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R1X

R1X

R1X

R1X

R1X

R1X

R1X

A C

B

70 32 32

3 3

CL CL CL

HR2

R1

R1

R1

R1

R1

R1

R1

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R1X

R1X

R1X

R1X

R1X

R1X

R1X

A C

B

70 32 32

3 3

CL CL CL

HR2

R1

R1

R1

R1

R1

R1

R1

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R2

R1X

R1X

R1X

R1X

R1X

R1X

R1X

A C

B

70 32 32

3 3

CL CL CL

HR2

The side rails system of simply supported beams Butt of Z -

sections is suitable for buildings with one or more bays. This

system offers simple fixation to bearing frames by the cleats.

It is intended for smaller buildings, short or uneven spans or

for small loads.

This system can be used independently or in the

combination with other systems described in this

publication. This system can be used for the span up to

15 meters depending on load in effect. It is assumed that

the cladding secures the stiffness of sections against the

deviation. Details of cleats – see page 50.

A B C H

142 42 56 50

172 42 86 50

202 42 116 50

232 42 146 50

262 42 176 50

302 52 195 60

342 52 235 60

Figure 54: R1 and R1X (opposite side) R2

Design tables 67–68

Single span arrangement

Total lengthTotal length

35

The production processes managed

and controlled electronically allow

using the reference of individual

components according to the

customer request. (Maximum

number of characters is 5).

Holes in web are

of 18 mm diameter.

Side rails systems

C - sections / side rails system SleevedArrangement and details for structures with two and more bays

The system Sleeved optimises the use of sections through

inserting the sleeves in all the connections on the next-to-

last frames and alternate insertion into the connections

on inner frames. It is possible to use the Sleeved system

up to the maximum span of 15 meters depending on the

load in effect. It is assumed that the cladding secures the

stiffness of sections against the deviation. Details of cleats –

see page 50.

Single span arrangement Double span arrangement

Single span lengths can be supplied according to individual

requirements. The connections of the next-to-last frames are

reinforced by the sleeve and the connections of inner frames are

reinforced by alternate sleeves.

The side rails of end bays are single bay ones and the side

rails of inner bays are two bay ones. The maximum length

of individual sections is 15 meters; therefore, the maximum

possible span is 7.5 meters. The sleeves must be in each

connection of adjacent side rails – see figure bellow.

Design tables 65–66

Figure 55: typical single bay arrangement with marked locations of side rails and sleeves

Figure 56: typical two bay arrangement with marked location of side rails and sleeves

Pay attention to the manipulation with longer lengths.

36

The production processes managed

and controlled electronically allow

using the reference of individual

components according to the

customer request. (Maximum

number of characters is 5).

Side rails systems

H

C E

F

F

70 32 32D D

3 3

*

G

70D D 2323

C A

B

32 D 703

32 D3 3 3

3 3 3 3

*

*

*

*

32 32D D

General structural details

Figure 57: R1 and R1X (opposite side)

Axial frame distance

Axial frame distance

Axial frame distance

Axial frame distance

Axial frame distance

Variable overhang

Total length

Design tables 65–66

Holes in web are of 18 mm diameter.

* Alternatively made holes for the bracing placement

Sleeves C - sections

Range of sleeves C - sections includes the thickness

for each section height – see table.

A B C D E F G H

142 43 56 240 147 45.5 614 50

172 43 86 290 177 45.5 714 50

202 43 116 350 207 45.5 834 50

232 43 146 410 238 46.0 954 50

262 43 176 460 268 46.0 1054 50

302 53.5 195 610 308 56.5 1354 60

342 53.5 235 760 349 57.0 1654 60

Reference designation

Thickness mm

Weight kg

CS 142 2.0 2.64

CS 172 2.5 4.35

CS 202 2.7 6.00

CS 232 2.5 6.94

CS 262 2.9 9.55

CS 302 2.9 15.26

CS 342 3.0 20.81

Figure 58: R2

Figure 59: R3

Figure 60: R4 and R4X (opposite side)

37

Side rails systems

Z - sections / side rails system SleevedArrangement and details for the structures with two or more bays

Single span lengths can be supplied according to individual

requirements. The connections of the next-to-last frames are

reinforced by the sleeve and the connections of inner frames are

reinforced by alternate sleeves.

The side rails of end bays are single bay ones and the side rails

of inner bays are two bay ones. The maximum length of individual

sections is 15 meters; therefore, the maximum possible span is

7.5 meters. The sleeves must be in each adjacent connection of

side rails – see figure bellow.

Design tables 65–66

Figure 61: typical single bay arrangement with marking the location of side rails and sleeves

Figure 62: typical two bay arrangement with marking the location of side rails and sleeves

The system of continuous beams Sleeved optimises the use

of sections by inserting the sleeves into all the connections

on the next-to-last frames and alternate insertion into

the connection on inner frames. The Sleeved system can

be used up to the maximum span of 15 meters depending

on the load in effect. It is assumed that the cladding secures

the stiffness of sections against the deviation.

Cleat details – see page 50.

Single span arrangement Double span arrangement

38

The production processes managed

and controlled electronically allow

using the reference of individual

components according to the

customer request. (Maximum

number of characters is 5).

Side rails systems

General structural details

Figure 63: R1 a R1X (opposite side)

F

C A

E E

70

3 3

32 D 703 3232

* *

DD

32 D3 3 3

3 3 3 3

32 32D D

G

70D D 2323

C A

B*

*

*

*

*

Frame axial distance

Frame axial distance

Frame axial distance

Frame axial distance

Frame axial distance

Variable overhang

Total length

Design tables 65–66

A B C D E F G

142 42 56 240 44 50 614

172 42 86 290 44 50 714

202 42 116 350 44 50 834

232 42 146 410 44 50 954

262 42 176 460 44 50 1054

302 52 195 610 55 60 1354

342 52 235 760 55 60 1654

Wide flange

Wide flange

Wide flange Wide flange

Wide flange Wide flangeWide flange

Wide flange

Narrow flange

Narrow flange

Narrow flange

Narrow flange

Narrow flange

Narrow flange

Figure 65: R3

Figure 64: R2

Figure 66: R4 and R4X (opposite side)

39

Holes in web are of 18 mm diameter.

* Alternatively made holes for the bracing placement

Connection of the sleeve

to beams:

- 8 screws for sections

232 and higher

- 6 screws for sections

142–202

Side rails systems

Systems of side rail supports

In most frame structures, the wall cladding is fixed directly to

the side rails. So as to secure their stiffness, in many cases,

the use of supports and tie wires is required. The METSEC

systems offer extensive possibilities of support systems so

that they meet the load requirements placed on them.

40

Side rails systems

Requirements on reinforcement

Systems of side rails support

In most frame structures, the wall cladding is fixed directly to

the side rails. So as to secure their stiffness, in many cases,

the use of supports and wires ties is required. The side rails

can also be secured by hanging out into the eaves beam or

by the combination of mentioned systems.

Recommended manner of installation

• Fix the bottom side rail (R1)

and sleeves if required.

• Execute sufficient temporary support

of the side rail so as its straightness

is secured.

• Fix the second side rail R2

and sleeves if required.

• Fix the side rail support and diagonal

tie rods between R1 and R2.

By stretching the tie rods, you will

secure that R1 and R2 do not show

any deflection.

• Continue to fix the remaining side rails

and supports in the direction

from the reinforcement between R1

and R2.

• After you finish the installation, remove

the temporary support.

Note: if the angle ∝ of diagonal tie rod

is less than 25°, use more supports –

example of the solution see Figure 70.

2.5 mmmax

R2

R1

SRS

∝< 25º

∝< 25º

10 mmax*

**

WDT

SRS

2.5 mmax

10 mmax*

R2

WDT

R1

SRS SRS

**

2.5 mmax

7.5 mmax*

R2

WDT

R1

SRS

**

Fixed to the eaves beam

C or Z side rail 2.5 mm

max

R2

R1

SRS

∝< 25º

∝> 25º

10 mmax*

**

WDT

SRS

2.5 mmax

10 mmax*

R2

WDT

R1

SRS SRS

**

2.5 mmax

7.5 mmax*

R2

WDT

R1

SRS

**

C or Z side rail

2.5 mmmax

R2

R1

SRS

∝< 25º

∝< 25º

10 mmax*

**

WDT

SRS

2.5 mmax

10 mmax*

R2

WDT

R1

SRS SRS

**

2.5 mmax

7.5 mmax*

R2

WDT

R1

SRS

**

C or Z side rail

Fixed to the eaves beam

* Maximum height mentioned in figures is intended for the cladding weight 15 kg/m2. If the cladding weight is larger, the maximum height must be proportionately shortened.

** In all the cases when the maximum recommended height is exceeded, another line of wires ties must be used – see Figure 67–69.

The connection reinforced by the anti sag bar (see page 29).

Figure 67: span 3.2–6 m

Figure 68: span 6.1–10 m

Figure 69: span 10.1–15 m Figure 70: arrangement of tie rod

∝ < 25°

41

Side rails systems

Oval holes in brackets allow the wires tie angle pitch 25°–65°.

Wire diagonal ties (WDT)

B

A A

SRS

V1

7035 3570

B

A A

SRSSRS

V5

V2

7035 3570

B

AAAA

SRSSRSSRS

V6

V3

V7

V4

7035 3570 7070 70 70

SRS

7070

SRS

7070

SRS

70

SRS

7070

SRS

7070

SRS

70

* *2828

45 x 45 x 2 100M12

2828

SRS

7070

B

A A

SRS

V1

7035 3570

B

A A

SRSSRS

V5

V2

7035 3570

B

AAAA

SRSSRSSRS

V6

V3

V7

V4

7035 3570 7070 70 70

SRS

7070

SRS

7070

SRS

70

SRS

7070

SRS

7070

SRS

70

* *2828

45 x 45 x 2 100M12

2828

SRS

7070

B

A A

SRS

V1

7035 3570

B

A A

SRSSRS

V5

V2

7035 3570

B

AAAA

SRSSRSSRS

V6

V3

V7

V4

7035 3570 7070 70 70

SRS

7070

SRS

7070

SRS

70

SRS

7070

SRS

7070

SRS

70

* *2828

45 x 45 x 2 100M12

2828

SRS

7070

Figure 71: arrangement for diagonal wires ties for span 3.2–6.1 m (side rail span)

Figure 72: arrangement for wires diagonal ties for span 6.1–10.1 m

Figure 73: arrangement for wires diagonal ties for span 10.1–15.0 m

Holes in side rails

Holes in cross bars

Holes in side rails

Holes in side rails

(Span)

Orifices in cross bars

(Span)

Holes in side rail

(Span)

Span - 105 2

Span - 105 3

Span - 105 4

Span - 140 4

Span - 140 4

Span - 105 4

Span3

Span - 105 3

Span - 105 2

Holes in cleat

Holes in cleat

Holes in cleat

Diagonal wires tie METSEC offer elegant solutions of sys-

tem of side rails supports from the perspective of preparing

the product documents and also from the perspective of the

installation itself.

The wires tie are supplied completely assembled due

to preventing the loss of individual components. They

are equipped with an adjustable end, which enables

the stretching.

For the production specification, it is necessary to know the

centre between the side rails and distance of holes in side

rails to which the wire tie will be fixed.

It is important that the brackets are always screwed to the

hole in the cleat closest to the pillar.

Side rail centre

Cross bar span

Side rail centre

WDT WDT

WDT

WDT WDT WDT WDT

WDT

42

Side rails systems

Side rails supports

B

A A

SRS

V1

7035 3570

B

A A

SRSSRS

V5

V2

7035 3570

B

AAAA

SRSSRSSRS

V6

V3

V7

V4

7035 3570 7070 70 70

SRS

7070

SRS

7070

SRS

70

SRS

7070

SRS

7070

SRS

70

* *2828

45 x 45 x 2 100M12

2828

SRS

7070

B

A A

SRS

V1

7035 3570

B

A A

SRSSRS

V5

V2

7035 3570

B

AAAA

SRSSRSSRS

V6

V3

V7

V4

7035 3570 7070 70 70

SRS

7070

SRS

7070

SRS

70

SRS

7070

SRS

7070

SRS

70

* *2828

100F13

2828

SRS

7070

45 x 45 x 2

B

A A

SRS

V1

7035 3570

B

A A

SRSSRS

V5

V2

7035 3570

B

AAAA

SRSSRSSRS

V6

V3

V7

V4

7035 3570 7070 70 70

SRS

7070

SRS

7070

SRS

70

SRS

7070

SRS

7070

SRS

70

* *2828

45 x 45 x 2 100M12

2828

SRS

7070

B

A A

SRS

V1

7035 3570

B

A A

SRSSRS

V5

V2

7035 3570

B

AAAA

SRSSRSSRS

V6

V3

V7

V4

7035 3570 7070 70 70

SRS

7070

SRS

7070

SRS

70

SRS

7070

SRS

7070

SRS

70

* *2828

45 x 45 x 2 100M12

2828

SRS

7070

B

A A

SRS

V1

7035 3570

B

A A

SRSSRS

V5

V2

7035 3570

B

AAAA

SRSSRSSRS

V6

V3

V7

V4

7035 3570 7070 70 70

SRS

7070

SRS

7070

SRS

70

SRS

7070

SRS

7070

SRS

70

* *2828

45 x 45 x 2 100M12

2828

SRS

7070

B

A A

SRS

V1

7035 3570

B

A A

SRSSRS

V5

V2

7035 3570

B

AAAA

SRSSRSSRS

V6

V3

V7

V4

7035 3570 7070 70 70

SRS

7070

SRS

7070

SRS

70

SRS

7070

SRS

7070

SRS

70

* *2828

45 x 45 x 2 100M12

2828

SRS

7070

B

A A

SRS

V1

7035 3570

B

A A

SRSSRS

V5

V2

7035 3570

B

AAAA

SRSSRSSRS

V6

V3

V7

V4

7035 3570 7070 70 70

SRS

7070

SRS

7070

SRS

70

SRS

7070

SRS

7070

SRS

70

* *2828

45 x 45 x 2 100M12

2828

SRS

7070

B

A A

SRS

V1

7035 3570

B

A A

SRSSRS

V5

V2

7035 3570

B

AAAA

SRSSRSSRS

V6

V3

V7

V4

7035 3570 7070 70 70

SRS

7070

SRS

7070

SRS

70

SRS

7070

SRS

7070

SRS

70

* *2828

45 x 45 x 2 100M12

2828

SRS

7070

Figure 74: V1

Figure 76: V2

Figure 79: V5 – lines 302 and 342

Figure 75

Figure 77: V3 Figure 78: V4

Figure 80: V6 – lines 302 and 342 Figure 81: V7 – lines 302 and 342

Holes in cleat

Cladding side

Cladding side

Cladding side

Cladding side

Cladding side

Cladding side

WDT

WDT

WDT WDT

WDT WDT

WDT

WDT

WDT

WDT

Recommended manner of installation

Side rail supports are installed between

the side rails according to mentioned

rules.

Side rail supports are made of hot-dip

galvanised steel.

SRS = side rail supportWDT = wire diagonal tie

It shows to the screw of the cleat closer to the column face. It shows to the screw of the cleat closest to the cladding.

Distance between side rails

(max. 2.5 m)

Lines 142–262 Lines 302–342*standard orifice pitch

43

Side rails systems

44

Side rails systems

X

Y

X

Y

X

Y

X

Y

Attic frame

Figure 82 Figure 83

The attic columns can be formed

of two C - sections constructed as

a complex component with cleats.

Sections can be supplied as individual

components, which are assembled

on site before installing them

in the frame.

The attic columns composed from

C - sections offer cost saving solution

in comparison with classical sections.

The attic columns are fixed directly

to columns with the bounce 8 mm due

to the cladding installation –

see Figure 82–83.

All the attic side rails can be fixed

to the attic columns by standard

cleats fixed to the column before its

installation to the frame.

View X

Cleat

Attic column

Side railCleat

Column tie beams

Purlin View Y

Cleats on the column

(primary frame component)

Cleats on the column

(primary frame component)

45

Side rails systems

A A

AA

A A

AA

A A

AA

Window trimmer

By using C - sections as trimmers of windows in the

combination with side rail from C - sections, you will acquire

sufficient surface for the fixation of the window itself and for

the cladding and other necessary components. The window

trimmers should be, in an ideal case, of the same height

as the side rail and then they can be connected by standard

trimmer cleats. Through the use of counterformed holes,

you will acquire flat surface.

Window trimmer

Counterformed holes C - section = vertical window trimmer

Packing plate

Side rail of C - sections

Trimmer cleat

Packing plate

Cladding

Horizontal side rail

Standard trimmer cleat

Side rail support of C - sectionWire diagonal tie

Side rails of C - sections

Window side rail

Window side rail

Figure 84: There is an example of the arrangement of wall with windows and its necessary reinforcement by wire ties and side rail support.

Figure 85: connection of window trimmer and side rail Figure 86: section A-A

46

Side rails systems

A A

AA

A A

AA

A A

AA

A A

AA

A A

AA

Door posts

C - sections METSEC can be used as door posts.

The connection of door posts and side rails from

C - sections of same height is carried out with the help

of standard trimmer cleats.

By using the counterformed holes, you will acquire a flat

surface for easier fitting of the door itself.

C - section door header

Counterformed holes

Packing plate

Trimmer cleat

Vertical door post of the same height as the side rail

Z or C - section / side rail

Z or C - section /

side rails

C - section / door post

Figure 87: typical arrangement of side rails at doors

Figure 89: connection of door post of C - sections Figure 90: front view

Figure 91: standard

trimmer cleat

Figure 88: section A-A

Figure 92: example

of connection of two

C - sections

47

Side rails systems

Accessory components

Accessory componentsGable posts

It is possible to design the components mentioned here

in the programme MetSPEC. For these components,

C - sections connected back to back are used as depicted

in figures.

The connected components are formed by connecting

the C - sections across the web with pairs of screws with

pitches specified in the programme and placed on standard

measuring axes (the washer is necessary under the screw

head and nut).

Fixation

The post must be adequately fastened to the main frame

at the top and the bottom so that the coefficient for the effici-

ent length is 0.85H. The end connections will be done with

2 or 4 screws in the web placed on standard gauge lines.

The design of cleats, which are a part of the rafter, is not

possible to make in the programme MetSPEC and they have

to be designed so as to carry the required equipment. The