XXVI$ENANGRAD$xxvi.enangrad.org.br/_assets/files/anais/2015/... · foz$do$iguaÇu,$2015$!...

Transcript of XXVI$ENANGRAD$xxvi.enangrad.org.br/_assets/files/anais/2015/... · foz$do$iguaÇu,$2015$!...

FOZ$DO$IGUAÇU,$2015$!

XXVI$ENANGRAD$$$$$$$$$$$$$$$$$

$$$$

$$$$$$

$IMPROVING BUSINESS PERFORMANCE THROUGH COMBINING LEAN, SIX

SIGMA AND THEORY OF CONSTRAINTS INTO AN INTEGRATING APROACH Felipe Eugenio Kih GontijoJovane Medina Azevedo

Adam Carl Christoffersson Jesper Tobias Bengtsson

!!

XXVI$ENANGRAD$$$$$$$$$$$$

ÁREA$TEMÁTICA:$GESTÃO$DE$OPERAÇÕES$E$LOGÍSTICA$CÓDIGO:$GOL$

$$$$$$$$$$$$$$

TÍTULO$$$

IMPROVING$BUSINESS$PERFORMANCE$THROUGH$COMBINING$LEAN,$SIX$SIGMA$AND$THEORY$OF$CONSTRAINTS$INTO$AN$INTEGRATING$APROACH$$

.$$

! !

!!

$IMPROVING$BUSINESS$PERFORMANCE$THROUGH$COMBINING$LEAN,$SIX$SIGMA$AND$

THEORY$OF$CONSTRAINTS$INTO$AN$INTEGRATING$APROACH$$!

!!Abstract:!In$ today's$ globalized$ and$ competitive$ landscape,$ companies$ seek$ systems$ that$ promote$ gains$ in$efficiency$and$profitability.$Among$the$various$methodologies,$there$are$three$that$have$a$consolidation$in$ their$ use,$ which$ are$ the$ Theory$ of$ Constraints,$ Lean$ Manufactoring$ and$ Six$ Sigma.$ These$methodologies$have$been$widely$ treated$separately,$assigning$ rewards$ to$promoted$systems.$Later,$some$researchers$have$begun$to$propose$combinations$of$these$methodologies,$emerging$integration$and$hybrid$systems.$This$article$deals$with$the$joint$use$of$such$methodologies$in$an$application$where$two$production$lines$of$a$Brazilian$company,$demonstrating$that$an$integrated$approach$can$improve$the$performance$of$a$business.$For$this$it$proposes$an$exploratory$and$descriptive$research,$seeking$to$ raise$ proposals$ and$ experiences$ of$ others,$ and$ to$ adapt$ the$ combination$ of$ methodologies$ for$applying$ the$enterprise$ in$question.$Complementing$ is$prepared$ in$a$case$study$where$ the$potential$outcomes$are$evaluated.$$Key!words:$Theory$of$Constraints,$Lean$Manufactoring$and$Six$Sigma.$!Resumo:!No$ atual$ cenário$ globalizado$ e$ competitivo,$ as$ empresas$ buscam$ sistemas$ capazes$ de$ promover$ganhos$ em$eficiência$ e$ lucratividade.$Dentre$ as$ várias$metodologias,$ existem$ três$ que$ apresentam$uma$consolidação$na$sua$utilização,$que$são$a$Teoria$das$Restrições,$A$Manufatura$Enxuta$e$o$Seis$Sigma.$ Essas$ metodologias$ já$ foram$ amplamente$ tratadas$ de$ forma$ separada,$ atribuindo`se$vantagens$inerentes$aos$sistemas$promovidos.$$Posteriormente,$alguns$pesquisadores$começaram$a$propor$combinações$entre$essas$metodologias,$surgindo$integrações$e$sistemas$híbridos.$Esse$artigo$trata$da$utilização$conjunta$das$referidas$metodologias$numa$aplicação$em$duas$linhas$de$produção$de$ uma$ empresa$ brasileira,$ demonstrando$ que$ uma$ abordagem$ integrada$ pode$ melhorar$ o$desempenho$de$um$negócio.$Para$isso$é$proposto$uma$pesquisa$exploratória$e$descritiva,$buscando`se$ levantar$ as$ propostas$ e$ experiências$ de$ outros$ autores,$ bem$ como$ adaptar$ a$ combinação$ das$metodologias$para$a$aplicação$na$empresa$em$questão.$Complementando$é$elaborado$de$um$estudo$de$caso,$onde$os$potenciais$resultados$são$avaliados.$$$$$Palavras!chaves:$Teoria$das$Restrições,$Manufatura$Enxuta$e$Seis$Sigma$$ $

!!

1.! INTRODUCTION!!As$globalization$intensifies,$competition$grows,$and$customer$demands$increase,$the$need$to$

refine$business$performances$is$constantly$getting$higher.$Continuously$improving$has$become$vital$to$succeed,$and$survive,$on$ the$market$of$ today.$As$Bergman$and$Klefsjö$ (2003,$p.42)$ state:$ “anyone&who& stops& improving& soon& stops& being& good”.$ Most$ companies$ have$ realized$ this$ fact,$ and$implemented$quality$management$and$process$ improvement$methodologiesm$ two$of$which$ that$have$become$ popular$ are$ Lean$ and$ Six$ Sigma.$ Theory$ of$ Constraints$ (TOC)$ has$ also$ gained$ a$ lot$ of$attention$since$ the$ release$of$ the$novel$The&Goal,$which$was$written$by$Eliyahu$M.$Goldratt$ in$1984$(Goldratt,$2004).$

Moreover,$ in$ recent$years$studies$have$shown$how$all$ three$of$ these$methodologies$can$be$combined$to$achieve$synergistic$effects.$Authors$such$as$Da$Silva$et$al.$(2011),$Pacheco$(2014),$Pine,$Scheller$ and$ Miguel$ (2013),$ Spector$ (2006),$ and$ Utyama$ Godinho$ Filho$ (2013)$ and$ Votto$ and$Fernandes$(2014)$has$presented$studies$comparing$these$methodologies$and$proposing$combinations$of$these$methods,$or$additions,$performing$new$hybrid$methodologies$that$incorporate$systematic$and$advantages$of$each.$

The$ results$ are$ positive.Pirasteh$ and$ Farah$ (2006),$ for$ example,$ experienced$ powerful$financial$gains$from$their$research$on$a$combined$method.$Subsequently$Sproull$(2009)$and$Pirasteh$and$Kannapan$(2013)$have$developed$their$own$roadmaps$for$how$to$make$use$of$the$benefits$from$Lean,$Six$Sigma$and$TOC$through$an$integrated$approach.$$

This$ is$ also$ the$ purpose$ of$ this$ reportm$ to$ demonstrate$ how$ an$ integrated$ approach$ can$ be$used$ to$ analyze$ and$ improve$ the$ performance$ of$ a$ business.$ In$ this$ paper$ present$ a$ study$ in$ a$Brazilian$factory,$where$two$production$lines$were$analyzed$according$to$these$methodologies,$where$the$potential$results$show$up$interesting$in$terms$of$productivity$and$quality$

$2.! THEORY!AND!LITERATURE!REVIEW!

In$order$ to$demonstrate$how$Lean,$Six$Sigma$and$Theory$of$Constraints$ can$be$combined,$they$are$first$briefly$described$individually.$$$2.1$ Lean$

Lean$Manufacturing$ is$a$production$method$ that$origins$ from$ the$Toyota$Production$System$(Womack$et$al.$1990).$It$ is$based$around$eliminating$waste$and$creating$flow.$Waste$is$anything$that$does$not$add$value$to$the$customer.$Hence,$Lean$is$about$operating$as$resource`efficient$as$possible$(Bellgran$and$Säfsten,$2010).$

The$ seven$ wastes$ are$ according$ to$ Liker$ (2004):$ transportation,$ inventory,$ motion,$ waiting,$over$production,$over$processing,$and$defects.$Liker$(2004)$also$describes$the$four$P’s$of$The$Toyota$Production$System,$which$can$be$seen$as$an$overview$of$the$principles$and$practices$of$Lean:$

•$ Philosophy:&Basing$decisions$on$a$long`term$thinkingm$•$ Process:$Continuous$flow,$pull`system,$levelling,$continuous$improvementsm$•$ People&and&partners:$Develop$your$people$and$partnersm$•$ Problem& solving:& Go$ and$ see$ for$ yourself,$ solve$ root$ problems,$ aim$ to$ be$ a$ learning$

organization.$$

The$key$points$of$lean$manufacturing$are:$•$ Immediate$Total$quality$`$go$for$the$"zero$defect",$and$detection$and$solution$of$problems$

at$the$source.$•$ Minimizing$waste$`$elimination$of$all$activities$ that$have$no$added$value$and$safety$nets,$

the$use$of$scarce$resources$optimization$(capital,$people$and$space).$•$ Continuous$ improvement$ `$ reducing$costs,$ improving$quality,$ increasing$productivity$and$

information$sharing$•$ Processes$"pull"$`$the$products$are$removed$by$the$end$customer,$and$not$pushed$to$the$

end$of$the$production$chain.$•$ Flexibility$ `$ can$ quickly$ produce$ different$ lots$ of$ wide$ range$ of$ products$ without$

compromising$efficiency$due$to$lower$production$volumes.$

!!

•$ Construction$ and$ maintenance$ of$ a$ long`term$ relationship$ with$ suppliers$ having$agreements$to$share$risk$and$cost$information.$

The$lean$manufactoring$tools$include$continuous$analysis$process$(kaizen),$production$"pull"$(JIT$/$Kanban)$and$elements$/$failsafe$processes$(Poka`Yoke).Lean$is$basically$all$that$concerns$getting$right$materials$at$the$right$place$in$the$right$amount,$minimizing$waste,$being$flexible$and$open$to$change.$$$2.2$ Six$Sigma$

Six$ Sigma$ is$ a$ methodology$ that$ focuses$ on$ reducing$ unwanted$ variation$ in$ business$processes.$Its$concept$was$firstly$introduced$by$Motorola$in$the$1980s$(Bergman$and$Klefsjö,$2003).$$A$defect$is$defined$as$nonconformity$of$a$product$or$a$service,$with$what$was$originally$specified.$$

The$origin$of$Six$Sigma$is$the$PDCA$cycle$(Paln,$Do,$Check$and$Act).$But,$differentment,$this$methodology$is$focused$on$obtaining$financial$results$and$quality$of$planned$and$clearly.$In$addition$to$controlling$ the$ processes,$ Six$ Sigma$ promotes$ changes$ in$ organizations,$ promoting$ continuous$improvements$in$processes,$products$and$services.$

The$improvement$procedure$in$Six$Sigma$is$called$DMAICm$Define,$Measure,$Analyze,$Improve,$and$Control.$Within$these$steps,$a$number$of$statistical$tools$are$used$with$the$ultimate$aim$to$reduce$variability$(Montgomery,$2009).$

$2.3$ Theory$of$Constraints!

Goldratt$ introduced$TOC$through$his$novel$The&Goal.$The$methodology$ is$based$around$ the$bottlenecks$of$an$organization.$The$capacity$of$these$processes$is$equal$to,$or$below,$the$demand$put$upon$ them.$Within$TOC,$ it$ is$ viewed$ that$ the$ capacity$of$ the$bottlenecks$equals$ the$ capacity$of$ the$whole$system,$which$corresponds$to$proverb$that$“a$chain$is$only$as$strong$as$its$weakest$ link”.$The$system$ “Drum`Buffer`Rope”$ is$ also$ presented$ in$ The$ Goalm$ the$ “drum”$ is$ the$ bottleneck$ that$determines$ the$ pace$ for$ the$ system,$ the$ “buffers”$ protect$ the$ bottleneck$ and$ system$ from$ variation,$and$the$“rope”$is$the$material$releasing$function$(Goldratt,$2004).$

The$ TOC$ reasoning$ is$ based$ on$ the$ concepts$ of$ cause$ and$ effect$ and$ the$ interdependent$relationship$of$the$elements$of$a$system,$where$every$element$of$the$system$depends$on$each$other$in$some$way,$and$that$the$overall$performance$is$intrinsically$linked$to$the$performance$of$the$joint$as$a$whole$and$not$the$individual$and$isolated$performance$of$each$part$of$the$system,$thus$discarding$the$great$location.$(Goldratt,$2004).$$

Goldratt$defines$ in$ "The$Goal"$ (2004)$as$constraint$of$a$system,$anything$ that$prevents$ it$ to$improve$ its$ performance$ in$ relation$ to$ the$ target$ set,$ that$ is,$ the$ factor$ that$ restricts$ system$performance$ as$ a$ whole.$ This$ concept$ is$ also$ known$ as$ bottleneck.$All$ tangible$ system,$ such$ as$ a$ for`profit$ venture,$ must$ have$ at$ least$ one$ restriction.$ Following$ this$reasoning,$it$created$the$continuous$optimization$process$of$TOC,$which$is$guided$by$the$overall$goal$of$the$organization$and$consists$of$five$steps.$$2.4$ Integration$of$Lean,$Six$Sigma$and$Theory$of$Constraints!

All$of$these$methods$has$its$own$characteristics$and$focus,$but$also$has$some$unusual$spots,$and$other$complementary.$Thus,$many$authors$have$proposed$additions$for$better$results.$

Da$Silva$et$al$(2011)$proposed$the$integration$of$Lean$Manufacturing$and$Six$Sigma$to$obtain$higher$productivity$and$quality$in$the$production$of$parts$for$the$automotive$industry.$According$to$the$authors,$ this$ integration$ provides$ a$ better$ operational$ performance,$ with$ Lean$ Manufactoring$streamlining$value$streams$and$promoting$the$reduction$of$waste$and$the$Six$Sigma$systematizing$the$control$and$analysis$of$changes$in$production$processes.$

Salah,$Rahim$and$Carretero$ (2010)$analyze$ the$possibility$of$combination,$which$ for$authors$are$six:$

•$ Lean$Manufactoring$as$principal$methodology$and$Six$Sigma$as$additional$supportm$•$ Six$ Sigma$ as$ principal$ methodology$ and$ the$ joint$ use$ tool$ s$ Lean$ Manufactoring,$

particularly$the$DMAICm$

!!

•$ Lean$ Manufactoring$ and$ Six$ Sigma$ being$ used$ separately,$ dealing$ with$ issues$relevant$to$the$scope$of$eachm$

•$ Lean$ Manufactoring$ and$ Six$ Sigma$ in$ parallel,$ dealing$ with$ the$ same$ problems$separatelym$

•$ Lean$Manufactoring$and$Six$Sigma$continuously$applied$to$solve$the$same$problemsm$•$ Integration$in$fact$the$two$methodologies.$

$Pinheiro,$ Scheller$ and$ Miguel$ (2013)$ also$ proposed$ that$ integration,$ warning$ that$ the$ two$

methodologies$ are$ central$ processes$ in$ an$ organization,$ which$ ultimately$ interfering$with$ the$whole$culture$of$the$company.$Thus$the$result$is$not$only$a$junction$such$methodologies,$but$an$integration,$forming$a$new$concept.$

Another$ combination$ of$ methodologies$ is$ between$ Theory$ of$ Constraints$ and$ Lean$Manufactoring.$Utiyama$Godinho$and$Son$(2013)$conducted$a$research$on$the$comparison$between$the$ two$methodologies.$Among$ these$comparisons,$ some$authors$defendema$ integration$of$ the$ two$methodologies,$such$as$Dettmer$ (2001)$and$Wang,$Cao$and$Kong$ (2009),$which$proposes$a$hybrid$approach,$ taking$ advantage$ of$ TOC$ advantages$ in$ dealing$ with$ restrictive$ resources$ and$ the$systematic$Lean$Manufactoring$to$reduce$waste.$

Votto$ and$ Fernandes$ (2014)$ proposes$ a$method$ of$ joint$ implementation$ in$ a$ custom`made$capital$ goods$ industry,$ in$ order$ to$ optimize$ the$ production$ flow$ and$minimize$ variations$ inherent$ in$production$ processes.$ In$ his$ case$ study$ the$ integration$ of$ methodologies$ brought$ as$ a$ result$ the$reduction$of$lead$times,$a$better$standard$of$meeting$the$demands$and$increased$on`time$delivery.$

The$ combination$ of$ the$ three$ methods$ is$ the$ focus$ of$ study$ Pacheco$ (2014),$ which$ was$concerned$to$assess$the$limits$of$these$potential$integrations.$For$this,$the$author$analyzed$the$points$of$convergence$and$divergence$of$methodologies,$concluding$that$although$there$are$characteristics$of$differences$in$approach$and$even$operation$of$incompatibility,$there$are$several$additional$factors$that$make$the$integration$provides$a$new$possibility,$and$that$there$a$vast$field$of$research$to$be$explored$on$the$subject.$

Already$ Spector$ (2006)$ states$ that$ the$ integration$ of$ Six$ Sigma$ and$ Lean$Manufactoring$ is$already$an$established$fact,$since$both$work$with$operational$discipline$concepts.$But$many$companies$still$ lack$a$systemic$vision$and$an$ongoing$effort$ to$focus$the$decisions$to$be$reached$overall$goal$of$the$company,$which$is$the$focus$of$TOC.$!2.5$ Comparison$of$Lean,$Six$Sigma$and$Theory$of$Constraints!

Nave$(2002)$presents$the$following$table$to$illuminate$the$differences$and$similarities$between$Lean,$Six$Sigma$and$TOC:$$Table$2.1$Comparison$of$Lean,$Six$Sigma$and$Theory$of$Constraints$! Six$Sigma$ Lean$ Theory$of$Constraints$Theory& Reduce$Variation$ Remove$waste$ Manage$constraints$Applications&procedures&

1.$Define$2.$Measure$3.$Analyze$4.$Improve$5.$Control$

1.$Identify$value$2.$Identify$value$stream$3.$Flow$4.$Pull$5.$Perfection$

1.Identify$constraint$2.Exploit$constraint$3.Subordinate$processes$4.Elevate$constraint$5.Repeat$cycle$

Focus& Problem$focused$ Flow$focused$ System$constraint$Assumptions& A$ problem$ exists.$

Figures$ and$ numbers$are$valued.$$System$ output$improves$ if$ variation$ is$reduced.$

Waste$ removal$ will$improve$ business$performance.$$Many$ small$improvements$ are$better$ than$ systems$analysis.$

Emphasis$ on$ speed$and$volume.$$Uses$existing$ systems.$Process$interdependence.$

Primary&effect& Uniform$process$output$ Reduced$flow$time$ Fast$throughput$$Secondary&effects& Less$waste.$ Less$variation.$ Less$waste.$

!!

Fast$throughput.$Less$inventory.$Improved$quality.$

Uniform$output.$Less$inventory.$Improved$quality.$

Less$inventory.$Improved$quality.$

Performance&measurement&system&

Fluctuation$ Flow$ Throughput$

Criticisms& System$ interaction$ not$considered.$Process$ improved$independently.$

Statistical$ or$ system$analysis$not$valued.$

Minimal$worker$input.$Data$ analysis$ not$valued.$

!

As$ is$ evident,$ the$ three$ methodologies$ have,$ according$ to$ Nave$ (2002),$ different$ starting$points$and$focus$but$with$the$common$ultimate$goals$to$achieve$less$waste,$higher$quality,$ improved$flow$and$less$variation.$

$2.6$ Combining$Lean,$Six$Sigma$and$Theory$of$Constraints!

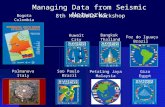

As$mentioned$in$the$introduction,$studies$have$earlier$been$made$concerning$how$to$combine$Lean,$ Six$ Sigma$ and$ TOC$ into$ an$ integrated$ approach.$ Pirasteh$ and$ Farah$ (2006)$ present$ some$interesting$findings$from$their$research,$when$they$conducted$a$study$at$a$global$electronics$contract$manufacturer$with$21$plants,$45.000$employees$and$211$ team$ leaders.$Based$on$ local$preferences,$earlier$experience,$and$expertise,$11$plants$applied$Six$Sigma,$4$plants$applied$Lean,$and$6$plants$applied$TLS$(TOC$Lean$Six$Sigma),$in$order$to$reduce$the$costs$at$the$company.$The$results$from$the$study$are$displayed$in$Figure$2.1.$

$

$Figure$2.1$Contributions$to$cost$savings$from$the$study$conducted$by$Pirasteh$and$Farah$(2006)$$

As$Figure$3.1$discloses,$a$combination$of$TOC,$Lean$and$Six$Sigma$represented$89%$of$the$total$cost$saving$at$the$company,$whereas$Lean$represented$4%$and$Six$Sigma$7%.$This$provides$a$clear$example$of$the$power$that$may$come$from$combining$the$three$approaches.$

Literatures$about$how$to$integrate$the$three$methodologies$have$also$yielded$a$few$alternative$roadmaps$ in$how$ to$do$so.$Pirasteh$and$Kannappan$ (2013)$call$ their$approach$ integrated$TOC$and$Lean$Six$ Sigma$ (iTLS).$ They$ explain$ that$ studies$ have$ shown$ that$ iTLS$ deliver$ at$ least$ four& times&higher&financial&results$ than$an$individual$ implementation$of$any$of$the$approaches.$The$seven$steps$to$implement$iTLS$are$displayed$in$Table$2.2.$

89%

4%7%

Percentage)of)contribution)to)cost)savings

TLS

Lean

Six!Sigma

!!

$Table$2.2$The$seven$steps$to$implement$iTLS$(integrated$Theory$of$Constraints$Lean$Six$Sigma)$

1.$ $ 2.$ $ 3.$ $ 4.$ $ 5.$ $ 6.$ $ 7.$ $Mobilize$and$focus$

Exploit$ the$constraint$

Eliminate$sources$ of$waste$

Control$process$variability$

Subordinate$feeder$activities$

Remove$constraints$and$stabilize$

Re`evaluate$system$

`$Mission$`$Analyze$`$ Identify$problem$`$ Identify$constraint$`$ Scope$ of$work$

`$ Focus$ on$constraint$`$ Identify$value$`$ Value$stream$`$QFD$`$ Root$cause$

`$ Measure$processes$`$Analyze$`$ Cause$ and$effect$`$FMEA$`$ Implement$change$

`$ Identify$control$parameters$`$ Establish$control$plans$`$Pursue$flow$perfection$`$ Variance$analysis$$

`$ Sub`ordinate$feeder$activities$to$ the$constraint$`$ Implement$and$ control$metrics$`$Revise$SOP$

`$ Implement$poka`yoke$`$ Focus$ on$prevention$systems$`$ Standard`ization$`$ Involve$employees$`$Reviews$`$ Train$ and$educate$

`$Go$to$step$1$`$ Identify$ and$prioritize$ next$bottleneck$

TOC$ Lean$ Six$Sigma$ Lean$ TOC$(Pirasteh$and$Kannappan,$2013)$$

Sproull$(2009)$refers$to$his$combined$approach$as$the$Ultimate$Improvement$Cycle$(UIC).$This$cycle$consists$of$four$main$phases,$with$three$sub`steps$within$each$phase.$The$UIC$(Sproull,$2009)$is$presented$in$Figure$2.2.$$

$Figure$2.2$The$Ultimate$Improvement$Cycle$(Sproull,$2009)$!

!!

2.7$ Synthesis!The$ reviewed$ literature$ seem$ to$ be$ relatively$ cohesive$ in$ the$ beliefs$ that$ an$ integrated$

approach$ should$ be$ based$ on$ the$ principle$ that$ TOC$ provides$ the$ focus$ of$ where$ to$ target$improvement$ efforts,$ while$ Lean$ and$ Six$ Sigma$ provide$ the$ tools$ needed$ for$ improvement.$ This$ is$specifically$expressed$by$Sproull$(2009),$and$it$can$also$be$seen$in$the$seven$stages$of$iTLS$(Pirasteh$and$ Kannappan,$ 2013).$ The$ exact$ steps$ to$ take$may$ however$ differ$ to$ some$ extent,$ as$ is$ evident$when$revising$the$presented$roadmaps.$$!3.! METHOD!!

In$order$ to$ investigate$how$Lean,$Six$Sigma$and$Theory$of$Constraints$can$be$combined$ to$evaluate$and$ improve$business$performance,$ this$article$ is$based$on$both$a$ literature$review$and$an$empirical$study$at$a$manufacturing$company.$$

First,$ earlier$ research$ was$ reviewed$ concerning$ alternative$ roadmaps$ for,$ and$ the$ studied$benefits$of,$integrated$approaches.$This$was$done$to$gain$some$fundamental$knowledge$of$the$subject$in$question.$Thereafter$the$empirical$study$took$place,$during$three$months,$at$a$manufacturing$plant$of$the$Brazilian$company$Intelbras,$where$two$production$lines$were$analyzed.$Through$letting$principles$from$Theory$of$Constraints$set$the$focus$for$improvement$efforts,$and$subsequently$utilizing$tools$and$thinking$ from$Lean$and$Six$Sigma,$a$combined$approach$was$used$ to$examine$ the$production$ lines$and$identify$potential$improvements.$The$work$that$was$performed$at$Intelbras$is,$in$this$article,$broken$down$ into$ a$ series$ of$ phases$ to$ clarify$ how$ the$ chosen$ approach$ used$ parts$ from$ all$ three$methodologies.$$

However,$ the$suggested$ improvements$have$not$been$ implemented$at$ the$company$and$no$financial$returns$have$therefore$been$investigated.$Thereby,$the$empirical$study$merely$deals$with$the$initial$ phasesm$ analyzing$ the$ current$ performance$and$ finding$ potential$ improvements.$ The$ reviewed$literatures,$on$the$other$hand,$present$roadmaps$for$the$whole$process$of$integrating$Lean,$Six$Sigma$and$Theory$of$Constraints$into$a$combined$approach.$And$they$also$provide$evidence$of$the$positive$financial$effects.$Thereby$ it$ is$believed$that$ the$ literature$review$and$the$empirical$study$complement$each$other.$$$$$!4.! EMPIRICAL!STUDY!!

A$small$study$during$ the$course$of$ three$months$was$conducted$at$a$manufacturing$plant$of$the$Brazilian$company$Intelbras,$regarding$how$to$analyze$production$ lines$through$a$combination$of$Lean,$Six$Sigma$and$TOC.$The$company$has$around$2000$employees,$and$its$main$areas$of$business$are$telecommunications$and$security$systems.$$

Two$ production$ lines$ were$ investigatedm$ these$ will$ be$ referred$ to$ as$ the$ “Line$ of$ Cordless$Phones”$ and$ the$ “Central$Assembly$ Line”.$ The$ former$ produces$ cordless$ home$phones,$ and$ has$ a$relatively$ stable$ demand$ and$ low$ product$ and$ process$ variety,$ while$ the$ latter$ produces$ PABX$systems$and$has$relatively$low$demand,$with$a$lot$of$product$and$process$variety.$$

Due$ to$ lack$ of$ resources,$ this$ empirical$ study$ could$ only$ be$ aimed$ at$ an$ analysis$ of$ the$production$ lines$ and$provide$ suggestions$ for$ potential$ improvementsm$ hence$no$ improvements$were$actually$implemented$and$their$effects$cannot$be$validated.$

The$work$ with$ analyzing$ the$ production$ lines$were$ structured$ according$ to$ what$ was$ learnt$through$ the$ literature$ studym$ Theory$ of$ Constraints$ set$ the$ focus$ for$ where$ to$ target$ improvement$efforts,$and$Lean$and$Six$Sigma$(with$some$additional$help$from$TOC)$provided$thinking$and$tools$for$how$ to$ find$ underlying$ problems$ at$ the$ production$ lines,$ as$ well$ as$ to$ generate$ improvement$alternatives.$ The$ work$ that$ was$ done$ is$ explained$ in$ the$ subsequent$ sections,$ where$ it$ has$ been$broken$down$into$a$sequence$of$phases.$These$phases$have$also$been$named$in$retrospect$for$further$clarification,$ and$ they$ highly$ resemble,$ with$ some$ modifications,$ the$ application$ procedure$ of$ Six$Sigma$ (DMAIC).$ This$ is$ because$ the$ work$ consisted$ of$ improving$ existing$ processes,$ and$ for$ that$purpose$DMAIC$ is$ well$ suited.$ A$ small$ number$ of$ figures$ will$ be$ included$ as$ well,$ as$ examples$ of$measurements,$suggested$changes$etc.$that$was$conducted,$or$thought$of,$during$these$stages.$$$

!!

4.1$ Phase$1:$Define$The$first$step$is$named$“Define”.$The$scope$of$the$study$was$setm$which$production$lines$and$

products$ to$ focus$on,$as$well$as$ the$ involved$processes$and$ the$available$ timeframe.$Layouts$of$ the$production$ lines$ and$ the$ flow$ of$materials$ were$ drawn$ in$ order$ to$ attain$ a$ general$ overview$ of$ the$processes$and$how$they$were$connected.$$$4.2$ Phase$2:$Measure$to$focus$

In$the$second$stage,$the$drawings$made$in$the$preceding$step$were$used$as$a$type$of$process$map,$to$identify$the$value$stream$in$the$production$lines.$The$processes$of$the$production$lines$were$also$ investigated$ in$ more$ detail,$ and$ it$ was$ attempted$ to$ identify$ the$ bottlenecks.$ This$ was$ done$through$ both$ qualitative$ and$ quantitative$ methodsm$ the$ production$ lines$ and$ their$ work`in`progress$(WIP)$ were$ studied$ through$ visual$ inspection,$ as$ well$ as$ through$ timing$ processes$ and$ performing$mathematical$calculations.$This$corresponds$to$the$thinking$of$“go$and$see$for$yourself”,$value$stream$mapping,$ and$ the$ wastes$ from$ Lean,$ combined$ with$ collection$ and$ presentation$ of$ data$ that$ is$common$within$Six$Sigma.$The$overall$idea$of$this$step,$to$identify$bottlenecks,$originally$comes$from$TOC.$$4.3$ Measuring$capacities$of$processes$

The$ first$calculations$were$done$ to$estimate$ the$capacities$of$each$process$ in$ terms$of$ their$maximum$ output$ of$ products$ per$ hour$ and$ day.$ Since$ the$ Line$ of$ Cordless$ Phones$ had$ a$ few$processes$working$extra$shifts,$it$was$interesting$to$investigate$both$the$hourly$and$daily$capacities$of$this$line.$

$$Figure$4.1$Capacities$of$processes$in$production$line$of$cordless$phones$$

In$Figure$3.1,$the$names$of$the$processes$are$located$at$the$right$hand$side.$Since$TOC$state$that$the$capacity$of$the$bottleneck$equals$the$capacity$of$the$system,$100%$in$the$graph$represents$the$capacity$of$ the$bottleneck.$Noticeable$ is$ that$ the$capacity$of$ the$process$“Adjustment”$ is$much$ lower$than$the$others.$The$bars$to$the$right$display$the$capacities$if$all$resources$in$the$extra$shift$are$spent$at$Adjustment.$The$same$types$of$graphs$were$also$made$for$the$Central$Assembly$Line,$in$an$attempt$to$ identify$ its$ bottleneck(s).$ However,$ it$ was$ noticed$ that$ different$ products$ had$ different$ bottleneck$processes$in$that$production$line.$$$4.4$ Measuring$work`in`progress$(WIP)$

The$stock$levels$within$the$production$lines$were$also$measured$at$a$number$of$occasions.$In$the$ Line$ of$ Cordless$ Phones,$ it$ was$ through$ visual$ inspection$ concluded$ that$ the$ production$ line$

0%

50%

100%

150%

200%

250%

300%

350%

Maximum!capacities!per!hour

Maximum!capacities!per!day!(with!extra!shifts!at!

Adjustment)

Manual!Insertion

Remove!board!from!frame

Guillotine

Adjustment

Heat!Seal

Heat!Seal!Test

Complementary

!!

suffered$from$a$lot$of$WIP.$The$waste$and$value$adding$time$of$the$total$amount$of$time$the$units$spent$in$ the$ system$were$ therefore$ evaluated.$ And$ it$ could$ be$ estimated$ that$ the$ value$ adding$ time$was$below$0.1%m$hence$99.9%$of$the$time$a$unit$spent$ in$the$system$was$spent$ in$queue.$Consequently,$this$measuring$was$mostly$done$with$the$wastes$of$Lean$in$mind.$

At$ the$Central$Assembly$Line,$ it$was$qualitatively$concluded$that$ the$stock$ levels$varied$ to$a$conspicuous$ extent.$ However,$ the$ amount$ of$ WIP$ was$ not$ as$ big$ as$ within$ the$ Line$ of$ Cordless$Phones.$Therefore$ it$was$decided$ to$quantitatively$ investigate$ this$variation$ in$stock$ levels.$Thereby$the$philosophy$of$Six$Sigma,$to$reduce$variation,$was$considered$here.$ In$Figure$3.2,$ the$stock$ level$variation$is$displayed.$Two$products$were$followed,$and$TRI$and$Final$Assembly$were$the$processes$subsequent$to$the$stocking$points$that$were$most$deeply$studied.$

$$$$$Figure$4.2$Stock$level$variation$during$one$day$at$the$Central$Assembly$Line$$

The$ vertical$ axis$ represents$ the$ amount$ of$ stock$ keeping$ units,$ and$ the$ horizontal$ axis$represents$the$time$of$the$day$when$the$stock$was$counted.$During$these$measurements,$it$was$also$noted$ that$ the$ processes$ were$ working$ on$ different$ products.$ Consider$ for$ example$ the$ two$ lines$representing$stock$at$Final$Assemblym$ the$stock$keeping$units$of$Product$1$ is$decreasing$ throughout$the$ day,$ whereas$ the$ stock$ of$ Product$ 2$ is$ increasing.$ This$ is$ due$ to$ that$ Final$ Assembly$ is$ only$working$on$Product$1,$and$TRI$is$mainly$working$on$Product$2.$$4.5$ Phase$3:$Analysis$

After$ the$ measuring$ phase,$ the$ results$ were$ analyzed$ to$ identify$ problems$ and$ possible$improvements.$In$this$phase,$the$idea$to$identify$bottlenecks$from$TOC$was$still$in$mind,$as$well$as$to$decrease$ waste$ and$ improve$ flow$ (Lean),$ and$ reduce$ variation$ (Six$ Sigma).$ The$ two$ studied$production$ lines$ presented$ some$ different$ issuesm$ the$ Line$ of$ Cordless$ Phones$ had$ one$ bottleneck$process$ with$much$ lower$ capacity$ than$ the$ others$ in$ the$ system,$ which$ created$ a$ lot$ of$WIP.$One$additional$ explanation$ is$ that$ this$ process$ was$ working$ extra$ shifts,$ while$ its$ preceding$ processes$usually$were$not,$which$pushed$ these$processes$ to$produce$at$a$higher$ rate$ to$keep$ the$bottleneck$process$ from$ being$ starved$ during$ its$ extra$ shifts.$ It$ was$ also$ concluded,$ through$ reviewing$ the$production$layout,$that$the$design$of$the$Line$of$Cordless$Phones$was$not$optimal.$

The$Central$Assembly$Line$in$turn,$was$concluded$to$have$problems$with$its$inherent$variationm$both$in$terms$of$product$complexity$and$its$vast$product$variety.$Also,$the$variation$displayed$in$Figure$3.2$occurred$mainly$because$the$processes$in$the$production$line$were$working$on$different$products.$Therefore,$as$one$process$manufactured$Product$2,$and$the$subsequent$process$Product$1,$all$units$of$ Product$ 2$ piled$ up$ in$ stock.$ There$ was$ a$ Just`In`Time$ system$ with$ Kanban$ cards$ in$ place$ that$probably$caused$ these$effects.$ It$was$ therefore$suspected$ that$ this$system$was$not$optimal$ to$cope$

0

50

100

150

200

250

300

350

08:00 10:00 12:00 14:00

Product!1:!TRI

Product!1:!Final!Assembly

Product!2:!TRI

Product!2:!Final!Assembly

!!

with$the$variation$in$the$production$line.$It$was$also$determined$that$the$most$problematic$processes$in$this$production$line$were$TRI$and$Final$Assembly.$$4.6$ Phase$4:$Measure$and$Analyze$areas$of$focus$

After$the$analysis$made$in$the$preceding$step,$it$was$determined$where$to$focus$improvement$efforts.$ In$order$to$further$ investigate$potential$ improvements,$some$“measuring”$was$required$again.$At$the$Line$of$Cordless$Phones,$the$bottleneck$process$had$been$identified$as$Adjustment.$So$in$this$phase,$that$process$was$put$under$more$scrutiny.$At$the$Central$Assembly$Line,$the$focus$was$put$on$two$ processes$ called$ TRI$ and$ Final$ Assembly,$ while$ the$ overall$ coordination$ of$ the$ line$ was$ also$considered$for$further$study.$At$this$phase,$the$bottleneck$processes$were$investigated$to$detect$non`value$adding$actions$that$the$operators$at$these$processes$performed.$$$

When$ separating$ value$ adding$ and$ non`value$ adding$ tasks,$ it$ was$ detected$ that$ at$ the$bottleneck$of$the$Line$of$Cordless,$the$operators$were$collecting$and$transporting$batches$before$and$after$they$had$performed$the$value$adding$activities.$After$timing$this$action,$it$was$estimated$that$this$non`value$adding$work$amounted$to$roughly$14$hours$per$month.$These$14$hours$were$resources$that$could$ be$ spent$ on$ increasing$ the$ output$ of$ the$ bottleneck$ process,$ and$ thereby$ the$whole$ system,$instead$of$the$being$wasted.$$$$$

At$ the$Central$Assembly$ Line,$ this$ phase$ consisted$of$ observing$ the$ problematic$ processes$TRI$and$Final$Assembly.$It$was$noted$that$Final$Assembly$was$almost$utilized$to$its$maximum,$as$the$capacity$of$ its$ testing$equipment$was$simply$not$sufficient.$An$ interesting$finding$was$also$that$when$the$capacities$of$the$processes$in$this$production$line$had$been$measured,$TRI$had$not$presented$any$problems.$Its$capacity$seemed$sufficient.$However,$WIP$was$still$accumulating$in$front$of$this$process.$Now,$when$the$process$was$put$under$more$thorough$scrutiny,$it$was$discovered$that$the$operators$at$this$process$were$also$performing$a$number$of$non`value$adding$ tasks.$These$tasks,$combined$with$the$fact$that$the$process$(which$is$a$testing$process)$often$had$to$be$reiterated$due$to$quality$issues,$and$ the$ aforementioned$ problems$ with$ the$ coordination$ of$ the$ line,$ were$ probable$ reasons$ for$ the$problems$at$TRI.$$4.7$ Phase$5:$Generate$improvement$alternatives$$

For$the$Line$of$Cordless$Phones,$it$was$concluded$that$improvement$efforts$should$be$focused$on$its$bottleneck$processm$Adjustment.$In$order$to$increase$its$capacity,$its$operators$should$focus$on$value$adding$tasks,$and$the$waste$of$the$non`value$adding$transportation$activities$could$for$instance$be$performed$by$a$“feeder”$or$an$operator$from$a$non`bottleneck.$Perhaps$the$workforce$could$also$be$scheduled$so$that$this$process$is$operated$during$breaks.$Additionally,$Adjustment$could$be$made$the$“drum”$ of$ the$ production$ linem$ hence$ all$ other$ processes$ should$ work$ according$ to$ its$ speed.$ This$would$increase$the$communication$between$the$bottleneck$and$the$material$releasing$function$(called$Manual$ Insertion)m$ so$ that$ this$ process$ does$ not$ produce$ quantities$ that$ will$ solely$ end$ up$ in$ stock$before$ the$bottleneck.$A$change$of$ layout$was$also$suggested,$which$ is$displayed$ in$Figure$3.3$and$Figure$3.4.$The$main$suggested$change$is$to$switch$places$of$the$processes$“Adjustment”$and$“Heat$Seal”.$ The$ arrows$ in$ these$ figures$ represent$ the$ flow$ of$ materials.$ Combined$ with$ this$ change$ of$layout,$ it$was$further$suggested$that$the$batch$size$is$decreased$by$50%$percent$(from$100$units),$at$least$up$until$the$bottleneck.$This$would$increase$the$flexibility$of$the$production$line,$and$could$enable$keeping$smaller$quantities$in$stock.$$$

!!

$Figure$4.3$Current$layout$of$the$Line$of$Cordless$Phones$$

$Figure$4.4$Suggested$layout$change$of$the$Line$of$Cordless$Phones$$

The$ Central$ Assembly$ Line$ is$ more$ complex,$ and$ harder$ to$ improve.$ However,$ it$ was$discovered$that$the$overall$coordination$of$the$production$line$might$have$to$be$changed.$As$of$now,$a$just`in`time$system$with$Kanban$cards$ is$ in$place,$which$may$not$be$optimal$ for$a$production$ line$of$this$sort,$with$a$lot$of$inherent$variation$and$a$discontinuous$flow.$This$system$means$that$the$Kanban$cards,$and$thereby$the$stock$keeping$units,$before$each$process$must$reach$the$level$that$signals$to$start$production.$This$makes$the$flow$even$more$disruptive.$If$all$processes$were$working$on$the$same$product$at$the$same$time,$the$flow$would$be$more$even.$This$might$mean$that$some$processes$are$not$fully$utilized$all$ the$ time,$but$ to$alleviate$ the$pressure$on$processes$will$ increase$ their$ability$ to$deal$with$fluctuating$demand.$$

As$TRI$ is$a$problematic$process,$ it$might$be$beneficial$ to$decrease$the$number$of$non`value$adding$activities$that$its$operators$perform$as$well.$However,$over`optimizing$this$process$will$not$help$if$its$capacity$exceeds$the$subsequent$process$(Final$Assembly).$Increasing$the$quality$of$the$products$that$come$into$TRI$will,$ if$possible,$be$beneficial$as$wellm$ the$amount$of$rework$at$ this$process$could$then$decrease.$Poka`yoke$is$an$example$of$a$tool$that$could$be$used$for$this,$even$though$it$was$not$investigated$exactly$how$to$implement$it$in$this$study.$

!!

!!!5.! CONCLUDING!DISCUSSION!

The$ empirical$ study$ in$ Chapter$ 4$ was$ described$ to$ illuminate$ how$ the$ first$ steps$ in$ an$approach$combining$Lean,$Six$Sigma$and$TOC$can$be$conducted.$The$end$of$ this$example$ is$ in$no$way$the$end$of$ the$ improvement$process$at$ the$company,$as$the$suggested$ improvements$were$not$implemented.$ Therefore,$ no$ financial$ results$ can$be$ given$ from$ this$work$ either.$However,$ to$ use$ a$combined$approach$has$been$proven$successful$in$earlier$research,$as$was$described$in$the$literature$review$of$this$article.$The$method$used$in$the$empirical$study$of$this$article$is$summarized$in$Table$5.1.$$$$Table$5.1$Integrated$approach$used$in$the$empirical$study$Phases$ Actions$ Approaches$included$ Examples$ of$ tools$

used$Define& Scope$ of$ project:$ processes,$

products,$limitations$$ Project$ charter,$

production$layouts$Measure& to&focus&

Measure$ in$ order$ to$ identify$bottleneck(s)$and$variation.$

TOC,$Six$Sigma,$Lean$ “Go$ and$ see$ for$yourself”,$ data$collection,$ run$charts,$ histograms,$process$mapping$$

Analyze& Identify$ bottleneck(s)$ and$underlying$ problems$ (such$ as$sources$of$waste$and$variation).$$

TOC,$Six$Sigma,$Lean$ Cause`and`Effect$diagrams,$brainstorming,$identification$ of$value$stream$

Measure&and& Analyze&areas& of&focus&

Put$ bottlenecks$ under$ deeper$scrutiny.$ Identify$ and$ measure$waste$ and$ variation$ at$bottleneck(s).$$

Six$Sigma,$Lean$ “Go$ and$ see$ for$yourself”,$ data$collection,$ run$charts,$histograms$

Generate&improvement&alternatives&

How$ can$ the$ capacity$ of$bottleneck(s)$ be$ increased?$How$ can$ variation$ be$decreased$ and$ waste$eliminated?$ How$ can$ the$system$be$better$coordinated$to$promote$flow$and$throughput?$$

TOC,$Lean,$Six$Sigma$ Creative$ thinking$(e.g.$ brainstorming)$about$ how$ to$eliminate$ waste,$decrease$ variation$and$ coordinate$system.$

$In$ this$ empirical$ study,$ it$ was$ mostly$ attempted$ to$ improve$ the$ flow$ of$ materials$ and$ to$

decrease$ work`in`progress$ in$ the$ production$ lines.$ If$ the$ work$ would$ have$ been$ focused$ on$ for$example$ensuring$product$and$process$quality$instead,$other$types$of$combinations$of$practices,$tools$etc.$might$have$been$more$beneficial.$ In$other$words,$how$ to$ combine$ the$ three$methodologies$will$differ$to$some$extent,$depending$on$the$nature$of$the$issue$at$hand.$

It$ is$ nonetheless$ believed,$ due$ to$ both$ the$ reviewed$ literature$ and$ the$ empirical$ study,$ that$TOC$ is$ a$ suitable$ and$ relatively$ easy$method$ for$ initiating$ and$ focusing$ improvement$ efforts,$which$subsequently$can$be$realized$through$reducing$waste$and$promoting$flow,$the$primary$goals$of$Lean,$as$well$as$reducing$variation$and$controlling$processes$and$quality$via$the$principles$and$tools$from$Six$Sigma.$This$is$due$to$that$improvement$efforts$should$be$focused$on$bottlenecks,$since$the$capacity$of$bottlenecks$equals$the$capacity$of$the$whole$system$(Goldratt,$2004).$In$general$terms,$this$is$how$an$integrated$approach$should$be$used$to$analyze$and$improve$business$performance.$

For$ further$ research,$ it$ would$ naturally$ be$ interesting$ to$ view$ an$ integrated$ improvement$process$all$the$way$up$until$after$the$implementation$of$the$suggested$changes,$to$be$able$to$measure$its$ effects.$ The$ studies$ that$ have$ been$ made$ by$ Pirasteh$ and$ Farah$ (2006)$ and$ Pirasteh$ and$

!!

Kannapan$ (2013),$provide$some$demonstration$of$ the$ financial$gains$of$ combining$Lean,$Six$Sigma$and$ TOC.$ However,$ more$ research$ with$ studied$ profits$ would$ be$ useful$ to$ really$ determine$ and$validate$the$benefits$of$an$integrated$approach.$

$References!BELLGRAN,$ M.$ and$ SÄFSTEN,$ K.$ (2010)$ Production& Development:& Design& and& Operation& of&Production&Systems.&Springer`Verlag$London$Limited.$$BERGMAN,$ B.$ and$ KLEFSJÖ,$ B.$ (2003)$Quality& from& Customer& Needs& to& Customer& Satisfaction.$Studentlitteratur,$Lund.$Second$edition.$DA$SILVA,$I,B.,$MIYAKA,$D.I,$BATOCCHIO,$A.,$AGOSTINHO,$O.L.$Integrating$the$promotion$of$Lean$Manufacturing$ and$ Six$ Sigma$methodologies$ in$ search$ of$ productivity$ and$ quality$ in$ an$ auto$ parts$manufacturer.$Gest.$Prod.,$São$Carlos,$v.$18,$n.$4,$p.$687`704,$2011.$DETTMER,$H.$W.$ $Beyond$ Lean$Manufacturing:$Combining$ Lean$Manufacturing$ and$ the$Theory$ of$Constraints$ for$ Higher$ Performance.$ Port$ Angeles,$ 2001.$ Disponível$ em:$<http://goalsys.com/books/documents/TOCandLeanPaper`rev.1.pdf>.$Acesso$em:$14$ago.$2010.$$GOLDRATT,$ E.$ (2004)$ The& Goal:& A& Process& of& Ongoing& Improvement.& The$ North$ River$ Press$Publishing$Corporation,$Great$Barrington,$MA.$Third$revised$edition.$$$LIKER,$ J.$ (2004)$ The& Toyota& Way:& 14& Management& Principles& from& the& World's& Greatest&Manufacturer.$McGraw`Hill.$MONTGOMERY,$ D.$ (2009)$ Statistical& Quality& Control:& A& modern& introduction.$ John$ Wile$ &$ Sons,$Tempe,$Arizona.$Sixth$edition.$NAVE,$D.$(2002)$How&to&compare&Six&Sigma,&Lean&and&the&Theory&of&Constraints.$American$Society$for$Quality,$New$York.&PACHECO,$D.$A.$J..Teoria$das$Restrições,$Lean$...$limites$e$possibilidades$de$integração.$Production,$v.$24,$n.$4,$p.$940`956,$oct./dec.$2014.$PINHEIRO,$T.H.m$SCHELLER,$A.C.m$MIGUEL,$P.A.C.$Intregration$of$Six$Sigma$with$Lean$Production:$An$Analysis$Through$Multiple$Cases.$Revista$Produção$Online,$Florianópolis,$SC,$v.13,$n.$4,$p.$1297`1324,$out./dez.$2013.$PIRASTEH,$ R.$ and$ KANNAPAN,$ S.$ (2013)$ The& synergy& of& continuous& process& improvement& –&Integrating& lean,&Six&Sigma&and& theory&of&constraints&can&multiply& their&benefits.$ Industrial$Engineer:$IE,$June$2013m$volume$45,$number$6m$pages$41`45.$$PIRASTEH,$R.$and$FARAH,$K$(2006)$Continuous&Improvement&Trio:&The&top&elements&of&TOC,&lean,&and&six&sigma&make&beautiful&music&together.$APICS$magazine,$May$2006m$pages$31`33.$&$SALAH,$ S.m$ RAHIM,$ A.m$ CARRETERO,$ J.A.$ The$ Integration$ of$ six$ sigma$ and$ lean$ management.$International$Journal$of$Lean$Six$Sigma,$v.1,$n.3,$p.$249`274,$2010.$SPECTOR,$ R.$ How$Constraints$Management$Enhances$Lean$and$Six$Sigma.$Supply$Chain$Management$Review,$jan$2006.$SPROULL,$B.$(2009)$The&Ultimate&Improvement&Cycle:&Maximizing&Profits& through&the&Integration&of&Lean,&Six&Sigma,&and&the&Theory&of&Constraints.$Productivity$Press.$UTIYAMA,$ M.H.R.m$ GODINHO$ FILHO,$ M.m$ Literature$ on$ the$ comparison$ between$ the$ theory$ of$constraints$and$ lean$manufacturing:$ review,$ classification,$ and$analysis.$Gest.$Prod.,$São$Carlos,$ v.$20,$n.$3,$p.$615`638,$2013.$WANG,$ Y.m$ CAO,$ J.m$ KONG,$ L.$ Hybrid$ Kanban$ Conwip$ Control$ System$ Simulation.$ In:$ IEEE$INTERNATIONAL$CONFERENCE$ON$INTELLIGENT$COMPUTING$AND$INTELLIGENT$SYSTEMS,$2009,$Shanghai.$Proceedings.$ICIS,$2009.v.$2,$p.$666`670.$VOTTO,$ R.G.m$ FERNANDES,$ F.C.F..$ Produção$ enxuta$ e$ teoria$ das$ restrições:$ proposta$ de$ um$método$para$implantação$conjunta$na$Indústria$de$Bens$de$Capital$sob$Encomenda.$Gest.$Prod.,$São$Carlos,$v.$21,$n.$1,$p.$45`63,$2014.$