X-RAY GENERATOR HF1 G/26 - starunited.com.cn · Technical data sheet HF1 G/26 IMD Generators Srl...

Transcript of X-RAY GENERATOR HF1 G/26 - starunited.com.cn · Technical data sheet HF1 G/26 IMD Generators Srl...

Technical data sheet

HF1 G/26

Doc.008984 Data 11/11/2014

Pagina 1 di 14

HV MAX VOLTAGE OUTPUT: 49 kV

HV RIPPLE FREQUENCY: 40 kHz

POWER OUTPUT: 8 kW

X-RAY GENERATOR HF1 G/26

MODEL: HF1 G/26 CLASS: I B (IEC60601-1)

CODE: XRG.14.C19.001 S/N:

Viale Matteotti, 28/A 24050 Grassobbio BERGAMO ITALY

+39 035-52.63.44 FAX +39 035-52.60.86

Technical data sheet

HF1 G/26

IMD Generators Srl Doc.008984 Data 11/11/2014

Viale G. Matteotti 28/A – 24050 – Grassobbio (Bergamo) – Italy Pagina 2 di 14

Index of contents

1 General description .......................................................................................... 3 2 Classification ................................................................................................... 3 3 Technical characteristics ................................................................................... 4

3.1 High voltage output connectors ..................................................................... 4 3.2 Generator electric characteristics ................................................................... 4 3.3 H.V. transformer power supply ...................................................................... 4 3.4 Filament power supply .................................................................................. 4 3.5 Output signals ............................................................................................. 5 3.6 Thermal characteristics ................................................................................. 5 3.7 Mechanical characteristics ............................................................................. 5 3.8 Conditions of use ......................................................................................... 6 3.9 Electromagnetic compatibility (EMC) .............................................................. 6 3.10 Electric diagrams .................................................................................. 7 3.11 PSM06/2M Interface board ..................................................................... 8

4 Labelling ......................................................................................................... 9 5 Symbols ....................................................................................................... 10 6 Installation ................................................................................................... 10

6.1 Unpacking ................................................................................................. 10 6.2 Mechanical interface ................................................................................... 10 6.3 Housing .................................................................................................... 10 6.4 Electrical installation .................................................................................. 11

6.4.1 Power connection ............................................................................... 11 6.4.2 Connection for filaments power supply .................................................. 11 6.4.3 Protective earth connection ................................................................. 11

7 Maintenance ................................................................................................. 12 7.1 Checks and inspections ............................................................................... 12 7.2 Cleaning and disinfection ............................................................................ 12

8 Risks ............................................................................................................ 13 8.1 Generator hazards ..................................................................................... 13

9 Disposal of the device .................................................................................... 13 10 Declaration of responsibility ............................................................................ 14

Technical data sheet

HF1 G/26

IMD Generators Srl Doc.008984 Data 11/11/2014

Viale G. Matteotti 28/A – 24050 – Grassobbio (Bergamo) – Italy Pagina 3 di 14

1 General description

The HF1 G/26 generator is a medical device which has been developed to power supply X-

ray tubes for radiography and fluoroscopy application, designed and manufactured with the

aim of achieving a major quality in radiation field.

The 40kHz H.V. output rectified frequency guarantees a very low ripple and improves the

H.V. rise time applied to radiogenic insert.

In order to power supply the X-ray tube this generator has to be properly connected to a

high frequency inverter. In this document suitable inverter models are mentioned.

The original release of this manual is in Italian language. For further information, please

refer to Italian version.

WARNING: No modification of this equipment is allowed.

2 Classification

CLASSIFICATION EN 60601-1

Type of protection against short circuits Class I

Operational mode Continuous operation with

intermittent loading

Unit not to be used in the presence of an inflammable anaesthetic mixture with air

or nitrous oxide

CLASSIFICATION 93/42/EEC DIRECTIVE

In accordance with Annex IX of 93/42/EEC

directive Class II b

The HF1 G/26 generator is classified as a Class IIb medical device, as determined by

93/42/EEC Annex IX Rule 10:

“Active devices intended to emit ionizing radiation and intended for diagnostic

and therapeutic interventional radiology including devices which

control or monitor such devices, or which directly influence their

performance, are in Class IIb.”

Technical data sheet

HF1 G/26

IMD Generators Srl Doc.008984 Data 11/11/2014

Viale G. Matteotti 28/A – 24050 – Grassobbio (Bergamo) – Italy Pagina 4 di 14

3 Technical characteristics

3.1 High voltage output connector

Compatible to Claymount CA-3 type receptacle (complying to NEMA XR-7).

3.2 Generator electric characteristics

H.V. output rectified ripple frequency

40 kHz

Nominal power

8 kW

(40 kV 200mA)

0,1 sec

Maximum voltage to X-ray tube 49 kVDC

Anode to Ground 49 kVDC

Maximum current in X-ray tube (radiography) Please refer to the X-ray tube load charts

200 mA

Voltage ripple at maximum power < 1 %

Rise time at the maximum power < 1 ms

Type of power supply See chap. 3.3

3.3 H.V. transformer power supply

Supply the H.V. transformer in compliance with the reported characteristics, by using IMD

Generators HF1 CAN M8/39, HF1 M8 CMF or IMD Generators equivalent one.

Screw

terminals Input characteristics Radiography / Fluoroscopy

A, B

Type of power supply ~ Single phase

Operating frequency 20 kHz

Max input voltage 350 Vpk

Max input current 200 Apk

3.4 Filament power supply

Filament power supply is not included in this HF1 G/26 generator.

Technical data sheet

HF1 G/26

IMD Generators Srl Doc.008984 Data 11/11/2014

Viale G. Matteotti 28/A – 24050 – Grassobbio (Bergamo) – Italy Pagina 5 di 14

3.5 Output signals

For Output signals please see chapt. 3.11

3.6 Thermal characteristics

Thermal safety

Cut-off temperature 60°C ± 5 °C

Type of contact Normally closed

Rubber bellow expansion volume 0.12 dm3

3.7 Mechanical characteristics

Aluminum case structure

Dimensions (see figure)

Weight (approx.): 10.5 kg

Technical data sheet

HF1 G/26

IMD Generators Srl Doc.008984 Data 11/11/2014

Viale G. Matteotti 28/A – 24050 – Grassobbio (Bergamo) – Italy Pagina 6 di 14

3.8 Conditions of use

Transport and storage conditions

Range of temperature 0° – 50° C

Relative humidity 20 – 90 %

Atmospheric pressure 700 – 1060 hPa

Working conditions

Range of temperature 10° – 40° C

Relative humidity 30 – 75 %

Atmospheric pressure 700 – 1060 hPa

3.9 Electromagnetic compatibility (EMC)

This apparatus is in compliance with the standard IEC 60601-1-2 that defines the max.

allowed emission levels from electronic devices and required immunity from interference

caused by externally generated electromagnetic fields.

It is not, however, possible to exclude radio signals coming from transmitters such as

mobile phones or similar mobile radio devices. These and other transmitting devices,

including those in compliance with EMC standards, may influence the proper functioning of

medical apparatus when used in proximity and with a relatively high transmitting power.

Therefore, the use of radio equipment in proximity to electronically controlled system must

be avoided in order to eliminate any interference risk.

Any transmissions by mobile radio equipment must be avoided.

Mobile phones must be switched off in zones close to the unit.

These rules must be applied when the unit is switched on (that

means connected to the mains and ready to use).

Technical data sheet

HF1 G/26

IMD Generators Srl Doc.008984 Data 11/11/2014

Viale G. Matteotti 28/A – 24050 – Grassobbio (Bergamo) – Italy Pagina 7 di 14

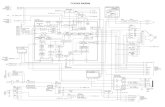

3.10 Electric diagrams

Here below it is possible to see how to connect the HF1 G/26 generator to the HF1CAN M8/39 inverter through

the PSM06/2M interface board:

Technical data sheet

HF1 G/26

IMD Generators Srl Doc.008984 Data 11/11/2014

Viale G. Matteotti 28/A – 24050 – Grassobbio (Bergamo) – Italy Pagina 8 di 14

3.11 PSM06/2M Interface board

Interface board layout

Signal Pinout Characteristics

kV+ CP1: 1 Scale factor 1V = 10 kV

Analog signal 0 ÷ 4.9 VDC

mA+, mA- CP1: 5, 4 Current signal

Analog mA Type of signal

THERMIC

SWITCH CP2: 1, 2

Thermal safety switch Normally closed switch

Logic signal

GND CP1: 2 Signal GND

A / B / GND Screws Power connectors

Technical data sheet

HF1 G/26

IMD Generators Srl Doc.008984 Data 11/11/2014

Viale G. Matteotti 28/A – 24050 – Grassobbio (Bergamo) – Italy Pagina 9 di 14

4 Labelling

PICTURE 1: Label placed on the generator

PICTURE 2: Label position on the generator

Label position

Technical data sheet

HF1 G/26

IMD Generators Srl Doc.008984 Data 11/11/2014

Viale G. Matteotti 28/A – 24050 – Grassobbio (Bergamo) – Italy Pagina 10 di 14

5 Symbols

The symbols that have been used are illustrated below:

Symbol Meaning Position

Caution: see the attached documentation Unit label

Equipment that requires a correct disposal

(2002/96/EC) Unit label

Manufacturer Unit label

Protective earth Unit

~ Alternate current Technical data sheet

6 Installation

To install the device in a radiological system, look over the information reported below.

ATTENTION –Everybody who uses or connects the equipment to a X-ray

tube configures a medical system, and is therefore responsible that the

system complies with the requirements of the system standard IEC

60601-1-3 and IEC 60601-2-54.

Be sure to proper connect and manage the thermal safety switch of the generator

in order to avoid dangerous overheating and/or mechanical damages to the case

structure.

6.1 Unpacking

ATTENTION – Unpack with caution to avoid mechanical damages of the

chassis and the electronic board.

6.2 Mechanical interface

Install the generator through the six anchorages Ø5.5mm visible in the drawing at the

chapter 3.7.

6.3 Housing

CAUTION – It is recommended to install the generator totally housed in a

protection case, avoiding mechanical damages and preventing the direct

contact by the user/patient otherwise customer must guarantee that

temperature of the parts that are likely to be touched doesn’t exceed the

maximum temperature allowable by the table 23 of the IEC 60601-1 third

edition.

Technical data sheet

HF1 G/26

IMD Generators Srl Doc.008984 Data 11/11/2014

Viale G. Matteotti 28/A – 24050 – Grassobbio (Bergamo) – Italy Pagina 11 di 14

6.4 Electrical installation

6.4.1 Power connection

For general characteristics check chap. 3.3. The connection through a shielded cable is

suggested as follows:

Connection terminals A / B

Cable 4 x 2,5mm2 shielded

Consisting of single isolated conductors with a

formation of 2 x 2,5mm2 per phase

Maximum length 5,5 m

Nominal insulation 600 VDC

6.4.2 Connection for filaments power supply

Not applicable

6.4.3 Protective earth connection

The connection through an electrical cable is suggested as the follows:

Connection terminal Nominal cross section 1 x 6 mm2

Maximum length 5.5 m

Technical data sheet

HF1 G/26

IMD Generators Srl Doc.008984 Data 11/11/2014

Viale G. Matteotti 28/A – 24050 – Grassobbio (Bergamo) – Italy Pagina 12 di 14

7 Maintenance

Generators requires regular checks and maintenance.

Regular inspections and maintenance are aimed to maintain good operation and service

safety serve and to protect the patient and operator from hazards due to any eventual

breakage of mechanical parts.

The maintenance program reported below includes checks to be observed by the

manufacturer of the equipment where generator is installed and must be carried out by

expressly authorised personnel.

CAUTION - IN THE CASE OF REPLACEMENT OF ANY COMPONENT, USE ORIGINAL SPARE

PARTS ONLY.

THIS GENERATOR HAS BEEN DEVELOPED TO POWER SUPPLY X-RAY TUBES. SINCE HIGH

VOLTAGE DISCHARGES IN THE X-RAY TUBES CAN BE FREQUENTLY OBSERVED, IMD

GENERATORS RECOMMENDS TO PROPERLY PERFORM SEASONING OF THE TUBE WHEN IT

IS NEEDED IN ORDER TO AVOID DAMAGES THAT COULD BE CAUSED TO THE GENERATOR

DURING RELEVANT HV DISCHARGES IN THE X-RAY TUBE. (PLEASE OBSERVE X-RAY TUBE

MANUFACTURER SEASONING RECOMMENDATIONS).

7.1 Checks and inspections

Please carry out the periodical checks listed in the following table.

These checks must only be carried out by qualified personnel.

VERIFICA / CHECK

Integrity of the warning and danger labels.

Absence of cracks, clefts, oil spills, corrosions and deformations.

Absence of unusual noise in the generator during X-ray

emission.

Generator mechanical fixing and general state.

Electronic board fixing and general state.

7.2 Cleaning and disinfection

This generator doesn’t need particular operations of cleaning and disinfection; in case of

cleaning of its surfaces or other parts of the equipment in which it is installed, cleaning

products have not to be used if produce explosive, gaseous mixtures. If they are used

make sure that gases are dispersed before switching on the generator.

Technical data sheet

HF1 G/26

IMD Generators Srl Doc.008984 Data 11/11/2014

Viale G. Matteotti 28/A – 24050 – Grassobbio (Bergamo) – Italy Pagina 13 di 14

8 Risks

Proper use and safe operating practices with respect to generators are responsibility of

equipment users.

The manufacturer provides information on its products and associated hazards, but it

assumes no responsibility for after-sale operating and safety practices.

Appropriate safe operating practices should be employed.

All persons who work with X-ray tube head or equipment which utilizes such devices must

take precautions to protect themselves against radiation exposure and possible serious

bodily injury.

Do not operate this generator except in accordance with information included in: this

Technical Data Sheet, these precautions and any additional information provided by the X-

ray tube manufacturer and/or competent safety authorities.

8.1 Generator hazards

HIGH VOLTAGE

All generators for X-Ray tubes operate at voltages high enough to kill through electrical

shock. Equipment designed should prevent personnel contact with high voltages. When

direct access to the generator or X-ray tube is required, the primary circuits should be

disconnected.

HOT OIL

Relevant heat occurs in the generators after prolonged operation. This heat is exchanged

through the dielectric oil to the external generator surfaces and then radiated to the air.

Misuse of the generator can result in a damage of the housing causing hot oil to escape,

potentially resulting in scalds or burns. Take precautions to avoid such damages. Be sure to

be in compliance with the use specifications of the manufacturer and to comply the

installation recommendations.

DON’T USE THE GENERATOR IF H.V.+ IS NOT PROPERLY CONNECTED TO

THE X-RAY TUBE.

9 Disposal of the device

Once the product is at the end of its use it must be disposed following the enforced rules

concerning the separate collection of waste and it cannot be treated as a simple urban

waste.

The symbol means that the product has the requirements requested by new directives

introduced for the environmental protection (2002/95/EC, 2002/96/EC,

2003/108/EC) and it must be disposed properly once its life cycle is ended.

When the device has reached the end of its life it must be disposed at the proper

centres for the separate collection of electrical and electrical wastes, or it must

be returned to the reseller or to the manufacturer in case you want to replace

the product with another equivalent new one.

The proper separate collection helps to avoid possible negative effect on the environment

and on health and it facilitates the second use and the re-cycle of materials of which the

device is composed of. Ask for further information to the local authorities about the areas

dedicated to the wastes disposal.

Who does not dispose the product following here above mentioned, will be responsible in

front of the enforced rules.

Technical data sheet

HF1 G/26

IMD Generators Srl Doc.008984 Data 11/11/2014

Viale G. Matteotti 28/A – 24050 – Grassobbio (Bergamo) – Italy Pagina 14 di 14

10 Declaration of responsibility

IMD Generators is only responsible for the safety of its products when their repair

and/or modification has been carried out by IMD Generators or by personnel

expressly authorised by IMD Generators itself.

IMD Generators shall not be held responsible in any way for malfunction, damage

and/or danger due to incorrect use of the system or to disregard of the maintenance

Regulations.

The manufacturer of the equipment where the device is installed should take care of

proper device use by trained and qualified operators.

All the technical in formations and those relevant for the compliance may be required to

the manufacturer (93/42/EEC directive and following amendments):

Viale Matteotti, 28/A 24050 Grassobbio BERGAMO ITALY

+39 035-52.63.44 FAX +39 035-52.60.86

Technical data sheet

Control unit HF1 Mammo 8kW LC

Doc.010575 Data 13/03/2017

Pagina 1 di 19

CONTROL UNIT HF1 Mammo 8kW LC

CODE: IRI.37.208.001 S/N:

Viale Matteotti, 28/A � 24050 Grassobbio � BERGAMO � ITALY

� +39 035-52.63.44 � FAX +39 035-52.60.86

Technical data sheet

Control unit HF1 Mammo 8kW LC

IMD Generators Srl Doc.010575 Data 13/03/2017 Viale G. Matteotti 28/A – 24050 – Grassobbio (Bergamo) – Italy Pagina 2 di 19

Index of contents

1 General description .................................................................................... 3

2 Classification ............................................................................................. 3

3 Technical characteristics ............................................................................. 4

3.1 Electric characteristics and I/O (power) ..................................................... 4

3.2 Input / Output (signals) ............................................................................ 5

3.2.1 Digital protocol of communication and interfacing ................................ 6

3.3 Performances of the control unit .................................................................... 7

3.3.1 Inverter .......................................................................................... 7

3.3.2 Filament ......................................................................................... 7

3.3.3 Stator driver ................................................................................... 7

3.4 S219/M Logic board ................................................................................. 8

3.5 Mechanical characteristics ........................................................................ 11

4 Labelling .................................................................................................. 13

5 Conditions of storage and usage ................................................................. 14

6 Electromagnetic compatibility (EMC) ........................................................... 14

7 Symbols .................................................................................................. 14

8 Installation .............................................................................................. 15

8.1 Unpacking ............................................................................................. 15

8.2 Mechanical installation ............................................................................. 15

8.3 Electrical installation ............................................................................... 16

9 Maintenance ............................................................................................ 17

9.1 Checks and inspections to be carried out by the user .................................. 17

9.2 Cleaning and disinfection ......................................................................... 17

10 Risks ....................................................................................................... 18

10.1 Control unit hazards ............................................................................. 18

11 Disposal of the device .............................................................................. 18

12 Declaration of responsibility ....................................................................... 19

Technical data sheet

Control unit HF1 Mammo 8kW LC

IMD Generators Srl Doc.010575 Data 13/03/2017 Viale G. Matteotti 28/A – 24050 – Grassobbio (Bergamo) – Italy Pagina 3 di 19

1 General description

This HF1 Mammo 8kW control unit is a sophisticated device which features in just one single

product many functions of a mammographic unit such as power inverter, filament board and

rotating board. In order to complete the presentation of this unit it is important to mention

the integrated digital interface standard buses (CAN-BUS and/or RS232 Option) which allow

the final system manufacturer to reduce the integration efforts to implement X-ray

equipment, as a matter of fact, the integrator needs just to communicate to one single logic

board (S219) which is in charge to distribute all the commands to all the power stadiums of

the unit. A simple and easy power interface connectors solution completes the introduction

of this product.

The integrated power inverter converts the direct input current into an alternating current,

in particular this product transforms the DC input into a 20kHz AC output with variable

amplitude depending on the input set values and feedback signals which comes from its

load. The typical load of this apparatus is a high voltage transformer with cascade rectifying

circuitry which power supplies a X-ray tube. Due to this a 40kHz ripple frequency is overlaid

on the high voltage output into the load. The logic board of the unit is in charge to control

in a closed loop the final X-ray tube voltage according to input and feedback signals. It is

also possible to control different X-ray output power and exposure timing.

The integrated filament board is in charge to fire up the filament of the insert in order to

modulate the desired anodic current in the load supervised by the electronic control board

while the stator driver board is involved in the stator power supply to control the speed

rotation of the X—ray insert.

WARNING: Written authorization to IMD Generator S.r.l. is mandatory prior to any

modification for the unit use with function other than the ones foreseen.

2 Classification

CLASSIFICATION EN 60601-1

Type of protection against short circuits Class I

Degree of protection against direct and

indirect contacts Not applicable

Operational mode Continuous operation with

intermittent loading

Unit not to be used in the presence of an inflammable anaesthetic mixture with air

or nitrous oxide

Technical data sheet

Control unit HF1 Mammo 8kW LC

IMD Generators Srl Doc.010575 Data 13/03/2017 Viale G. Matteotti 28/A – 24050 – Grassobbio (Bergamo) – Italy Pagina 4 di 19

3 Technical characteristics

3.1 Electric characteristics and I/O (power)

All the control unit interface connectors are from Molex (except power GND).

In order to connect the unit, following headers are needed:

CP1 = 2ways Minifit SR 42816 series connector

CP2 = 3ways Minifit SR 42816 series connector

CP3 = 8ways (4x2) Minifit Jr 5557 series connector

CP4 = 3ways Microfit 43645 series connector

CP5 = 4ways (2x2) Microfit 43645 series connector

CP6 = 6ways (3x2) Microfit 43020 series connector

GND = M5 brass nut

Terminals Input / Output characteristics

CP1-1,2

Input power supply (Inverter + Filament + Stator power supply)

Single phase

230Vac 50/60Hz

Rated input max power

11kVApk

(max 32Apk) Depending on the exposure

parameters

Max input current protection breakers 32A 400Vac aM 20kA

Recommended thermo-magnetic circuit

breaker

Un = 230Vac 50/60Hz

In = 32A

Number of poles = 2

Protection class = C

as per IEC-EN 60898

GND Screw

GND Connected to the

Control unit chassis

Control unit interface connectors layout

Technical data sheet

Control unit HF1 Mammo 8kW LC

IMD Generators Srl Doc.010575 Data 13/03/2017 Viale G. Matteotti 28/A – 24050 – Grassobbio (Bergamo) – Italy Pagina 5 di 19

Terminals Input / Output characteristics

CP2-1,2 Power output

Single phase

20kHz

(Max 210Vacrms )

CP3,1: (LF)

CP3,2: (SF)

CP3,3: (CM)

CP3,4: GND

Filament power board output:

(LF) = Large Focus

(SF) = Small focus

(CM) = Common

Single phase

16kHz

(Max 5.0Arms)

CP3,5: (P)

CP3,6: (S)

CP3,7: (C)

CP3,8: GND

Stator driver power board output:

(P) = Main phase

(S) = Shifted

(C) = Common

Single phase +

shifted phase

50Hz

(Max 230Vacrms / 7Apk)

3.2 Input / Output (signals)

For connectors positioning and description please observe picture at chapter 3.1

Terminals Signal Block diagram

CP4-1,3

(CP4-2: GND)

INPUT

CAN BUS

CP5-1,2

INPUT

Digital*

Command

X-Ray

CP5-3,4

OUTPUT

Digital*

HV > 85%

Technical data sheet

Control unit HF1 Mammo 8kW LC

IMD Generators Srl Doc.010575 Data 13/03/2017 Viale G. Matteotti 28/A – 24050 – Grassobbio (Bergamo) – Italy Pagina 6 di 19

Terminals Signal Block diagram

CP6-4,5

INPUT

Digital

Thermal

safety switch

This input manages the normally closed contact which

comes from the safety switch in the load.

CP6-1 mA+

CP6-2 mA-

INPUT

Analog

Feedback

Anodic mA

These inputs have to be connected to the load as

indicated in the chapter 8.3

CP6-3

(CP6-6=GND)

INPUT

Analog

Feedback

kV+

These inputs have to be connected to the load as

indicated in the chapter 8.3

*For digital inputs a 12 ÷ 24Vdc is recommended

3.2.1 Digital protocol of communication and interfacing

All the inputs and outputs commands / feedbacks are available by digital I/O communication

(CAN-BUS). For digital communication protocol please refer to the IMD Generators document

number 007078 and/or eventual subsequent modifications and additions (please ask to IMD

Generators for updated documents).

The CAN-BUS is available on the connectors CP4. For hardware interfacing and connectors

pinout please refer to the chapter 3.2 and 8.3 (Electrical installation).

Technical data sheet

Control unit HF1 Mammo 8kW LC

IMD Generators Srl Doc.010575 Data 13/03/2017 Viale G. Matteotti 28/A – 24050 – Grassobbio (Bergamo) – Italy Pagina 7 di 19

3.3 Performances of the control unit All the mentioned performances are related to Imd Generators Mammographic generator HF1 series.

3.3.1 Inverter

Pulsed load output power 8 kW

(200mA @ 40 kV 0,1 sec)

kV Range 22 ÷ 49 kVDC

Max RAD mode load output 200mA @ 40 kV

(0,1 sec)

Max FLUORO pulsed mode load output 200mA @ 40 kV

(25 fps)

Max frame per second rate 30 fps

3.3.2 Filament

Max load output power 65VA

(5A @ 13V)

3.3.3 Stator driver

Steady state nominal power 280 VA

Maximum surge power (launch max 1sec) 1600 VA

Technical data sheet

Control unit HF1 Mammo 8kW LC

IMD Generators Srl Doc.010575 Data 13/03/2017 Viale G. Matteotti 28/A – 24050 – Grassobbio (Bergamo) – Italy Pagina 8 di 19

3.4 S219/1 M Logic board

(the board is completely enclosed into the control unit chassis)

S219/1 logic board layout

Technical data sheet

Control unit HF1 Mammo 8kW LC

IMD Generators Srl Doc.010575 Data 13/03/2017 Viale G. Matteotti 28/A – 24050 – Grassobbio (Bergamo) – Italy Pagina 9 di 19

S219 LED description: Led from DL1 till DL14 are visible through the glass available on the chassis, for its positioning

please see at chapter 3.5

GREEN LED

• DL1 = ON (+24Vdc) when the Control unit is supplied and fuse F1 is OK.

• DL3 = ON (Control unit ready) when the Control unit is ready to receive commands

and no errors are there.

• DL11 = ON (Watch dog OK) when the internal microprocessor is running and the

inverter is ON.

• DL21= ON (Filament ready) when the filament current in the primary side of the

transformer is within factory set limits.

YELLOW LED

• DL8 = ON (X-ray command HW) when the safety hardware command is received

from the logic board.

• DL9 = ON (HV>85%) when the HV output in the load overtakes 85% of set kV that

means exposure has started.

• DL10 = ON (X-ray command SW) when the safety hardware command X-Ray is

received AND the internal firmware enables the X-Ray emission.

• DL12 = ON (PWM Command 1) when PWM command1 is sent to the driver board.

• DL13 = ON (PWM Command 2) when PWM command2 is sent to the driver board.

• DL14 = ON (PWM enable) when the firmware enables the PWM commands to driver

board.

• DL15 = ON (Stator driver run) when the firmware enables the stator driver to run.

• DL16 = ON (Stator driver ready) when the stator driver is ready (stator OK).

• DL17 = ON Not Used

• DL18 = ON Not Used

• DL19 = ON Not Used

• DL22= ON (Filament small focus) when the filament small focus is selected.

• DL23= ON (Hi mA Scale) when the high scale of mA reading is selected.

RED LED

• ALL = ON (Undervoltage Fault) when the S219 logic board power supply is lower

than 18Vdc.

• ALL = Blink (Not Calibrated Board) when the S219 logic board has to be calibrated

(factory procedure).

• DL2= ON (Communication error) when an error in the communication protocol is

detected.

• DL4= ON Not Used

• DL5= ON (kV overvoltage error ) when the kV feedback raises over the 110% of

the kV max value. It preserves load overvoltage condition.

• DL6= ON (kV start error) when the kV feedback doesn’t raise over 30kV within 4ms

from X-ray command ON. It shows a missing of feedback from the high

voltage stadium.

• DL6= Blink (kV discharge error) when the kV signal fall before the end of exposure, it

shows a kV discharge behavior

Technical data sheet

Control unit HF1 Mammo 8kW LC

IMD Generators Srl Doc.010575 Data 13/03/2017 Viale G. Matteotti 28/A – 24050 – Grassobbio (Bergamo) – Italy Pagina 10 di 19

• DL6 & DL7= ON (Thermal safety switch intervention) when the thermal safety switch of

the load has intervened.

• DL7= ON (over mA max error) when the anodic current exceed the max factory set

value.

• DL20= ON (Filament current Error) when the filament current exceed the max limit.

• DL20= Blink (Filament current Error) when the filament current is lower than min limit.

S219 POTENTIOMETERS description:

• P1 Filament working frequency adjust (factory set)

• P2 Inverter working frequency adjust (factory set)

S219 TEST POINTS description:

• Tp1 +5Vdc

• Tp2 GND

• Tp3 Filament working frequency

• Tp4 kV+ feedback (1V=10kV in the load)

• Tp5 kVTOT feedback (-1V=15kV in the load)

• Tp6 N.C.

• Tp7 Set kV (1V=15kV in the load)

• Tp8 Anodic mA in the load (1V=100mA)

• Tp10 Inverter working frequency

• Tp12 PWM output command1

• Tp13 PWM output command2

• Tp14 Filament current feedback 1V=1000mA

S219 signals directly available through the chassis:

At the chapter 3.2 it is possible to see the signals which are available at the connectors fixed

on the chassis, in particular:

• Can bus terminals.

• Hardware X-ray command input which guarantees the safety control of exposure starting.

• The output signal HV>85% that is available to detect the effective starting of exposure.

Technical data sheet

Control unit HF1 Mammo 8kW LC

IMD Generators Srl Doc.010575 Data 13/03/2017 Viale G. Matteotti 28/A – 24050 – Grassobbio (Bergamo) – Italy Pagina 11 di 19

3.5 Mechanical characteristics

Dimensions (see figures)

Unit: mm

Technical data sheet

Control unit HF1 Mammo 8kW LC

IMD Generators Srl Doc.010575 Data 13/03/2017 Viale G. Matteotti 28/A – 24050 – Grassobbio (Bergamo) – Italy Pagina 12 di 19

Weight (approx.) 14kg

Technical data sheet

Control unit HF1 Mammo 8kW LC

IMD Generators Srl Doc.010575 Data 13/03/2017 Viale G. Matteotti 28/A – 24050 – Grassobbio (Bergamo) – Italy Pagina 13 di 19

4 Labelling

Labels placed on the control unit

Labels position on the control unit

Label position

Technical data sheet

Control unit HF1 Mammo 8kW LC

IMD Generators Srl Doc.010575 Data 13/03/2017 Viale G. Matteotti 28/A – 24050 – Grassobbio (Bergamo) – Italy Pagina 14 di 19

5 Conditions of storage and usage

Transport and storage conditions

Range of temperature 0° – 50° C

Relative humidity (non condensing) 20 – 90 %

Atmospheric pressure 700 – 1060 hPa

Working conditions

Range of temperature 10° – 40° C

Relative humidity (non condensing) 30 – 75 %

Atmospheric pressure 700 – 1060 hPa

6 Electromagnetic compatibility (EMC)

It is not possible to exclude radio signals coming from transmitters such as mobile phones or

similar mobile radio devices, including those in compliance with EMC standards, may influence

the proper functioning of the apparatus when used in proximity and with a relatively high

transmitting power.

Therefore, the use of radio equipment in proximity to electronically controlled system must be

avoided in order to eliminate any interference risk.

Any transmissions by mobile radio equipment must be avoided.

Mobile phones must be switched off in zones close to the unit.

These rules must be applied when the unit is switched on (that

means connected to the mains and ready to use).

7 Symbols

The symbols that have been used are illustrated below:

Symbol Meaning Position

Caution: see the attached documentation

Unit /

Technical data sheet /

Unit label

Equipment that requires a correct disposal

(2002/96/EC) Unit label

Manufacturer Unit label

Protective earth Unit

~ Alternate current Technical data sheet /

Unit label

Dangerous voltage Unit

Warning: dangerous voltage Unit

Small focus Technical data sheet /

Unit

Large focus Technical data sheet /

Unit

Technical data sheet

Control unit HF1 Mammo 8kW LC

IMD Generators Srl Doc.010575 Data 13/03/2017 Viale G. Matteotti 28/A – 24050 – Grassobbio (Bergamo) – Italy Pagina 15 di 19

8 Installation To install the device in a radiological system, look over all the information reported in this

document. Furthermore IMD Generators suggests also to protect:

• 230Vac main power input with a couple of 32A 400Vac aM 20kA fuses as indicated

in the chapter 8.3.

ATTENTION – Accessory equipment connected to the control unit analog and

digital interfaces must be in compliance with the nationally harmonized IEC

standards. Furthermore all configurations shall comply with the system

standard IEC60601-1-1. Everybody who uses or connects the equipment

configures a medical system, and is therefore responsible that the system

complies with the requirements of the system standard IEC 60601-1-3 and

IEC 60601-2-54.

8.1 Unpacking

ATTENTION – Unpack the control unit with caution to avoid mechanical

damages of the chassis and interface connectors.

8.2 Mechanical installation

Install the control unit through the four M5 threaded holes fitted on its mechanical structure

(please refer to chapter 3.5).

CAUTION – It is recommended to install the control unit in a sheltered position, to

protect it from mechanical damages and prevent the direct contact by the

user/patient.

Please note that the components inside the control unit, during its working, could accumulate

a significant amount of heat. The control unit chassis was projected keeping in mind this and

a fan/blower inside helps to let the heat flowing outside the chassis. It is recommended to

choose a properly position that could let the control unit “breathe” in a well-ventilated area of

the final equipment.

Technical data sheet

Control unit HF1 Mammo 8kW LC

IMD Generators Srl Doc.010575 Data 13/03/2017 Viale G. Matteotti 28/A – 24050 – Grassobbio (Bergamo) – Italy Pagina 16 di 19

8.3 Electrical installation

Here below it is possible to see how to connect the HF1 Control unit Mammo 8kW to a HF1

G/26 generator equipped with the PSM26/2M interface board (Drawing number 009025):

Technical data sheet

Control unit HF1 Mammo 8kW LC

IMD Generators Srl Doc.010575 Data 13/03/2017 Viale G. Matteotti 28/A – 24050 – Grassobbio (Bergamo) – Italy Pagina 17 di 19

9 Maintenance The control unit requires regular checks. Regular inspections are aimed to maintain good

operation and service safety and to protect the patient and operator from electrical hazards.

This chapter reports the checks that have to be observed by the manufacturer of the

equipment where the control unit is installed and must be carried out by expressly authorized

and properly trained personnel.

CAUTION - In the case replacement of any component use only original

spare parts. NOTE: Against risks of fire hazards replace following fuses with ones

having the same rating:

Control unit fuses:

(Main power DC on the PSM03 board) F1 = 80A 660Vac gRB 200kA(BS88-FE / 77x17.1)

(Driver board PSM44 input AC) F1 = 1,5AT (ferrule 5x20)

(Filament power board S223 main input AC) F2 = 2AT (ferrule 5x20)

(Filament power board S223 DC) F1 = 1AT (ferrule 5x20)

(Stator driver board PSM20/1 Main AC input) F1 = F2 = 10AT (ferrule 5x20)

9.1 Checks and inspections to be carried out by the user

CHECKS

• Integrity of the warning and danger labels.

• Control unit mechanical fixing and general state.

• Integrity of wirings and connections

• Cleanness of inlet and outlet air masks

9.2 Cleaning and disinfection

The control unit doesn’t need particularly operations of cleaning and disinfection; in case of

cleaning of parts of the equipment in which it is installed, cleaning products have not to be

used if produce explosive, gaseous mixtures. If they are used, make sure that gases are

dispersed before switching on the control unit.

Technical data sheet

Control unit HF1 Mammo 8kW LC

IMD Generators Srl Doc.010575 Data 13/03/2017 Viale G. Matteotti 28/A – 24050 – Grassobbio (Bergamo) – Italy Pagina 18 di 19

10 Risks

The manufacturer provides information on its products and associated hazards, but it assumes

no responsibility for after-sale operating and safety practices.

Appropriate safe operating practices should be employed.

Do not operate this control unit except in accordance with information included in this

technical data sheet, these precautions, and any additional information provided by the

control unit Manufacturer and/or competent safety authorities.

Being the control unit installed together with an X-ray tube, see the X-ray tube technical data

sheet for hazards related to X-ray emission and for the precautions to be adopted during the

X-ray exposure.

10.1 Control unit hazards

VOLTAGE

The control unit is fed by dangerous mains voltage, so equipment designed should prevent

personnel contact with this apparatus.

When direct access to the control unit is required, the primary circuits should be disabled

waiting a minimum time of 5 minutes to allow a correct discharge of the inner control unit

capacitors.

11 Disposal of the device

Once the product is at the end of its use it must be disposed following the enforced rules

concerning the separate collection of waste and it cannot be treated as a simple urban waste.

The symbol here beside means that the product has the requirements requested

by new directives introduced for the environmental protection (2002/95/EC,

2002/96/EC, 2003/108/EC) and it must be disposed properly once its life cycle is

ended.

When the device has reached the end of its life it must be disposed at the proper

centres for the separate collection of electrical and electrical wastes, or it must be

returned to the reseller or to the manufacturer in case you want to replace the

product with another equivalent new one.

The proper separate collection helps to avoid possible negative effect on the environment and

on health and it facilitates the second use and the re-cycle of materials of which the device is

composed of. Ask for further information to the local authorities about the areas dedicated to

the wastes disposal.

Who does not dispose the product following here above mentioned, will be responsible in front

of the enforced rules.

Technical data sheet

Control unit HF1 Mammo 8kW LC

IMD Generators Srl Doc.010575 Data 13/03/2017 Viale G. Matteotti 28/A – 24050 – Grassobbio (Bergamo) – Italy Pagina 19 di 19

12 Declaration of responsibility

➠ IMD Generators is only responsible for the safety of its products when their repair

and/or modification has been carried out by IMD Generators or by personnel expressly

authorised by IMD Generators itself.

➠ IMD Generators shall not be held responsible in any way for malfunction, damage

and/or danger due to incorrect use of the system or to disregard of the maintenance

regulations.

➠ The manufacturer of the equipment where the device is installed should take care of

proper device use by trained and qualified operators.

All the technical information and those relevant for the compliance may be required to the

manufacturer (93/42/EEC directive and following amendments):

Viale Matteotti, 28/A � 24050 Grassobbio � BERGAMO � ITALY

� +39 035-52.63.44 � FAX +39 035-52.60.86