WORLD CEMENT - · PDF fileX preheater system, ... World Cement, reports from the Norcem...

Transcript of WORLD CEMENT - · PDF fileX preheater system, ... World Cement, reports from the Norcem...

WO

RLD

CE

ME

NT

April 2014w

ww

.world

cement.com

April 2014

FLSmidth is participating in the first Cement Professionals Trainingat the 2014 IEEE-IAS/PCA Cement Industry Technical Conference.

Review case studies and operational best practices for grinding andpyro processing. The training then utilizes our ECS/CEMulator™ softwareand simulates real-time plant conditions, giving operators the practicalknowledge and experience they need to ensure optimal plant operationand product quality.

We have the latest knowledge, expertise, and new ways of thinking thattranslate directly into on-the-job results.

For a complete list of training courses, visit www.flsmidth.com

Exerciseyour expertise

FLSmidth is participating in the first Cement Professionals Trainingat the 2014 IEEE-IAS/PCA Cement Industry Technical Conference.

Review case studies and operational best practices for grinding andpyro processing. The training then utilizes our ECS/CEMulator™ softwareand simulates real-time plant conditions, giving operators the practicalknowledge and experience they need to ensure optimal plant operationand product quality.

We have the latest knowledge, expertise, and new ways of thinking thattranslate directly into on-the-job results.

For a complete list of training courses, visit www.flsmidth.com

Exerciseyour expertise

[email protected] | 1-800-451-8798 www.tecowestinghouse.com

Laying the Foundation for Reliability

A Commitment to Reliability• WestinghouseLegacyDrivenbyTECOExperience• Rugged,ReliableMotors&DrivesfortheMostDemandingProcesses

• GlobalDesign,Manufacturing,&ServiceResources• LargeMotorRepair&EngineeredComponentCapabilities

Let TWMC be your foundation for the future...

Visit Us atBooth #607

Palladian Publications Ltd 15 South Street, Farnham, Surrey, GU9 7QU, ENGLAND

Tel +44 (0)1252 718999 Fax +44 (0)1252 718992 Email: [email protected] Website: www.worldcement.com

www.worldcement.com

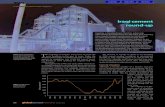

Norcem Towards the end of 2013, I visited the Norcem

Brevik cement plant in southern Norway. The plant was established in 1916 along the country’s coastline, offering a strategic

and logistical advantage in addition to a particularly picturesque backdrop. Brevik is one of just two cement plants in Norway, both of which are operated by Norcem, which was acquired by HeidelbergCement in 1999. The plant forms part of HeidelbergCement’s Northern Europe network across Norway, Sweden, Denmark and the Baltic Countries, which comprises a total of 54 cement terminals, the two production facilities in Norway, three cement plants in Sweden and one in Estonia.

Plant overview The plant has a clinker production capacity of 1.05 million tpa and a cement production capacity of 1.3 million tpa, although there are plans to increase this to 1.5 million tpa. Three different types of clinker are produced at the plant, allowing it to manufacture seven cement types. This includes two low-alkali clinkers, one of which is specially designed for use as oil well cement in the North Sea and the other for the construction of heavy structures. Clinker is stored across seven silos, and in total the plant has 80 000 t of silo capacity (clinker).

Around 95% of the cement produced is shipped out directly from the port onsite. A Haver & Boecker packer is

PLANT TOUR:

Norcem Brevik

PLANT TOUR:

Norcem Brevik

View from the preheater tower. The underground mine runs 350 m below sea level at its deepest point.

In October 2013, Louise Fordham visited HeidelbergCement’s Norcem Brevik plant in Norway to learn more about the site’s carbon capture testing project and impressive alternative fuels utilisation.

/2928\

28FEATURED ARTICLES

Andy Winston, CLARCOR Industrial Air (formerly GE Air Filtration), USA,

outlines various methods plants can take to comply with the new NESHAP

emissions standards.

with new

mact

Complying

Standards

IntroductionIn September 2015, the new National Emissions Standards for Hazardous Air Pollutants (NESHAP) for the cement industry will be enforced. The new particulate standards are 0.07 lb/t of clinker based on manual stack testing and 0.02 lb/t of clinker for new or reconstructed sources based on manual stack testing. If a plant’s kiln falls under this limit, plans have most likely been put in motion to meet the standards. In most cases, plans to comply with the new NESHAP regulations will include new equipment, rebuilding or converting existing

/57

57

WO

RLD

CE

ME

NT

April 2014w

ww

.world

cement.com

April 2014

OFC_WCT_April2014.indd 1 21/03/2014 16:50

Volume 45: Number 4April 2014 ISSN 0263 6050

ABOUT THISCOVER

Essroc Cement (Italcementi) started its new pyroprocessing line in late 2009 at its Martinsburg West Virginia plant, achieving full production. FLSmidth supplied the major pyroprocessing equipment, which included a 5-stage ILC Low NOX preheater system, ROTAX-2™ friction drive kiln, DUOFLEX™ kiln burner system, SF™ Cross-Bar® clinker cooler and auxiliary equipment for the upgrade project. The new line produces 5000 tpd of clinker and has successfully demonstrated the production rate. In addition to the equipment supply, FLSmidth also provided engineering, training and commissioning services to support Essroc’s efforts.

April 2014

CONTENTSWORLD CEMENT REGULARS09/ Comment11/ News19/ Keynote: Tackling the Skills GapAJ Jorgenson, The Manufacturing Institute, USA.

153/ Product News160/ Regional Report Fact Sheet

WORLD CEMENT PLANT TOUR28/ Plant Tour: Norcem BrevikLouise Fordham, World Cement, reports from the Norcem Brevik plant in Norway.

CASE STUDIES: NORTH AMERICA38/ From Heritage Plant to Production PowerhouseCraig Campbell and Joëlle Lipski-Rockwood, Lafarge North America Inc., USA.

45/ Corrosion Protection at Cemex OdessaLinas Mažeika, 3L&T Inc., USA.

ENVIRONMENTAL50/ HCl Control for MACT ComplianceWilliam Ciro, PhD, Cemex, and Melissa R. Sewell, Lhoist North America.

57/ Complying with New MACT StandardsAndy Winston, CLARCOR Industrial Air (formerly GE Air Filtration), USA.

62/ Combatting Corrosion in the Cement IndustryMidwesco Filter, USA.

71/ Reliable Kiln Inlet Gas AnalysisDan Kietzer, SICK Process Automation, USA, and Siegfried Andraess, SICK MAIHAK GmbH, Germany.

77/ SO2 Dry Scrubbing SystemsThierry Allegrucci, Fives Solios, Canada.

/3April 2014

World Cement

CONTACTDETAILS

EditorialManaging Editor: James Little [email protected]

Editor: Katherine Guenioui [email protected]

Assistant Editor: Louise Fordham [email protected]

Editorial Assistant: Rosalie Starling [email protected]

Contributing Editor: Paul Maxwell-Cook

DesignProduction: Natalie Callow [email protected]

SalesAdvertisement Director: Rod Hardy [email protected]

Advertisement Manager: Ian Lewis [email protected]

Advertisement Executive: Paul Heyworth [email protected]

WebsiteWebsite Editor: Callum O’Reilly [email protected]

Website Manager: Tom Fullerton [email protected]

Digital Editorial Assistant: Katie Woodward [email protected]

MarketingCirculation Manager: Victoria McConnell [email protected]

Reprint/Marketing Assistant: Catherine Gower [email protected]

PublisherNigel Hardy

50

139SUBSCRIPTION

RATESAnnual subscription (published monthly): £160 UK including postage/£175 (E260) overseas (postage airmail)/US$260 USA/Canada (postage airmail). Two year subscription (published monthly): £256 UK including postage/£280 (E416) overseas (postage airmail)/US$416 USA/Canada (postage airmail). Claims for non receipt of issues must be made within 4 months of publication of the issue or they will not be honoured without charge. Applicable only to USA and CanadaWORLD CEMENT (ISSN No: 0263-6050) is published monthly by Palladian Publications, GBR and is distributed in the USA by Asendia USA, 17B South Middlesex Avenue, Monroe NJ 08831 and additional mailing offices.Periodicals postage paid at New Brunswick NJ. POSTMASTER: send address changes to WORLD CEMENT, 17B South Middlesex Avenue, Monroe NJ 08831.Copyright© Palladian Publications Ltd 2014. All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any means, electronic, mechanical, photocopying, recording or otherwise, without the prior permission of the copyright owner. All views expressed in this journal are those of the respective contributors and are not necessarily the opinions of the publisher, neither do the publishers endorse any of the claims made in the articles or the advertisements.Uncaptioned images courtesy of www.bigstockphoto.com Printed in the UK.

“Over the past few years there have been significant improvements in the performance of DSI systems, such that their overall reliability and availability have greatly increased...”

April 2014

CONTENTS

107

/5April 2014

World Cement

MATERIALS HANDLING IN NORTH AMERICA84/ Getting Back on TrackRyan Grevenstuk, Flexco, USA.

91/ Dust-Free Loading at Holcim Ste. GenevieveDavid Beane and Nathan Browe, DCL, Inc., USA.

97/ Reliable Clinker HandlingFulvio Bassetti and Daniele Ricci, Magaldi Industrie S.r.l., Italy.

101/ Selecting Rotary Feeders for Alternative FuelsKirk Morton, Precision Machine and Manufacturing Inc., USA.

COOLERS107/ Reaping the Rewards of RecirculationThomas Weiss and Reinhard Koehler, IKN GmbH, Germany, and John Carlill, Steetley Dolomite Limited, UK.

115/ Keeping Your Clinker Cooler On TrackSebastian Frie, ThyssenKrupp Industrial Solutions, Germany.

TRAINING121/ Modern Training DemandsAlan Lorimer, Cement Performance International Ltd, UK.

125/ Training and Development as a Factor for SuccessDr Stefan Schäfer, Christoph Seidensticker and Ludger Thomas, VDZ, Germany.

TURNKEY PROJECTS129/ Turnkey Projects in Saudi ArabiaFrank Chambord, Fives FCB, France.

LUBRICATION, ADDITIVES & GRINDING131/ Open Gear LubricationKarl Bruno, Petron Corporation, USA.

139/ Grinding Additives for VRMs: Myth or Reality?Keith Marsay, W R Grace UK.

145/ Phosphorous EffectsM. Magistri, Mapei SpA, Italy.

149/ New Horizontal Seals in Ball MillsLuis García, Motofrenos S.A.S, Colombia.

For the Cement Industry we deliverworldwide proven cutting-edge technology:

� Raw Meal Silos / Cement Silos / Multicompartment Silos,� Cement terminals and Marine cement terminals,� Self-discharging cement carriers,� Ship loaders-/ unloaders for cement.� And all relevant components, made to measure.

IBAU HAMBURG – YOUR EFFICIENT PARTNERfor modern and effective bulk material handling.

� Storage, blending and dispatchof a greatly increased number of bulk materials,interground additives and mixed productsin the Cement-, Thermal Power- and Minerals Industry.

� Relevant technology experience

� Advanced international experience

IBAUHAMBURG

A MEMBEROF THE

HAVER® GROUP

IBAU HAMBURG • Rödingsmarkt 35 • D-20459 HAMBURG�+ 49 (0) 40 36 13 090 • Fax + 49 (0) 40 36 39 83

For more information please visit:

Dust-free loading procedures independent of any weather conditions: The M.V. GOLIATH reaching the Sydney Depot.

During the voyage on the River Seine in France: The cement barge of LAFARGE Cement.

Self-discharging cement carrierswith advanced systems, which are fully automated and able toachieve high loading and unloading rates. Unique for the IBAUconcept is the space saving midship tunnel design that integratesthe discharge equipment and divides the holds into a port sideand starboard compartment. The midship tunnel eliminates an

additional hold for the discharge equipment. The self unloadersare loaded and unloaded by means of IBAU Pumps, rotary pistonblowers and other IBAU components, all made to measure.In seaborne transportation as well as river / lake transport IBAUHAMBURG has an excellent projekt experience.

The revolutionary IBAU HAMBURG Tunnel concept: Midship tunnelwith the IBAU Pump and aeration panels.

The M.V. CEMSEA and the M.V. CEMSTARduring supply voyage.

Effective. Efficient.

www.ibauhamburg.de

IBAU IN THE CEMENT INDUSTRY: Self-discharging cement carriers

Innovation. Expertise.

Your solution provider.I BAU HAMBURG

From the first sketch to commissioning and maintenance:

3

Anzeige 2014_Cement Carrier_1.3:Layout 1 13.03.2014 21:59 Uhr Seite 5

Dust-free loading procedures independent of any weather conditions: The M.V. GOLIATH reaching Sydney.

with advanced systems, which are fully automated and able toachieve high loading and unloading rates. Unique for the IBAUconcept is the space saving midship tunnel design that integratesthe discharge equipment and divides the holds into a port sideand starboard compartment. The midship tunnel eliminates an

additional hold for the discharge equipment. The self unloadersare loaded and unloaded by means of IBAU Pumps, rotary pistonblowers and other IBAU components, all made to measure.In seaborne transportation as well as river / lake transport IBAUHAMBURG has an excellent project experience.

IBAU_Main.indd 1 17/03/2014 09:21

For the Cement Industry we deliverworldwide proven cutting-edge technology:

� Raw Meal Silos / Cement Silos / Multicompartment Silos,� Cement terminals and Marine cement terminals,� Self-discharging cement carriers,� Ship loaders-/ unloaders for cement.� And all relevant components, made to measure.

IBAU HAMBURG – YOUR EFFICIENT PARTNERfor modern and effective bulk material handling.

� Storage, blending and dispatchof a greatly increased number of bulk materials,interground additives and mixed productsin the Cement-, Thermal Power- and Minerals Industry.

� Relevant technology experience

� Advanced international experience

IBAUHAMBURG

A MEMBEROF THE

HAVER® GROUP

IBAU HAMBURG • Rödingsmarkt 35 • D-20459 HAMBURG�+ 49 (0) 40 36 13 090 • Fax + 49 (0) 40 36 39 83

For more information please visit:

Dust-free loading procedures independent of any weather conditions: The M.V. GOLIATH reaching the Sydney Depot.

During the voyage on the River Seine in France: The cement barge of LAFARGE Cement.

Self-discharging cement carrierswith advanced systems, which are fully automated and able toachieve high loading and unloading rates. Unique for the IBAUconcept is the space saving midship tunnel design that integratesthe discharge equipment and divides the holds into a port sideand starboard compartment. The midship tunnel eliminates an

additional hold for the discharge equipment. The self unloadersare loaded and unloaded by means of IBAU Pumps, rotary pistonblowers and other IBAU components, all made to measure.In seaborne transportation as well as river / lake transport IBAUHAMBURG has an excellent projekt experience.

The revolutionary IBAU HAMBURG Tunnel concept: Midship tunnelwith the IBAU Pump and aeration panels.

The M.V. CEMSEA and the M.V. CEMSTARduring supply voyage.

Effective. Efficient.

www.ibauhamburg.de

IBAU IN THE CEMENT INDUSTRY: Self-discharging cement carriers

Innovation. Expertise.

Your solution provider.I BAU HAMBURG

From the first sketch to commissioning and maintenance:

3

Anzeige 2014_Cement Carrier_1.3:Layout 1 13.03.2014 21:59 Uhr Seite 5

Dust-free loading procedures independent of any weather conditions: The M.V. GOLIATH reaching Sydney.

with advanced systems, which are fully automated and able toachieve high loading and unloading rates. Unique for the IBAUconcept is the space saving midship tunnel design that integratesthe discharge equipment and divides the holds into a port sideand starboard compartment. The midship tunnel eliminates an

additional hold for the discharge equipment. The self unloadersare loaded and unloaded by means of IBAU Pumps, rotary pistonblowers and other IBAU components, all made to measure.In seaborne transportation as well as river / lake transport IBAUHAMBURG has an excellent project experience.

IBAU_Main.indd 1 17/03/2014 09:21

OFF TO NEW HORIZONS

Hansaallee 24340549 DüsseldorfTel. +49 - 211 - 53 53 - 0Fax +49 - 211 - 53 53 - 500Email: [email protected]

Visit us atBooth 120 / 122

LOE_AD_America_Lay.indd 2 10.03.14 11:10

April 2014

EDITOR’S COMMENT

Katherine Guenioui, Editor [email protected]

If you’ve been looking at our website lately – and I assume you have – you’ll have noticed the recent spate of stories

coming out of Nigeria. It’s no secret that the Nigerian cement industry has been booming in recent years, led by Aliko Dangote’s Dangote Cement. In 2013, Nigeria became a cement exporter for the first time following huge capacity expansions across the country. Growth hasn’t eased yet, with reports this year of new cement plants, capacity expansions and significant investment in the sector – again, check our website for details.

The reason the industry has been making news over the last month or so, though, is a public outcry over cement standards. Poor quality cement is being blamed for building collapse, which is a relatively widespread problem in Nigeria. As recently as 1 March, I read a report of a three-storey building collapsing, trapping workers inside. Unfortunately, this was not an isolated incident, and a coalition of civil society groups and professional bodies has come forward to blame the cement industry and, specifically, the 32.5 grade cement.

At the time of writing, a technical committee has been convened to address the issue, led by the Standards Organisation of Nigeria (SON). The SON has

defended the cement industry, whose products meet national standards. Both the cement industry and the SON have suggested that the problem is not the product itself, but the way it is being used. On the first day of the meeting, Dr Joseph Odumobo, Director General of SON, said: “When the whole controversy began, we embarked on a basic survey and administered [a] questionnaire to different people who are stakeholders in the building and construction industry, asking basic questions and the response revealed that the people did not actually know what they were buying from the market. When they get to the market they just ask for a cement and at best they ask for a particular brand name of cement.”*

Given the growth of the cement industry in Africa, we started a new LinkedIn group last month called ‘Cement Industry: Africa and the Middle East’. This question of cement quality and building collapse was one of the first group discussions. We asked whether the cement industry is responsible for the way the product is used. One respondent pointed out that you could ask the same question of the pharmaceutical industry in relation to misuse of their product. All agreed a good solution was to make sure bags are properly labelled to help end users make the right choices. Several companies are also involved in training block makers in Nigeria to improve construction standards. Dangote has upgraded its plants to produce 52.5 grade cement. How do you think the industry should respond to the issue of building collapse? Join the discussion on LinkedIn now and keep up with the latest news at www.worldcement.com.

19/AJ Jorgensen tells how the manufacturing industry could be Tackling the Skills Gap. 50/

William Ciro, PhD, and Melissa R. Sewell present a case study on HCl Control for MACT Compliance.

28/Louise Fordham presents this month’s Plant Tour: Norcem Brevik. 107/

Thomas Weiss, Reinhard Koehler and John Carlill discuss a cooler project in Reaping the Rewards of Recirculation.

* http://www.thisdaylive.com/articles/son-boss-blames-building-collapse-on-misapplication-of-cement/171999/

/9April 2014

World Cement

A-C Equipment Services Corp. • 6737 W. Washington St., Suite 1400 • Milwaukee, WI 53214

414/475-2554 • Fax: 414/475-3328

www.a-cequipment.com

The Leader in Kiln Repair

A-C Equipment Services

RED-BLACK #3 AD 030513_AC BALLPLAYER AD 4.09 3/6/13 11:31 AM Page 1

April 2014

WORLD NEWS

/11April 2014

World Cement

NewsHighlights

To read more about these articles

go to:

Scan for the WORLD CEMENT iPhone/iPad App

Get the free mobile app athttp:/ /gettag.mobi

X Lafarge Tarmac appeals Competition Commission decision

X US construction spending on the up

X Bamburi Cement posts profit of KES3.7 billion for 2013

Indonesia HAZEMAG supplies impact crusher to Indonesia

Sinoma International Engineering Co., Ltd, has contracted HAZEMAG & EPR GmbH to supply a crushing plant for Indonesian cement manufacturer PT Cemindo Gemilang. The 10 000 tpd plant will be constructed in Bayah on the island of Java.

The crushing plant will consist of a large apron feeder, a wobbler feeder for pre-screening and an impact crusher with a 2.5 m rotor dia. and a 3 m rotor width. This is the largest impact crusher in the Hazemag product range. A second smaller apron feeder will enable the plant to process two different raw materials simultaneously.

In addition to the main component of limestone, two different types of clay will be crushed. All three materials have previously been tested in the Hazemag pilot plant and the system concept was determined on the basis of this investigation. The mixture of limestone and clay requires the use of a wobbler, which screens out the finer fragments of material before the crusher. The wobbler was carried out in three stages in order to effectively perform the screening, as tumbling of the material and detachment of fines occurs at every stage.

Due to the very compact appearance of the limestone with large feed sizes a heavy impact crusher was selected, as maximum impact energy can be used for the crushing

process. Thereby, a high degree of size reduction is achieved. The crusher is equipped with a robust GSK-rotor and a HAZtronic® hydraulic impact apron support system, which allows easy adjustment of the impact aprons and provides a very high level of operational safety. The total plant capacity is 2500 tph, making it one of the most powerful crushing plants in the world. Delivery of the plant is scheduled for the end of 2014.

Germany HeidelbergCement takes over logistics firm

HeidelbergCement increased its holding in Kerpen & Kerpen GmbH & Co. KG from 30% to 100% in exchange for new shares. The logistics company operates a fleet of silo trucks, transporting and trading cement, flyash and other powdery materials in Germany, Belgium, Holland, Luxembourg, France, Switzerland and Austria. The cement producer first acquired its 30% stake in the company in 1999, before entering into a management contract in 2003, the minimum terms of which expired at the end of 2013. Kerpen & Kerpen will now be fully integrated into HeidelbergCement’s business in Germany and will form the core of transport logistics, which are set to be centrally organised in the future.

HAZEMAG GSK-rotor.

April 2014

WORLD NEWS

12\April 2014World Cement

8 – 14 May 2014interpack

Düsseldorf, Germanywww.interpack.com

14 – 16 May 2014 CEM 2014

Istanbul, Turkeywww.cem.uk.com

19 – 21 May 20146th CBC 2014

São Paulo, Brazilwww.cbcimento.com.br

24 – 26 June 2014Hillhead 2014

Buxton, UKwww.hillhead.com

30 September – 2 October 2014 POWTECH 2014

Nuremberg, Germanywww.powtech.de/en

8 – 10 October 2014ILA General Assembly & Information

Exchange ForumVancouver, Canada

Germany Kreisel announces takeover of Bavarian bulk material specialist

Kreisel GmbH & Co. KG has taken over Schäffer Verfahrenstechnik GmbH & Co. KG, which declared insolvency in 2013. This will enable Schäffer Verfahrenstechnik GmbH to continue to manufacture bulk material mountings and power units at its facility in Thierhaupten, whilst maintaining the jobs of the company’s 30 or so members of staff. Mario Sonntag, previously Head of Purchasing and Materials Management at Kreisel, will be responsible for managing the newly founded Schäffer Verfahrenstechnik GmbH.

The takeover will strengthen Kreisel’s position in southern Germany while also extending its product range.

India Gebr. Pfeiffer to supply five mills to new Indian cement manufacturer

Gebr. Pfeiffer SE and its Indian subsidary Gebr. Pfeiffer (India) Pvt. Ltd received an order from Kolkata-based Emami Cement Ltd for the supply of four MVR mills and an MPS mill for coal grinding. Emami Cement, an enterprise of the private Emami Group of Companies, is new to the cement industry. The decision to set up a greenfield cement facility in Chhattisgarh and various grinding plants in the east of India was preceded by a detailed analysis of the market situation.

The order includes a 610 tph MVR 6000 R-6 roller mill with a 6700 kW installed drive power for raw material grinding, with material being ground to a fineness of 15% R 90 µm. Three MVR 6000 C-6 mills will be supplied for cement grinding, each featuring an installed drive power of 6700 kW and capable of producing 335 tph of cement. The grinding plants will also be designed to allow flyash cement and granulated blastfurnace slag to be ground to a fineness of 3800 cm2/g acc. to Blaine and 4000 cm2/g acc. to Blaine, respectively. An MPS 3350 BK vertical roller mill will produce 80 tph of hard coal, ground to a fineness of 15% R 90 µm, which will be used as fuel for the cement rotary kiln.

While Gebr. Pfeiffer SE will supply the core components of the mills and the gear units from Europe, Gebr. Pfeiffer (India) will provide components such as housing of the mills and classifiers, the steel foundation parts, as well as the interior parts of the classifiers. In addition, it will design the plant layout and provide technical advice to the customer.

Timor-Leste New 1.5 million tpa cement plant to be built in Baucau

The establishment of a new cement plant in Timor-Leste has been announced by the country’s government. The 1.5 million tpa plant will be built in the city of Baucau, an area with an estimated 100 years worth of limestone reserves.

Some 30% of the plant’s output will supply the domestic market. The remaining cement will be exported to Australia. Perth-based BGC and Swan Energy are jointly co-investing in the project.

Construction of the new site is scheduled to commence in January 2015 and is expected to take two years. Around 3000 jobs will be created during the construction phase and a further 1000 jobs once production begins at the plant.

When it comes to reliability, Jan and Volker have their

minds on a preventative approach. They inspect and test

every component of the system. The hydraulic power

pack is assembled, configured and operated as it will

be in the field. Both normal and extreme conditions are

simulated. Only when Jan and Volker agree that all tests

have been completed to their full satisfaction is the

hydraulic power pack allowed to leave the IKN test

facility for shipment to the client. It is due to the ex-

pertise and experience of IKN Engineers, like Jan and

Volker, that our customers can expect 100% reliability.

“AFTER I HAVE INSPECTED

EVERY PART OF THE

HYDRAULIC POWER PACK

I AM 100% SURE

THAT IT WILL OPERATE

FLAWLESSLY.“

Volker, Electrical Engineer

Systems Design at IKN

IKN Hydraulic Power Packs. The driving force behind our coolers.

E N G I N E E R I N G T H E F U T U R Ewww.ikn.eu

IKN_Anzeige_A4_hoch_131021.indd 1 21.10.13 11:16

April 2014

WORLD NEWS

14\April 2014World Cement

Europe Report on EU ETS released

Climate Strategies has published the following release concerning the launch of ‘Carbon Control and Competitiveness Post-2020: The Cement Report’:

‘“Cement industry top management now has little confidence in the EU ETS; structural reform is needed to help investment in energy efficiency and innovation, and reduce energy costs and carbon emissions in Europe,” said Karsten Neuhoff, from the German Institute for Economic Research (DIW Berlin), launching a key new economic report. Neuhoff is lead author of the report on the European cement industry by the international research network Climate Strategies. The study looks at the experience of the European cement sector with the EU ETS and other energy and climate policy instruments.

The EU ETS was a key focus of attention from top management in its early years, but its relevance has slumped drastically. Carbon intensity of cement production has improved by 3 – 5% in total, but mainly as a result of incentives outside the EU ETS. Industry responds to changes of policy and regulation, but so far free allocations and a low carbon price have meant the ETS has not provided sufficient economic incentive to stimulate further emission reductions.

The report finds no evidence of ‘carbon leakage’ to date, either from operational changes or from a shift of investment outside Europe. Free allocations of emission allowances may take the credit for that, but they have also undermined incentives for cost-effective emissions reductions. Without any significant cost pass-through, major mitigation options

cannot be pursued; since customers are unlikely to select other cement types with lower clinker content in the absence of economic incentives, firms will not develop new low-carbon cement types without prospects of future market demand, and the building industry currently has limited incentives for using cement more efficiently.

“Our report identifies two options for combining leakage protection and an effective carbon price for consumers,” said Neuhoff. “First, inclusion of clinker and also cement imports in the EU ETS is already proposed in the EU ETS Directive. However implementation is challenging, as it has to be coordinated internationally to avoid political repercussions. Second, the same economic effect can be achieved with a charge on the consumption of clinker linked to the EU ETS. This additional option to address carbon leakage in the EU ETS directive would complement free allowance allocation at production level, and thus reinstate the full carbon price signal.”

The report concludes that the EU ETS is essential to guide and incentivise industry, but on its own it is insufficient to unlock much of the emission reduction potential in the cement sector. Coordination with, and adaptation of, other existing and new policies will be required to enable the realisation of low- carbon options. This includes enabling policies – like codes and standards, engaging policies – like labelling and reporting, – and support for investment in CCS, innovative materials and new building practices, as well as an effective carbon price.’

The report can be found at www.climatestrategies.org.

USA New coalition formed to increase support for federal programmes in minerals science

Fifteen organisations have formed the new Mineral Science and Information Coalition (MSIC) to campaign for increased investment in minerals science and information functions. Reliable supplies of mineral resources form the backbone of the US economy and national security. In order to maintain robust supply chains of critical mineral materials and make informed decisions regarding the use of land, the US government and industry require access to accurate, timely information on mineral resources and on the domestic and global flow of minerals and mineral materials.

Over the past decade, federal programmes in minerals science, research, information, data collection and analysis have been overlooked. During this time, funding for the US Geological Survey’s Mineral Resources Programme has decreased by some 30% in constant dollar terms. The coalition requests that the government increases its investment and

support for federal minerals research, information gathering, analysis and forecasting to sustain economic prosperity and ensure national security.

Current members of the Minerals Science and Information Coalition include the Aluminum Association, American Exploration & Mining Association, American Geosciences Institute, Associated Equipment Distributors, Association of American State Geologists, Geological Society of America, Industrial Minerals Association – North America, Interstate Mining Compact Commission, Materials Research Society, National Electrical Manufacturers Association, National Mining Association, National Stone, Sand and Gravel Association, Portland Cement Association, Society for Mining, Metallurgy & Exploration Inc. and the Society of Economic Geologists. Other groups are in the process of joining the coalition.

More UptimeFlexco provides solutions to keep your belt up and running — and less time at the belt means more time to spend on other areas of your business.

More OutputTogether, we can identify opportunities to optimize your system and maximize your output.

More ProfitAnd more output results in more profit to your bottom line. Let us measure your business the way you do — start with an assessment from Flexco.

BE IN THE KNOW.

AVOID COSTLY PROBLEMS DOWN THE LINE. REQUEST A BELT CONVEYOR ASSESSMENT TODAY.

Comprehensive Belt Conveyor Assessments

exclusively from Flexco

124

3

IDENTIFYISSUES &

OPPORTUNITIES

OPTIMIZEPRODUCTIVITY

IMPLEMENTSOLUTIONS

ASSESSFACILITY

To schedule an assessment or download a white paper, visit www.flexco.com/intheknow

FLX-14025_AssmntAd_FP4c-A4-Apr-WC.indd 1 3/13/14 5:03 PM

April 2014

WORLD NEWS

16\April 2014World Cement

FLSmidth opened a new office in Barranquilla, Colombia, in January, increasing its presence in the Colombian market and enhancing its local service offerings.

Sinoma Int. (Tianjin) won an EPC contract to modify and update YTL Perak-Hanjoong cement plant’s coal system. The contract was signed at YTL Corporation Berhad’s headquarters in Malaysia in February.

Reliance Cement Company Private Ltd announced its expansion into the Uttar Pradesh market in India. The cement manufacturer now operates plants in Uttar Pradesh, Madhya Pradesh and Butibori Maharashtra.

Lafarge Canada Inc. (Eastern Canada) has launched its new CSR platform, Deep Roots – Part of our communities: past, present, and future. Through this initiative, Lafarge will support projects in four areas: water; environment; sustainable construction; the Canadian forces, veterans and their families.

Worldwide Industry appointments

FLSmidthFLSmidth & Co. A/S has appointed Lars Vestergaard as new Chief Financial Officer (CFO) and a member of the Group Executive Management, effective 1 April 2014. Vestergaard succeeds Ben Guren, who has decided to leave the company due to personal reasons.SiemensSiemens’ Financial Services (SFS) unit has appointed Gunnar Skagerlind as Sales Leader for the industry sector in the Nordic region, covering Sweden, Finland, Norway and Denmark, in order to further develop the market for equipment finance. Skagerlind will be responsible for establishing strategic partnerships with equipment vendors and original equipment manufacturers (OEMs) in industry, construction and transport.

Skagerlind brings wide-ranging experience from Société Générale, where he worked as Nordic Sales Manager for the industry market for over five years. He also spent 10 years at GE Capital Equipment Finance in various sales and managerial roles.

HolcimThe Board of Directors of Holcim Ltd will nominate Jürg Oleas for election as a new Board member at the annual general meeting on 29 April 2014. Jürg Oleas holds an MSc in mechanical engineering from the Swiss Federal Institute of Technology in Zurich and is currently the CEO of GEA Group AG, a Düsseldorf-based mechanical engineering company. Before joining the GEA Group, he spent nearly 20 years with ABB and the Alstom Group, where he held several management positions.

The Board will also propose the election of Wolfgang Reitzle as the new Chairman, succeeding Rolf Soiron, who has been the Chairman for the past 11 years and a member of the Board for 20 years.

Turkish Cement Manufacturers’ AssociationMehmet Göçmen was elected as the Chairman of the Turkish Cement Manufacturers’ Association (TCMB) at the TCMB 56th General Assembly Meeting, succeeding Mustafa Güçlü, who has served as Chairman since June 2011.

Göçmen is currently Sabanci Holding Cement Group President, after joining the company in 2003. He was previously employed as both General Manager and Executive Vice President of Human Resources at Akçansa A.S. CalPortlandSteve Coppinger was recently promoted to Vice President of Engineering Services at CalPortland. Coppinger previously served as Director of Engineering Services at the company.

UK The UK’s cement industry publishes its first EPD

The UK cement industry has published its first Environmental Product Declaration (EPD), covering 100% of domestically produced cement and declaring the sector’s lifecycle environmental impact. The UK Average Portland Cement EPD was independently verified and approved by the Institut Bauen und Umwelt (The Institute for Construction and Environment). EPDs for concrete products are under development, the product category rules for which are currently being finalised.

Another milestone within the industry was celebrated in March of this year – the Mineral Products Association’s fifth anniversary. The MPA was established in March 2009 through the merger of the Quarry Products Association, the British Cement Association and The Concrete Centre. Since its founding, its membership has increased from 266 to 482. The MPA now represents 13 different product groups and works closely with QPA Northern Ireland, MPA Scotland, British Precast, the British Association of Reinforcement and the Refined Bitumen Association.

HEKO Ketten GmbHEisenbahnstraße 2 | 58739 Wickede (Ruhr), Germany | Telephone +49(0)2377-9180-0 | Fax +49(0)2377-1028 | E-Mail: [email protected]

www.heko.com

HEKO componentsfor bucket elevators� Round link chains

� Central chains

� Plate link chains

� Rollers and Sprockets

� Bearings

� Buckets

HEKO offers the whole range of chains and other wear parts for bucket elevators

and chain conveyors. Proven in thousands of elevators and conveyors, worldwide.

Anzeige_BW_09_00:Anzeigenentwurf 06.03.2009 18:32 Uhr Seite 1

>

>

>

>

>

>

Competitive offer for new kilns and drive refurbishmentsReduction of Total Cost of OwnershipIncreased reliabilitySelf aligning for kiln movements and deformationsNo influence of kiln behaviour on gear meshingApproved by major cement producers www.cmdgears.com

THE BOGIFLEX KILN DRIVE,T.C.O. REDUCTION SOLUTION

Ask for your quote: [email protected]

®

>

>

>

>

>

>

Competitive offer for new kilns and drive refurbishmentsReduction of Total Cost of OwnershipIncreased reliabilitySelf aligning for kiln movements and deformationsNo influence of kiln behaviour on gear meshingApproved by major cement producers www.cmdgears.com

THE BOGIFLEX KILN DRIVE,T.C.O. REDUCTION SOLUTION

Ask for your quote: [email protected]

®

>

>

>

>

>

>

Competitive offer for new kilns and drive refurbishmentsReduction of Total Cost of OwnershipIncreased reliabilitySelf aligning for kiln movements and deformationsNo influence of kiln behaviour on gear meshingApproved by major cement producers www.cmdgears.com

THE BOGIFLEX KILN DRIVE,T.C.O. REDUCTION SOLUTION

Ask for your quote: [email protected]

®

CMD_Layout.indd 1 18/03/2013 10:14

April 2014

KEYNOTE

AJ Jorgenson / The Manufacturing Institute, USA, talks corporate, educational and community involvement in addressing the skills gap that faces US manufacturing.

There is a lot of debate and a lot of confusion, so let me be clear: the skills gap is real and it’s only getting worse.

According to the Bureau of Labor Statistics, the US currently has 297 000 open manufacturing jobs. In the report, ‘Building a Talent Pipeline for the Future’, released by The Manufacturing Institute and Accenture in March 2014, more than 80% of manufacturers in the United States reported a moderate to severe shortage of highly-skilled workers.1 The report also states that more than 50% of companies plan to increase US-based production by at least 5% in the next 5 years.The Society of Manufacturing Engineers predicts that the shortage of skilled workers could increase to 3 million jobs by 2015 due to retirements and the manufacturing renaissance.

Regardless of the exact figure, each of those open jobs cost manufacturers – in cycle time, downtime and overtime. According to the report, ‘Building a Talent Pipeline for the Future’, the average company in our survey reported a 12% increase in overtime cost, a 10% increase in downtime and an 8% increase in cycle time. Manufactuers want to fill those positions. With so many Americans out of work and so many manufacturers

wanting to hire, how can there be any open jobs? The answer is: the skills gap.

People and skillsContributing to the workforce pipeline challenges are issues like demographics, misperceptions, deficits in our education system and technological advances. According to the US Department of Labor, the percentage of manufacturing workers aged over 55 years has significantly increased since 2000 to over 18% of skilled manufacturing workers.2 With a pending wave of retirements, the demand for skilled manufacturing workers adds urgency to the current skills gap.

The Manufacturing Institute has taken action to address these issues.

The Manufacturing Institute is a Washington, DC-based organisation dedicated to improving and expanding the manufacturing industry in the United States. We are best described as the authority on the attraction, qualification and development of world class manufacturing talent. Our goal is for every manufacturer to have access to skilled talent and every individual in America a clear path to a good manufacturing job.

Tackling the Skills Gap

Manufacturing careers offer good salaries and exciting opportunities...But they are often

misunderstood in the eyes of young people, and the parents and teachers who influence them.

/19April 2014

World Cement

April 2014

KEYNOTE

Led by Jennifer McNelly, President, The Manufacturing Institute is a 501(c)(3) non-partisan affiliate of the National Association of Manufacturers. With over 20 years of experience, McNelly drives an agenda focused on improving and expanding manufacturing competitiveness in the United States, and helping the industry to develop a talent pipeline for generations to come.

Based on proven best practices, the Manufacturing Institute has developed a framework to help close the manufacturing skills gap. Through a three-step framework, manufacturers can take control of their future.

Three steps to changeThe first step is to change the perception of manufacturing careers to reflect its true status as the most advanced, high-tech industry in the country.

Manufacturing is the industry upon which the economic success of our nation was built. Today, technology and innovation drive growth within the sector

and keep the industry current. Modern manufacturing is again changing our economic landscape and influencing the direction of our future.

Manufacturing careers offer good salaries and exciting opportunities to be on the cutting edge of new technologies and products. But they are often misunderstood in the eyes of young people, and the parents and teachers who influence them. Seven out of ten parents want manufacturing in their community – but only three out of ten encourage their children to pursue manufacturing careers. When parents, teachers and guidance counsellors talk, their kids listen.

To attract the next generation workforce the image of manufacturing must be reinvented to reflect its far-reaching impact in both national and global markets. The prestige is there; we need to showcase it.

There are two proven initiatives that are making a difference in the eyes of young people: Manufacturing Day and Dream It. Do It.™

Manufacturing Day (MFG DAY) addresses common misperceptions about manufacturing by giving manufacturers an opportunity to open their doors and show, in a coordinated effort, what manufacturing is — and what it isn’t. By working together during and after MFG DAY, manufacturers will begin to address the skilled labour shortage they face, connect with future generations, take charge of the public image of manufacturing and ensure the ongoing prosperity of the whole industry. Supported by a group of industry sponsors and co-producers, MFG DAY is designed to amplify the voice of individual manufacturers and coordinate a collective chorus of manufacturers with common concerns and challenges. In 2013, manufacturers hosted over 830 events to showcase what we make in America. Over 30 000 students and 11 000 parents and teachers participated in a Manufacturing Day event on 4 October 2013. With the support of manufacturers, we can double that engagement next year.

The Dream It. Do It. (DIDI) network is the grassroots authority on influencing the perception of manufacturing careers by leveraging strategic partnerships to attract and recruit a qualified manufacturing workforce. Launched in 2005, the DIDI programme was created to change the public perception of manufacturing. Today, there are 27 programmes across the country working as a united voice to recruit students into manufacturing while providing knowledge about the industry to parents, teachers and counsellors. Unique to other efforts, DIDI offers local manufacturers, schools, community-based organisations and other stakeholders the opportunity to partner with a respected national platform to promote manufacturing as a top tier career choice in the United States. In 2013, Dream It. Do It. reached over 250 000 students, making a difference in their perceptions about what a manufacturing career can offer.

Table 1. Ranking of industries viewed by respondents as most important to maintain a strong national economy in the US

Industry Rank

Manufacturing 1

Energy 2

Healthcare 3

Technology 4

Financial services 5

Retail 6

Communications 7

Aggregate ranking of sectors by all respondents. Source: ‘Boiling Point? The skills gap in US Manufacturing’.

Table 2. Ranking by respondents of industry preference if they were beginning their career today

Industry Rank

Technology 1

Energy 2

Healthcare 3

Communications 4

Manufacturing 5

Financial services 6

Retail 7

Aggregate ranking of sectors by all respondents. Source: ‘Boiling Point? The skills gap in US Manufacturing’.

20\April 2014World Cement

You will need to be a subscriber to read the full edition. Please log in to www.worldcement.com

or alternatively click here to subscribe.

For more information about the comprehensive World Cement subscription package, please contact us:

www.worldcement.comE: [email protected]

T: +44 (0)1252 718999

THAT WAS A SAMPLE OF

APRIL ISSUE

DON’T WANT TO MISS OUT?