Worked Example 1 - Tipperary Energy...

Transcript of Worked Example 1 - Tipperary Energy...

Worked Example 1

Q: Work out the Pump Efficiency, Power consumption by the pump and the motor.

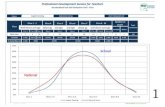

In 1994 the system was designed to pump at a Total dynamic head of 75m and an average

flow rate of 6720m3 per day. The KSB Multitek 125 10.2 was chosen with the 270mm

diameter impellor. The motor is a 92% efficient 110kw motor, Good practise C. 1994.

Determine:

1. The pump flow rate at that head.

2. The Pump efficiency at that point.

3. Calculate the operating hours per day assuming it operates to a reservoir on an on-

off control using a level sensor.

4. The electrical load on the motor (shaft power/ motor eff)

5. The kwh per m3

6. The total annual running cost.

1 kwh = 15cents, head is 75m

Answers:

1. 320m3/hour or 7680 per24 hrs

2. 81%

3. 6720/7680 = 21

4. 81kw/ 92% = 88

5. 88/320 = 0.275 kWh/m3

6. 0.275*365*6720*.15= € 101,228

Worked example 2 demand change over time.

Over the last 15 years, the demand has risen substantially to 9120 m3 / day and the

station is using the standby pump to deliver the additional flow into the reservoir. The

increased head losses in the pipe due to the extra flow has added a further 12m of

headloss (now 87m) when the second pump is running. Assuming two identical pumps,

what is the new operating point of the pump when the second pump is now working?

Determine:

1. Each pump flow rate at that head.

2. The Pump efficiency at that point.

3. Calculate the operating hours per day assuming it operates to a reservoir on an on-

off control using a level sensor. (to keep calculations simple - both pumps come

on together)

4. The load on the motor

5. The kwh per m3

6. The total annual running cost.

Answers:

1. 200m3 / hour ( 400 total) and 9600 total per day

2. 72%

3. 9120/9600 * 24 = 22.8 hours

4. 134kw/.92 = 146

5. 146/400 = 0.364 kWh/m3

6. 0.364*365*9120*.15= € 181,800

Worked Example 3 Select a new pump

Over the last 15 years, the demand has risen substantially to 9120 m3 / day and you want

to be able to supply (a new commercial park being planned) for the foreseeable future

9600m3/ day using one pump (92m head). You have selected the The KSB Multitek 125

10.1 with a 305mm dia impellor. The Motor is a Brook Crompton Premium efficiency

IEC 3 motor with an efficiency of 96.2%.

Determine:

1. Pump flow rate at that head.

2. The Pump efficiency at that point.

3. Calculate the operating hours per day assuming it operates to a reservoir on an on-

off control using a level sensor. The load on the motor

4. The kwh per m3

5. The total annual running cost.

6. Annual Savings versus example 2

7. Simple payback – Assumed cost €40k

Answers:

1. 400m3 / hour

2. 79%

3. 9120/10320 * 24 = 21.2 hours

4. 125kw/.962 = 130

5. 130/400 = 0.325 kWh/m3

6. 0.325*365*9120*.15= € 162,200k

Calculate the annual savings for the pump replacement?

€181,800 – €162,200 = 19,600k

What would the expected cost & Payback be (assuming it cost 40k installed)?

Simple payback of 2.1 years

Worked example 4 VSD controls

Given the above pump can operate on a VSD at 48Hz at a flow rate of 9120 m3 per day,

(head of 87m) draws (shaft) 120kW, calculate the parameters again.

Determine:

1. Pump flow rate at that head.

2. The Pump efficiency at that point.

3. Calculate the operating hours per day assuming it operates to a reservoir on an on-

off control using a level sensor. (to keep calculations simple - both pumps come

on together)

4. The load on the motor

5. The kwh per m3

6. The total annual running cost.

7. Savings due to controls

8. Payback for the VSD

Answers:

1. (380*88/367) / 120 = 80%

2. 24 hours

3. 115kw/.962 = 120

4. 120/380 = 0.315 kWh/m3

5. 0.315*365*9120*.15= € 162,825

How much did the extra controls having the pump match demand versus on/ off save?

€4915

What is the simple payback assuming a €8,000 increase for a VSD versus a soft start?

1.62 Years

Baureihe--Größe

Type--Size

Modèle

Tipo

Serie

Tipo

Nenndrehzahl

Nom. speed

Vitesse nom.

Velocità di rotazione nom.

Nominaal toerental

Revolutiones nom.

Laufrad--ø

Impeller Dia.

Diamètre de roue

ø Girante

ø Waaier

ø Rodete

Projekt

Project

Projet

Progetto

Projekt

Proyecto

Pos.--Nr.

Item No.

No. de pos.

Pos.--Nr.

Positienr.

Pos.--Nr.

Angebots--Nr.

Project No.

No. de l’offre

Offerta--No.

Offertenr.

Offerta--No.Division Pompes Industrie et Eau

KSB S. A.Allée de Sagan -- B.P. 18936004 Châteauroux

Multitec 125 10.1

1.4408 2900 1/min

K1777.452/10/1

0 500 1000 1500 2000 2300US.gpm

0 500 1000 1500 1900IM.gpm

0 50 100 150l/s

0 100 200 300 400 500 540m /h3

0 100 200 300 400 500 540m /h3

Förderstrom/Flow/Débit/Portata/Kapaciteit/Caudal

200

300

400

ft

60

80

100

120

45

135

m

Förderhöhe

TDH

Hauteur

Prevalenza

Opvoerhoogte

Altura

50

100

150

200

hp

50

100

150

30

kW

Leistungsbedarf

Power Input

Puiss. abs.

Potenza ass.

Opgenomen

vermogen

Potencia nec.

20

40

ft

5

10

2

13

mNPSHR

♣ ξΒζ

ø274

78.9

2020 30 40 5060

70

70

75

75

78

78

ø274

Axial

ø305

80.9

20 30 40 505060

70

70

75

75

78

78

80

80

ø305

Radial

Werkstoff/Material/MatériauMateriale/Materiaal/Material

22, 23, 30

Laufradaustrittsbreite/Impeller outlet width/Largeur à la sortie de la roueLuce della girante/Waaier uittredebreedte/Anchura de salida rodete

20,0 mm20,0 mm

86

Baureihe--Größe

Type--Size

Modèle

Tipo

Serie

Tipo

Nenndrehzahl

Nom. speed

Vitesse nom.

Velocità di rotazione nom.

Nominaal toerental

Revolutiones nom.

Laufrad--ø

Impeller Dia.

Diamètre de roue

ø Girante

ø Waaier

ø Rodete

Projekt

Project

Projet

Progetto

Projekt

Proyecto

Pos.--Nr.

Item No.

No. de pos.

Pos.--Nr.

Positienr.

Pos.--Nr.

Angebots--Nr.

Project No.

No. de l’offre

Offerta--No.

Offertenr.

Offerta--No.Division Pompes Industrie et Eau

KSB S. A.Allée de Sagan -- B.P. 18936004 Châteauroux

Multitec 125 10.2

1.4408 2900 1/min

K1777.452/11/1

0 500 1000 1500 2000 2300US.gpm

0 500 1000 1500 1900IM.gpm

0 50 100 150l/s

0 100 200 300 400 500 540m /h3

0 100 200 300 400 500 540m /h3

Förderstrom/Flow/Débit/Portata/Kapaciteit/Caudal

100

200

300

ft

20

40

60

80

100

m

Förderhöhe

TDH

Hauteur

Prevalenza

Opvoerhoogte

Altura

50

100

hp

40

60

80

25

90

kW

Leistungsbedarf

Power Input

Puiss. abs.

Potenza ass.

Opgenomen

vermogen

Potencia nec.

20

40

ft

5

10

2

13

mNPSHR

♣ ξΒζ

ø243

79.5

2020 30 40 50 60 6570

70

75

75

78

78

ø243

Axial

ø270

81.5

20 30 40 50 60 65

65

70

70

75

75

78

78

81

81

ø270

Radial

Werkstoff/Material/Matériau

Materiale/Materiaal/Material22, 23, 30

Laufradaustrittsbreite/Impeller outlet width/Largeur à la sortie de la roueLuce della girante/Waaier uittredebreedte/Anchura de salida rodete

20,0 mm20,0 mm

88

© TEA. www.tea.ie 1

Water Services Energy Training

William Moynihan, Manager, Kerry Energy Agency

Paul Kenny, Senior Consultant, Tipperary Energy Agency

© TEA. www.tea.ie 2

Examples

4 examples:

1. Basic operating point of a given system (as designed)

2. Over time, demand has increased, 2nd pump operating

on system, work out the new operating point

3. Select a new point for the maximum that will be

required in the future

4. Given a Variable speed drive curve, work out the new

operating point for current demand

© TEA. www.tea.ie 3

Example 1

Q: Work out the Pump Efficiency, Power consumption by the pump and the

motor.

In 1994 the system was designed to pump at a Total dynamic head of

75m and an average flow rate of 6720m3 per day. The KSB Multitek 125

10.2 was chosen with the 270mm diameter impellor. The motor is a 92%

efficient 110kw motor, Good practise C. 1994.

Determine:

1. The pump flow rate at that head.

2. The Pump efficiency at that point.

3. Calculate the operating hours per day assuming it operates to a reservoir

on an on-off control using a level sensor.

4. The electrical load on the motor (shaft power/ motor eff)

5. The kwh per m3

6. The total annual running cost.

1 kwh = 15cents, head is 75m

© TEA. www.tea.ie 6

Q3: Operating hours per day:

= Required flow

Max Flow per hour *24

= 6720 * 24

320*24

= 21 hours per day

Example 1

© TEA. www.tea.ie 8

Q4. Power = shaft power (from graph)/ motor eff= 81/0.92

= 88kW

Q5. kWh/ m3 = motor power/ flow

= 88/320

= 0.275 kWh/m3

Q6. Annual cost

= kWh/m3 x Flow per annum x cost /kwh

= 0.275 * 365 * 6720 * 0.15

= €101,228

Example 1

© TEA. www.tea.ie 9

Worked example 2 demand change over time.

Over the last 15 years, the demand has risen substantially to 9120 m3 / day and the

station is using the standby pump to deliver the additional flow into the reservoir.

The increased head losses in the pipe due to the extra flow has added a further

12m of headloss (now 87m) when the second pump is running. Assuming two

identical pumps, what is the new operating point of the pump when the second

pump is now working?

Determine:

1. Each pump flow rate at that head.

2. The Pump efficiency at that point.

3. Calculate the operating hours per day assuming it operates to a reservoir on an

on-off control using a level sensor. (to keep calculations simple - both pumps

come on together)

4. The load on the motor

5. The kwh per m3

6. The total annual running cost.

Example 2

© TEA. www.tea.ie 11

Q3: Operating hours per day:

= Required flow Or Average flow

Flow per hour *24 flow per hour

= 9120 * 24

9600

= 22.8

Example 2

© TEA. www.tea.ie 13

Q4. Power = shaft power (from graph)/ motor eff= 134/0.92

= 146kW

Q5. kWh/ m3 = motor power/ flow

= 146/400

= 0.364 kWh/m3

Q6. Annual cost

= kWh/m3 x Flow per annum x cost /kwh

= 0.364 * 365 * 9120 * 0.15

= €181,800

Example 2

© TEA. www.tea.ie 14

Over the last 15 years, the demand has risen substantially to 9120 m3 / day

and you want to be able to supply (a new commercial park being

planned) for the foreseeable future 9600m3/ day using one pump (92m

head). You have selected the The KSB Multitek 125 10.1 with a 305mm

dia impellor. The Motor is a Brook Crompton Premium efficiency IEC 3

motor with an efficiency of 96.2%.

Determine:

1. Pump flow rate at that head.

2. The Pump efficiency at that point.

3. Calculate the operating hours per day assuming it operates to a reservoir

on an on-off control using a level sensor. The load on the motor

4. The kwh per m3

5. The total annual running cost.

6. Annual Savings versus example 2

7. Simple payback – Assumed cost €40k

Example 3

© TEA. www.tea.ie 16

Q3: Operating hours per day:

= Required flow Or Average flow

Flow per hour *24 flow per hour

= 9120

400

= 22.8

Example 3

© TEA. www.tea.ie 18

Q4. Power = shaft power (from graph)/ motor eff= 125/0.962

= 130kW

Q5. kWh/ m3 = motor power/ flow

= 130/ 400

= 0.325 kWh/m3

Q6. Annual cost

= kWh/m3 x Flow per annum x cost /kwh

= 0.325 * 365 * 9120 * 0.15

= €162,200

Q7. Annual savings for pump replacement

= 182,600 – 162,200 = 20,800

Q8. Simple payback

= 40,000/20,800 = 2 years

Example 3

© TEA. www.tea.ie 19

Given the above pump can operate on a VSD at 48Hz at a flow rate of 9120

m3 per day, (head of 87m) draws (shaft) 120kW, calculate the parameters

again.

Determine:

1. Pump flow rate at that head.

2. The Pump efficiency at that point.

3. Calculate the operating hours per day assuming it operates to a reservoir

on an on-off control using a level sensor. (to keep calculations simple -

both pumps come on together)

4. The load on the motor

5. The kwh per m3

6. The total annual running cost.

7. Savings due to controls

8. Payback for the VSD

Example 4

© TEA. www.tea.ie 21

Q3: Operating hours per day:

= Required flow Or Average flow

Flow per hour *24 flow per hour

= 9120 * 24

9120

= 24

Example 4

© TEA. www.tea.ie 23

Q4. Power = shaft power (from graph)/ motor eff= 115/0.962

= 120kW

Q5. kWh/ m3 = motor power/ flow

= 120/380

= 0.315 kWh/m3

Q6. Annual cost

= kWh/m3 x Flow per annum x cost /kwh

= 0.315 * 365 * 9120 * 0.15

= €157,285

Q7. Cost and payback 162,200- 157,285 = 4,915

Q8. 8,000/ 4,915 = < 1.62 years

Example 4