Woodsmith Shaker Style Workbench

-

Upload

richeklund -

Category

Documents

-

view

244 -

download

4

Transcript of Woodsmith Shaker Style Workbench

-

8/13/2019 Woodsmith Shaker Style Workbench

1/22

SHAKER-STYLEWORKBENCH

2012 August Home Publishing Co.

-

8/13/2019 Woodsmith Shaker Style Workbench

2/22

-

8/13/2019 Woodsmith Shaker Style Workbench

3/22

-

8/13/2019 Woodsmith Shaker Style Workbench

4/223 WoodsmithPlans.com WS20028 2012 August Home Publishing Co. All Rights Reserved.

How-To: Mortise & Counterbore

Patternbit

Center piece of template is

width of mortise

A

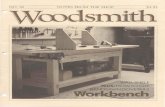

The first requirement for anyworkbench is, of course, stability.It needs to be able to stand up tothe weight of heavy projects, blowsfrom a mallet, and the racking

forces of hand planing.And while the solid-wood topyoull add later provides part of thesolution, it all starts with a sturdy

base. For that, I relied on heavy-duty

legs, rails, and stretchers assembledusing mortise and tenon joinery.

I started work on the base by building two rock-solid end assem- blies. Although the left end needs toaccommodate the leg vise and has afew different details, the construc-tion of both is similar. Stretchers tiethe ends together.

LEGS. The end assemblies beginwith a pair of legs. All but the left

front leg are 31

2" square. In order toaccommodate the leg vise, the leftfront leg is wider (6").

I glued up 8/4 stock to attain thenecessary thickness for the legs.

If you cut them a little oversize,its a simple matter to joint themsquare and plane them to finalthickness and width.

JOINERY. After the legs are cut andsquared up, you can turn yourattention to the joinery. But beforeyou begin, youll want to labeleach leg according to its position.No two legs are the same, so itsimportant to avoid confusion. I

also laid out the position of every joint on the face of each leg while Ihad them on the bench.

All of the legs have mortises for both the upper and lower rails .

Mortise. Attach the template to the legwith double-sided tape. Then use a plungerouter to rout the mortises.

A

B

A

A

9%/8

31 !/2

3%/8

8 !/4

6 !/2

2

5 &/8

3

12 !/4

3

31 !/2

3%/8

VISE LEG

LEG

3!/2

1#/4

8 &/8

1

2!/4

Mortise is!/2"deep

1

!/8" roundover onbottom and side edges

NOTE: All parts are

glued up from 8/4 stock

NOTE: All mortises in 3 !/2"- squarelegs are centered on width

Mortiseis 2"deep

2

6

starting with the LEGS

SIDE SECT.VIEW

2

1!/8 2

&/16

2#/16

B

3!/2

2#/4" square

mortise

a.

BACK VIEW

Lamb's tongueand chamfer onoutside corner of legs only

LEG

Ad.

TOP SECTIONVIEW

3!/2

&/16"dia.

1

!/2

2

3!/2 A

c.

ENDSECT.VIEW

Waste

Template

A

a.

Drill 2"-dia.counterbore

first, thenthe 1 !/8"-dia.through hole

Forstner bit

B

Drilling Bolt Holes. After routingthe stretcher mortises, drill the boltholes at the drill press.

2#/16 2" dia.

1!/8"dia.

ENDSECTION

VIEW

B

a.

Drill &/16 "-dia.through hole ,centered onmortise width

A

Drilling the Counterbore. Drill the largediameter hole rst, then swap bits anddrill the through hole of the leg vise screw.

SIDESECTION

VIEW

2

1&/8"dia.-hole

1!/4

!#/16"-dia.through

hole

B

b.

-

8/13/2019 Woodsmith Shaker Style Workbench

5/22

And they also have mortises for thestretchers. Because these mortisesare all quite long and deep, I used aplunge router to cut them.

To guide the router, I made atemplate for each mortise. Thistechnique guarantees theyre allsized accurately. It also leaves very

smooth walls in the mortises toensure strong glue joints.

ROUTER TEMPLATES. Theres nothingfancy about the templates that Imade. All you need to do is usesome scrap wood or plywood toassemble them. Just cut two piecesto the width of the mortise and gluethem between two longer pieces,making sure to size the opening tomatch the mortise.

After laying out the location,affix the template to the leg withdouble-sided tape and begin rout-ing. Start with a dado-cleanout bit,then switch to a pattern bit. The leftdrawing at the bottom of the previ-ous page has the details. Take severalshallow passes, increasing the depthafter each one. Then clean up the cor-ners using a chisel.

LAMBS TONGUE. Now, you can starton the lambs tongue chamfer onthree of the legs. (The vise leg doesnot share this prole.) For this, start

by installing a chamfer bit in therouter table. I also marked the cen-terline of the bit on the fence. Thisway, you can make start and stopmarks on the leg blank to denethe length of the chamfer. You cansee what I mean in the How-To boxat right. Youll complete the lambstongue with a chisel.

BOLT HOLES. At this point, I drilledthe bolt holes in the stretcher mor-tises on the back legs. By drillingthem now, you can use the drill

press to keep them straight andmake sure theyre centered on thewidth of the mortises.

As you can see in the right draw-ing on page 3, I also routed anothersquare mortise to hold the vise hard-ware on the back side of the leg. ThenI drilled holes in the vise leg for thevise screws. On the front side, thehole for the vise screw needs to becounterbored for the nut. For this, I

just used a Forstner bit.

LAMB'S TONGUETEMPLATE(full size)

Round

Hollow

Centerlineof bit

FIRST: Pivot leginto bit so that toplayout line alignswith bit centerline

Layout line

SECOND: Pull leg away from bit when second layout line reachesbit centerline

Tall aux.fence

4

6 !%/16

B

Refine the hollow with a carving knife

Work fromboth sides to

shape hollow

Waste

Chamfer

Take light cutsto prevent tearout

Avoid marringchamfer surface

Carving the Prole. Take light cuts and payattention to the grain direction as you roughout the prole with bench or paring chisels.

Completing the Rough-Out. Make thelast few paring cuts with the grain andcheck the prole from both sides.

Rening the Shape. A carving knife is the perfect tool for cleaning up the chiseled surfaces and rening the prole.

END VIEW

!/2!/2

1&/16 "-dia.chamfer

bit

a.

Stopped Chamfer. The key to accurate stopped chamfers is thelayout marks on the workpiece and the fence. After that, all you needto do is match them up and hold the workpiece at while routing.

Use a chisel to square up ends

of chamfer

B

Waste

V-notch blockshelp to secureleg whilechiseling

Lay template alongleg chamfer and legedge to trace lamb'stongue profile

Square the Ends. Youll need to clean upthe ends of the chamfers with a chisel beforemoving on to carving the lambs tongue.

Lamb's Tongue Prole. Use the templateabove to trace the lambs tongue proleonto the sides of the workpieces.

Use a dowel with sandpaper to clean up hollow

Hand sand round to smooth

surface

Sanding. If necessary, wrap a small pieceof 220-grit sandpaper around a 1 2"-dia.dowel for the nal cleanup.

1

2

4

3

5

6 7

How-To: Lambs Tongue

4 WoodsmithPlans.com WS20028 2012 August Home Publishing Co. All Rights Reserved.

-

8/13/2019 Woodsmith Shaker Style Workbench

6/225 WoodsmithPlans.com WS20028 2012 August Home Publishing Co. All Rights Reserved.

How-To: Tenons & Notches

Ripfence

#/4"dadoblade

C

Once youve completed the four legs,its time to get busy on the rails andstretchers. The rails connect each pairof legs and form the end subassem-

blies. After that, youll connect thetwo ends with the three stretchers.

RAILS. As you can see in the draw-ing above, the two rails are dif-

ferent widths, but both need a1"-thick x 2"-long tenon. You canstart by cutting both rails to finallength and width.

TENONS. The box below shows howI cut the tenons using a dado bladeand a long auxiliary fence on themiter gauge. I also set the rip fenceto match the length of the tenon.Now you can cut the tenons by rais-ing the blade to sneak up on a snugt in the mortises you cut in the legs

earlier. Then cut the small notch inthe upper rails (detail a).CUT THE RABBET. Youll notice that the

upper rails are rabbeted on the top

edge to form a long tongue. Thistongue ts into a dado youll cutin the benchtop later. I cut the rab-

bets using the dado blade in thetable saw by attaching an auxiliaryrip fence and burying part of the

blade. Then, its a simple matter tocut perfect rabbets. The left draw-

ing at the bottom of the next pageshows the details.STRETCHER MORTISE. The lower rail ha

a shallow mortise in order to hold

Tenons. With a long auxiliary fence on themiter gauge and the rip fence used as a

stop, cut the tenons using a dado blade.

D

C

NOTE: Tenons are pinned in mortises

with #/8"-dia. x 3 "walnut dowels

#/4"-dia. x #/4"-deephole to store board

jack peg

UPPER RAIL

LOWERRAIL

C

D

NOTE: Rails are madefrom 1 #/4"-thick stock

26

22

1

#/8"-dia. x 3"walnut dowel

&/16 "-dia.hole

10 !/217

1

1

3

4!/2

91#/4

Drill #/8"-dia. x 2 !/2"-deep holefor dowel pinsafter assembly

6 !/4

Add !/16 " chamfer around end of dowels before inserting

Notch cut at front end of rail only

completing the BASE F RAME

#

8 !/4

1

#/8

#

#

D

b.

!/2!/2

#/8

#/81

4!/8C

2

!/4

a.

FRONTSECTION

VIEW

1#/4

!/2

6 !/4 4!/2

D

2!/4

c.

Dowe

sits!/1

proudof leg

surfac

Leg

C

d.

Aux. ripfence

C

CRipfence

Tall aux.

miter fence

Upper Rail Notch. Install an auxiliaryrip fence and bury part of the dadoblade to cut the notch in the upper rail.

Shoulder Cuts. You can use the same blade and fence setup to makethe shoulder cuts on the tenons.

END VIEW

2

#/8

a.

END VIEW

2

#/8

a.

END VIEW

!/4

!/2

a.

-

8/13/2019 Woodsmith Shaker Style Workbench

7/226 WoodsmithPlans.com WS20028 2012 August Home Publishing Co. All Rights Reserved.

Aux.fence C

#/4"dado blade

Rabbets. Using the auxiliary ripfence again, cut the long rabbets toform the tongue on the upper rail.

F

TemplatePlungerouter with pattern bit

Clean upcorners with

chisel

1!/21#/4#/4" radius

NOTE: Rout pocket in multiple passes

D

Cleanup cornerswith chisel

!/2"dadoclean-out

bit

Stretcher Pockets. The bearing on a patternbit follows the template to rout the pockets inthe back and center stretchers.

Stretcher Mortise. Attach the templateto the lower rail with double-sided tapeand rout the stretcher mortise.

Rabbets, Mortise, & Pockets

ENDVIEW

#/8

!/2

a.

END SECTION VIEW

D

Template

!/21

a.

B

Template

1!/2

F ENDSECT.VIEW

a.

the center stretcher. The box belowwalks you through the process. Imade a template and routed out thewaste, then squared up the mortisewith a chisel. Finish up by drillingthe holes for the bolts.

At this point, you can dry fit therails into the legs and clamp every-

thing in position. After making sureeverything is square, drill the holesfor the dowel pins at the positionsshown in the main drawing and detaild on the previous page. Remove theclamps and cut the walnut dowels tolength. Brush glue in the mortises, onthe tenons, and on the dowels, thenassemble the ends.

STRETCHERS

The two end assemblies are joinedwith three stretchers: One at the

back, one at the front, and one cen-tered on the lower rails. While themortise and tenon joints on the endrails are glued, the stretchers are

joined using long bolts. This is agreat way to allow for periodicallytightening up the base.

RIP TO WIDTH. The stretchers aremade from 1 3 4"-thick stock rippedto the widths shown in the drawingabove. After ripping them, cut eachone to nal length.

Each stretcher also requires a1

2"-long tenon on both ends. While allare the same length and thickness,youll note that the tenons on the

upper back stretcher are a little dif-ferent. There is no shoulder cut onthe upper edge. Instead, this edgeof the tenon sits flush with the top ofthe leg (detail d).

POCKETS. The back and centerstretchers have another feature D-shaped pockets in the back. Thesepockets hold the nuts and washers

for the bolts (details b and c). Tocut the pockets to shape, I madeanother router template, as shownin the right drawing below.

PLATES. As a nishing touch, I madedecorative plates for the ends ofthe center rail. (Details in ShopNotebook on page 19.) The bolts tthrough the plates.

ASSEMBLY. Now its time to assem- ble the base. Just t the stretchersinto the mortises (without usingglue) and drill the holes into the

end grain of the stretchers usingthe holes in the rails as your guide.Then add the nuts, bolts, and wash-ers to complete the assembly.

NOTE: Back and center stretchers areattached with #/8"-dia. x 8"carriage

bolts, nuts, and washers

NOTE: Stretchersare made from 8/4 stock

G

F

E

FRONT STRETCHER

CENTERSTRETCHER

BACK STRETCHER

58 57

#/8"-dia. x 8"carriage bolt

Shop madealuminum

plate, refer to page 19

4

7

3

NOTE: Front stretcher isassembled without glue

59 #/458 #/4

55 !/254 !/2

#/8

!/8"roundover

G#/8

#/8

#/8

!/2 a.

BACK VIEW

2EBack

leg

1!/4

F

Lower rail

1!/4

d.

TOP SECTION VIEW

F

5 !/2 1#/41!/2

Lower rail

Aluminum plate

b.

Back leg

E

1!/2

TOP SECTION VIEW

4 1#/4c.

{ The decorativplate also seras a washer.

-

8/13/2019 Woodsmith Shaker Style Workbench

8/227 WoodsmithPlans.com WS20028 2012 August Home Publishing Co. All Rights Reserved.

Rip blade

Outfeed support

As I said earlier, mass is importantin a workbench. And this laminated,solid-wood top provides mass inspades. Assembling the top in nar-rower sections is the way to go. Thismethod also allows you to make a fewpreparations for the tail vise assembly.

PREPARE THE BLANKS. The rst step ina successful glueup is to start withproperly planed and square blanks.

The strips will be turned on theirsides to expose the edge grain in theassembled top, so by planing both

sides you effectively joint the edgesthat will be glued up. Remember,youll be planing the assembled sec-tions later, so dont cut the pieces tonal width or length yet. This givesyou the option of cutting off anychecking or planer snipe and plan-ing the sections to nal thickness.

RIP THE STRIPS. I started at the tablesaw with a good rip blade. Just set

the rip fence and rip the stock into18 strips (this gives you one extra tohelp out with grain matching).

LAY OUT THE STRIPS. Now you canarrange the strips for the bestappearance. Once you have a lay-out you like, mark the top so youcan reassemble the strips in order.(I used a triangle mark as shown inthe center drawing below.)

GLUING UP SUBASSEMBLIES. The maidrawing shows how I grouped thestrips into subassemblies. The idea

is to glue up each subassembly, thenatten and thickness them by run-ning them through the planer.

Ripping. Rip the individual strips a littlebit wide. This allows you to plane the

glued-up sections to nal width.

70

70

80 #/4

7 !/4

1

59 !/2

3#/4

2

NOTE: Top sections are madefrom 1 #/4"-thick hardwood, ripped into 3 !/8"widths and turned on their sideto expose straight edge grain

NOTE: Bench dog section and back stripof benchtop are glued on after cutting the

dadoes on the underside of the benchtopNOTE: Finished widthof top is 29 #/4"

3!/2

NOTE: Benchtopis glued up in sections to

allow planing prior to final assembly

J

BENCH DOG STRIP

H

I

TAILVISE SECTION

H

H

BENCHTOP

H

NOTE: See ShopNotebook, page 16, for

more information about routing bench dog holes

86 !/2

!/2

12

1

!/2

FRONT SECTION VIEW

3#/4

!/2 21

1!/4

H

!/2

c.

building theTOP

FRONT SECTION VIEW

1

!/4!#/16

85

J

b.

Planing. After gluing up the sections, scrap off the glue squeezeout and runeach section through the planer.

A large triangleallows you to

reassemble the strips in order

Grain Matching. Experiment with differ-ent color and grain patterns until youre

satised, then mark the nal positions.

TOP VIEW

1!/16

!!/1

Benchdogholes

5 #/4a.

How-To: Build the Laminated Benchtop

3 !/8

ENDVIEW

a.

-

8/13/2019 Woodsmith Shaker Style Workbench

9/228 WoodsmithPlans.com WS20028 2012 August Home Publishing Co. All Rights Reserved.

Finally, assemble them all to formthe full-sized benchtop. All this con-tributes to an easy final assembly of

just a few joints.I started by breaking the main

part of the benchtop into three sec-tions of four or five pieces each. (Ileft the outside piece off for now.)

I also glued up another, shorter sec-tion for the tail vise.

Before you get started, let me giveyou a piece of advice. When gluingup multiple segments, the key to suc-cess is to be thoroughly prepared.Dry assemblies, including layingout the clamps, help everything goaccording to plan.

With your clamps and cauls inplace, assemble each section withglue. After the glue dries, removethe squeezeout with a scraper andhead over to the planer.

DADOES. The next step is to rout thedadoes on the underside of each sec-tion. You can see how I did it in thedrawings below. I started with thewider dado on the end of the outsidesection that holds the ange blockfor the tail vise. After that, you canglue up the main slab and rout thetwo dadoes on the main section to tover cleats attached to the base.

THE DOG HOLES. The tail vise will line

up with a series of square dog holesin the benchtop. I routed the dogholes using a simple template and

pattern bit. For the details on thisquick and easy template, turn toShop Notebook on page 20.

FINAL ASSEMBLY. For the nal assem- bly, simply spread glue on the edgesof each section and clamp them alltogether. I also used clamps withcauls spanning the width of theassembly to help keep each jointaligned. After the glue dries, scrap

off the squeezeout and clean up thetop. Then you can cut the assembled benchtop to nal length.

CLEATS. With the top complete, youcan turn your attention to the twocleats that help secure the top to the

base. You dont need to add glue inthe benchtop dadoes or on the ten-ons on the base. The cleats attach tothe rails and reinforce the joint. Youcan see the elongated screw holesin detail b that allow the wood tomove. After cutting the cleats to

length, all you need to do is cut therabbets and drill the screw holes.Then attach them to the rails.

22 &/8

23 #/4

86 !/2 29 #/4

#8 x 2"Fh woodscrew

#8 x 2 !/2"Fh woodscrew

H BENCHTOP

J

BENCH DOG SECTION

K

LEFT CLEAT

RIGHT CLEAT L

Back holes incleats enlongated to allow top

expansion!/4"

roundover

NOTE: If you plan to add the drawer cabinet on page 15, don't attach

the benchtop to the base at this time

24 !/2

16 !/2

5 !/4

16 #/8

TOP SECTION VIEW

(Top removed)

1!/8

2%/8

!/4"-dia.hole

K

Vise legUpper

left rail

1!/2

a.

FRONTSECTION

VIEW

L

H1!/2

1

Upper rail

Dadoes intop fit over top of rails

c.

TOP SECTION VIEW

(Top removed)

&/8 &/8

3!/4

!/2!/4

L

Right back leg

Back stretcher

Right upper

rail

b.

Guidefence

Strips arecut flushat ends

H

Wide Dado. Mark the location of thedado, then clamp a pair of guides to theunderside of the top to rout the dado.

Dog holetemplate

Patternbit

J

NOTE: For moreon making this

jig, see page 20

Dog Holes. Once again, I relied on a templateand a pattern bit to rout the recesses thatwill hold the bench dog.

Flush at ends

Guide

Narrow Dado. Use the same techniqueto rout the narrow dado that ts on thetongues on the end assemblies.

Dadoes & Dog Holes

1

!/2 H!/2" straight bit

ENDVIEW

a.

SECTION VIEW J

Template!!/16

a.

2

!/2!/2" straight bit ENDVIEW

a.

-

8/13/2019 Woodsmith Shaker Style Workbench

10/229 WoodsmithPlans.com WS20028 2012 August Home Publishing Co. All Rights Reserved.

1#/4"Forstner

bit

NOTE: Drill throughentire workpiece

Waste shown for proper part orientation

U 2#/4

10 !/8 2

Dado. With an auxiliary fence on the miter gauge, nibble away the waste to create a square recess for the ange.

20

4#/8

1#/4

12 2%/8

16 !/2

3!/2

4!/2

4!/2 1!/4

!/2"-dia.hole through

#/8

2 7 !/2 2

1!/8"-dia. x 3"-deep hole

18 #/4

4#/8

10 !/2

1!/4

41!/8"-dia.

through hole

1!/8"-dia. x 12"hardwood dowel

!/2" x 16 !/2"- !/4"Baltic birch plywood

#6 x #/4" Fhwoodscrew

#/8"-dia. x 4"lag bolt

with washer TAIL VISE

END BLOCK

M

TAIL VISE SIDE BLOCK

N

TAIL VISE TOP BLOCK

O

P

TAIL VISE FRONT BLOCK

FILLERSTRIP Q

GUIDE RAIL SIDE

R

GUIDE RAIL END

S T

GUIDE STRIP

FLANGE BLOCK

U

1!/8"-dia.vise screw

1!/2"-dia.knurled knob

1!/8" I.D.rubber O-ring

#/4"-dia. x #/4"-deep hole

centered onend of dowel

Dog holes spaced 5 #/4"center-to-center

1#/4

3!/8 3 2

2%/8

3!/2

1!/4

1!/4

23

U

Dadoblade

Ripfence

2!/2 Aux.

miter fence

Aux.miter

fence

B

#/4" dadoblade

Notch & Rabbet. First cut the notch forthe guide rail, then ip the block over andcut the long rabbet on the opposite face.

T

S R

ON

END SECTION VIEW

10 !/8 2 !/2

2

#/4UBenchtop

dado

Tail vise assembly attached through flange block

into dado of benchtop

2#/4

%/8

b.

One of the features I was determinedto include on this bench was a classictail vise. This type of vise is very ver-satile, especially for hand-tool work.

A tail vise can hold workpieces flat between a pair of bench dogs, andthe opening in the vise jaws can beused to hold awkward shapes andlong workpieces vertically.

START WITH THE BASICS. The tail vise endand side blocks dene the shape andsize of the vise, so theyre the rstorder of business. For the end block

I laminated 8/4 stock, then cut the block to nal size and drilled the11 8"-dia. hole for the vise screw.

DOG HOLES. The side block alsohouses three dog holes that point the

opposite direction from holes in the benchtop. I routed these using thesame basic template, but reversedthe angle of the slots.

FINGER JOINTS.

The vise body calls foa tough joint. I chose to use a nger joint here because it offers so muchglue surface. Turn to Shop Notebookon page 19 for more details.

adding the TAIL V ISE

How-To: Make the Flange Block

3!/2

%/8%/8%/8

1#/4

M

N

%/8%/8%/8

a.

Drill. After the mounting holes aredrilled, install a Forstner bit and drill thelarge-diameter hole for the ange.

2#/4#/8

&/16

END VIEWa.

2

#/8

END VIEWa.

-

8/13/2019 Woodsmith Shaker Style Workbench

11/22

TOP BLOCK. The next piece to addis the top block. Its the piece thatrides on a guide strip attached tothe benchtop. After cutting it tosize, I cut the long groove on theedge at the table saw with a dado

blade (Figure 1).To keep the top block aligned

with the end block during assem- bly, I added a dowel. Just drill a holein the top block, then use a dowelcenter to transfer the position to theend block (Figure 2). Now glue thetop block in place.

FRONT BLOCK. The front block housesthe end of the vise screw. All youneed to do here is drill the holefor the end of the screw. Glue itush with the front edges of theside block and top block. Figure 3shows how I added a ller strip tocover the dog holes.

GUIDE RAIL. A guide rail assemblycompletes the moving portion ofthe vise. Its simply an L-shaped

bracket that ts on the underside.I used a bridle joint to connect the

side and end pieces of the rail (Fig-ures 4 and 5). Then, mark the loca-tion of the end and front blocks andcut the rabbets.

After assembling the guide rail,attach it to the end block and the

front block with screws (no glue), asshown in Figure 6.GUIDE STRIP. I made a guide strip for

the vise out of Baltic birch plywood.After cutting it to size, just drill thecountersunk screw holes as shown.Then, attach the guide strip to the

bench using screws.VISE HANDLES. I made a pair of cus-

tom vise handles from 1 1 8"-dia.maple dowel. Youll need to drill a 3 4"-dia hole in the ends of the dowelfor the knobs.

You can nd out more about theknobs and other hardware thatI used for the bench under theSources on page 21.

FLANGE BLOCK. The ange block holdsthe ange for the vise screw. The

box on the previous page showshow to make the block. Install theange with screws (Figure 7), thenuse lag screws to attach the block tothe benchtop in the 2"-wide dadoyou cut earlier.

!/4" dadoblade

O

Ripfence

Top Block. Cut the centered groove onthe top block by making the rst cut,then ipping the block for a second pass.

How-To: Build the Tail Vise

Top of top block flush with topedge of side block

Dowel center

O

M

N

Dowel Hole. First drill a hole for the dowelin the top block. Then use a dowel center totransfer the hole location to the end block.

END VIEW

!/2!/4

%/8

a.

M

N

QP

O

End of filler strip fitsinto inside corner of end and side blocks

Sides of filler block and front block areglued to inside face

of side block

Q

Front Block & Filler Strip. In addition tohousing the vise screw, the front block and ller

strip cover the edges of the dog holes.

Tall aux.fence

Ripblade

R

Bridle Joint. Install a tall, auxiliary ripfence and use a push block to cut the

groove in the end of the side guide rail.

2

ENDVIEW

!/4

!/4a.

Dadoblade

Aux. miter fence

Ripfence

S

END VIEW

!/4

!/4 2

a.

M

N

Q

P S

R

O

#8 X 1 !/2" Fhwoodscrew

!/2

2

NOTE: Guide rail is just screwed in place (no glue)

Bridle Joint Tongue. Sneak up on a snug-tting tongue by slowly raising thedado blade between passes.

Attaching the Guide Rail. Predrill andcountersink holes for #8 screws and then attachthe guide rail to main body of the tail vise.

Attach Flange to Block. Carefully tthe ange into the recess and secure itin position with screws.

FLANGE BLOCK U

#10 x 1 !/2"Fh woodscrew

Flange fitsin dadoflush at topand bottom

U

#/8" x 4" lag screws with washers

Vise screw bracket attached with #8 x 1 !/2" Fh woodscews

R S

P

M

Flange

Vise screw

NOTE: Flangeblock screwed to undersideof benchtop

Final Steps. All that remains is to add the vise screw bracket and handle before attaching theange block to the bench.

1 2

4

5

3

6

7 8

10 WoodsmithPlans.com WS20028 2012 August Home Publishing Co. All Rights Reserved.

-

8/13/2019 Woodsmith Shaker Style Workbench

12/2211 WoodsmithPlans.com WS20028 2012 August Home Publishing Co. All Rights Reserved.

Chisel mortise tofit square nut

Back of leg vise

Vise side profilelayout line

Drilling. Use the holes in the vise leg to position the matching holes in the vise,then drill them out using a Forstner bit.

1!/8"-dia.vise screw

1!/8"-dia. x 12"hardwoo d dow el

1!/8" I .D.rubbe r o-ring

1!/2"-dia .k nurled knob

# /4"-10c ap nut w ith was her #/4"-10

square nut

# /4"-10 x 13"thread ed rod

#/4"-10 x 3"k nurled

knob

Flang e bolt

wit h screw s

V

LEG VISE

! /8"-thick leathe r pad cut-to-f it

Vise le g

#10 x 1 !/2" Fhwoodscrew

Vise plate

#8 x 1!/2" Fhwo odscre w

Leg viseblank

Cut towaste

side of layout line

Hole for a Square Nut. The next step isto chisel out a square hole for the large nuton the back side of the vise.

Inside Face. Cut the curves of the vise atthe band saw. Start with the inside face,ending in a tight curve at the jaw.

Up to this point, the traditionalworkbench bears a striking resem-

blance to a more modern design.Thats no surprise since the needs

of a woodworker today are largelythe same as they ever were. But theaddition of the leg vise leaves nodoubt that this is a departure fromthe modern world.

The leg vise is really just a lever,with an adjustable pivot point at the

bottom and a moveable jaw on top.Both rely on threaded steel rods.

The combination provides plenty ofholding power.In addition to the workbench's

practicality, I also wanted to add aunique feature to make it stand apart

from other benches a stippledpattern on the face. For this, I used arotary tool, a few different bits, anda fair amount of patience. The ShopTip on the next page has the details.

VISE FACE. Once youve drilled theholes in the leg for the vise hard-ware, you can get to work on thevise face. After gluing up and cut-ting the blank to size, the nextstep is to drill the holes for the

two vise screws and threaded rod.The How-To box below walks youthrough the process. Youll alsoneed to chisel out a square mortisefor the nut in the lower hole.

installing the LEG V ISE

6

25 !/4

FRONT VIEWSIDE SECTION

VIEW

3!/2

6

8 &/8

1!/8"-dia.hole

3#/4"-dia.hole

#/4

Mortisefor

squarenut

1!/2"-dia.counterbore

!/2"radius

!/2

1" radius

2 !/2

1&/8

a.

SIDESECTION

VIEW V

Viseleg

Flange

Leather pad

b.

SIDESECTION

VIEW

Depth of washer

Squarenut

Capnut

V

Vise leg

Threaded rod

Knurled knob

c.

SIDESECTIONVIEW

Depth of square nut

Viseback

a.#/4"

Forstner bit

Leg viseblank

NOTE: Drill holesthrough blank

How-To: Build the Leg Vise

-

8/13/2019 Woodsmith Shaker Style Workbench

13/2212 WoodsmithPlans.com WS20028 2012 August Home Publishing Co. All Rights Reserved.

SHAPING. With that done, you canstart shaping the vise. As youcan see, its curved on the outsideface, tapered on both sides, andrecessed on the inside to create theprotruding jaw. I did most of thiswork at the band saw.

In order to make sure you have a

flat surface to rest on the band sawtable, youll need to make the cuts inthe sequence shown below. I started

by working on the inside face. Withthe piece on edge, all you need to dois make a straight cut, curving at theend near the jaw (right drawing atthe bottom of the previous page).

The box below shows thesequence and techniques for shap-ing the rest of the leg vise. Note thatthe area near the vise screw fittingstays flat. With the cuts completed,you can feather in the curves witha little sanding. After cutting thetapers, I glued a piece of leather tothe jaw to protect workpieces heldin the vise.

STIPPLING. Stippling is simply add-ing a textured look to a field bycarving dimples. Its an easy thingto do, but adds an interestingdetail to the vise.

ROTARY TOOL. I used a rotary toolto do the carving. The great thing

about these tools is the wide arrayof small bits available for this kindof work. I relied on just three ballmill bits to get the look shown inthe photo at right.

I started by defining the borderwith a veining bit. The top draw-ing in the Shop Tip shows how todo this. After completing the border,

it was just a matter of creating therandom textured pattern with the1 32"-dia. and the 1 8"-dia. bit.

MOUNTING THE VISE. The nal stepis to attach the vise to the leg.

I began by attaching the angefor the vise screw into the back ofthe leg. Its held in place with fourscrews. Next, mount the knurled

knob in the lower hole of the leg.After that, its just a matter ofthread ing the rods through andscrewing the vise plate to the viseand the cap nut below.

Use double- sided tape toattach spacer to insideface of vise

Outside. Cut the sweeping arcs of theoutside face. Stop each cut at the at spot

surrounding the vise screw.

Layout line

NOTE: Sand surfaces smoothafter cutting

Sides. Attach a spacer to the cutout area inthe inside face to hold the workpiece level. Thismakes cutting out the sides a snap.

Use a veiningbit to cut a

shallow V-notchon field border layout line

Layout line

Border. It pays to experiment on a pieceof scrap to get a feel for the veining bit.Then use it to carve the border.

SECTIONVIEW

Spacer holds workpiece level

Counterbore todepth of washer

thickness

1!/2"Forstner bit

Start by making largest dimples

randomly spaced

%/32"-dia.ball bit

Fill in space between previous dimples using

!/8"-dia. ball bit

Start Large. Begin ina corner with the large( 5 32"-dia.) bit rst.

Go Small. Move tothe smaller bit to ll in

some of the spaces.

{ Stippling addan interestingvisual detail tthe leg vise.

Shop Tip: Stippling the Vise

FRONT VIEW

Lay vise plate and washer

in place tolay out border curves

#/4

#/4

#/4

Shaping the Leg Vise

Bottom Screw Hole. Use aForstner bit to drill a shallowcounterbore for the washer.

-

8/13/2019 Woodsmith Shaker Style Workbench

14/22

-

8/13/2019 Woodsmith Shaker Style Workbench

15/2214 WoodsmithPlans.com WS20028 2012 August Home Publishing Co. All Rights Reserved.

A Legs (3) 31 2 x 31 2 - 311 2B Vise Leg (1) 31 2 x 6 - 311 2C Upper Rails (2) 1 3 4 x 41 2 - 26D Lower Rails (2) 1 3 4 x 9 - 26E Back Stretcher (1) 1 3 4 x 4 - 58F Center Stretcher (1) 1 3 4 x 7 - 59 3 4

G Front Stretcher (1) 1 3 4 x 3 - 55

1 2

H Main Bench Slab (1) 3 x 241 2 - 861 2I Tail Vise Section(1) 3 x 31 2 - 70J Bench Dog Section (1) 1 3 4 x 3 - 70K Left Cleat (1) 11 2 x 1 - 22 7 8L Right Cleat (1) 11 2 x 1 - 23 3 4M Tail Vise End Block (1) 31 2 x 4 3 8 - 101 2N Tail Vise Side Block (1) 1 3 4 x 4 3 8 - 20O Tail Vise Top Block (1) 13 4 x 31 2 - 161 2P Tail Vise Front Block (1) 25 8 x 31 2 - 41 2Q Tail Vise Filler Strip (1) 3 8 x 25 8 - 12R Guide Rail Side (1) 3 4 x 2 - 18 3 4S Guide Rail End (1) 3 4 x 2 - 71 2

T Guide Strip (1)1

4 x1

2 - 161

2U Flange Block (1) 2 x 2 3 4 - 101 8V Leg Vise (1) 31 2 x 6 - 25 1 4

W Board Jack (1) 3 4 x 8 - 21 3 16X Board Jack Rails (2) 1 4 x 3 8 - 541 2 (1pc.) 12" x 12" Leather (1) 1 1 2" x 12" - 1 8" -Thick Aluminum Plate (6) 3 8" -dia. x 8" Carriage Bolts w/ Nuts & Washers (2) 1 1 8" -dia. Vise Screws

(1) 3 4" -10 x 36" Threaded Rod

(2) 3 8" -dia. x 36" Walnut Dowel (8) #8 x 2" Fh Woodscrews (14) #8 x 1 1 2" Fh Woodscrews (2) 3 8" -dia. x 4" Lag Screws w/ Washers (17) #6 x 3 4 Fh Woodscrews (8) #10 1 1 2 Fh Woodscrews (1) 1 1 8" -dia. x 36" Maple Dowel (4) 1 1 2" -dia. Knurled Knobs (4) 1 1 8" -Inside Diameter Rubber O-Rings (2) Square Bench Dogs (1) 3 4" -10 x 3" Knurled Knob (1) 3 4" Flat Washer

(1) 3

4" -10 Cap Nut (1) 3 4" -10 Square Nut (1) 1 2" -dia. x 3" Hardwood Dowel

Materials & Supplies

1#/4" x 7 !/4"- 96" Fir (9.7 Bd. Ft.)

1#/4" x 7 !/4"- 96" Fir (9.7 Bd. Ft.)

1#/4" x 9 !/4"- 96" Fir (12.3 Bd. Ft.)

1#/4" x 7 !/4"- 96" Fir (7 Boards @ 9.7 Bd. Ft. each)

1#/4"x 7 !/4"- 96" Fir (9.7 Bd. Ft.)

1#/4" x 7 !/4"- 96" Fir (9.7 Bd. Ft.)

1#/4" x 7 !/4"- 96" Fir (9.7 Bd. Ft.)

1#/4" x 7 !/4"- 60" Fir (6.1 Bd. Ft.)

HH

J H

I I V

RQ

X

K L

S U

A A

A

A

A

A

C B BP

P

N D

C D

M M

G

E V

O

W

1#/4" x 9 !/4"- 60" Fir (7.7 Bd. Ft.)

U F

Also Needed: !/2"x 16 !/2"- !/4" plywood strip for part T

Cutting Diagram

-

8/13/2019 Woodsmith Shaker Style Workbench

16/2215 WoodsmithPlans.com WS20028 2012 August Home Publishing Co. All Rights Reserved.

The Shaker-style workbench project will give you yearsof great service in the shop. This simple cabinet and shelfmake the bench even more useful.

The cabinet features five drawers: a deep drawer inthe center flanked by a pair of shallow drawers on eachside. Youll also note that the cabinet only fills a portionof the opening beneath the bench and is topped by a

shelf. This makes it easy to keep tools, hardware, andsupplies close at hand when working at the bench without cluttering up the benchtop.

Just like the workbench, I built the cabinet with rock-solid joinery. The plywood case features tongue anddado construction. And its tough to make a strongerdrawer joint than the locking rabbet.

The drawer fronts and face frame of the cabinet arefinished with an old-fashioned milk paint. This com-plements the heirloom quality of the workbench whileproviding an interesting contrast to its oil finish. It allcomes together for a first-class shop fixture.

Get even more from your heirloom workbench by adding a cabinet that features a bank of drawers topped with a large, open shelf.

workbench storageCabinet & Shelf

{ Drawer Cabinet . You cant beat handy storage. This setof drawers offers plenty of storage and versatility to keepyour tools where you need them, within easy reach.

Heirloom Project

-

8/13/2019 Woodsmith Shaker Style Workbench

17/22

-

8/13/2019 Woodsmith Shaker Style Workbench

18/2217 WoodsmithPlans.com WS20028 2012 August Home Publishing Co. All Rights Reserved.

#8 x 1 !/2" Fhwoodscrew

2@!/32

14 #/8

5 !/2

10#/4

20 &/8

11 !/4#/4

11

3

L

K

J

IH

G

F

SMALL DRAWER SIDE

F

G

SMALL DRAWER FRONT

SMALL DRAWERBOTTOM

LARGE DRAWER

FRONT

J

LARGE DRAWER

SIDE

LARGE DRAWERBOTTOM

LARGE DRAWER BACK

I

DRAWERRUNNER

NOTE: Drawer fronts, backs, and sidesare made from !/2"-thick hardwood.Drawer bottoms, stops, and runnersare made from !/4"plywood

M

DRAWERSTOPS

21 #/8 5 #/8

5 #/8

14&/8

Now that the case is complete, thedrawers are the next order of busi-ness. Since the drawer fronts getpainted, I used poplar for the front,

back, and sides. The drawer bottomis made of plywood.

BUILD THE DRAWERS. The drawers aresized to create a 1 16" gap all aroundwhen placed in the cabinet. Theyare joined with locking rabbets,and the bottom ts in a groove.After cutting the parts to size, see

the How-To box below to make thelocking rabbet joints.When the drawer joinery is

complete, cut the groove for the bottom on the inside face of eachworkpiece, as shown in detailb. The drawer sides also need

a centered groove to fit over thedrawer runners. I cut this groove

before I assembled the drawer.This way, the front of the drawerremains intact. You can use a chiselto complete the groove throughthe drawer backs after assembly(right drawing below).

Your final steps for the drawersare to cut the bottom to size andassemble the drawers.

DRAWER RUNNERS. The drawers are

used to position the runners in thecase, as shown in detail c. Start bycutting the runners to size and drill-ing a countersunk hole near eachend. Check the t of the runner ina drawer groove, and sand for asmooth, sliding t.

Next, insert the drawers in thecase. At the front and back, useshims to establish a 1 16" gap aaround the drawers. Then insertthe runners from the back (marginillustration at left). Measure and

mark the location of the runners,and install them with screws.BACK & STOPS. With the runners in

place, you can now glue and clampthe back to the case. The backseals the contents of the cabinet andholds the drawer stops.

add the DRAWERS & S HELF

!/4!/2

J

GTall aux.

fence

G J

Aux. miter gauge fence

!/4

Take light, paring cuts toremove waste

DRAWERBACK

F I

Aux. miter gauge fence

!/4

!/4

Groove. Install a tall auxiliaryrip fence to cut a groove in eachend of drawer fronts and backs.

Tongue. Use the miter gaugeto cut the inside tongue tolength to t into the side.

Side Groove. A chisel cuts aclean notch to continue the side

groove through the back.

Dado. Now cut a kerf dado ateach end of the side pieces tohold the tongues.

How-To: Make Locking Rabbet Drawer Joinery

!/16 " shim

Use shimsfor

spacing

SECTION VIEW

#/4

#/4

#/4

J

G#6 x #/4" Fh wood-

screw

c.

TOP VIEW

!/8

!/4H

G

F

a.

!/4" ply.

SECTION VIEW !/4

!/2

#/4b.

Add Runners. Withthe drawer on shims,slide the runner intoplace and mark itslocation. Then screwit in place.

shim!/16"

-

8/13/2019 Woodsmith Shaker Style Workbench

19/2218 WoodsmithPlans.com WS20028 2012 August Home Publishing Co. All Rights Reserved.

Speaking of the drawer stops,there are four of them attachedto the inside of the back, one eachfor the two sets of end drawers andtwo for the center drawer.

The two stops on either end havecountersunk holes drilled beforetheyre attached to the interior of

the case. These holes are for screwsused to attach the cabinet to the cen-ter stretcher on the workbench. Oncethe holes are drilled, apply glue toall the stops and hold them in placeon the inside case back for about aminute until the glue sets up.

FINISH UP. The back and the interiorare now complete, so you can turnyour attention to nishing the exte-rior of the cabinet. Youll add paintand hardware in these nal steps.

For a finish, I used milk paint onthe front of the drawers and cabinet.Then I installed the drawer pulls.

Before installing the cabinet, youneed to add four shelf cleats to theworkbench to support the ends ofthe shelf. As you can see in the illus-tration and detail b at right, theseare just strips of wood that are cut tosize and screwed to the lower rails ateach end of the bench.

Then you can attach the cabinetto the bench by driving screws

through the stops at the back of thecase to hold the cabinet to the cen-ter stretcher. Now slide the drawersinto the cabinet.

58 #/4

24 !/8

#/4

1

#/4

54 !/2

10 !/8

P

O

N

SHELF CLEAT

SHELF

SHELF EDGING

NOTE: Add cabinet and shelfbefore installing benchtop

NOTE: Shelf is #/4" plywood. Cleatsare hardwood. Edging is Douglas fir

NOTE: Cabinet removedfor clarity

A Case Top/Bottom (2) 3 4 ply. - 111 4 x 531 2B End Panels (2) 3 4 ply. - 111 2 x 7C Divider Panels (2) 3 4 ply. - 111 4 x 6D Edging (1) 1 4 x 3 4 - 140 rgh.E Back (1) 1 4 ply. - 7 x 54F Small Drawer Sides (8) 1 2 x 221 32 - 11

G Small Drawer Fronts/Backs (8)1 2 x 2

21 32 - 14

7 8H Small Drawer Bottoms (4) 1 4 ply. - 10 3 4 x 14 3 8

I Large Drawer Sides (2) 1 2 x 5 3 8 - 11J Large Drawer Front/Back (2) 1 2 x 5 3 8 - 21 3 8K Large Drawer Bottom (1) 1 4 ply. - 10 3 4 x 207 8

L Drawer Runners (10) 1 4 ply. - 3 4 x 111 4M Drawer Stops (4) 1 4 ply. - 3 x 51 2N Shelf Cleats (4) 3 4 x 1 - 10 1 8O Shelf (1) 3 4 ply. - 24 1 8 x 58 3 4P Shelf Edging (1) 1 4 x 3 4 - 541 2

(20) #6 x 3 4" Fh Woodscrews

(8) #8 x 11 2" Fh Woodscrews (5) Drawer Pulls w/Screws

!/2"x 5 !/2"- 96" Poplar (3.7 Sq. Ft.) #/4" x 3"- 72" Poplar (1.5 Bd. Ft.)

!/2"x 5 !/2"- 96" Poplar (3.7 Sq. Ft.)

DF F F F F F F F

J J I I

G G GG

GG

G G N ALSO NEEDED: One 48"x 96" Sheet of !/4" Birch Plywood,One 48"x 96" Sheet of #/4" Birch Plywood NOTE: Part P is cut from Douglas fir

Materials, Supplies, & Cutting Diagram

3 #/8

2 #/8

TOP VIEW

!/4 &/8P

O

Cleats alignwith top ofcenter stretcher

SECTION VIEW

O

N

#8 x 1 !/2"

Fh woodscrew

a. b.

SHELF. A shelf on top of the bank ofdrawers makes a great place to keeptools close at hand. You can cut theshelf to size and then notch out the

front corners with a jig saw to taround the legs (detail a).The shelf gets an edging strip

to conceal its front plywood edge.

Cut this strip to size and then glueand clamp it in place.

Now lower the shelf in placefrom above so that it rests on the

cleats. Secure the workbench top(page 7) and the board jack (page13) to complete your new, great-looking workbench.

-

8/13/2019 Woodsmith Shaker Style Workbench

20/2219 WoodsmithPlans.com WS20028 2012 August Home Publishing Co. All Rights Reserved.

Cutting Long Finger JointsCutting the nger joints in thetail vise end block for the Shak-er-style workbench is a simpletask with a dado blade installedon the table saw.

But when it came to cuttingthe nger joints in the matingside block, I couldnt use thesame technique. The nger jointson the side block are 3 1 2" long too long to cut with an 8"-dia.dado blade. So I had to come upwith another method.

I started by using the fingersalready cut on the end block to

lay out the notches on theside block (Figure 1). Then,in order to get a deeper cut,I swapped out my dado

blade for a standard rip blade and cut each notch bymaking a series of passes, asshown in Figure 2.

Even with a 10"-dia. blade though, I couldn tcut the notches to their fulldepth. So the remaining wasteneeds to be removed by hand.This is simply a matter of cut-ting along the sides of each notch

with a hand saw, as shown in thephoto above. (I used a Japanese-style rip saw.) Then the remain-ing waste can be removed witha chisel (Figure 3).

Making Draw Bolt PlatesThe end assemblies of the work-

bench base are tied together witha stretcher. Theyre connectedwith carriage bolts and nuts. Apair of shop-made plates are usedwith the carriage bolts. Theseserve two purposes they adda decorative element but also actas washers for the bolts.

To make the plates, I started bylaying out the profile on a pieceof 1 8"-thick aluminum bar stock.Using a hack saw to remove the

bulk of the waste, I roughed outthe rounded profile at each end.Then you can use files to refinethe profile and create the cham-fers on the edges, as in Figure 2.

To create the square holes forthe carriage bolts, start by drill-ing a 3 8"-dia. hole near each endof the plate. Then with a smalltriangular file, you can squareup the holes to hold the carriage

bolts (Figure 3). The last step isto paint the plates and carriage

bolts using a black spray paint.

Use fingers cut onend block to lay out fingers on side block

Tall aux.fence

Take multiple passes to remove

waste betweenfingers

Ripblade

Pare away remaining waste

with chisel

2 31

%/84 !/2

Hack saw

File profileedges smooth

Square uphole with file

2 31

NOTE: Enlarge pattern 200%

5 #/4

1!/2

#/8

#/8

#/32"chamfer

%/8

&/16

%/8"rad .

!/8

-

8/13/2019 Woodsmith Shaker Style Workbench

21/2220 WoodsmithPlans.com WS20028 2012 August Home Publishing Co. All Rights Reserved.

Making Round TenonsTo create the round tenon on the end of the

board jack peg for the Shaker-style workbench,I used a clever router table technique.

SETUP. As you can see in the drawing at right,the diameter of the tenon is determined by theheight of the router bit.

An auxiliary fence covers the opening in the

router table fence and acts as a stop to controlthe length of the tenon. And a support blockclamped to the top of the router table helps tocontrol the workpiece.

To establish the shoulder of the tenon, holdthe dowel used for the peg against the support

block and slowly push it into the bit until theend contacts the fence. Then rotate the dowelclockwise to cut the shoulder of the tenon.

The rest of the waste can be nibbled away bymoving the workpiece back and forth over the

bit until the tenon is complete.

Dowel is rotatedover !/2" straight bit

to create rabbet

Backer board keeps dowel

centered over bit

Aux.fence

Auxiliary fenceand backer board are secured withclamps

Auxiliaryfence

END VIEW

!/2" straight bit #/16

#/4

Routing Dog HolesArmed with a template, a mortising bit, anda router, creating consistent dog holes for theworkbench is a snap. The template straddlesthe workpiece and is held in place with ascrew. The bearing of the mortising bit ridesagainst an opening in the template to create aperfectly shaped dog hole.

As you can see in the drawing at left, the tem-plate consists of two guides attached to a pair ofcleats at a 5 angle. One of the guides is notched

to create the recess for the head of the bench dog.To use the template, simply position it on theworkpiece and secure it with a screw.

Note: The dog holes in the tail vise side blockface in the opposite direction of the dog holes inthe top of the bench. So to rout the tail vise dogholes, youll have to remove the guides fromthe cleats and ip them over. Then repositionthe cleats to straddle the wider side block.

9!/2

2 !/2

2 !/2

@%/32

1!/32

9!/2

Notched guide

Guide

Cleats

Cleat bottom

Cleat bottom

#8 x 1 !/4" Fhwoodscrew holdstemplate secureto dog rail

Dog rail

NOTE: Template is madefrom #/4" plywood.Cleat bottoms are

!/4" hardboard

!/4

!#/16

Notched guideGuide

Dograil edge

Cleat

Cleat TOPVIEW95

a.

Cleat bottom

Cleat Dog rail

Guide

Hold-down screw

END SECTION VIEWb.

a.

-

8/13/2019 Woodsmith Shaker Style Workbench

22/22

Woodsmith Store800-444-7527

Lee Valley800-871-8158leevalley.com

McMaster-Carr630-600-3600mcmaster.com

Rockler800-279-4441

rockler.com

MAILORDER

SOURCES

Project SourcesThe Shaker-style workbench requiressome hardware, including tail visescrews (70G01.52) and bench dogs(05G02.01), both of which can befound at Lee Valley .

Youll also need a 3" knurled

knob (6121K132), a 3 4"-10 acorn nut(91875A190), and 1 1 2" knurled knobs(6121K25). All of these were pur-chased from McMaster-Carr .

The workbench was nished withtwo coats of General Finishes Seal- A-Cell wiping varnish. Paste wax wasalso applied to the benchtop.

For the storage cabinet in the work-bench, youll need cast Victorian pulls(02W26.32) from Lee Valley , and bluemilk paint (39130) which is availableat Rockler .