Wirebonding Tutorial 2014 · 2017. 3. 1. · Hong Meng Ho1*, ,Yee Chen Tan1, Wee Chong Tan3, Heng...

Transcript of Wirebonding Tutorial 2014 · 2017. 3. 1. · Hong Meng Ho1*, ,Yee Chen Tan1, Wee Chong Tan3, Heng...

Wirebonding Tutorial

Jonathan Harris CMC Laboratories, Inc.

Basic Wirebonding Mechanism

Bond formation process • Material from bonding wire and

pad material in intimate contact • Apply energy: thermal,

mechanical (ultra-‐sonic) • A bond is formed between the

two materials

Types of Bonds that Form in Wirebonding

Type of Bond Example Systems Comments

Intermetallic compounds (IMC) between the wire and pad form bond

Au/Al, Al/Ni, Cu/Al, (AuAg)/Al

Distinct interfacial layer. Properties of that layer determine bond reliability.

Diffusion bond forms where wire material and pad material inter-‐diffuse.

Au/Ag, (AuAg)/Au No distinct interface. Bonding layer is diffuse extending into both the pad and the wire. This type of bond is characterized by very high reliability.

Atomic welding-‐ direct atom to atom bonding at microscopically clean interfaces

Au/Au No distinct interface but narrower distribution than diffusion bond. Characterized by very high reliability.

Diffusion Bonds

Basic Wirebonding Mechanism

What is the bonding layer? • If the wire and pad are the same (Au/

Au) or very similar (Au/Ag) material– a diffusion bond forms

• Diffuse region where atoms from the two materials are mixed. No distinct interface

Region where Au from the ball and Au from the pad are mixed together– called a diffusion bond

Wirebonding with Ag and Au

Properties of Ag

• Nobility (tendency to oxidize) Ag is in between Ni and Au

• Very ductile • Unlike Cu, Ag will not work harden • Forms a “continuous solid solution” with Au • Ag does form a sulfide (Ag2S)

– Sulfur from air pollution – Sulfide layer acts like an oxide– will inhibit wirebond formation

– Some organic additives or coatings inhibit sulfide formation and do not effect wirebonding

Au/Ag Solid Solution• Au and silver atoms are

similar in size • Au and Ag have the same

crystal structure (FCC)

Au/Ag Solid Solution• Au and silver atoms are

similar in size • Au and Ag have the same

crystal structure (FCC) • Continuously soluble in

each other • No intermetallic

compounds are formed

Au/Ag Solid Solution• Au and Ag atoms are similar in

size • Au and Ag have the same

crystal structure (FCC) • Continuously soluble in each

other • No intermetallic compounds are

formed • Au and Ag in contact– Au will

diffuse into the Ag layer and the Ag will diffuse into the Au layer

• Distinct interface between the two layers disappears

• Eventually one layer is formed with Au and Ag evenly distributed

Au Pad Silver Wire

Diffuse Bond extends into pad and wire Silver in pad Au in wire

Au Wire on Ag Pad

• Very common type of wirebond for power applications

• Au ball bond on Al (device) followed by secondary Au stitch bond on a Ag plated lead-‐frame

IMC Bonding Mechanism

Basic Wirebonding MechanismWhat is the bonding layer? • Bond occurs by forming a distinct

reacted layer between the wire and pad

• Atomic constituents to form this layer comes from both materials

• Reacted layer(s) can be one or more different compounds

• These layers are called Inter-‐metallic Compounds or IMCs

• The IMCs form the bond between the pad and wire

• Details of the IMC composition and morphology determine the bond reliabilityAl

Region where Au from the ball and Al from the pad have reacted to form a AuAl IMC compound(s)

Reacted Intermetallic Compound (IMC) Bonding Layer

Cu Wire Wire

Cu WireCuAl IMC bonding Layer formed by reaction and inter-diffusion

Al Bond Pad

Bonding Layer

F. W. Wulff, C. D. Breach, D. Stephan, Saraswati and K.J. Dittmer Materials & Applications Centre Kulicke & Soffa (S.E.A.) Pte. Ltd #04-05

TECHplace II Block 5002 Ang Mo Kio Ave 5 Singapore 569871

Key Characteristics for IMC in Wirebonding

• The IMC is the bonding phase so the presence of an IMC layer is required to form a bond for some material systems (Ni/Al, Au/Al, Cu/Al)

• Ideal characteristics for wirebonding IMC: – High coverage of the interface (60% minimum for a reliable bond)

– Thin • Key consideration: IMC thickness increases with subsequent temperature exposure – Device burn-‐in – Encapsulation material curing

Why is a Thin IMC Preferred

• IMC are mechanically brittle– so thicker IMC layers can fracture

• IMC materials have high electrical resistance– so a thick IMC can add electrical resistance to the wirebond

• As IMCs grow thicker– vacancies, impurities and other defects coalesce to form bulk defects such as voids or cracks which decrease bond reliability

Au and Cu wirebonding to Al Pads

Ball Bonding Process with Cu

• Ball formed in a plume of N2/H2. – N2 prevents oxidation of Cu during EFO by flushing away air – Small amount of H2 will reduce Cu2O à Cu metal: Cu2O + H2 à

H2O + 2Cu

• Impact of Cu2O formation on ball surface: – Cu2O will prevent bond formation= no sticks – Cu2O will diffuse into Cu making it harder = cratering of substrate

(discussed later) • Ball bonding parameters such as Bond Force, Ultrasonic energy

must be optimized for Cu in a DOE

Impact of Cu Ball Formation Atmosphere

Au and Cu Wirebonding to Al Pads

Al Pad

Cu Wire Au Wire Au wire on Al Pad

AuAu

Au

AuAl

AuAl

Cu wire on Al Pad

CuAlCuAl

Cu

Cu

Cu

Both systems can form 5 different IMC compounds with Al Metal

IMC Formation Reactions-‐ Heat of Formation of IMC

• –ΔH for a reaction means the reaction will occur (exothermic– heat is given off)

• Example: oxidation of a metal like Cu or Ti has –ΔH • Example of a wirebonding reaction: 4Au (wire) + 1Al (pad) à

Au4Al –ΔH = 18.5J/gram. AuAl IMC formation is very favorable. • 18.5 J of energy are given off for each gram of Au4Al that is created • Magnitude of –ΔH is a measure of how favorable a reaction will be

– Large –ΔH means very favorable – Small –ΔH means it will occur but not very aggressively – +ΔH means the reaction will not occur unless external heat or energy is

applied

Au and Cu Wirebonding to Al Pads

Al Pad

Cu Wire Au Wire Au wire on Al

Δ(J/g)

Au -‐18.5

Au -‐20

Au -‐19.8

AuAl -‐16.3

AuAl -‐10.2

Cu wire on Al

ΔH (J/g)

CuAl -‐6.13

CuAl -‐5.44

Cu -‐4.77

Cu -‐4.25

Cu -‐3.2

-‐ΔH is much larger for Au-‐Al IMC compared to Cu-‐Al IMC so AuAl formation is highly favorable compared to Cu-‐Al IMC formation.

Au and Cu Wirebonding to Al Pads As-‐Bonded IMC Thickness

Al Pad

Cu Wire Au Wire

As bonded IMC layer is much thinner for Cu/Al system compared to Au/Al

Growth of IMC Thickness at Elevated Temperatures

• Two key factors • Favorability of reaction (magnitude of –ΔH )-‐ chemical species that are reacting

• Diffusion kinetics of wire material and bond pad material through the IMC layer-‐ specific composition and morphology of the IMC layer

Comparison of IMC Growth on Al Pads: Au and Cu

• Aging time of 5 hours • IMC thickness vs. temperature • AuAl lMC layer is much thicker than

CuAl at same temperature • At 350C, CuAl is 8µm, AuAl is >45µm

Cu and Al diffusion through CuAl compounds are much slower than Au and Al diffusion through AuAl compounds.

IMC thickness vs. time for fixed temperature

Deley et al, Semicon Singapore 2005

Cross Section of Cu Wirebond after HTS—Very Thin IMC Layer

250C 200 hrs

250C 1000 hrs

Au/Al Wire Bond Microstructure

Au Wire

Au-Al IMC Phases

Al Pad

Karpel et al.Adi Karpel, Giyora Gur, Ziv Atzmon, and Wayne D. Kaplan Department of Materials Engineering, Technion – Israel Institute of Technology, Haifa 32000, Israel Kulicke & Soffa Bonding Tools, Yokneam Elite, 20692 Israel

Au/Al Microstructural Changes During HTS

2 hours at 175C Isolated Voids

Center Region of Wire Bond

Karpel et al.Adi Karpel, Giyora Gur, Ziv Atzmon, and Wayne D. Kaplan Department of Materials Engineering, Technion – Israel Institute of Technology, Haifa 32000, Israel Kulicke & Soffa Bonding Tools, Yokneam Elite, 20692 Israel

Au/Al Microstructural Changes During HTS

24.hours at 175C Line of voids has formed at the interface. Some voids are large.

Center Region of Wire Bond

Karpel et al.Adi Karpel, Giyora Gur, Ziv Atzmon, and Wayne D. Kaplan Department of Materials Engineering, Technion – Israel Institute of Technology, Haifa 32000, Israel Kulicke & Soffa Bonding Tools, Yokneam Elite, 20692 Israel

Au/Al Microstructural Changes During HTS

24.hours at 175. Voids have coalesced to form cracks which become initiation sites for wirebond failure

Edge Region of Wire Bond

Adi Karpel, Giyora Gur, Ziv Atzmon, and Wayne D. Kaplan Department of Materials Engineering, Technion – Israel Institute of Technology, Haifa 32000, Israel Kulicke & Soffa Bonding Tools, Yokneam Elite, 20692 Israel

Au/Al Microstructural Changes During HTS

HTS à AuAl IMC growth à void formation à Void coalesce à crack formation à potential for wirebond failure

Adi Karpel, Giyora Gur, Ziv Atzmon, and Wayne D. Kaplan Department of Materials Engineering, Technion – Israel Institute of Technology, Haifa 32000, Israel Kulicke & Soffa Bonding Tools, Yokneam Elite, 20692 Israel

Au on Al Wirebond Reliability77% IMC coverage. Voids only at edges of wire bond. Shear strength of 6.5 grams/mil2 . Wire pull of 10 grams with neck failure.

63% IMC coverage. Small voids at center and larger voids at edges of wire bond. Shear strength of 5.5 grams/mil2. Wire pull of 10 grams and neck failure.

34% IMC coverage. Voids throughout the interface region. Shear strength <4.5 grams/mil2. Wire pull of 4 grams with lift-off failure mode.

Jamin Ling, Ziv Atzmon, Dominik Stephan, Murali Sarangapani Kulicke & Soffa, Semicon Singapore 2008

Au on Al Wirebond Reliability

Osborne, M., J.Ling, et al., IMAPS Dev Pkg Conf, March 2005

Au on Al Wirebond Reliability77% IMC coverage. Voids only at edges of wire bond. Shear strength of 6.5 grams/mil2 . Wire pull of 10 grams with neck failure.

63% IMC coverage. Small voids at center and larger voids at edges of wire bond. Shear strength of 5.5 grams/mil2. Wire pull of 10 grams and neck failure.

34% IMC coverage. Voids throughout the interface region. Shear strength <4.5 grams/mil2. Wire pull of 4 grams with lift-off failure mode.

Because AuAl IMC grows thick with time/temperature, it is critical to have high IMC coverage as-bonded to maximize bond reliability

Jamin Ling, Ziv Atzmon, Dominik Stephan, Murali Sarangapani Kulicke & Soffa, Semicon Singapore 2008

Summary of IMC Growth for Cu on Al

• Initial IMC is extremely thin • Growth rate of CuAl IMC during high temperature storage is much slower than AuAl

• Thin IMC should provide a more robust and reliable wirebond

Summary of IMC Growth for Au on Al

• AuAl IMC grows more rapidly than CuAl IMC • Thick AuAl IMC results in a tendency to form large voids and cracks at the Au wire/ pad interface

• High coverage initial bond is critical to maximize IMC reliability

Another Key Consideration– Mechanical Properties of Au and Cu Wirebonds on Al

Concept of Work Hardening

• When metals are exposed to repeated mechanical stress, they become harder

• This is why you can break a ductile copper wire by flexing it back and forth many times– the flex point becomes hard and brittle and the “ductile” wire will crack

• Deformation and ultrasonic energy during wirebonding will significantly work harden the wire

• Cu is harder than Au • Cu will work harden more than Au

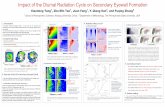

Work Hardening in a Ball Bond-‐ FEA• FEA simulation of wirebond process

showing expected high stress areas (susceptible to work hardening)

• More metal stress on edges of ball where more deformation of the metal occurs during bonding

Hong Meng Ho1*, ,Yee Chen Tan1, Wee Chong Tan3, Heng Mui Goh2, Boon Hoe Toh1, Jonathan Tan1, and Zhao Wei Zhong3 1Kulicke & Soffa Pte. Ltd, 2Kulicke & Soffa (S.E.A.) Pte. Ltd, 3Nanyang Technological University * 6, Serangoon North Ave 5, #03-16, Singapore 554910

Micro-‐hardness Analysis of Au and Cu Wire after Bonding

• Micro-‐hardness for Au and Cu ball bonds vs. position

• Much higher hardness for Cu vs. Au

• Work hardening for both Cu and Au on edges of ball as predicted by the FEA stress model

• Degree of work hardening is much larger for Cu compared to Au

• At the edge of the Cu ball, hardness of 130 Hv– compared to 75-‐80 Hv for Au

Hong Meng Ho1*, ,Yee Chen Tan1, Wee Chong Tan3, Heng Mui Goh2, Boon Hoe Toh1, Jonathan Tan1, and Zhao Wei Zhong3 1Kulicke & Soffa Pte. Ltd, 2Kulicke & Soffa (S.E.A.) Pte. Ltd, 3Nanyang Technological University * 6, Serangoon North Ave 5, #03-16, Singapore 554910

Cu Hardness Implications

• More stress is transmitted to the underlying substrate during bonding for harder wire – More stress for Cu vs. Au – More stress for heavily work hardened Cu compared to less work hardened Cu

• Can result in fracture of the underlying substrate during bonding (cratering)

• Can result in micro-‐cracking of the substrate during bonding which subsequently fractures during post bond stress (such as temperature exposure)

Crater in a Si Substrate from Cu Ball Bond

Cu Wirebonding Summary

• Cu wire on Al pads form an ideal IMC structure – Very thin – Very slow growth during temperature exposure – This is due to the fundamental chemistry of the Cu/Al reaction (small –ΔH, slow diffusion of Cu and Al through the IMC)

– Cu/Al wirebonds rarely fail due to defective IMC structure which is typical of Au/Al bonds

Cu Wirebonding Summary

• Cu wire is much harder than Au and will work harden during bond formation – Work hardening is a basic property of Cu – Will be worse with dissolved Cu2O – Balls are harder on edges where they are deformed under the capillary

– Implication of harder Cu is more cratering during initial bonding

– Cratering can also occur after HTS from growth of micro-‐cracks in the substrate formed during bonding

– Cratering is most common failure mode for Cu wirebonded to Al

Au on Al Wirebonding Summary

• Au and Al IMC grows faster and thicker than an ideal IMC structure

• Potential for void growth and subsequent wirebond failure

• Potential for failure increases with decreasing initial IMC coverage

• Reliability testing indicates initial coverage should be >66% for reliable bonding

• Au work hardening is minor reducing probability of cratering

Wirebond Pad Material Considerations

Pad Deposition and Metallurgy

Deposition Technology Metallurgy Comments

Thin Film Al, Au Sputtering or evaporation at wafer fab

Plated Au, Ni, Ag, Electrolytic or electroless

Thick Film Au, Ag Al2

Pad Contamination and Impact on Wirebond Reliability

Type of Contamination Impact Source

Metal oxide (CuO, NiO) Poor bonding strength Diffusion from underlying plated layers

Organic contamination Poor bonding strength Plating bath contamination (spent additives, dissolved photo-‐resist)

Halogen contamination Degradation of bond strength over time

Cleaning chemicals, resins or epoxies

Ni Impurity on Au Pad

• Au/Au wirebond reliability • Ni diffuses to Au surface and then Ni à NiO

• Small concentration of NiO dramatically increases bond lifting

Harman, Wirebonding in Microelectronics

Impurity Concentration during Wirebonding

Initial bond

Impurities in pad

Impurity Concentration during Wirebonding

Initial bond

Impurities in pad

HTS

IMC growsà pad impurities get concentrated in IMC layerà amplifies the impact of small impurity concentration

Plasma Treatment• Impurities on the wirebond pad can decrease wire pull strength and

wire pull consistency – Residual organic from die attach – Organic contamination from plating – Ni oxide contamination on Au from plating

• Plasma can be used to remove these contaminants – Oxygen plasma for organics – Argon plasma for non-‐organics (Ni-‐oxide) – Note that oxygen plasma can only be used for non-‐oxidizing metal pads such as

Au – For Al or Ni pads, Ar plasma must be used – For very thin Au (over Pd), non-‐sputtering oxygen plasma must be used to avoid

removing the Au layer

Plasma Cleaning Impact

Mean PullCpK

Bonding Wire Considerations

Mechanical Deformation of Wire Bond Wire

• Alteration of mechanical properties from U/S exposure • Deformation from capillary or wedge • Plastic deformation to form loop • Resistance to viscous force from molding compound during

packaging (transfer molded device) • Mechanical fatigue from temperature and power cycling

during device operation

Key Considerations

• Stress state of wire • Resistance to metal fatigue • Corrosion resistance • Elongation • Breaking load • Electrical conductivity • High Frequency characteristics • Size of heat affected zones (HAZ) after bonding

Elongation and Breaking Load Trade-‐Offs

Smooth Loop formation No wire breaks during bonding

No wire deformation or sagging after formation.

Wire deformation and sagging after formation

Wire breaks during bonding

Low elongation, high breaking load

High elongation, low breaking load

Gold Wire Alloying Effects

Additives to 99.99% pure Au wire. Be and Ca increase the break strength and increase the re-crystallization temperature which decreases the HAZ after bonding. Data from Williams Advanced Materials (Bond wire supplier)