Why i don't use cycle time in Kanban

-

Upload

andy-carmichael -

Category

Technology

-

view

931 -

download

0

Transcript of Why i don't use cycle time in Kanban

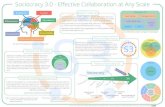

Why I don't use Cycle Time in KanbanAndy Carmichael@andycarmich

Some people* say Cycle Time (CT1) is...

the time between delivery of items...

0.5 days in this case * Ohno, Womack & Jones (1996), Chew (2000), Liker (2004), Lean Lexicon (2008) and others

Some people* say Cycle Time (CT2) is...

the time an item stays in the process...

5 days in this case

* Hopp and Spearman (2000), Reinertsen (2009) and others

Others use: Time in process (TIP), Flow Time, Wait Time

I call this Lead Time* (or TIP)

* George (2002), Anderson (2010) and others

I call this the reciprocal of Delivery Rate* (or Throughput)

i.e. 2 items per day in this case

Others use: Throughput, Arrival Rate, Rate of Completion

* George (2002), Anderson (2010), Little (2011) and others

Little's Law

Delivery RateLead Time =

WIP

Note: The bar denotes "average"

ThroughputTIP =

WIP

or

A nasty special case: when WIP = 1Little’s Law expressed using the 2 definitions of Cycle Time is:

So when WIP=1…

This special case compounds the confusion since so often the concepts are explained with a simple example where WIP = 1

CT2 = WIP * CT1

CT2 = CT1 !!!

Stop starting...Start finishing