Wellman Field Case History - CO2 & ROZ … 11 - 13, 2013 Wellman Field Case History 2 Midland, Texas...

-

Upload

doankhuong -

Category

Documents

-

view

214 -

download

0

Transcript of Wellman Field Case History - CO2 & ROZ … 11 - 13, 2013 Wellman Field Case History 2 Midland, Texas...

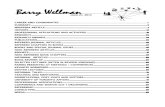

December 11 - 13, 2013

Wellman Field Case History

2

Midland, Texas

Presented at the 19th Annual CO2 Flooding Conference

Bruce Howard – VP Engineering

Trinity EOR, LLC

Wellman Field Case History

Locator Map and Geologic Overview

Reservoir Properties Summary

Primary Flood Summary

Secondary Flood Summary

Tertiary Flood

Overview of Process

Brief History

Forecasting Production

Well work Overview

Future Plans

Summary / Conclusions

2

Presentation Outline

Wellman Unit Locator Map

3

22

[TRINITY TO INSERT MAP SHOWING

HIGH LEVEL LOCATION OF WELLMAN] Wellman

Unit

Wellman Field is part of the Horseshoe Atoll Complex

Pinnacle Reef structure of 2100 Acres

Wolfcamp / Cisco formation at a depth

of approximately 9200’ - 10,000’

Limestone with a 8.5% average

porosity and an OOIP of 127 MMSTB

Extensive exposure and erosion

Vugular porosity is a large part of the

storage and delivery system

Evidence of widespread fracturing

Fracture porosity is a small part of the

storage but a large part of the delivery

system

Some sections of intercrystalline

porosity

Intercrystalline porosity is a small part

of the storage and delivery system

Two main pinnacles with vertical relief

of over 800’

Limited active Permian /Pennsylvanian

water drive

4

26

N S

E

W

Wellman Field Geological Summary

Wellman Field Reservoir Properties Summary

Original Oil in Place = 127 MMSTB

Original O/W Contact = -6680’ ss

Maximum Oil Column Thickness = 824’

Average Porosity = 8.5%

Initial Water Saturation = 20%

Residual Oil Saturation to Water = 35%

Average Core Permeability = 135 md

Initial Reservoir Pressure = 4105 psi, Oil Bubblepoint = 1250 psi

Initial Reservoir Temperature = 151o F

Initial Oil Gravity = 43.5 API, Water Specific Gravity = 1.13

Initial Oil Formation Volume Factor = 1.3, Initial Solution Gas Oil Ratio = 405 Scf/STB

Initial Oil Viscosity = 0.43 cp, MMP (100% CO2) = 1600 +/- 50 psi

Vertical Core Flood Oil Saturation to CO2 < 10%

5

1

10

100

1,000

10,000

1950 1955 1960 1965 1970 1975 1980

DA

ILY

RA

TE

S

Oil BOPD

Produced TotGas MCFPD

Produced Water BWPD

HCGOR

Oil Recovery

Avg Resv Pressure

Wellman Field Primary Production History

Primary production started

in 1950 unitized in 1978

Reservoir pressure initially

dropped from 4105 to 3000

psi until the 3000 B/D Oil

allowable was established

The allowable lowered to

1500 B/D and pressure

slowly increased to 3100

psi

The allowable was

increased to 7500 B/D in

1966 reservoir pressure

dropped below the 1250

psi bubblepoint by 1976

Field producing GOR

remained fairly low

High vertical permeability

likely caused a secondary

gas cap to form

Recovery during this

period was 33% of OOIP

6

6000 BOPD Initial Peak Rate

3000 then 1500 BOPD Allowable

Allowable Lifted

Wellman Field Secondary Production Summary

Started makeup water

injection 6/1979 with 4

wells below OWC

Pressure increased

from 1050 to 1600 psi

by 1983 (end of

Waterflood Only

Period)

Field remained at top

allowable of 9300

BOPD for most of this

period

Bottom water flood

moved the Oil Water

contact from -6680’ to

-6300’ss

Incremental recovery

during this period was

11% of OOIP (44%

P+S)

Calculated volumetric

sweep efficiency of

93%

7

10

100

1,000

1,000

10,000

100,000

1979 1980 1981 1982 1983

HC

GO

R,

Reco

very

% O

OIP

DA

ILY

RA

TE

S,

B/D

MC

F/D

Oil BOPD

Produced TotGas MCFPD

Produced Water BWPD

Water Inj BWIPD

Avg Resrv Press

HCGOR

Oil Recovery

Wellman Unit Vertical CO2 Flood Overview

8

Overview Vertical CO2 Flood

Vertical CO2 flood where CO2 is injected

into the top of the structure and

mobilizes waterflood residual oil from the

rock as the CO2 contact moves down

through the formation creating an oil-

column between the CO2 (above) and

water (below)

Producing wells are completed near the

oil-column and then recompleted deeper

over time, as the CO2-oil contact is

moved deeper

Oil production is expected to continue to

grow as the oil column is thickened and

additional temporarily abandoned wells

are returned to production

Wellman’s performance and geology has

been well-documented by the EOR

industry and is considered one of the

best performing CO2 floods on record

― SPE papers 11129, 22898 and 48948

23

100

1,000

10,000

100,000

100

1,000

10,000

100,000

1983 1984 1985 1986 1987 1988 1989 1990 1991 1992 1993 1994 1995 1996 1997 1998 1999 2000 2001 2002 2003 2004 2005 2006 2007 2008 2009 2010 2011 2012 2013 2014

Oil R

ate

, H

C G

OR

, R

eco

very

% O

OIP

Daily W

ate

r an

d C

O2 R

ate

s

Produced TotGas MCFPD CO2 Purchase MCFPD

Produced Water BWPD Water Inj BWIPD

CO2 Inj MCFPD CO2 Sales MCFPD

Oil Recovery Oil BOPD

Avg Reserv Press

Wellman CO2 Production History

9

Peak oil from historical,

bottom up waterflood

End CO2

purchases

Sell CO2

Resume CO2 Purchase

Union Texas Mobil Wiser Petrosource /Trinity

Start CO2

purchase

10

100

1,000

10,000

100

1,000

10,000

100,000

2004 2005 2006 2007 2008 2009 2010 2011 2012 2013 2014

Oil R

ate

, H

C G

OR

, R

eco

very

% O

OIP

Daily W

ate

r an

d C

O2 R

ate

s

Produced TotGas MCFPD CO2 Purchase MCFPD

Produced Water BWPD Water Inj BWIPD

CO2 Inj MCFPD CO2 Sales MCFPD

Oil BOPD Oil Recovery

Wellman Recent CO2 Production History

10

Wellman Calculated Contact History

11

26

Nearing maximum column thickness

Current OWC -6510’ Initial CO2

Injection

CO2 Blow

down

CO2 Purchases

Brief Wellman CO2 Teritiary Flood History

Started in 1983 by Union Texas with 3 Crestal Injectors

CO2 Purchase rates ranged 4 - 15 MMcf/D, averaging 8.2 MMcf/D

Recycled CO2 rates varied from 3 - 27 MMcf/D, averaging 18 MMcf/D

Oil production dropped during this period from 8500 to 2000 BOPD, averaging 4440 BOPD

Active water injection in the reef drove the O/W up from -6300’ to -6150’ ss

Sporadic and ineffective completions limited ability to produce the oil column

Oil column during this period shrank from 400’ to 20’

Operated by Mobil from 9/1991 to 10/1993

CO2 purchase rates ranged 15 - 18 MMcf/D, averaging 16 MMcf/D

Recycled CO2 rates varied from 23 -27 MMcf/D, averaging 25 MMcf/D

Oil production dropped during this period from 2000 to 1200 BOPD, averaging 1480 BOPD

Water Re-injection continued and the O/W moved down from -6150’ to -6250’ ss

Little to no well work was done to recomplete producers into the oil column

Oil column during this period grew slightly from 20’ to 25’

12

Brief Wellman CO2 Tertiary Flood History

Operated by Wiser Oil Co from 10/1993 until 3/2005

CO2 Purchase rates ranged 5 - 15 MMCFPD until 10/2001 when purchase was stopped, 6.8 MMcf/D average

CO2 Production rates ranged 2 - 21 MMCFPD during CO2 blown down from 5/2003 to 3/2005, 3.4 MMcf/D average

Oil production dropped during this period varied from 50 to 2200 BOPD, averaging 1100 BOPD

The O/W contact moved from -6300’ to -6380’ ss until CO2 blowdown, where it ended at -6314’

Wiser was active working over many wells during this period

Oil column during this period shrank from 25’ to 0’

Operated by Petrosource / Sandridge / Trinity from 3/2005 until Present

CO2 blowdown was immediately stopped and CO2 purchases resumed

Oil production increased during this period from 17 to 2300 BOPD, averaging 1100 BOPD

The O/W contact lowered from -6380’ to -6510’ ss with higher CO2 purchase volumes and disposal of all produced water

Over 16 producers have been returned to production

Over 50 Plugdowns have been successfully executed since 2006

Oil Column during this period has grown from 0’ to 45’

o This thicker oil column has allowed for much higher per well rates

o The “average” oil column producer at Wellman now makes over 200 BOPD

13

Wellman Performance Model

14

26

Tank Model – Primary Inputs

Producing well count

CO2 purchases

Water withdrawal

Waterflood Residual Oil Sat, Sorw = Srw = 0.35

CO2 Flood Residual Oil Sat, Sorc = 0.105

Reservoir Pressure current 2200 psi

Pore volume vs Depth

Tank Model – Primary Calculations

CO2 contact depth

Water contact depth

Oil column thickness

Oil column correlations used

o BOE/d per well

o Total GOR

o BW/d per well

Oil, water and gas production forecast, SPE 22898

o Vo = (Sorw – Sorc) iCO2 BCO2 / (Bo ΔS)

o ΔS = (1- Srw – Sorc)

Correlations used as model inputs have proven very reliable

0

10

20

30

40

50

60

70

80

90

100

110

120

130

140

150

160

170

180

190

200

0 10 20 30 40 50 60

Oil P

rod

ucti

on

Ra

te (B

OP

D/w

ell)

Estimated Oil Column Thickness (feet)

Oil Column Thickness vs Oil Rate Per Well

Forecast 1983-1990 1991-1997 2006-Present

Wellman Modeled Forecast vs Actuals

15

Highly accurate tank model relative to historic results

10

100

1,000

10,000

2000 2002 2004 2006 2008 2010 2012 2014 2016 2018 2020

Wellman Unit - Planned 2015 Plant Start

Produced Oil BOPD Oil Forecast

Actual performance has confirmed

the tank model accurately

forecasts future production rates

Historical CO2 and Oil - Water Contacts

16

Plug downs are repeated until the oil column reaches the base of the transition zone -6720’ss

Log indicated CO2 contact

Plugdown Date Response Date

CO2 / Oil Contact

Oil / Water Contact

Wellman Wellwork Summary

17

30

Based on the Previous Tank Model estimates

and current logged CO2 contacts, producers

are plugged down every 18 -24 mos

Old perforations are isolated in the plug down

procedure using packers and an isolation string

Successfully returned 16 producers, 3 deep

disposal and 1 CO2 injector to active service

No new drills needed to date

20 of 21 successful returns to production

Ongoing work

9 – 10 plug downs expected annually until the

contacts reach the original OWC

Contact currently moves about 2 ft/month

Wellman Unit Operations Overview

18

In service – April 2011

Design Capacity – 4,000 BOPD | 40,000 BWPD | 50 MMcf/d

Wellman Central Tank Battery

22

Wellman Unit Future Plans

Compression expansion complete by March 2014

Return all required Wells to Production / Injection by December 2015

NGL Recovery Plant complete by January 2015

19

Wellman Unit Future Plans, Compression Expansion

20

Recycle Compression

22

Current Capacity of 45 MMcf/d

Expanding to 50 MMcf/d by March 2014

Wellman Future Plans, Return to Production

21

Successfully returned 16 producers,

3 deep disposal and 1 CO2 injector

to active service

No new drills needed to date

20 of 21 successful returns to

production

19 of 28 total wells planned for

reactivation completed to date

9 additional wells are scheduled for

return to production to complete

project development (4) in 2013, (3)

in 2014, (2) in 2015

22

14

39

21

13

22

12

08

66-

0866-

08

66-

-66

80

- 6680

-6

68

0

08

66-

OW

C

SWD

SWD

SWD

SWD

SWD

G

G

G

SWD

SWD

G

202

Edwards 1Edwards 1A

507

406 503405 505

602512407

510

404502

302W

403601

410 504

513411

408

508401301

402501

506303

CO Scales 1409511

809

201

801

804

Scales 1701 703705

810 706204

704A

704203

805802702

807A808101 803

807

806

Lyons 1

509

405-ST

203-ST

408-ST

409-ST

510-ST

805-ST

807-ST

Burnett 1

801-ST Proposed

FEET

0 1,000

AFE prepared

SWD Deep

SWD Shallow

monitor well

Return to Production Candidate

Water Withdrawal well

CO2 injector

oil well

PETRA 7/19/2013 3:56:01 PM

Most Wellman well work substantially completed

Wellman Unit Future Plans NGL Plant

22

19

Finalizing the evaluation of construction

and design options for the installation of

a 50 MMcf/d inlet capacity NGL plant to

process rich Wellman NGL stream

currently being re-injected

Add on to our existing recycle compression

scheme, taking the gas stream from the

2nd stage discharge and returning to the 3rd

stage suction

Designed to maximize the recovery of the

C4+ and provide C5+ for crude blending

for sale into the crude line.

A truck rack with NGL bullets will be

constructed

NGL sales line is also being evaluated

3rd party owned and operated with fee

taken as a percentage of the production

Expected max NGL rate of over 1000 B/D

1st Stage 2nd Stage 3rd Stage

NGL Recovery

Plant

CO2 Rich Gas

to Re-injection

(~1700 psi)

Inlet Gas

from Battery

(~160 psi)

NGL

Sales

Stabilized NGL

to Crude Sales

Plant Bypass Valve

Wellman Unit Summary / Conclusions

The Wolfcamp Reservoir in Wellman has performed in almost a tank like manner under

Water and CO2 flooding

A world class reservoir that will recover almost 80% of OOIP

Almost all capital investment has been made reach over 3000 BOPD and 1000 Bbl NGL /

Day in 2015

The field will have almost new facilities

Almost all required producing wells have been returned to production

Trinity has a good track record of plugging down to stay in the oil column

23

Wellman Unit Acknowledgments

Thanks to the Following Trinity Team Members for making this possible

Trinity Management Team for Permission to share the story

Greg West and John Milam – Architects of the current flood strategy

Jerry Metcalf and his Field Team – Amazing track record in a difficult environment

Dean Soderstrom – Senior Project Engineer, Bob Altany – Senior Geologist

Bill Harryman – Senior Engineering Technician

24