Relative susceptibility To weathering. Products of Weathering.

Weathering of hardened concrete causes and suggested...

Transcript of Weathering of hardened concrete causes and suggested...

Weathering of hardened concrete causes and suggestedremediesDharam Paul

Cement concrete behaves like an artificial calcareous rock and is vulnerable to weathering,resulting in a shortened life span of the structure. Damage to concrete due to weathering has beenstudied in simulated laboratory conditions on over 540 concrete specimens. The experimentalresults confirmed that the concrete suffer damages and consequently loses its compressivestrength to the extent of 30 percent to 40 percent. A richer concrete with lower water-cementratio and replacement of 20 percent cement, by weight with flyash is shown to enhance theresistance to weathering. Based on the data obtained, it is recommended that flyash be addedto concrete hydraulic structures like canal linings, spillways and dams.

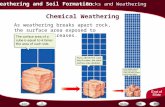

Currently cement concrete mixes are designed fordesired strengths, and structures built from them aredesigned to last for a particular period only. However,looking in retrospect over the last hundred years, use ofconcrete has shown that this building material is veryvulnerable to the natural phenemenon of weatheringand aging. Based on present day concepts of concretemix design technology, it is assumed that the concrete isnot significantly affected by weathering, and hence, verylittle, if any, corrective factors are included in the mixdesign to compensate the weathering affects on concrete.However, this assumption is wholly wrong as concretestructures are slowly and progressively affected byvarious natural weathering agencies such as cyclicthermal changes, alternate wetting and drying andintrastatial volume changes due to chemical processesof hydration, oxidation, carbonation, hydrolysis, etc.These weathering agents act independently and in unison,supplementing each other, and slowly, but progressivelycause fatigue, exhaustion, decay, deterioration, andweakening of the cementing bonds with consequent lossof durability and danger to the stability of the structure.It is, therefore of paramount importance to study andassess the weathering affects and to suggest someeconomical and efficient remedial measures to combatit. This paper discusses the results of such a study undersimulated laboratory conditions.

ObjectiveThe objective of the study was to qualitatively, as well asquantitatively assess the ill effect of various weatheringagents on the durability and strength of concretes undersimulated laboratory conditions. The scope also includedsuggesting remedial measures to combat and mitigate theloss of strength due of weathering.

Literature reviewLiterature research has revealed that very little work hasbeen done on the behaviour and performance of cementconcrete under weathering conditions, and practicallyno concerted efforts have been made in the past to evolveany remedial measures. The fact that the problem hasproduced so little results, further highlighted the necessityand importance of the current work.

MethodologyThe methodology was so planned as to subject thevarious samples to simulated laboratory conditions.The various ingredients of the concrete mix, namelygravel, sand, and cement, were taken in predeterminedand varying proportions, having water-cement ratios

Dr Dharma Paul, Assistant Research Officer, Irrigation and Power ResearchInstitute, Amritsar, Punjab

of 0.35, 0.45, 0.60, and 0.75. Cube samples of size178 x 178 x 178mm and beams of size 400 x 75 x 75mmwere cast.

Another set of cubes and beam samples as detailedabove were prepared replacing 20 percent of the currentby weight with flyash from Delhi thermal plant keepingthe mix proportions and water-cement ratios constantfor both the plain and pozzolanic cement concretesamples.

For all cube and beam samples, uniform consistencywas maintained at 50mm to 65mm slump and 92.0percent to 94.0 percent compacting factor.

All cubes and beams prepared from plain as well aspozzolanic concrete, after being numbered were curedunder controlled conditions in water for 7 days and28 days ; some specimens were cured in steam for 7 days.After curing, the specimen were stored in a fog-roomfor further testing.

The concrete samples, after curing, were subjected tocyclic wetting and drying treatment. Each cycle consistedof wetting the sample in water for 16 hours andsubsequent drying in an automatic, thermostaticallycontrolled oven at 100°C for 8 hours. Reference samplesof six cube and six beams were been separately preservedfor comparison. After treatment for 100 cycles and 300cycles, the respective batch specimens were tested forcompressive strength, taking the compressive strengthof unweathered reference specimens as a base. Therelative percent loss in compressive strength due toinduced accelerated cyclic wetting and drying action hasbeen calculated for plain as well as pozzolanic cementconcrete specimens, and the results recorded in Table 1.

Discussion of resultsSince the significance of the present study revolvesround the performance and behaviour of concrete,it will be worthwhile to understand the nature ofconcrete.

In nature, several oxides are present in rock, the mostcommon being Na 20, K20, CaO, MgO, Si02, Fe203 andA1 303. Out of these oxides, some are leached awaycomparatively more easily than others. There is pre-ferential leaching of oxides during the weathering(cyclic wetting and drying) of natural rock. Manygeologists, including Goldish (1938), Steidmann (1908),and Leith and Mead (1915) have indicated removal ofoxides in rocks and it is generally agreed that CaO isleached away with utmost ease from natural rockduring weathering1,23.

Cement contains about 62.50 percent of Ca0 and assuch, concrete behaves like an artificial calcareous rock.

APRIL 1983 97

Type of concrete Type of curing Wetting anddryingcycles

Percentage loss of strength

M400 M300

M200 M100

:17 0.75 35.3 42.9

:18 0.60 27.6 37.4

: 9 0.45 23.6 29.9

: 8 0.35 19.3 23.4

M100

4 : 10

M200

4: 8

M300

4: 5

M400

4 : 3.2

TABLE 1 Results of loss of strength of plain and pozzolanic concrete due to simulated weathering

corn- flexural corn- flexural corn- flexural corn- flexuralpressive strength pressive strength pressive strength pressive strengthstrength strength strength strength

7 days in water at 27°C 100 28.6 28.7 34.9 33.3 30.8 29.7 40.0 43.7300 33.3 34.2 39.4 36.0 38.5 50.0 50.0 50.0

Plain concrete 28 days in water at 27°C 100 16.0 21.4 20.0 23.5 22.2 21.5 23.8 42.9300 19.3 23.4 23.6 29.9 27.6 37.4 35.3 42.9

7 days in steam underatmospheric pressure 100 15.7 19.1 15.2 25.0 20.0 18.7 22.9 35.9

300 16.7 19.3 19.0 28.5 22.7 35.0 27.8 35.9

7 days in water at 27°C 100 24.1 24.9 23.4 29.5 30.0 30.8 45.8 44.5300 26.7 26.9 22.9 33.3 39.4 50.0 53.3 52.7

20 percent replace-ment by flyash 28 days in water at 27°C 100 10.7 16.6 14.2 20.1 21.6 23.0 27.8 40.0

300 13.3 14.9 13.3 23.8 22.2 33.3 37.5 41.77 days in steam underatmospheric pressure 100 11.4 11.0 12.0 20.8 17.2 18.8 19.1 30.8

300 11.8 14.4 10.0 22.2 19.0 33.2 26.4 30.8

During the process of hydration of portland cement,significant amount of CaO is available as free lime,which, under cyclic wetting and drying is leached outin the form of Ca(OH) 2. This slow, but progressive leach-ing consequently results in the development of secondaryporosity and subsequently causes the weakening of theconcrete structures. This weathering process on concretestructures results from the action of rain and sun, butin the case of concrete hydraulic structures like canals,dams, etc a similar effect is produced by the fluctuatingflow of water.

Differently designed and cured specimens weresubjected to 100 and 300 cycles of alternate wetting anddrying in laboratory under simulated and controlledconditions. The extent of weathering suffered by thesespecimens has been assessed in terms of the loss ofcompressive as well as flexural strengths of thesespecimens and the results recorded in Table 1. A perusalof the results reveals that plain concrete specimenssuffer loss in compressive strength and flexural strengthdue to cyclic wetting and drying action.

In it is interesting to note that the effect of inducedweathering under different simulated conditions onlaboratory specimens is influenced by the followingfactors

richness of the mixperiod of curingwater-cement ratiopresence of pozzolana

(v) duration of simulated weathering action

It is worthwhile to determine and discuss the effectof the above factors individually, one by one, so as toarrive at a clear understanding of the problem and todevise remedial measures.

The loss in the compressive and flexural strengthsof richer M-400 concrete was of the order of 19.3percent and 23.4 percent respectively, while it was 35.5percent and 42.9 percent respectively in the case of thelean M-100 specimens, when subjected to 300 cyclesof weathering effect. Experimental results positively indi-cate that richer concrete specimens are more resistant toweathering effect than lean concrete. The phenomenonmay be explained by the fact that rich concrete mixesare more impermeable and thus are capable of moreeffectively resisting any interstatial ingress of water.

A perusal of the results in Table 2 shows the effect ofweathering on the concrete specimens prepared withdifferent water-cement ratios. Loss in compressive aswell as flexural strengths of concrete mixes with the lowwater-cement ratio, 0.35 is of the order of 19.3 percentand 23.4 percent, respectively as compared to 35.3percent and 42.9 percent, respectively for specimenshaving a water-cement ratio of 0.75. It is interestingto note that with the change in water-cement ratio from0.35 to 0.75 the loss in strength is almost doubled.This outlines the obvious that concrete with a low watercement ratio is better able to withstand weatheringeffects.

Table 3 shows the effect of weathering on concretespecimens subjected to differential curing. It showsthat specimen cured in water for 7 days suffered more

TABLE 2 Effect of simulated laboratory weathering on the concrete mixes

Serial no Cement concrete grade

Ratio

Water- Percent losscement

cement : sand : gravel

ratio compressive

flexuralstrength

strength

Note: Results rounded off to arrive at convenient ratio of the different mixes

98 INDIAN CONCRETE JOURNAL

Serial Grade of cement concrete and presence of flyashno.

Percentage loss of strength

compressive strength flexural strength

damage due to induced weathering and lost their com-pressive and flexural strengths to the tune of 39.4percent and 36.0 percent, respectively as compared tosimilar specimens M-300, cured in water for 28 dayswhen the loss under identical conditions was 23.6percent and 29.6 percent, respectively. However, thespecimens cured in steam for 7 days and subjected tosimilar weathering conditions exhibited the best per-formance and their respective loss of strength was19.6 percent and 28.5 percent, respectively. Theseresults confirm that prolonged curing is the best safe-guard against natural weathering. This is explained bythe fact that prolonged curing produces completehydration improving the hardness and impermeability.

Table 4 shows that plain concrete specimens sufferedmore damage from simulated weathering compared tothose specimens in which 20 percent cement by weighthas been replaced by pozzolana flyash and keeping all theother conditions constant. A typical case for comparisonis the designed M-300 concrete specimen, with andwithout flyash pozzolana, cured in water for 28 days andsubjected to 300 weathering cycles. Loss of compressiveand flexural strengths without flyash was of the orderof 23.6 percent and 29.6 percent respectively, whereasin the specimen in which flyash pozzolana has replaced20 percent cement, it was 13.3 percent and 23.8 percent

TABLE 3 Statement showing effect of weathering(300 cycles) on the duration of curing

Serial Duration of Percent loss in strengthno. curing

compressive flexuralstrength strength

7 days in water 39.4 36.028 days in water 23.6 29.9

3. 7 days in steam 19.0 28.5

Note: All samples in M-300 concrete.

consecutively losing their strengths of upto 50 percent.This loss in strength can be effectively minimized byusing richer concrete with a low water-cement ratio andprolonged curing.

Replacing 20 percent of cement by weight with flyashhelps in combating the effects of weathering resulting inprolonging the effective life of the structure.

AcknowledgementThe author would like to thank Mr Gurcharan Singh,Research Officer, Concrete Technology Division for hishelp and guidance while the processing and analysingthe experimental data reported in this paper.

TABLE 4 Effect of weathering on the concrete with 20 percent replacement off cement by flyash

100

300

100

300

cycles cycles cycles cycles

M-300 cement concrete with 28 days curingwithout flyash 20.0 23.6 23.46 29.6with flyash 14.2 13.30 20.14 23.8

respectively. The improved durability obtained throughflyash addition can be explained by the fact that the flyasheffectively fixes and inhibits the release of Ca'o` from theconcrete mass, thus preventing the development ofsecondary porosity.

Conclusions and recommendations

It can be safely concluded that concrete hydraulicstructures suffer damages due to cyclic wetting and drying

References

GOLD1CH, S. S. A study in rock Weathering. Journal of Geology,1938, Vol 46, pp. 17-58.LEITH C. K. and MEAD, W. J. Metamorphic Geology. NewYork, 1915, pp. 16-17.STEIDMANN, EDWARD. A graphic comparison of alteration ofrocks by Weathering with their alteration by hot solution.Economic Geology, 1908. Vol 3, pp. 381-409.

-Annual Review 1978-79. Irrigation and Power ResearchInstitute, Amritsar.

(Continued from page 96)

ConclusionWhile designing for function and economy, thecomponents of an industrial structure shall be providedto be not only technically sound but also practicable forexecution with the available resources. Latest designand construction practices may be adopted after studyingthe acceptable alternatives available, to meet the func-tional demands economically, instead of merely follow-ing the conventional methods in vogue.

AcknowledgementThe author would like to express his grateful thanks toMr V. V. Satyanarayana, Additional Chief Engineer(Civil), Mining and Allied Machinery CorporationLimited, for his cooperation and guidance. The author is

thankful to Mr R. G. Mahendru, currently CMD, BharatCoking Coal Limited, and Mr S. P. Mathur currentlyRD, for their sustained advice and help during theexecution of the project.

Thanks are due to the Chairman-cum-ManagingDirector, Central Mine Planning and Design InstituteLimited, for permitting this paper to be published.

References

RAO, RAMAMOHAN, Y. Construction features of shaft collarand head frams in a coal mining project. Journal of Institute ofEngineers (India), M.N. March 1979. Vol 59, pp.

RAO, Y. R. Winding-head gear; design and analysisCMPDIL Journal, January 1977. Vol 1.

3. RAO, Y. R. Design and analysis of Winder foundation.CMPDIL Journal, November 1977. Vol 2.

APRIL 1983 99