We build safety into every valve, then we help you keep it there â„¢

Transcript of We build safety into every valve, then we help you keep it there â„¢

Company Profile

Dresser Consolidated, a business unit of Dresser, Inc. is

headquartered in Hous-ton, Texas (USA). We are a worldwide leader and a full service provider of dependable pressure relief solutions for all phases of the petroleum, power and process industries.

With over 100 years of innovation and techni-cal leadership, Dresser Consolidated can solve the most challenging application scenarios. We

deliver to our cus-tomers cutting

edge technol-ogy, consistent quality, and superior expertise—

from the initial

design phase through long-term maintenance and support services.

Consolidated valves are designed and manufac-tured to the most demanding U.S. and global standards such as ASME, API, Pressure Equipment Directive (PED) and ISO 9000. Our commitment to efficient and safe operations worldwide is further evidenced by our contri-butions to international organizations advanc-ing pressure relief valve (PRV) technology. Dress-er Consolidated is one of only three test centers in the world that is certified for steam, air and water certification testing by the National Board of Boiler and Pressure Vessel Inspectors.

We build safety into every valve, then we

help you keep it there ™

expertise n applications n products n support n successes

n OurMission To design, engineer,

manufacture, market and service the critical equipment that forms the backbone of pres-sure relief manage-ment across industries throughout the world.

n Establishedin1879

n NumerousTechnicalFirsts

n GlobalQualityStandards

n WorldwideLocations

Max

iflow

®–t

heg

loba

llea

deri

nth

epo

wer

mar

ket.

Customer ProfileDresser Consolidated custom-ers include end users, OEMs and engineering companies, large and small, throughout the world from many different industries:

n Electric Power Generationn Chemicaln Petrochemicaln Oil & Gas Productionn Oil & Gas Transmissionn LNGn Refiningn Pulp & Paper

Product PortfolioThe Consolidated® family of spring loaded, pilot operated and power actuated valves are continuously and reliably per-forming in plants around the world. Our product portfolio consists of:

n Maxiflow® 1700, 2700, 1811, 1511, 1541/1543 and 2478 Safety Valves

n Electromatic® 3500 Power Actuated Relief Valves

n 1900, 1900/P, 19000 and 1982 Safety Relief Valves

n 2900, 3900, 4900 and 13900 Pilot Operated Safety Relief Valves

n Nuclear Service ASME Section III and VIII Valves

Investing in Technology and Global ManufacturingDresser Consolidated has integrated Lean Manufactur-ing techniques with Six Sigma methodologies to maximize the performance of all its plants. A global engineering database ensures uniform product stan-dards worldwide. Comprehen-sive water, steam, and air test facilities with full ASME Section I and VIII approval are available at most plants.Alexandria, Louisiana (USA)

n 247,000 sq. ft. diverse manufacturing

n Established in 1961n Over 50 CNC Machines

Skelmersdale, Lancashire (U.K.)n 170,000 sq. ft. diverse

manufacturingn Established in 1966n Products manufactured

to meet European and Middle Eastern market requirements

Suzhou (P.R. China)n 80,000 sq. ft. diverse

manufacturingn Recently established,

custom built facility

Over a century of design, production and application engineering has made Consolidated® safety and safety relief valves the

recognized standard for overpressure protection

Someofourindustry-leadingPRVsfromanextensiveproductportfolio.

State-of-the-artCNCmachinetools—OKUMAMC-800H.

Suzhou(P.R.China)plant—ourlatestmanufacturingfacility.

World-class Valve Selection and ServiceOur valve experts will put their extensive pressure relief valve experience to work for you, selecting the best valves for your operational requirements and budget. We offer:

n Experienced project management to ensure your complete satisfac-tion, from bid request through shipment and startup

n SRVS™— advanced pres-sure relief valve sizing and selection software with custom designed interface for INtools®* with optional electronic data transfer capabilities

n Safety-optimized systems engineered with our extensive knowledge of codes, applications, and service conditions

After Market Support ServicesWhen installation, mainte-nance and repairs are done right the first time, even the best valve in the world gets better. To achieve complete customer satisfaction, we have established a global network of Green Tag® service and repair centers that are avail-able and on-call to ensure your equipment stays online effi-ciently and safely. Valve Survey

n Comprehensive and accu-rate record of all pres-sure relief valve service

n Identification of problem valves and valve inter-changeability

Inspection of the Valve & Installation

n Visual evaluation of the installation for compli-ance to codes and regulations

n Written evaluation cover-ing compliance issues, discrepancies and corrective actions

Testing n On-site and in-place

testing using the Dresser Consolidated® EVT® testing device

n High-capacity shop testing with steam, air or water

Repair n Audited facility with

Dresser Consolidated® inspection criteria and critical dimensions

n Fully trained and certi-fied pressure relief valve technicians

n Original manufacturer replacement parts

Inventory Controln Global access to spare

parts inventories n Recommended cost-

effective inventories ValvKeep®

n Comprehensive computer-based valve management service

n Historical data storage and permanent record tracking

n Maintenance scheduling and planning

n Repair intervals validated by maintenance history of each valve

Globalaccesstoinventory.

Best Under Pressure™

DRESSERDIRECT

What makes Consolidated® successful is not how long we’ve been in business, but how much we offer

our customers—day in and day out

ElectronicValveTester(EVT®)foronlineandin-servicetestingtopreventcostlyshutdowns

Success StoriesSafety valve upgrades provide savings and simplicity“A major utility company had to delay startup because parts were not on site …Further study revealed a large number of different safety valve designs from four different suppliers.”“There is a 40% decrease in safety valve spare parts inventory and the quality of repair has noticeably improved.”

Improving turbine operating efficiency“A power plant was experiencing frequent failure rates with pressure relief valves installed to protect turbine gland seals from overpressure.”“Since the implementation, Consolidated’s 2900 POSRV has performed flawlessly allowing the plant to operate efficiently.”

Economizer relief valve damage eliminated“Damage to safety valves due to chatter is a common problem for economizers and …”“The successful operation of the 2900-40 POSRV eliminated downtime with an annual savings of $6.5 million.”

Safety valve failures eliminated at major Asian olefins company“A major Asian olefins company, using a competitor’s safety valve on their boiler, was experiencing severe chatter and seat leakage.”“Twenty-four safety valves on twelve boilers were replaced with the 1700 Type Maxiflow® safety valve. The valves have been leak tight and trouble-free, delivering annual cost savings and improved financial performance to the olefins company.”

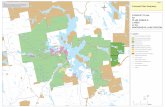

We’re right at your doorstep

Call 1-800-245-VALV(8258) to find a local Dresser Certified Green Tag® Service Center

Dresser, Inc. Headquarters: Main Manufacturing: 16240 Port Northwest Drive LA Hwy. 3225 @ US Hwy. 167N Houston, TX 77041 P.O. Box 1430 Telephone: + (1) 832 590 2634 Alexandria, LA 71309 Fax: + (1) 713 953 0959 Telephone: + (1) 318 640 2250 Fax: + (1) 318 640 6222 www.dresser.com

����

� ������������ ��

������

������ ����

�

��

�

��

�

��

��

�

��

�Green Tag Centers �

Manufacturing Plants

�

�

�

�

�

�

�

�

�

�

Sales Offices

�

SM

Copyright 2005 Dresser, Inc. All Rights Reserved. PRV-11/2005 All trademarks and registered trademarks used in this document are owned by Dresser, Inc.

* INtools is a registered trademark of Intergraph Corp.

�