Water Spec Amended 06

-

Upload

girish-nair -

Category

Documents

-

view

217 -

download

0

Transcript of Water Spec Amended 06

-

8/2/2019 Water Spec Amended 06

1/82

i

TABLE OF CONTENTS

ABBREVIATIONS...............................................................................................................................................................1

SECTION WA PREAMBLE...................................................................................................................... ........................5

WA1 PREAMBLE ........................................................................................................................................................5

DEVELOPMENT APPROVAL PROCESS ........................................................................................................................6

SECTION WB GENERAL.................................................................................................................................................9

WB1 DEFINITION.......................................................................................................................................................9WB2 REFERENCE STANDARDS......... ......................................................................................................................9

SECTION WC DESIGN REQUIREMENTS...................................................................................................................13

WC1 GENERAL.........................................................................................................................................................13WC2 PIPE SIZE..........................................................................................................................................................13WC3 STATIC HEAD..................................................................................................................................................13WC4 PLANS...............................................................................................................................................................13WC5 EASEMENTS............................ ........................................................................................................................14

WC6 PIPES AND FITTINGS......................................................................................................................................14WC7 PIPELINES ON OTHER PROPERTIES.............................................................................................................15WC8 CROSSINGS......................................................................................................................................................15WC9 MAINS IN CUL-DE-SACS................................................................................................................................15WC10 SERVICE CONNECTIONS...............................................................................................................................15WC11 LOCATION OF WATER MAINS....................................................................................................................187WC12 FIRE HYDRANTS.............................................................................................................................................18WC13 RESILIENT SEATED VALVES........................................................................................................................18WC14 TRENCH STOPS AND CONCRETE BULKHEADS .........................................................................................20WC15 THRUST AND ANCHOR BLOCKS..................................................................................................................20WC16 COVER OVER PIPELINES................................................................................................ ...............................20WC17 PROXIMITY TO OTHER SERVICES...............................................................................................................20

WC18 DUCTILE IRON PIPE .......................................................................................................................................20WC19 TELECOMMUNICATION CONDUITS............................................................................................................21WC20 CONCRETE ENCASEMENT............................................................................................................................21WC21 PRESSURE REDUCING VALVE AND PRESSURE RELIEF VALVES...........................................................21WC22 WATER METER PIT ........................................................................................................................................21WC23 FLANGED FITTINGS AND PIPEWORK..........................................................................................................22WC24 NUTS, BOLTS AND WASHERS.......................................................................................................................22WC25 CROSS CONNECTION CONTROL AND BACKFLOW PREVENTION DEVICES.........................................22WC26 MAINS PRESSURE INQUIRY..........................................................................................................................22WC27 ESSENTIAL FIRE HYDRANTS........................................................................................................................22WC28 AIR VALVES....................................................................................................................................................22WC29 WATER SUPPLY PUMP STATIONS................................................................................................................22

SECTION WD GENERAL CONSTRUCTION REQUIREMENTS ..............................................................................25

WD1 BEFORE COMMENCING WORK ....................................................................................................................25WD2 PUBLIC LIABILITY INSURANCE ...................................................................................................................25WD3 LOCATION OF WORKS AND ADDITIONAL WORKS................................................. ..................................25WD4 DEVELOPERS SUPERVISORY STAFF ..........................................................................................................25WD5 COVER OVER PIPELINES............................................................................................ ...................................26WD6 NOISE CONTROL.............................................................................................................................................26WD7 PRESERVATION OF FLORA...........................................................................................................................26WD8 TRAFFIC MANAGEMENT...............................................................................................................................26WD9 CONSTRAINTS ON SERVICE .........................................................................................................................26WD10 OCCUPATIONAL HEALTH AND SAFETY.....................................................................................................26WD11 ROAD CROSSINGS (FOR COUNCIL OWNED ROADS)............................................ .....................................26

WD12 TEMPORARY ROAD CLOSURES (FOR COUNCIL OWNED ROADS) ..........................................................27WD13 EROSION AND SEDIMENT CONTROL..........................................................................................................27

-

8/2/2019 Water Spec Amended 06

2/82

Lismore City Council

Specification for the Design & Construction of Water Reticulation Pipework

July 1999ii

WD13.1 General .................................................................................................................................................... 27

WD13.2 Erosion and Sediment Control.................................................................................................................. 27

WD13.3 Erosion and Sediment Control Plan.......................................................................................................... 28

WD14 DUST CONTROL ............................................................................................................................................. 28WD15 EXISTING SERVICES ..................................................................................................................................... 28

WD15.1 Developer to Inform Themself................................................................................................................... 28

WD15.2 Cost of Relocation or Replacement of Existing Services ........................................................................... 28

WD16 EARTHWORKS................................................................................................................................................ 29WD16.1 General .................................................................................................................................................... 29

WD16.2 Excavation for Pipeline............................................................................................................................ 29

WD16.3 Dewatering............................................................................................................................................... 31

WD16.4 Support of Excavations............ ................................................................................................................. 31

WD16.5 Safe Working In A Confined Space ........................................................................................................... 31

WD16.6 Backfill, Compaction and Additional Compaction .................................................................................... 31

WD16.7 Restoration of Surfaces............................................................................................................................. 32

WD16.8 Tunnelling ................................................................................................................................................ 33

WD17 PIPE BEDDING................................................................................................................................................ 33WD17.1 General .................................................................................................................................................... 33

WD17.2 All Pipes................................................................................................................................................... 33

WD18 LAYING AND JOINTING OF PIPES ............................................................................................................... 34WD18.1 General .................................................................................................................................................... 34

WD18.2 Jointing .................................................................................................................................................... 34

WD18.3 Cutting of Pipes........................................................................................................................................ 34

WD18.4 Tolerances for Pipeline............................................................................................................................. 35

WD18.5 Fire Hydrants ........................................................................................................................................... 35

WD18.6 Valve and Hydrant Chambers....................................................................................... ............................ 35

WD18.7 Street Markings ........................................................................................................................................ 35

WD18.8 Trench Stop .............................................................................................................................................. 36

WD18.9 Concrete Bulkheads.................................................................................................................................. 36

WD18.10 Thrust and Anchor Blocks......................................................................................................................... 37

WD18.11 Protection of Pipelines and Fittings.......................................................................................................... 37

WD18.12 Corrosion Protection (if required for repair of damaged coatings on valves and fittings) ........................ 37WD18.13 Connection to Existing Charged Water Mains .......................................................................................... 38

WD19 WATER SERVICE CONNECTIONS, DOWNSIZING AND DISCONNECTION AND MINOR WORKS ....... 39WD19.1 Water Service Connections ....................................................................................................................... 39

WD19.2 Domestic Services Requiring a Road Crossing (refer standard drawing WD19.2).. ...... ...... ...... ...... ...... .... 39

WD19.3 Domestic Services NOT Requiring a Road Crossing ................................................................................. 39

WD19.4 Downsizing Water Services....................................................................................................................... 39

WD19.5 Water Services Greater Than 65 mm......................................................................................................... 39

WD19.6 Disconnection of Water Services............................................................................................................... 39

WD19.7 Water Meters and Quarter Turns.............................................................................................................. 40

WD19.8 Water Meter Relocation............................................................................................................................ 40

WD19.9 Water Meters............................................................................................................................................ 40

WD19.10 Minor Works............................................................................................................................................. 40

WD19.11 Notice Required........................................................................................................................................ 40WD20 TESTING..................................................................................................................... ..................................... 40

WD20.1 General .................................................................................................................................................... 40

WD20.2 Pressure Testing of Pipelines.................................................................................................................... 41

WD20.3 Hydrostatic Pressure Test......................................................................................................................... 41

WD20.4 Testing of Pipelines .................................................................................................................................. 41

WD20.5 Acceptance............................................................................................................................................... 43

WD20.6 Equipment and Procedure for Testing....................................................................................................... 43

WD20.7 Defects ..................................................................................................................................................... 43

WD21 FLUSHING AND STERILISATION ................................................................................................................. 43WD21.1 Flushing ................................................................................................................................................... 43

WD21.2 Water Quality Testing............................................................................................................................... 43

WD21.3 Sterilisation.............................................................................................................................................. 44WD21.4 Flushing of Sterilisation Water ................................................................................................................. 44

-

8/2/2019 Water Spec Amended 06

3/82

iii

WD22 WORK-AS-EXECUTED DRAWINGS ..............................................................................................................44WD22.1 General.....................................................................................................................................................44

WD22.2 Developer to Supply Work-as-Executed Drawings.....................................................................................45

WD23 RELEASE OF LINEN PLAN....................................................................................................... ......................45WD24 DEFECTS LIABILITY PERIOD........................................................................................................................45

APPENDICES.....................................................................................................................................................................46

APPENDIX A WATER RETICULATION CHECKING SHEET ................................................................................48

APPENDIX B WATER CONNECTION CARD............................................................................................................49

APPENDIX C NOTICE TO COMMENCE WORK......................................................................................................50

APPENDIX D MAINS PRESSURE INQUIRY APPLICATION...................................................................................51

APPENDIX E WATER SYSTEM ASSETS ...................................................................................................................51

APPENDIX F SEWER DISCONNECTION/WATER SERVICE DISCONNECTION/DOWNSIZING CARD...... ...53

APPENDIX G PERMIT TO CARRY OUT MINOR WORKS ON COUNCILS WATER AND SEWERAGE

SYSTEMS................................................................................................................................................54

APPENDIX H CONSENT TO ENTRY..........................................................................................................................56

DRAWINGS .......................................................................................................................................................................58

LIST OF DRAWINGS .....................................................................................................................................................60

-

8/2/2019 Water Spec Amended 06

4/82

Lismore City Council

Specification for the Design & Construction of Water Reticulation Pipework

July 1999iv

LIST OF TABLES

TABLE 1: FLATS AND HOME UNITS SIZE OF WATER SERVICES.......................................................................... 16

TABLE 2: MINIMUM COVER OVER PIPELINES........................................................................................................... 20

TABLE 3 MINIMUM CLEAR WIDTH OF TRENCH....................................................................................................... 30

TABLE 4: PIPE BEDDING GRADING.............................................................................................................................. 33

TABLE 5: UPVC TEST PRESSURES................... ............................................................................................................. 41

TABLE 6 WATER QUALITY LIMITS............................................................................................................................. 44

Document Details

File: F:\USERS\TINAI\My Documents\Procedures & Standards\WATERSP DJ draft4.DOCF:\USERS\BRIANB\My Documents\Brian\Waterspec

Last Save 2 Date: 23-May-06Last Print Date: 23-May-06

This document has been prepared using Microsoft Office 97 and Autocad V14 & printed on recycled paper

-

8/2/2019 Water Spec Amended 06

5/82

Lismore City Council

Specification for the Design & Construction of Water Reticulation Pipework

July 19991

ABBREVIATIONS

AS - Australian Standards

BSP - British Standard Pipe

CALM - Department of Conservation and Land Management (now part of DLWC)

DI - Ductile Iron

DICL - Ductile Iron Cement Lined

DLWC - Department of Land and Water Conservation, NSW

DPWS - Department of Public Works and Services, NSW

EPA - Environment Protection Authority, NSW

FRC - Fibre Reinforced Concrete

m - Metre

mm - Millimetre

OTR - Other than rock

PE - Polyethylene

PRV - Pressure Reducing Valve

RTA - Roads and Traffic Authority, NSW

uPVC - Unplasticised polyvinyl chloride

-

8/2/2019 Water Spec Amended 06

6/82

Lismore City Council

Specification for the Design & Construction of Water Reticulation Pipework

July 19992

-

8/2/2019 Water Spec Amended 06

7/82

Lismore City Council

Specification for the Design & Construction of Water Reticulation Pipework

July 19993

SECTION WA

PREAMBLE

-

8/2/2019 Water Spec Amended 06

8/82

Lismore City Council

Specification for the Design & Construction of Water Reticulation Pipework

July 19994

-

8/2/2019 Water Spec Amended 06

9/82

Lismore City Council

Specification for the Design & Construction of Water Reticulation Pipework

July 19995

SECTION WA PREAMBLE

WA1 PREAMBLE

a. This Specification sets out Lismore City Councils requirements for the design andconstruction of water reticulation pipework.

b. For ease of use, this Specification has been divided into a Design Section and a ConstructionSection.

c. Alternative design and/or construction techniques may be considered provided sufficientdocumentation is supplied by the Developer to indicate that this complies with the relevantAustralian Standards and has been approved for use by Sydney Water or Melbourne Water.

d. This Specification applies to the design and construction of:-i) Water supply main of uPVC or ductile iron cement lined pipe;ii) Standard appurtenances such as fire hydrants and stop valves;iii) Water services and crossings;iv) Downsizing/Disconnection of water services; andv) Construction of pressure reducing and pressure relief valves.

-

8/2/2019 Water Spec Amended 06

10/82

Lismore City Council

Specification for the Design & Construction of Water Reticulation Pipework

July 19996

Council will review draft design if requested

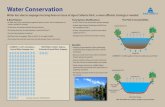

DEVELOPMENT APPROVAL PROCESS

Release Deposit (oncompletion of any required

works on defects)

Final Inspection

Apply for releaseOf deposit

submit

Development Application

with Preliminary Plans

submit

"Engineering Design Plans"

Review preliminary plans to ensure that thedevelopment can be incorporated into the waterreticulation system.

Review if

necessary

Issuestamped

plan/Construction

certificate

Approval for Releaseof Linen

Plan

Seek advice from Council regarding existing water

main locations and ca acity.

Review detailed design plans and long sections

Apply for

"Notice to Commence Work"

ConstructionIns ection

Ins ection

Ins ectionTesting

submit

Work as Executed Drawings,

Asset Sheet &

Security Deposit

DAApproval

Defects Liability Period 52 weeks

Review if

necessary

Commissioning

Developer Activities Council Activities

-

8/2/2019 Water Spec Amended 06

11/82

Lismore City Council

Specification for the Design & Construction of Water Reticulation Pipework

July 19997

SECTION WB

GENERAL

-

8/2/2019 Water Spec Amended 06

12/82

Lismore City Council

Specification for the Design & Construction of Water Reticulation Pipework

July 19998

-

8/2/2019 Water Spec Amended 06

13/82

Lismore City Council

Specification for the Design & Construction of Water Reticulation Pipework

July 19999

SECTION WB GENERAL

WB1 DEFINITION

a. Hereinafter, the Developer shall mean the Property Developer named in the respectiveDevelopment Application; his agent; employee; Consultant; Sub-Contractor or any other

person who is engaged on the provision of water supply to the development.b. Council shall mean the Lismore City Council.c. A plumber is a Licensee as defined in the NSW Code of Practice Plumbing and Drainage.d. The Water and Wastewater Manager shall mean Councils Manager - Water and Wastewater

or his nominated representative. Similarly, the Works Manager and the Parks and ReservesManager shall mean Councils Manager Works, and Councils Manager Parks andGardens or his nominated representative respectively.

e. The Water and Wastewater Inspector shall be as nominated by the Water and WastewaterManager.

f. Works means the whole of the work to be undertaken in accordance with thisSpecification.

g. Where Council is engaged as a contractor for the provision of water supply to thedevelopment, this Specification shall prevail and the meeting of any requirements of theDevelopment Application shall remain the responsibility of the applicant.

WB2 REFERENCE STANDARDS

AS 1111 - ISO Metric hexagon commercial bolts and screws

AS 1112 - ISO Metric hexagon nuts, including thin nuts, slotted nuts and castlenuts

AS 1449 - Wrought alloy steels - stainless and heat-resisting steel plate sheet andstrip

AS 1463 - Polyethylene pipe extrusion compounds

AS 1477 - Unplasticised PVC (uPVC) pipes and fittings for pressure

applications.

AS 1646 - Elastomeric seals for waterworks purposes

AS 1742 - Manual of Uniform Traffic Control Devices

AS 1831 - Iron casting -Spheroidal or nodular graphite cast iron.

AS 2032 - Installation of uPVC pipe systems.

AS 2280 - Ductile iron pressure pipe and fittings.

AS 2436 - Guide to noise control on construction, maintenance and demolitionsites

-

8/2/2019 Water Spec Amended 06

14/82

Lismore City Council

Specification for the Design & Construction of Water Reticulation Pipework

July 199910

AS 2544 - Grey iron pressure fittings.

AS 2638 - Sluice Valves for waterworks purposes.

AS 2837 - Wrought alloy steels - stainless steel bars and semi-finished

products

AS 2865 - Safe Working in a confined space

AS 3680 - Polyethylene sleeving for ductile iron pipelines.

AS 3855 - Suitability of plumbing and water distribution systems productsfor contact with potable water.

AS 3879 (Int) - Solvent cements and priming fluids for use with unplasticised

PVC (uPVC) pipes and fittings.

AS 3952 - Water Supply DN80 Spring hydrant valve for generalpurposes.

AS 4130 - Polyethylene (PE) pipes for pressure applications.

AS 4131 - Polyethylene (PE) compounds for pressure pipes and fittings.

AS 4158 - Thermal-bonded polymeric coatings on valves and fittings for

water industry purposes.

AS 4087 - Metallic flanges for water works purposes.

AS/NZS - Quality systems: Model for quality assurance in ISO 9002production, installation and servicing.

AS 3500 - The National Plumbing and Drainage Code and the NSW Codeof Practice Plumbing and Draining.

These standards listed are not exhaustive and other standards may be called upon as

required.

Wherever a Standard Specification or Code is specified herein, it shall mean the latestedition and/or amendment of that Specification or Code at the issue of the stampedapproval plans.

-

8/2/2019 Water Spec Amended 06

15/82

Lismore City Council

Specification for the Design & Construction of Water Reticulation Pipework

July 199911

SECTION WC

DESIGN REQUIREMENTS

-

8/2/2019 Water Spec Amended 06

16/82

Lismore City Council

Specification for the Design & Construction of Water Reticulation Pipework

July 199912

-

8/2/2019 Water Spec Amended 06

17/82

Lismore City Council

Specification for the Design & Construction of Water Reticulation Pipework

July 199913

SECTION WC DESIGN REQUIREMENTS

WC1 GENERAL

a. When designing water reticulation to be constructed in accordance with this Specification,the following points are to be complied with -

i) The design is to be in accordance with this Specification unless required otherwise bylegislation;

ii) all water supply systems shall be designed, installed and maintained so as to preventcontaminants from being introduced to Councils potable water supply system; and

iii) Design works not covered in this Specification are to meet the relevant AustralianStandards, Sydney Water or Melbourne Water requirements and manufacturers

recommendations.

WC2 PIPE SIZE

a.

Water supply reticulation is to be sized to cater for proposed future requirements within thedevelopment.

b. For any non-residential development or for any development comprising the equivalent ofmore than ten (10) single dwelling lots, Council may require the Developer to provide

evidence that the proposed pipework will result in an adequate water supply pressure in thedevelopment at all times.

c. If Council requires a larger size main for some other purpose, Council will require theinstallation of the larger size main and Council will negotiate on an individual basis, theadditional cost to be paid. Council will inform the Developer if a larger size main is required

when Engineering Design Plans are submitted.

WC3 STATIC HEAD

a. Static head to each lot should be between 30m and 60m with a minimum static head of 20munder peak instantaneous demand at the property boundary.

b. The desirable maximum design head is to be 70m. If the design head is greater than 70m,Councils Water and Wastewater Manager shall be consulted as to the best way of reducing

the pressure. This could be achieved by the use of a pressure reducing valve and pressurerelief valve incorporated into the reticulation or by individual pressure reducing valves at theproperty boundary.

WC4 PLANS

a. Preliminary design plans are to be submitted with the development application for initialassessment.

b. Final design plans should be drawn at a scale of 1:500 or 1:1,000 and show the followingdetails:-

- Lot boundaries and lot numbers.- Road centreline chainages.

- Location and size of water mains and services.- Location and distances of hydrants, stop valves, scour valves, air valves, pressurereducing valves and other fittings.

-

8/2/2019 Water Spec Amended 06

18/82

Lismore City Council

Specification for the Design & Construction of Water Reticulation Pipework

July 199914

- Location on plan and long section of all drainage lines, sewer lines undergroundelectricity and other utility service lines crossing the water main.

- Location of all drainage lines, sewer lines, underground electricity and other utilityservice lines within 500 mm of the main.

- Road crossing locations.- Offset distance of each line from the nearest boundary.- All heights and inverts to AHD.- Erosion Sediment Control Plan.

c. Final design plans are to be submitted with a checking sheet as given in Appendix A.d. The Developer shall submit to Council four (4) sets of final design drawings of the proposed

reticulation system for the respective development. The Developer shall not commenceconstruction of any part of the reticulation prior to receiving a set of the drawings with

Councils stamp of approval imprinted thereon. Council shall return the plans within four (4)weeks of their receipt provided no amendments are required.

WC5 EASEMENTS

a. Where, in the opinion of Council, an easement is required over any section or sections of thewater reticulation constructed to service the subject development, the Developer shall, at nocost to Council, execute a registered easement in Councils favour over such section(s) ofworks. The area of land to be included in the easement shall be as directed by Council.

WC6 PIPES AND FITTINGS

a. All pipe used in the construction of the reticulation shall comply with the following:-i) Pipe diameter shall not be less than 100mm nominal size for residential development;ii) Pipe diameter shall not be less than 150mm nominal size for industrial and commercial

development or 2 x 100mm (one on each side of road in the foot way);

iii) Pipe material shall be uPVC PN16 series II M RRJ (AS 1477);(O RRJ pipe cant be used without prior approval from Lismore Water)

iv) Pipe shall not be less than PN16 and the Developer shall install a pipe of adequate classto withstand the static head applicable (without the PRV in operation) to the respectivedevelopment as stipulated by Council;

v) Pipe shall be new and manufactured by a manufacturer accredited by the StandardsAssociation of Australia;

vi) Pipes shall be rubber-ring jointed and shall be handled and installed in accordance withthe manufacturers recommendations unless this Specification directs otherwise;

vii) Rubber rings shall be natural rubber and comply with AS 1646 and shall not contain rootinhibitor; and

viii)DICL pipes (K9) can be used in lieu of uPVC pipes. The pipes are to be suitablywrapped except when concrete encased (see Clause WC20).

These requirements are to be stated in the drawings.

b. All fittings used in the construction of the water reticulation shall comply with the following:

-

8/2/2019 Water Spec Amended 06

19/82

Lismore City Council

Specification for the Design & Construction of Water Reticulation Pipework

July 199915

i) fittings shall be manufactured from cast iron or ductile iron and shall be nylon coated orcoated with fusion bonded epoxy. Any damage to protective coating shall be restored inaccordance with the manufacturers recommendations;

ii) fittings shall be new and manufactured by a manufacturer accredited by the StandardsAssociation of Australia and shall have the standards mark; and

iii) corrosion resistant metallic material shall be used for all components that have surfaceswhich cannot be coated and tested.

WC7 PIPELINES ON OTHER PROPERTIES

a. Where it is necessary to locate a pipeline in a property which does not form part of therespective development, the Developer shall, at the time of submitting his design drawings to

Council, also submit a Consent of Entry form (see Appendix H) and a copy of the planshowing the water layout affecting that property, signed by said property owner.

b. Pipelines in private properties will require an easement as per Clause WC5.WC8 CROSSINGS

a. Where a pipeline crosses a main road, railway line or creek, or where the constructioninvolves in any way, other features which may be under the control of any Authority, the

work shall be carried out in accordance with the requirements of that Authority. TheDeveloper shall obtain approval to carry out the work from the Authority concerned andsubmit proof of same to Council prior to the commencement of the work. It will be the

Developers responsibility to advise the Authority, and to complete any required writtennotification, of his intention to construct, prior to commencement of work.

WC9 MAINS IN CUL-DE-SACS

a. Where the cul-de-sac incorporates a pathway to an adjacent street or ends in a park, thewater main is to extend through the pathway or park so that a dead end is not created in themain.

b. Where a pathway or park is not provided, the main is to lop back onto itself around theCul-de-sac.

c. If the cul-de-sac is sloping downwards, a scour tee and a single check valve draining to thestorm water system shall be installed before the hydrant as per drawing WC9.

WC10 SERVICE CONNECTIONS

a. The Developer shall provide a service connection to each lot.b. Domestic service connections shall be designed in accordance with the details on Drawings

WC10, WD19.2 and WD19.3 and this Specification, and shall finish inside each property at a

distance of 0.5 metres from the street boundary and 0.5 metres from the side boundary.

c. Except where otherwise approved or directed by the Water and Wastewater Manager,service connections laid beneath existing paved carriageways and footpaths and under privateconcrete driveways shall be installed without disturbing the pavement other than byexcavating access pits and trenches if such are necessary. The pipes may be placed under the

pavement either by boring and jacking or by inserting the pipes through bored holes.

-

8/2/2019 Water Spec Amended 06

20/82

Lismore City Council

Specification for the Design & Construction of Water Reticulation Pipework

July 199916

d. Unless otherwise stipulated by Council, all pipes used in the service connection (includingroad crossings) shall be Type A as-drawn copper pipes conforming to Table 1 of AS 1432and all fittings and joints shall be silver brazed using alloy of silver content not less than 5%.

Bends in the pipe shall be made carefully so as not to damage the pipe wall or to reduce thebore of the pipe, alternatively, elbows may be used.

e. Alternatively, blue line PE pipe (PE80, type B, PN16 (AS 4130 (int)) and alpha 16 fittings(or equivalent) can be used. PE pipe to be laid with copper trace wire or metallic detectiontape to be attached to the copper pipe as directed by Council. If PE pipe is used, Table 1

refers to internal diameters of the PE pipe. Fittings are also to meet the requirements ofClause WC6.

f. Service connections to single dwelling allotments shall be 20mm size. For multiple dwellingsites the service connection shall be of the following sizes:-

Table 1: Flats and Home Units Size of Water Services

Minimum requirements (normally up to 30 metres)Connection to Water Main

Community

Titles, Rural

Landsharing

Communities

(multiple

occupancies),

duplexes, flats

or units

Nominal Size of

Service (from

Water Main to

the 1st Domestic

Branch)

Connection

Type

No. of

Drillings

Nominal Size

of Drillings

Nominal Size of

Water Meter

1

23 - 5

20

2532

Drilling

DrillingDrilling

1

11

25

2525

20

2025

6 - 10

11 - 16

40

50

Drilling

Drilling

2

2

25

25

40

40

17 - 50

51-100

65

80

100

Drilling

Tee

Tee

2

(1 x 80mm)

(1 x 100mm)

25

-

-

50

50

80

Note: All applications for a joint water service to connect thirty (30) or more such dwelling

shall be accompanied by a list of fixtures.

g. For commercial and industrial developments the service connection shall be of sufficient sizeto meet fire fighting requirements and shall be as approved by the Councils PlanningDepartment and/or the NSW Fire Brigade.

h. Domestic Service Road Crossings shall be 32mm minimum nominal size. For commercial orindustrial developments or where more than two dwellings are to be served by the road

crossing, the pipe diameter shall be designed to meet the requirements of AS 3500.

i. Unless authorised by the Water and Wastewater Manager, the maincock or valve shall beinstalled in the water main at a point opposite the water meter location. The water serviceshall be laid to meet the water main at right angles, and shall be laid directly to the watermeter location.

j. Service connections shall be on the opposite side boundary to the NorthPower service.k. Water services shall be stood up and crimped as per drawing WC10.

-

8/2/2019 Water Spec Amended 06

21/82

Lismore City Council

Specification for the Design & Construction of Water Reticulation Pipework

July 199917

l. DI pre-tapped fittings shall be accepted, provided they comply with AS 2280 and ClauseWC6.

-

8/2/2019 Water Spec Amended 06

22/82

Lismore City Council

Specification for the Design & Construction of Water Reticulation Pipework

July 199918

WC11 LOCATION OF WATER MAINS

a. The water main is to be located 1.0m behind the back of kerb as per drawing WC11.b. The water main is to be located on the high side of the street.

WC12 FIRE HYDRANTS

a. Spring hydrants shall be manufactured to satisfy the requirements of AS 3952 and consist ofthe following -

i) Nominal diameter socket by 80mm flanged hydrant tee.ii) 80mm diameter spring hydrant.iii) 80mm diameter ductile iron hydrant risers, installed as required to provide a clear space

of not less than 200mm nor more than 450mm between the top of the hydrant and theunder side of the surface box (Drawing WC12).

iv) Flanged fittings are to be joined with approved gaskets and 316 stainless steel bolts.v) Shall be treated internally and externally with a factory applied thermal bonded polymericcorrosion protective coating that shall comply with the requirements of AS 4158 and be

applied by the fluidized bed technique.

b. Hydrants shall be spaced:-i) At intervals of 60m maximum and shall be located generally in line with side boundaries

of adjacent lots.

ii) At all dead ends.c. Where water mains are located on both sides of a street, hydrants are to be staggered so that

they are spaced at 30m intervals.

WC13 RESILIENT SEATED VALVES

a. Valves shall be located at the beginning of all branches and shall be located so that themaximum length of pipe which can be isolated does not exceed 200 metres.

b. Sluice valves shall be a resilient seated type suitable for a working pressure of 1600 KPa andconforming to AS 2638.

c. The stem material shall be grade 431 stainless steel in accordance with AS 2837, with anintegral thrust collar.

d. The direction of closing shall be clockwise.e. The wedge shall be cast in Ductile Iron and fully encapsulated in an approved synthetic

rubber conforming to AS1646. Partially coated wedges are not acceptable.

f. The valve body, bonnet and top castings shall be manufactured from Ductile Iron and fullyenveloped with a fusion powder coating, applied by the fluidised bed technique, conformingto AS 4158. Alternatively, components may be manufactured from an approved corrosion

resistant material without protective coatings.

g. All fasteners shall be of high grade steel and completely isolated from the externalenvironment.

h. The stem seal shall be effected by a minimum of two O rings, which are able to be replacedunder full working pressure.

i. Resilient Seated Valves and Chambers shall be designed as per Drawing WC13.

-

8/2/2019 Water Spec Amended 06

23/82

Lismore City Council

Specification for the Design & Construction of Water Reticulation Pipework

July 199919

-

8/2/2019 Water Spec Amended 06

24/82

Lismore City Council

Specification for the Design & Construction of Water Reticulation Pipework

July 199920

WC14 TRENCH STOPS AND CONCRETE BULKHEADS

a. Where a water main is laid at a grade of between 7.5% and 15%, trench stops shall beconstructed at 6m intervals.

b. Where a water main is laid at a grade between 15% and 50% concrete bulkheads shall beconstructed at 6m intervals.

c. If a water main is to be laid at a grade steeper than 50%, the water main designs are to besubmitted to with the Water and Wastewater Manager for approval.

d. Trench stops and concrete bulkheads shall be constructed as per Drawing WC14.e. Councils Water and Wastewater Inspector may direct the placement of more trench stops or

concrete bulkheads if the site conditions necessitate it.

WC15 THRUST AND ANCHOR BLOCKS

a. Thrust and anchor blocks shall be constructed at valves, flexibly jointed bends, tees,enlargers, reducers and dead ends or any other point where unbalanced forces resulting frominternal pressures will occur as per Drawing WC15.

WC16 COVER OVER PIPELINES

a. The minimum depth of cover to be provided for water mains and water services shall be asfollows:-

Table 2: Minimum Cover over pipelines

Location of Pipe Minimum Cover

Subject to vehicular Loading:Sealed Roadways 600 mm

Unsealed Roadways uPVC 750 mmUnsealed Roadways other 600 mm

Elsewhere 600 mm(Note: Minimum cover is measured from Top of Kerb)

WC17 PROXIMITY TO OTHER SERVICES

a. The separation (both vertically and horizontally) between water pipes and electrical cablesand gas pipes shall be at least 450 mm. A greater separation could be required by the Waterand Wastewater Manager. (Refer to STD WC19B)

b. The vertical separation between water pipes and storm water pipes shall be aminimum 150 mm.

WC18 DUCTILE IRON PIPE

a. All ductile iron pipe shall be cement lined. Where ductile iron pipe is buried in anyapplication, it shall be polyethylene sleeved in accordance with the pipe manufacturers

recommendation and Clause WD 18.11(b), except if it is concrete encased.

-

8/2/2019 Water Spec Amended 06

25/82

Lismore City Council

Specification for the Design & Construction of Water Reticulation Pipework

July 199921

b. Any above ground pipeline shall be constructed using ductile iron cement lined pipe to adesign approved by the Water and Wastewater Manager and shall be painted to an approvedcolour to blend in with the surrounding environment.

WC19 TELECOMMUNICATION CONDUITS

a. The provision of telecommunication cable reticulation to the development shall be at theDevelopers cost.

b. Telecommunication conduits could be installed in the same trench as the water supply mainsand service crossings.

i) The Developer shall liaise with the Telecommunication Authorities and co-ordinate allaspects of the installation of the Telecommunication conduit and shall be responsible formeeting the required Specifications.

ii) The installation of Telecommunication conduits shall be laid in accordance with thedetails of Drawing WC19 and Clause WC11.

WC20 CONCRETE ENCASEMENT

a. Where pipes have less cover than specified, they shall be encased in concrete. As analternative, a 100 mm concrete slab may be approved.

b. When uPVC pipes are encased in concrete, then the following should be carried out:i) fully wrap the pipe with a compressible material, such as felt, with a minimum thickness

of 5% of the pipe diameter, for example 5 mm for 100 mm pipe

or

ii) flexible (rubber ring) joints shall be located at the entry to and exit from the concrete asin Drawing WC20.

WC21 PRESSURE REDUCING VALVE AND PRESSURE RELIEF VALVES

a. All pressure reducing valves and pressure relief valves are to be designed by a qualifiedconsultant. These design calculations are to be submitted to the Water and Wastewater

Manager for approval.

b. Pressure reducing valves and pressure relief valves are to be designed and constructed as perdrawing WC21.1 and WC21.2.

c. The location of pressure reducing valves and pressure relief valves are to be approved by theWater and Wastewater Manager before installation.

WC22 WATER METER PIT

a. If a water meter pit is required, details of this meter pit are to be submitted to the Water andWastewater Manager for approval.

b. Any testable backflow prevention devices are to be constructed above ground.

-

8/2/2019 Water Spec Amended 06

26/82

Lismore City Council

Specification for the Design & Construction of Water Reticulation Pipework

July 199922

WC23 FLANGED FITTINGS AND PIPEWORK

a. All flanged fittings and pipework to be designed to the requirements of Table C, AS 4087.WC24 NUTS, BOLTS AND WASHERS

a. All nuts, bolts and washers (including assembly nuts and bolts) shall be stainless steel to AS2837 and AS 1449 respectively, Grade 316, with an anti-seizing paste used in assembly(Locktite nickel anti seize threat lubricant or equivalent).

b. All stainless steel nuts and bolts other than bolts which form an integral part of an article shallcomply with the metric standards AS 1111 and AS 1112.

WC25 CROSS CONNECTION CONTROL AND BACKFLOW PREVENTION DEVICES

a. Cross connection control and backflow prevention devices shall be designed as per therequirements of AS 3500.

WC26 MAINS PRESSURE INQUIRY

a. Mains pressure enquiry applications are to be submitted on a form as given in Appendix Dwith the payment specified in Councils current Fees and Charges.

WC27 ESSENTIAL FIRE HYDRANTS

a. If a Council fire hydrant is used to satisfy the fire fighting requirements for a commercial orindustrial development, then the Water and Wastewater Manager is to be notified of the

location of this fire hydrant. If Council has to relocate this fire hydrant because of the

reconstruction of water mains or for any other reason, then the owner shall be responsible formeeting the required fire fighting requirements.

WC28 AIR VALVES

The location, size and type of air valve together with an adequately sized valve box or chambershall be as shown on the drawings. The following conditions shall apply to air valves:

a. Air valves shall be as shown on the drawings and shall be manufactured from DI or FibreglassReinforced Nylon;

b. Sealing of air bleed hole shall preferably be by a float made of non-corrosive, non-reflectivematerial sealing against a flexible seat. Where the float is a flexible material, the float shall berestrained from rotating i.e. it seals on the same place at all times; and

c. Air valves up to and including 50mm in size shall have a BSP threaded fitting with a 50mmBSP threaded stainless steel riser pipe (where required) while larger Air valves shall have aflanged fitting drilled in accordance with AS 4087 Figure B5. All Air valves shall be installed

with a suitable isolating valve to allow the removal of the Air valve for maintenancepurposes.

WC29 WATER SUPPLY PUMP STATIONS

a. The Water and Wastewater Manager is to be contacted prior to the investigation and designof a water supply pump station that is required in connection with the water supply to thedevelopment. Council shall provide the design standards for the pump station.

-

8/2/2019 Water Spec Amended 06

27/82

Lismore City Council

Specification for the Design & Construction of Water Reticulation Pipework

July 199923

SECTION WD

GENERAL CONSTRUCTION REQUIREMENTS

-

8/2/2019 Water Spec Amended 06

28/82

Lismore City Council

Specification for the Design & Construction of Water Reticulation Pipework

July 199924

-

8/2/2019 Water Spec Amended 06

29/82

Lismore City Council

Specification for the Design & Construction of Water Reticulation Pipework

July 199925

SECTION WD GENERAL CONSTRUCTION REQUIREMENTS

WD1 BEFORE COMMENCING WORK

The Developer shall not commence construction on any part of the water supply before:

a. receiving a set of design drawings with Councils stamp of approval imprinted thereon and,b. have submitted a Notice to Commence Work as given in Appendix C (at least two weeks

prior to construction commencing). The developer must advise in writing of any proposed

changes in supervising staff; and/or

c. filling in the appropriate form (eg: Minor Works Permit - Appendix G).WD2 PUBLIC LIABILITY INSURANCE

a. Before commencing work, the Developer shall take out a Public Liability Policy insurancewhich shall indemnify Lismore City Council against all loss of, or damage to the property ofLismore City Council and from and against any claim, demand, action, suit or proceeding that

may be made or brought by any person against Lismore City Council, the Water andWastewater Manager, or the employees, professional consultants or agents of Lismore CityCouncil or any of them in respect of personal injury to or the death of any person

whomsoever or loss of, or damage to any property whatsoever arising out of, or as aconsequence of the construction or maintenance of the works by the Developer or hisemployees, agents or contractors and also from any costs and expense that may be incurred in

connection with any such claim, demand, action, suit or proceeding.

b. The Public Liability Policy of insurance shall be for an amount not less than $10,000,000; andc. Prior to the commencement of any work, Council shall sight evidence of the current policy.

WD3 LOCATION OF WORKS AND ADDITIONAL WORKS

a. The locations of the water mains, hydrants, stop valves and water services shall beconstructed as shown on the Approved Layout and Detail Plans in accordance with Councilsstandard drawings referenced in this Specification. The pipelines shall be laid to grades,lengths and location shown on the drawings except where deviations are approved by

Councils Water and Wastewater Manager.

b. Should it be determined during the construction work or after the setting out of allotmentboundaries that additional works are necessary to ensure the water supply meets Council

standards. Council reserves the right to require that this work shall be completed to its

satisfaction.

WD4 DEVELOPERS SUPERVISORY STAFF

a. The on-site works of the Developer, including any associated sub-contract work, shall at alltimes be supervised and administered by a full-time, responsible representative of theDeveloper.

b. The Developer shall be present at all site meetings arranged by the Water and WastewaterInspector.

c. In addition, where dictated by the extent and type of work involved, the Developer shallprovide full-time, on-site foremen well experienced in the particular type of work involved.

-

8/2/2019 Water Spec Amended 06

30/82

Lismore City Council

Specification for the Design & Construction of Water Reticulation Pipework

July 199926

Also, all pipe laying is to be undertaken by a suitably qualified plumber, drainer or pipe layerand all house connections by a suitably qualified plumber.

WD5 COVER OVER PIPELINES

a. The minimum depth of cover to be provided for water mains and water services shall be asgiven in Clause WC16.

b. Less cover may be permitted where protection of the pipelines has been approved byCouncils Water and Wastewater Manager.

WD6 NOISE CONTROL

a. The noise level generated by plant and equipment on-site shall not exceed the limits set by AS2436, or limits set by any applicable Act or Government Regulation.

WD7 PRESERVATION OF FLORA

a. The Developer shall not destroy, remove or clear any trees or shrubs without the priorapproval of the Parks and Reserves Manager or without Development Consent.

WD8 TRAFFIC MANAGEMENT

a. The Developer, if required, shall undertake traffic management to meet the RTArequirements.

WD9 CONSTRAINTS ON SERVICE

a. Construction works shall be undertaken in accordance with applicable Federal and State Actsof Parliament, Guidelines and Codes of Practice, Council policies and local laws.

WD10 OCCUPATIONAL HEALTH AND SAFETY

a. The Developer shall comply with the NSW Occupational Health and Safety Act, 1983.b. The Developer shall meet any requirements of WorkCover Codes of Practice.c. The Developer shall comply with the Construction Safety Act.

WD11 ROAD CROSSINGS (FOR COUNCIL OWNED ROADS)

a. The Developer shall not excavate any sealed or unsealed road pavement without theexpressed permission of the Works Manager.

b. Prior to excavating a road, concrete path, kerb and gutter and kerb outlet, a Road OpeningPermit must be obtained from Council and the fees applicable paid.

c. Road crossings will conform with Standard Drawings.d. Any excavation within paved areas shall be backfilled with metal dust mechanically

compacted in layers not more than 150mm thick.

e. The Developer shall restore any damaged road pavement to the satisfaction of the WorksManager.

-

8/2/2019 Water Spec Amended 06

31/82

Lismore City Council

Specification for the Design & Construction of Water Reticulation Pipework

July 199927

WD12 TEMPORARY ROAD CLOSURES (FOR COUNCIL OWNED ROADS)

a. Where it is necessary to temporarily close a road for any work associated with the installationof the water reticulation, the Developer shall obtain the approval of Works Manager before

any temporary road closure is carried out.

b. Council may give approval for temporary road closures provided the following conditions arecomplied with:-i) The Developer can show that it is impractical to undertake the road crossing by partially

closing the road.

ii) The closure being suitably signposted and lit to the satisfaction of Works Manager.iii) A suitable detour route, as approved by the Works Manager, being available.iv) Traffic management to meet the RTA requirements and Traffic Control Plans to be

submitted to Works Manager for approval.

v) The closure being advertised in the local press and on radio at least seven (7) days inadvance, the advertisements to specify the period and purpose of the closure and details

of the alternative route(s). Cost of advertising shall be borne by the Developer.vi) The Developer shall notify local Police, Ambulance, Fire Brigade and Bus Companies in

writing at least seven (7) days before closure.

WD13 EROSION AND SEDIMENT CONTROL

WD13.1 General

a. Take all steps necessary to protect the environment and in particular, comply with therequirements of this clause (WD13).

b. The Developers attention is directed to the following publication:i) Urban Erosion and Sediment Control, Revised Edition 1992 (prepared by CALM); andii) Urban Erosion and Sediment Control Field Guide (prepared by CALM).

WD13.2 Erosion and Sediment Control

a. The Developer shall adopt such measures as may be necessary for erosion, contamination andsediment control, during construction, including the following where applicable:

progressive restoration of disturbed areas; temporary drains; temporary fencing; diversion and dispersal of concentrated flows to points where the water can pass through

the site without damage;

spreader banks or other structures to disperse concentrated runoff; construction and maintenance of silt traps to prevent the discharge of scoured materials

to downstream areas.

b. All temporary works shall be removed when they are no longer required.

-

8/2/2019 Water Spec Amended 06

32/82

Lismore City Council

Specification for the Design & Construction of Water Reticulation Pipework

July 199928

WD13.3 Erosion and Sediment Control Plan

a. The Developer shall prepare an Erosion and Sediment Control Plan to the requirements ofDLWC and EPA and these plans are to be submitted with the detailed design plans to theWater and Wastewater Manager. The plan shall be implemented and maintained for the

duration of the Works.

b. The Erosion and Sediment Control Plan shall consist of diagrams and supportingdocumentation indicating the following:

i) The drainage paths and inlets.ii) All proposed permanent and temporary erosion and sedimentation control measures and

related structures; and

iii) Dewatering and groundwater control and disposal methods.WD14 DUST CONTROL

a. The Developer shall take all reasonable steps to limit the creation of any dust nuisance whichmay arise during the construction of the works. The Water and Wastewater Manager maydirect that work cease until such time as any particular dust nuisance has been controlled to

their satisfaction.

WD15 EXISTING SERVICES

WD15.1 Developer to Inform Themself

a. In addition to the services shown on the drawings, other services may exist in all areas.b. It is the Developers responsibility to investigate the nature and location of all services which

might be encountered during the construction of the work and to consult with the variousservice authorities and property owners or occupants on this matter prior to commencingexcavation at any location. Failure by the Developer to inform himself and to take due care

in this regard shall not limit his liability for costs of all repairs, restoration or any lossesarising from any damage to the service.

c. All costs associated with the failure and repairs of the services damaged by the Developershall be borne by the Developer.

WD15.2 Cost of Relocation or Replacement of Existing Services

a. Where an existing underground pipe, conduit, cable or power pole (hereafter referred to asservice and which is to remain in operation after construction of the Works) occupies thesame space in which a pipeline or other appurtenance is required to be positioned, the cost ofrelocation, temporary removal, temporary support or replacement shall be borne by theDeveloper. This shall also apply where an existing service is parallel or nearly parallel to or

vertically above or below the proposed pipeline within the width of excavation specified inClause WD5 or which physically interferes with the construction of the pipeline or theprotection or maintenance of the service and/or the pipeline.

b. The cost and the organisation of the relocation, diversion, temporary removal andreplacement or temporary support of any service shall be borne by the Developer.

c. Alternatively, at its discretion, the Council may approve the alteration of the location of theproposed water main or appurtenance.

-

8/2/2019 Water Spec Amended 06

33/82

Lismore City Council

Specification for the Design & Construction of Water Reticulation Pipework

July 199929

WD16 EARTHWORKS

WD16.1 General

a. All earthworks shall be carried out as set out hereafter.i) The Developer shall provide proper fencing, guarding, temporary signs, lighting and

watching of all temporary roadways, footways, guards and fences as may be rendered

necessary for accommodation and protection of foot passengers, vehicles, animals andthe public.

ii) At completion of work each day, the work site shall be fenced to isolate it from thepublic. Where necessary, fenced walkways and vehicular crossways shall be providedacross trenches to maintain access from carriageway to individual properties or withinindividual properties. All such installations shall be of adequate size and strength and

satisfactorily illuminated and signposted.

iii) If the Developer fails to carry out fencing and other protective work to the satisfaction ofthe Water and Wastewater Manager, and the need for such work is deemed to be urgent,

Council may arrange for the work to be carried out at the Developers cost.

iv) All excavations shall be to the lines, grades and forms shown on the drawings or asapproved by the Water and Wastewater Manager within the specified tolerances.

v) The Developer shall leave a clear space of 600mm minimum between the edge of anyexcavation and the inner toe of spoil banks. No excavated materials shall be stacked

against the walls of any building or fence without the written permission of the owner ofsuch building or fence. Topsoil from excavations shall be kept separate and utilised tomake good the surface after backfilling.

WD16.2 Excavation for Pipeline

a. Trenches shall be excavated within the tolerances specified hereinafter. Generally, it isexpected that trenches will be excavated with vertical sides. A typical trench section is givenin Drawing WC16.2.

b. Excavation Widthi) Minimum Trench Width for Pipelines

The minimum clear width of trench (inside internal faces of timbering or sheet piling, if

used) to a height of 150mm above the top of the pipe shall be as shown in Table 1hereafter.

-

8/2/2019 Water Spec Amended 06

34/82

Lismore City Council

Specification for the Design & Construction of Water Reticulation Pipework

July 199930

Table 3 Minimum Clear Width of Trench

NOMINAL SIZE OF PIPE MINIMUM CLEAR WIDTH OF TRENCH

(inside timbering or sheet piling, if any)

80 400

100 450150 450

200 500

225 550

250 550

250 550

300 600

375 700

400 700

450 750

500 850525 850

600 950

ii) The maximum width of trench shall be the outside diameter of the pipe barrel plus400mm. However, in timbered or travelling box excavated trenches, the width of trench

when measured to the outside of the support used, may be increased to a maximum of580mm plus the outside diameter of the pipe barrel.

iii) Extra Width ExcavationWhere the width of trench is greater than the maximum width specified in ClauseWD16.2(b)(ii), either as a result of over-excavation or due to collapse of one or both

walls of the trench from any cause whatsoever before or after laying of the pipe, theDeveloper shall remove all disturbed material from the trench. The Water andWastewater Manager may then direct one or more of the following:-

Bedding and laying, as specified further in this Section of this Specification, usingthe same pipe.

Installation of a heavier class of pipe. Filling the space between the pipe and the undisturbed ground on both sides of the

pipe and to a height of 300mm above the top of the pipe with a granular material of

the type approved for pipe bedding as specified in Clause WD17. Such granularmaterial shall be compacted in layers not greater than 150mm thick.

Bedding of pipe on concrete cradle extending a minimum of 100mm on each side ofthe outside diameter of the pipe, a minimum of 100mm under the barrel and to a

level above the bottom of the pipe of one quarter of the external diameter of thepipe.

Backfilling and compaction for the remainder of the trench shall be as directed by theWater and Wastewater Manager for the local conditions.

c. Excavation DepthFor all pipelines, excavation shall be carried out to a depth not less than 100mm below theunderside of the pipe barrel and socket or coupling.

-

8/2/2019 Water Spec Amended 06

35/82

Lismore City Council

Specification for the Design & Construction of Water Reticulation Pipework

July 199931

d. Bad Ground Conditions Requiring Extra Depth Excavation and Ballastingi) Where the Water and Wastewater Manager so directs, extra depth shall be excavated in

order to obtain a firm trench bottom. The portion so excavated shall be refilled to the

level required for bedding of the pipe with an approved fine non-cohesive material such

as sand or crushed fine rock, placed in layers 150mm thick and compacted by approvedmeans.

ii) Where the ground at the bottom of a trench is of a spongy or boggy nature, and theWater and Wastewater Inspector so directs, clean hard rock ballast, such as basalt ofnominal size 150 mm (85% passing 150 mm sieve and less than 20% passing 100 mm

sieve) shall be placed in layers and compacted by ramming into the boggy ground until anapproved firm foundation is obtained at the level required for bedding of the pipe. TheDeveloper shall remove any surplus soil displaced by placing of ballast and dispose of

same in a manner satisfactory to the Water and Wastewater Manager.

WD16.3 Dewateringa. General

Trenches shall be kept free of water after excavation and during construction. Any auxiliaryexcavation carried out in or adjacent to the trench excavation for that purpose shall be

backfilled by the Developer using materials and in a manner satisfactory to Councils Waterand Wastewater Manager. The Developer shall use external dewatering if directed by theWater and Wastewater Manager.

Internal dewatering can be undertaken by the use of sump pumps located in the bottom of thetrench.

b. External DewateringExternal dewatering shall mean a system of well points or other devices sunk in the ground in

the vicinity of the excavation and operated continuously from the time of excavation of thetrenches to the time the trenches have been backfilled.

i) The use of sump pumps located in the bottom of the trench or the bottom of a lateraltrench is not defined as external dewatering.

WD16.4 Support of Excavations

a. The Developer shall adequately support all excavations as the works proceed.WD16.5 Safe Working In A Confined Spacea. The Developer shall ensure that all work complies with AS 2865 (Safe Working in a

Confined Space).

WD16.6 Backfill, Compaction and Additional Compaction

a. When laying and jointing of a pipeline has been completed and backfilling is completed to aheight of two thirds the pipe barrel, the Developer shall request the Water and WastewaterManager to check the pipeline. The Water and Wastewater Inspectors shall carry out suchinspections within a reasonable time of each request. Council shall be given a minimum of

twenty four (24) hours notice before the required time of the inspection.

b. Backfilling shall not be completed until these checks have been made by the Water andWastewater Inspector.

-

8/2/2019 Water Spec Amended 06

36/82

Lismore City Council

Specification for the Design & Construction of Water Reticulation Pipework

July 199932

c. When backfilling for pipelines, metal dust only shall be placed within 150mm of the pipes.d. Backfill shall be compacted under and around the pipe and to a height of 150mm over the top

of the pipe.

e. Additional compaction is required for trenches subject to vehicular traffic. The additionalcompaction shall be by mechanical means and undertaken in 150mm layers.

f. When the excavated material is considered by Councils Water and Wastewater Manager tobe unsuitable for compaction then backfill material of a non-cohesive nature, such as sand ormetal dust, shall be imported. Surplus excavated material shall be removed and disposed ofto areas arranged by the Developer. Rocks or clumps of material larger than 150 mm will not

be allowed in any backfill.

g. Backfill shall be placed sufficiently high to compensate for expected settlement and furtherbackfilling shall be carried out or the original backfill trimmed at the end of the Defects

Liability Period in order that the surface of the completed trench may then conform with theadjacent surface. Surplus material shall be removed and disposed of to areas arranged by the

Developer who shall pay all costs involved in such removal and disposal includingcompensation or other payments to the owners of the lands to which surplus material isdisposed.

h. In locations where, in the opinion of Councils Water and Wastewater Manager, surplusmaterial left in the vicinity of the trench would not be objectionable, the surplus material maybe disposed by spreading neatly in the vicinity of the trench to the satisfaction of Councils

Water and Wastewater Manager in such a way as to minimise future erosion of the backfilland adjacent ground surfaces. The contractor shall maintain the backfill and adjacent grounduntil the expiry of the Defects Liability Period.

i. Where, within public or private property, the reasonable convenience of persons will requiresuch, Councils Water and Wastewater Manager may order trenches to be levelled off at thetime of backfilling, any subsequent settlement shall be made good by the contractor asrequired by placing additional fill.

j. Should the Developer tunnel under paving, kerb and gutter or other improved surfaces in lieuof trenching, backfilling shall be so carried out as to restore full support to those surfaces.The Developer shall remain responsible for the repair of the improved surfaces, if

subsequently damaged due to subsidence of the backfill, until the end of the Defects LiabilityPeriod.

k. Backfill for all roads and trafficable surfaces shall be with metal dust placed in layers notmore than 150mm thick and mechanically compacted.

WD16.7 Restoration of Surfaces

a. Pavements, lawns and other improved areas shall be thoroughly cleaned and left in the sameorder as they were at the commencement of Works. Where directed, lawns shall be restored

with turfs cut and set aside from the original surface or with turf imported from a sourceapproved by the Water and Wastewater Manager.

b. All restored surfaces shall be maintained in the condition to which they are restored until theexpiry of the Defects Liability Period, notwithstanding that any deterioration of the restoredsurfaces, and the need for their maintenance may or may not be due to defects which become

apparent or arise from events which occur during the Defects Liability Period. Pavementsshall be maintained with crushed metal, gravel or other suitable material allowing for

-

8/2/2019 Water Spec Amended 06

37/82

Lismore City Council

Specification for the Design & Construction of Water Reticulation Pipework

July 199933

consolidation and shall then be restored to a condition equivalent to that of the original

pavement.

WD16.8 Tunnelling

Where tunnelling has been used in lieu of trenching to avoid excavating through improvedsurfaces, backfill such as to restore full support to the surface. Repair any damage to the

improved surface which occurs at any time due to subsidence of the backfill.

WD17 PIPE BEDDING

WD17.1 General

a. When excavation of a trench has been completed and approved by the Water and WastewaterManager, the Developer shall provide for bedding of the pipe in accordance with therequirements of Clause WD17.2 (e).

WD17.2 All Pipes

a.

All pipes shall be bedded on metal dust to a depth of at least 100mm below the underside ofthe barrel and socket of the pipe. The bedding shall extend across the full width of the trench

and shall be well compacted under and around the pipe. Bedding shall finish at a height of150mm above the crown of the pipe.

b. PE pipe, depending on site conditions, are to have a 1mm copper trace wire (or detectabletape) laid in trench and soft soldered to copper stand pipe. (also see Clause WC10).

c. Pipe locating tape (Terra Tape) shall be laid along and directly over all pipelines includingservice lines. Minimum distance between the pipe and tape shall not be less than 300 mm.

d. Pipes shall be laid so as to provide 150mm minimum clearance to stormwater mains,sewerage mains, power poles or other structures. The separation between water pipes andelectrical cables shall be a minimum of 450 mm.(see Clause WC17 Refer STD WC19B).

e. Metal dust used for pipe bedding shall consist of a non-cohesive granular material free fromorganic or other deleterious matter and its grading shall fall within the following limits:-

Table 4: Pipe Bedding Grading

Sieve Size

Aperture Width(AS 1152)

Equivalent B.S.

(BS 410)

Percentage

Passing

9.5mm 3/8 inch 100

6.7mm 1/4 inch 90-100

425.0 m No. 36 40 - 90

150.0 m No. 100 0 - 10

-

8/2/2019 Water Spec Amended 06

38/82

Lismore City Council

Specification for the Design & Construction of Water Reticulation Pipework

July 199934

WD18 LAYING AND JOINTING OF PIPES

WD18.1 General

a. When the bedding for pipes has been prepared as specified and approved by the Water andWastewater Inspector, pipes shall be laid and jointed in accordance with the manufacturers

instructions and the provisions of this Specification.

b. All pipes, fittings, valves, etc., shall be of the class or wall thickness and size specified in thisSpecification. Before being laid all pipes, fittings, valves, etc., shall be cleaned and examined

by the Developer. Any damaged or defective pipe or fittings shall be replaced or repaired asinstructed by the Water and Wastewater Manager or as stated in this Specification.

c. Do not use any uPVC pressure pipe which is scratched or scoured to a depth greater than1mm.

d. At the end of each days laying, seal the end of the pipe to prevent ingress of trench materialor water. Do not leave tools in the pipe overnight.

WD18.2 Jointing

a. Joints in pipelines shall be flexible rubber ring joints (either roll-on rubber ring or skid type)or mechanical joints (either fixed flange or bolted gland type).

i) Skid Type Rubber Ring JointsFor pipes with skid type rubber ring joints, only the lubricant specified by the

manufacturer shall be applied in making the joint. When the joint is made, the witnessmark shall at no point be more than 1mm from the end of the socket.