Walls & Roofs Journal 2'11

-

Upload

media-in-africa -

Category

Documents

-

view

271 -

download

5

description

Transcript of Walls & Roofs Journal 2'11

Putting a lid on the Cape Town Stadium Museum of Art Glass & Aluminium innovations

IN THIS ISSUE: Corrosion in roof sheeting & fasteners

VOL 12.2 MARCH 2011 R38 incl. VAT

Rheinzink products are not only appealing from an architectural point of view. They are also an asset in construction: they make a valuable contribution to preserving the building fabric. To find out more about intelligent roof and façade-cladding systems, go to page 50.

Cover picture courtesy of Stefan Antoni Olmesdahl Truen Architects

ContentsVolume 12 • Number 2 • 2011

RegulaRs|| SHOPFRONT04 Colour trends for 2011

08 New security barrier concept

|| CONCEPTS & VISIONS12 Resnick Pavilion

|| GREEN DESIGN16 Nestle’s new green building

|| ARCHITECTIVES88 CEO of Italtile Ltd

89 Corobrik CEO reflects on prospects for 2011

93 School will save R50 000

FeaTuRes|| HIGH-SPEC PRODUCTS20 Sourcing, specifying & designing

26 All-in-one light weight tile adhesive

30 Construction chemicals

|| GLASS & ALUMINIUM PERFORMANCE32 Trends and innovations

38 Roller-style shutters

40 Flexible interior spaces

|| ROOFING & CEILINGS42 Challenges and solutions

50 Zinc - valuable building product

62 Sandton City extension

|| INTERIOR SPACES66 Offices of the future

74 Avant-garde wall coverings

78 Beat mould and moisture

RheinzinkRheinzink Titanium zinc comes to the South

African construction industry from Europe

where it has been used as roofing and exterior

wall cladding for over two hundred years

in inland and coastal climates. The metal’s

desirable attributes include long-lasting

service life, low to no maintenance, ease of

formability as well as numerous environmental benefits. The arrival

of zinc and its applications is timely, both from a building technology

and an environmental perspective.

Rheinzink Gmbh & Co KG have their factory in the Ruhr region of

Germany where they produce the material used for Roofing, Façade

Cladding and Water Drainage for the world market. Rheinzink have

marketing and sales outlets in 32 countries. Rheinzink (South Africa)

has established their marketing office in the Western Cape, with

Stephen Wilkinson as the Business Manager. Stephen has been with

Rheinzink for 13 years, seven of which were in the United Kingdom

and his wealth of knowledge in the usage of the products is shown

by the growth of sales throughout South Africa since 2005.

Rheinzink is stocked in South Africa through the distributors

Safintra (Pty) Limited as well as Two Oceans Metals CC.

The various applications are applied by skilled German craftsmen

who are currently training local artisans in the intricate and

specialised technique and of hard metal crafting.

Rheinzink has been specified on commercial and residential as well

as on Government projects such as the new Forensic Laboratories

in Cape Town as well as the renovation to the Central Governments

Offices in Pretoria.1612

M U LT I P L E AWA R D W I N N I N G P U B L I C AT I O N

TRade CommenT

Putting a lid on the Cape Town Stadium Museum of Art Glass & Aluminium innovations

IN THIS ISSUE: Corrosion in roof sheeting & fasteners

VOL 12.2 MARCH 2011 R38 incl. VAT

on The CoveR

PUBLIshER:Media in Africa (Pty) Ltdwww.mediainafrica.co.za

CONTACT INfORMATION: International: Tel +27 12 347 7530 • Fax +27 12 347 7523

E-mail [email protected] Box 25260, Monument Park, 0105, Republic of South Africa

First Floor, Unit G, Castle Walk Corporate ParkCnr Nossob & Swakop Streets, Erasmuskloof Ext. 3

ThE WALLs & ROOfs TEAM:Editor: Marlene van Rooyen – 083 327 3746

[email protected] Accounts Consultant: Shayne Lessing – 082 945 5030

[email protected]: Schalk Burger (1943 – 2006)

Journalist: Adrienne Brookbanks – 082 468 [email protected]

Business Unit Coordinator: Lorraine [email protected]

Publishing Manager: Liezel van der MerweFinancial Director: Fanie Venter

Financial Manager: Sietske RossouwAccountant: Denise Bakker

Design & Layout: Ilze Janse van RensburgProofreader: Angus Reed

Reproduction & Printing: Business Print Centre

WALLs & ROOfs focusses on the aesthetics of walls and roofs and

technicalities pertaining to the aesthetics. Readers are welcome to contact

us for any information. WALLs & ROOfs is published six weekly by

Media in Africa (Pty) Ltd. The views expressed by contributors are not

necessarily those of the editor or publisher. We accept no responsibility

for the accuracy of information published.

NEW PRODUCTs ABOUND!This issue of Walls& Roofs is once again filed to the brim with exciting projects and new products that will be sure to excite you. See all the latest products on the market from page 4.

In our Hi Spec feature we look at products you can specify for use in projects where performance is key. The products featured here have been used at, amongst others, Medupi Power Station, heavy traffic roadside interchanges and we also focus on you can add value to building products.

The realm of office space design is ever evolving. Depending on the company ethos and culture and their way of work and their processes, work space design has evolved to focus on efficiency, productivity and ergonomics.

We take a close look at the latest products, design features and thought leadership in this arena. Read more on this from page 20.

Our roofing feature this issue takes a look at corrosion of roof sheeting and fasteners: we examine the Classification and designation of corrosion resistance, the standards and expected life span of roof fasteners. Where does it all go wrong? What impacts the longevity of your roof? Read all about the correct fastener specification from page 42.

CondolenCesThe tragic accident that befell the Italtile family came as a massive shock to the industry. We would like to offerour condolences to their colleagues at Italtile and their family members during this trying time. Our thoughts are with you all.

Marlene van Rooyen

InsIghTs FRom The edIToR

WINNER: SAPOA Property Publication of the year. fINALIsT: PICA Awards 2010

aWaRds

Get the latest PRODUCT & TRADE INfO

ONLINE fOR freewww.mediainafrica.co.za

MULTIPLE AWARD WINNING PUBLICATION

shopFRonT

3

shopFRonT

4

NCS Colour has joined forces with international colour trend forecasters Global Color Research, creators of Mix Publications, to compile NCS Insight. This booklet, which is compiled in a handy fan-deck format, showcases 30 of the most important colours for 2011, lifted from the Mix Trends forecast books covering the year ahead.

“Transition is key for 2011. We’ve begun to emerge from the slump of the economy so the colours selected are a little more vibrant and positive than in recent seasons – a sign that people are beginning to dig into their pockets again and look to the future. We look to the realities of our world, encouraging ourselves away from solitude and into the richness of life,” explains Lisa Taylor, the Southern African Development Community distributor for the Natural Colour System (NCS).

The colours for 2011 reflect a stronger level of optimism. Neutral and yellow colours are prevalent in NCS Insight and the palette of colours is also starting to become warmer, opening out in chocolate browns, rich berry red and a vibrant orange.

“Green continues a steady growth in fresh vegetal shades through to aqua, while mysterious deep blue and purple cover the darker end of the spectrum. Grey scale tones are cool and smoky, contrasting well with warmer plaster shades in the palette,” says Taylor.

NCS Insight can be ordered as separate sheets in different sizes and gloss format or translated into RGB and CMYK in NCS Navigator on www.ncscolour.com. Complete trend forecasts for 2011, 2012 and 2013 can also be found on the website. v

NCS Colour Centre SATel: 011 486 3190E-mail: [email protected]: www.ncscolour.co.za

Colours: NCS S 5040-R20B •

NCS S 1080-R •

NCS S 0565-R •

NCS S 0530-Y90R •

NCS S 8010-Y50R •

NCS S 0585-Y70R •

NCS S 2060-Y40R •

NCS S 1040-Y20R •

NCS S 0550-Y •

NCS S 0510-Y •

NCS S 0560-G40Y •

NCS S 3050-G20Y •

NCS S 4050-B90G •

NCS S 3060-B40G •

NCS S 1510-B80G •

NCS S 0505-B •

NCS S 1030-B10G •

NCS S 4550-R90B •

NCS S 2020-R80B •

NCS S 1515-R40B •

NCS S 4050-R60B •

NCS S 7502-R •

NCS S 3010-Y40R •

NCS S 1005-Y50R •

NCS S 0502-Y •

NCS S 0804-R70B •

NCS S 2005-B •

NCS S 3502-R •

NCS S 8502-B •

Colour trends for 2011

Colour Samples: 30 fully coated standard NCS colours. Gloss: Semi matt 15-20 units. Samples: Sample size 35 x 104 mm. Print: The NCS colour notation printed on the reverse of each colour sample. Weight: 40 grams.Price R350.00 per fan with 20% of sales going to Animal Anti-Cruelty League www.aacl.co.za

nCs ColouRs foR 2011PRoduCt name: nCs insight 2011

“WIPE AND GO” paint uses same constituents as non-stick frying pansGraffitex has launched a new range of “wipe and go” paint coatings that can get rid of ingrained grime (including graffiti) without damaging the paintwork. What makes these paints different is that they contain polytetrafluoroethylene (commercially known as Teflon, the material that is best recognised for its use in non-stick frying pans).

The Graffitex product was developed locally some years ago for specialist applications and has now expanded into a complete range of water-based, plastic wall coatings for interior and exterior use, as well as a roof coating. A Cape Town company also known as Graffitex was launched in 2010 with the sole rights to manufacture and supply the

products to market. According to Graffitex owner Simon Beauclair, the technology is user- and environment-friendly. “The non-stick qualities of the coating prevent it from absorbing even marks such as pen, crayon and permanent marker. This makes the products ideal for hospitals, schools, day-care centres and other high-traffic areas where quick and easy cleaning is a priority,” says Beauclair.

Graffitex also manufactures a range of water-soluble sprays specifically designed to remove marks like these, along with daily dirt and grime, from the surface of the coatings simply by wiping them away. Even extreme graffiti can be removed using a heavy-duty cleaning gel known as “Wipe Out”. v

GraffitexTel: 021 712 9225E-mail: [email protected]: www.graffitex.co.za

The non-stick qualities of the coating prevent it from absorbing even marks such as pen, crayon and permanent marker.

shopFRonT

5

shopFRonT

6

ARCELOR MITTAL

shopFRonT

7

ARCELOR MITTAL

shopFRonT

8

“We’ve spent two years developing this product in conjunction with Meshtec in Thailand, the company that developed this industrial-grade mesh screen,

because the product had to be strong enough to cope with South African crime conditions,” said Nick Sacco, Trellidor’s business development manager.

Trellidor Clear Guard units have undergone rigorous standard tests for security screen doors and windows according to the Australian Standard (AS), including knife sheer, dynamic impact, jemmy and salt spray tests. The product surpassed all of these tests.

“We see these security screen doors and windows as a first choice for homes, corporate offices, commercial buildings, hospitals, police stations, eco-estates and game reserves, particularly in those projects where developers and architects are reluctant to specify the usual options in terms of security barriers.”

The units can be tailored in both single and double formats to fit a wide range of door and window styles. These include hinged, sliding and French doors, and casement, awning, sliding and fixed windows.

In addition to offering protection against unwanted intrusion, Trellidor Clear Guard also screens out up to 60% of the sun’s UV rays, controlling the internal temperature and improving energy efficiency. They allow air to flow freely into the home whilst preventing pests such as monkeys, baboons, flies, mosquitoes and snakes from getting inside.

Trellidor Clear Guard is manufactured at Trellidor’s SABS ISO 9001-certified Durban factory and is guaranteed against corrosion both inland and at the coast. v

Trellidor Tel: 031 582 7460 E-mail: [email protected] Website: www.trellidor.co.za

NEW, UNIqUE security barrier concept Trellidor has expanded its security barrier offering by launching a security system that is unlike any other currently available on the local market. Called Trellidor Clear Guard, it is an attractive alternative to conventional barriers, consisting of an aluminium frame with a high-tensile stainless steel mesh insert that offers protection without spoiling the view.

shopFRonT

9

shopFRonT

10

New colours launched for popular exterior paint brandDulux recently launched seven new earthy shades in their popular Weatherguard exterior paint range. Inspired by natural elements, Weatherguard’s new palette, which includes colours such as Bushveld, Karoo Land and Valerian Clay, was chosen to offer decorators more variety as well as the latest colour trends for 2011.

“Though brighter colours are slowly making their way onto exterior surfaces, it still seems that South African consumers prefer to colour the exterior of their homes with a palette that echoes our unique and beautiful outdoor environment. With an increasing awareness of greening our planet, trend mappers confirms our need to connect and co-exist with nature, and what better way to start than with the home,” says Sonica Bucksteg, Dulux’s in-house colour expert.

“The new Weatherguard range of colours has been inspired by natural elements. The mesmerising colour display of our local animals also served as our muse. Though Weatherguard’s existing colours remain a popular choice, our new palette has been exceptionally well received with the recently launched shades already making their way onto the exterior walls of South African homes,” says Dulux brand manager Mayan Desai.

Weatherguard is a particularly flexible paint in the market and it is one of the most popular brands for jobs that involve covering hairline cracks (measuring between one and two millimetres) which are prevalent in South African plaster work. The paint also hides minor imperfections and is tough, durable and water- resistant.

fine-textuRed foR exteRioR wallsFeaturing a synthetic rubber binder known as Maxiflex, •

Weatherguard offers lasting flexibility that enables the coating to expand and contract with substrate movement;Resistant to alkali, Weatherguard can be applied directly to •

bare plaster;It is reinforced with thousands of marble chips and provides •

a thick, flexible coat;The paint is water-based, making it easy to clean your •

brushes and rollers;Weatherguard allows spreading of up to 6 m²/l and its film •

build hides minor imperfections.

“Colouring our world remains an important part of the Dulux philosophy. And while Weatherguard’s DNA of flexibility and durability will enable the brand to continue doing its job of covering hairline cracks, it will also continue to protect and transform the appearance of South African homes,” concludes Desai. v

Dulux Tel: 0860 330 111E-mail: [email protected]: www.duluxtrade.co.za

100% MADE IN ITALy TILE RANGE TO TRANsfORM sPACEs

“Flow”, a new product by Ceramiche Caesar, is the ideal mix between a contemporary look and high technical performance. The product is the result of intensive research and 100% Made in Italy manufacturing, boasting six colours in a comprehensive range of chromatic shades.

With its three available surface finishes, natural, bright and miniscratched, Flow can be used in both residential and large commercial venues. v

For more information, visit www.caesar.it, to which full acknowledgement and thanks are given.

Builders Warehouse strengthens bond

Sika has extended the range of products it brands for Builders Warehouse to offer an entire waterproofing solution available in the retailer’s own-name packaging, with the launch of Builders Warehouse Brick Tite, Bitumen Tite and Slurry Tite; equivalent to Sika BlackSeal-

Brick, BlackSeal-Lastic, and SikaSeal Waterproofing Slurry. The end of 2010 has seen the success of the Sika BlackSeal

range and we have no doubt that 2011 will offer the same successes with the new Builders Warehouse ‘Tite’ range.

Builders Warehouse and Sika have formed a strong alliance over the years, with the popular retailer introducing its house range made up of Sika products. H2O Tite, Damp Tite and Fibre Tite are all existing products in the Builders Warehouse own-name brand. v

Sika South AfricaTel: 031 792 6500Email: [email protected]: www.sika.co.za

shopFRonT

11

The museum’s marble and glass-clad pavilion expands the museum’s exhibition space by 4 200m2 (45 000 square ft). The single-storey building is entirely open- plan, with a generous amount of natural

light filtering through the zigzagging roof. The flexibility of the building is one of the major contributing factors to the beauty of the building because exhibitors can pick the size of their exhibitions, as one isn’t bound to a box of a certain size. There are no inhibiting columns or partitions and visitors are free to choose their own path through the space.

A sense of scale in the expansive room is retained through the repetition of small structural details, such as faint columnar forms which rise out of the blank white walls, joints intersecting on the plate glass windows and air grates which break the monotony of the concrete floor.

Natural light, which is a challenging element to master in art museums, masterfully floods the gallery via a zigzagged roof with skylights and glazed exterior walls that span the building’s width.

“If you took a sectional look at the building, you would notice that the roof is designed to cut the southern light and soak in the northern light,” Renzo Piano says. “Light is what allows you to be rather extreme or radical when you are creating a space for art, without fearing competition with the artwork because light is always good for art.”

highlighting meChaniCal ComPonentsThe building’s mechanical systems are pushed to the exterior. Technical units as well as air-handling units are housed in giant, bulbous, duct-like components that are painted bright red. At night, the glass walls that line the pavilion transform the Resnick into a lantern structure.

Director of LACMA Michael Govan comments, “The building is more than a building: it expresses a lot of the fundamental

ConCepTs & vIsIons

12

ideas about the future of the museum and the definition of the museum. We wanted a place where the whole mission of the encyclopedic museum – the patchwork of cultures, the art of all time – could be in one place. The Resnick Pavilion is about mixing art of different times and places, but for me it’s just as important to mix audiences and to take forward this idea that we have a town square, that the audiences will mix.” v

Resnick pavilion The new wing of the Los Angeles County Museum of Art, designed by famed architect Renzo Piano, was opened in October 2010. The building was named in honour of Lynda and Stewart Resnick, whose US$ 45-million donation was the lead gift in Phase II of LACMA’s transformation campaign.

Natural light, which is a challenging element to master in art museums, masterfully floods the gallery via a zigzagged roof with skylights and glazed exterior walls that span the building’s width.

ConCepTs & vIsIons

13

Lynda and Stewart Resnick Exhibition Pavilion, Los Angeles Country Museum of Art

gReen desIgn

14

nestle’s new GREEN BUILDINGNestlé South Africa unveiled its new green head office located in Bryanston, Johannesburg, in October 2010. Walls & Roofs Magazine had the privilege of an exclusive walk-through, noting some of the key green initiatives (and a number of stimulating design ideas) that the company and the professional construction team have implemented in their state-of-the-art building.

“Today the term ‘green’ is used to describe all things environment-friendly, organic and sustainable. For Nestlé, ‘going green’ is our response to the environmental challenges

facing us today and enhancing the quality of our working environment. With these goals in mind, three years ago, we embarked on this journey of constructing our new environment-friendly head office,” says Nestlé’s Corporate Affairs Director Ravi Pillay.

The new building, which took four years to complete, aims to contribute to environmental sustainability as well as offer an improved employee comfort level. The 10 480 m2 area space features cutting-edge technology which includes special glass that reduces glare, an intelligent lighting system with motion features and electronic dimmable ballasts around the perimeter of the office space. The building’s atriums have been designed to allow the lights to dim and allow natural light to filter through, thus increasing energy conservation.

The building’s air-conditioning plant has also been specifically designed to employ ammonia chillers which use 40% less energy. Heat exchange water heaters have also replaced traditional geysers.

The company has applied for a Green Star Rating for its new head office. “The awarding process takes 12 to 18 months and we are confident that we will be certified “Green” by then,” says Pillay.

The structure of the building will maintain an increase in airflow into the access floor thus ensuring comfort for staff. “We wanted

to create a building that was open and airy to provide good ventilation,” says Etienne van Wyk, Nestlé’s Technical Director.

Jaco Swanepoel, the project manager from Nestlé, comments, “One of the requirements for an adequate amount of fresh air in an occupied space is 5 litres of fresh air per person, but we upped the amount to supply 7 litres of fresh air per second, per person.”

The 10 480 m2 area space features cutting-edge technology, including special glass that reduces the glare of the sun.

The former Nestlé building, which was located less than 5km from the new site, comprised nine floors. The new head office

Artist’s impression of the new Nestlé head office in Bryanston, Gauteng. Boogertman + Partners were the architects for the project.

in Bryanston

gReen desIgn

15

was designed in a two-storey, open-space design layout. The floor plates of the building are the size of two football fields. White sound, acoustic ceilings and access floors reduce all ambient noise. “The white sound creates a humming noise in areas where people are working to reduce disturbing chatter and other common sounds in the workplace,” says Swanepoel.

Numerous pause areas, a state-of-the-art coffee bar, in-house crèche, wellness centre, baby feeding room and a gym and pet area create a healthy, friendly and comfortable office environment. Livia Wright from Beads was the interior space planner for the project.

“The new head office is a result of 4 years of rigorous research, development and hard work to ensure that our economic activity has minimum damage on the environment.” concludes Swanepoel. v

Nestlé Tel: 011 514 6000E-mail: [email protected]: www.nestle.co.za

Rainwater harvesting has been implemented to provide water for the gardens.

Natural light flows into the building from central atriums.

Screens and canopies on northern and western façades.

gReen desIgn

16

At the end of last year, the Master Builders Association unveiled their new R10,5-million “green” head office in Westville, KwaZulu-Natal. The

four-storey building’s impressive spinning wind turbines and solar panels on the roof show the organisation’s commitment to lead by example as well as create an environment for members, and the public in general, to make use of the construction-related facilities.

“We decided on the renovation because we were no longer getting the best use out of the facility. We wanted to ensure that the building and its use aligned with our objective of providing a networking and information-sharing hub for members, industry stakeholders and the public. We also wanted to reduce our ecological footprint by becoming more energy- and water-efficient,” said the Association’s Executive Director, Brandon Abdinor, to the almost 300 members who attended the opening of the building.

“It’s a ‘one-stop-shop’ for members of the Association, and will be a mine of information for the public, DIY builders and people looking for builders and building products. We believe we have created a platform for members and consumers to use to their advantage. The exhibition space will be updated continually and will supplement the long-standing advisory capability to point people in the right direction,” explained Abdinor.

Bruce Luyt of LVE Construction, who was the main contractor, said the project was challenging, particularly because retrofitting had to be carried out while the building was occupied. “There were a lot of firsts for us but a very cooperative client and friendly relationships went a long way to ensuring the success that was attained,” said Luyt.

Bruce Clark from Durban-based Bruce Clark Associate Architects, the official architects, said the objective of the retrofitting exercise was to showcase how an

existing building can be retrofitted through the use of some simple interventions.

“Everything was done in a visual and accessible manner, such as how the solar water system works, where the batteries are stored, how much electricity is being used at any time and all the other environmentally friendly products and systems that we are implementing,” concludes Clark. v

Master Builders AssociationTel: 031 266 7070Website: www.masterbuilders.co.za

Master Builders GREEN their KZN head office

GREEN fEATUREs Airconditioning and lighting have been modified to make more efficient use of natural ventilation and light. The Perspex dome atop the heat-trap atrium was fitted with whirlies expelling hot air and drawing in cool.Solar photovoltaic panels (PVs) are sandwiched between some of the glass panels that make up an extremely large portion of the building. Nearly 200 batteries store the power and inverters create usable voltage.Two six-meter-high wind turbines have been installed on the roof to assist the PVs. The system generates power for computers, essential lighting and other devices linked within the building’s electrical grid.Rainwater harvesting is achieved with six water tanks capable of storing 30 000 litres which provide water for the lavatory cisterns and for the roof garden during periods of no rainfall.

Above: Francois Louw, President of Master Builders KZN, prepares to cut the ribbon officially marking the opening of the new facility with Executive Director Brandon Abdinor.

gReen desIgn

17

The new Ridgeside office development on Umhlanga Ridge, which Grinaker-LTA recently handed over to client The Umhlanga Rocks Property Trust, has the proud distinction of being only the second building

in the country to receive a Four Star rating for its design from the Green Building Council of South Africa (GBCSA).

This development, which was designed and built in accordance with the specifications set out by the GBCSA, also attained the highest design score ever achieved in the Green Star ranking – a total of 55 points. Ridgeside is an upmarket, four-storey office block with a three-level parkade. The total construction area was 30 183 m2.

Environmental considerations are also high on the agenda for Grinaker-LTA on a new project in Montague Park, Cape Town. The contractor’s R156-million contract to build a new Makro store here will see it recycling waste materials and keeping a vigilant eye on the nearby Duikersvlei, which was rehabilitated as part of Montague Park’s development, and forms one of the green spaces in this eco-friendly commercial and industrial park.

“As a member of the Green Building Council of South Africa, we are very proud to be part of these green building projects, and have the opportunity to demonstrate our commitment to this form of construction,” comments Grinaker-LTA executive director Neil Potgieter.

He notes that the site of the new Makro store is an old fertiliser factory, which was an eyesore and a pollution irritant in the area,

so the removal of this will, in itself, be a great change for residents and businesses in the surrounding areas.

“Environmental management is a prerequisite for this project, and we are ensuring that all the stipulations are met,” he adds.

Potgieter also stresses that Grinaker-LTA and the developer, the Eris Property Group, are committed to protecting and preserving Duikervlei. This ecologically sensitive area has, since its rehabilitation, attracted an abundance of bird life to the park. The project is due for completion in October 2011. v

Grinaker-LTATel: 011 578 6200 Fax: 011 578 6384 E-mail: [email protected] Website: www.grinaker-lta.com

Committed to keeping it “GREEN”

Ridgeside is an upmarket, four-storey office block with a three-level parkade.

gReen desIgn

ENGINEERING for education

At the SSI ‘Engineering for Education’ function held in Pretoria during the first week of February, master of ceremonies John Robbie said, “Education is about caring and the Lead SA campaign is about

partnerships between the Private Sector and Government, and with this initiative SSI is part of Lead SA.”

Representing the Minister of Basic Education, Mrs. Angie Motshekga at the function, Deputy Director- General for Basic Education Paddy Padayachee expressed the Department’s heartfelt gratitude to SSI for the sterling work to date that goes a long way in improving education in South Africa.

He said it was clear that SSI is passionate about uplifting education and skills transfer in the country, and reported that the learners supported by SSI had gained 39 distinctions and that two students from Soshanguve had achieved three distinctions each, in Maths, Science and Engineering Graphics & Design.

“SSI has risen to the challenge of effectively addressing the country’s technical skills shortage being fundamental to the survival of a developing nation,” he said. “This initiative is evidence of how we can work together and SSI has shown this through investment in the young, as mentoring is a critical learning intervention.”

He also commended SSI’s CEO for setting up and pioneering the programme and congratulated the company on its commitment to education in South Africa.He concluded by stating, “Working together we can do more to achieve quality education for all. Partnerships between business and government are crucial to the development of our country.”

Naren Bhojaram, CEO of SSI and headmaster of its Saturday Schools Initiative, believes that education is the soul of our country and that it is vital that we nurture our intellectual capability. When asked why SSI started its Saturday Schools programme, he replied, “Because we care and we are committed.”

SSI’s Saturday Schools Initiative aims to ‘polish’ students from underprivileged backgrounds who have shown potential, with additional mentoring and tutoring provided by qualified engineers from SSI, to achieve university entrance in the subjects of maths, science and engineering graphics & design.

SSI engineers and environmental consultants established its Saturday School Initiative with just one school and about 25 students in Alexandra, Gauteng, following a call in 2006 to the ‘captains of industry’ from the then deputy-president, Phumzile Mlambo-Ngucka, for the private sector to ‘get involved’ in addressing the parlous state of education and lack of technical skills in the country.

The initiative has grown; more than 170 students from 18 different schools now attend the SSI Saturday School initiative, operated from six of its branch offices around the country.

Attendance at the Saturday School is free of charge; attendees are selected in conjunction with day school heads of departments,

the school’s principal and the pupil’s parents. School administrators and teachers are volunteers from SSI’s

own ranks of professional engineers, technicians and scientists, and lessons are conducted at the pupils’ day schools in Alexandra, Bloemfontein, Cape Town, Durban, Pietermaritzburg and Pretoria. SSI allocates more than R1-million annually to support the initiative and intends to add more centres in the future. v

SSITel: 011 798 6522E-mail: [email protected]: at www.ssi-dhv.com

Naren Bhojaram of SSI congratulating Thabiso Baloyi, Saturday School Student; and Deputy Director-General of Basic Education Paddy Padayachee at the ‘Engineering for Education’ function held in Pretoria where the Ministry of Basic Education expressed its heartfelt gratitude to SSI

18

A WORLD RECORD

World’s Tallest Building: the Burj Khalifa (formerly Burj Dubai) opened on 17 Jan 2009 at 828 m, the tallest building ever, and the one with the most floors - 160 storeys. If the Mile High project in Jeddah ever gets completed, this will top out at 1 600m!

gReen desIgn

19

Camco, an international company specialising in climate change solutions, and Trade & Industrial Policy Strategies (TIPS), an independent economic policy research institution, recently released a case

study entitled the ‘Construction Industry’s Path towards a Low Carbon Trajectory’ with funding from the British High Commission. According to the case study, the South African construction industry has been increasingly focused on both the introduction of green practices and on energy-saving technologies.

Globally, the building sector is said to contribute more than one-third of total energy use and associated greenhouse gas (GHG) emissions in society. Major South African construction companies, such as Group Five and Murray & Roberts, are starting to pursue green practices and projects. This has, in some cases, involved voluntary compliance with the Green Building Council of South Africa’s (GBCSA) Green Star South Africa Office rating tool and the implementation of energy efficiency and demand side management measures.

Recent media reports have also indicated that some construction companies (including Group Five and Aveng) are moving quite discernibly into renewable energy (RE)

developments in the hope that they can secure a share of the renewables allocation under the Integrated Resource Plan (IRP) for electricity. In this regard, Group Five has set up a specific new unit which deals with RE projects and Aveng has recently appointed an environment manager for the Group. Aveng is particularly positioning itself around wind and solar energy for bids that will emerge in this sector in the near

future. Murray & Roberts have also adopted a new environment-friendly asphalt technology (Much Asphalt) that saves energy.

“A few key trends currently pertain to the construction sector as set out by Group Five and as observed for other firms in the sector. These are taking place in terms of complex changes which are setting the scene for changes in construction practices, an increased focus on the environment and the introduction of greener practices and technologies. However, clarity is required from the South African authorities in terms of environmental priorities as these influence the type of interventions, investment and training in which construction firms need to engage,” reads the case study. v

Camco GlobalTel: 011 253 3400E-mail: [email protected]: www.camcoglobal.com

TIPSTel: 012 431 7900 Email: [email protected]: www.tips.org.za

Local construction firms shIfTING fOCUs to green projects

For 85 years, Bayferrox iron oxides manufactured by Lanxess at its Krefeld-Uerdingen site in Germany have been adding colour to building projects around the world. Since production started back in 1926, over 12 million metric tonnes of these high-quality colour pigments have left the Lanxess plant on Germany’s River Rhine, which is the biggest plant of its kind in the world.

This makes Lanxess one of the world’s largest manufacturers of these pigments, and mounting global demand will necessitate further capital expenditures at all production sites.

The main beneficiaries of this are the construction industry and the surface coatings segment, which are among the biggest customers for these pigments. “For these industries, our pigments are absolutely indispensable because of their lightfastness,

weather stability, chemical resistance and environmental friendliness,” says Jörg Hellwig, head of the Inorganic Pigments business unit. “The product range now contains well over 100 different colour shades – and the number will continue to grow.” v

Lanxess (Pty) Ltd Tel: 011 457 4019 Fax: 011 457 4008 Email: [email protected] Internet: http://www.lanxess.com

SUSTAINABLE GROWTH for a global group of customers

hIgh-speC pRoduCTs

20

FeaTuRe

Facility managers: sourcing, specifying & designing for high-traffic zones

Facility managers can be seen as the people who connect the clients, electricians, cleaning companies and development managers to the design professionals, specifiers and architects. Sourcing the right products for high-traffic zones and ensuring that the right knowledge is received and transferred isn’t without its difficulties. Walls & Roofs takes a look at what real challenges and opportunities face the facility managers, specifiers and development managers behind some of South Africa’s biggest projects.

duRability, aesthetiCs and CleaningKulani Lebese, Head of Facilities Management at Growthpoint Properties (the largest JSE-listed property company in South Africa), says that facility managers are generally concerned with three things when it comes to choosing products that work for them as well as their tenants: durability, aesthetics and cleaner-friendly products. In order to ensure that tiles, cladding, lights and other services don’t need continuous maintenance, it is also essential that facility managers, architects, specifiers and cleaning companies communicate throughout the building or refurbishing process, says Lebese.

“Some of the most common product failures occur, for example, when new products are specified and the cleaning company isn’t informed about the correct cleaning methods. Another example is when the correct product is specified but it is installed incorrectly. When we choose product, we involve people from all areas of the project to analyse our options and determine what works and what doesn’t,” says Lebese.

univeRsal design: how faCility manageRs Can get it RightThe principle of universal design for high-traffic zones and corporate offices is based on the simple idea of “making it easy for your employees or customers to get what they need”. Although the concept of universal design is sometimes confused with principles of designing for the disabled, universal design means giving the building owners a competitive edge for their tenants and their tenants’ visitors.

DeAnna Radaj, a design consultant from American company Bante Design, says that facility managers have a unique place in implementing universal design. “By implementing its seven principles, it makes the job of facility managers and many of their duties easier. If the design scheme is done properly in the first place, the space’s occupants and any visitors can easily get around,” says Radaj (www.lowesforpros.com).

Radaj was referring to the seven principles of universal design which are: 1. Equitable Use; 2. Flexibility in Use; 3. Simple and intuitive use; 4. Perceptible information; 5. Tolerance for error; 6. Low physical effort; and 7. Size and space for approach and use.

“Implementing these changes can help reduce vacancies in properties as occupants may have to find other, more accessible, spaces as the need arises. It also adds value to the property itself, making it more marketable in a tough economy, as you are able to market property to a wider, diverse population group,” says Radaj.

Juan Herrero, a development manager at Growthpoint Properties, says that universal design basically boils down to enabling building tenants to maximise their spaces. “Some companies may be considering downsizing and the changes in their spaces need to be taken into account during the planning phase. A lot of companies are also opting for open-plan offices and facility managers have a great role to play along with interior designers and space planners to ensure that the services in the building work with the new office design,” says Herrero.

Herrero says that while space planners determine the office layout, development and facility managers need to analyse what will be needed to make sure all the employees have electricity outlets and airconditioning in the right spaces.

“If you are changing a corporate office from a cellular layout to an open-plan layout, you are basically knocking down a lot of walls – someone who was sitting at a desk next to a wall with a plug may suddenly find himself in the middle of the room, 15 m away from the nearest electricity point. Instead of having leads and cables across the floor, you can plan for the electrical supply cables to go through the ceiling cable trays – if your ceilings allow this type of service outlay – or you can install raised floors with

cable trunking running underneath,” says Herrero.“Similar problems can also arise with airconditioning when

moving from a cellular layout to open-plan. When you take down walls that used to separate people in an office, you may be creating hot and cold spots and you need to balance the difference in temperature,” says Herrero.

“Getting everyone involved in the planning process can save a property development company a lot of money,” explains Lebese. “Facility managers deal with the real problems of maintaining buildings, so they have in-depth knowledge of which products have a shorter or longer lifespan or high maintenance. Getting facility managers involved from the get-go is a sure way to get the most value out of your development or refurbishiment of buildings,” says Lebese.

hIgh-speC pRoduCTs

21

FeaTuRe

hIg

h-s

pe

C p

Ro

du

CT

s

WhAT Is UNIVERsAL DEsIGN?“Universal Design is the design of products and environments to be usable by all people, to the greatest extent possible, without the need for adaptation or specialised design.” – Ron Mace, one of the original Universal Design Movement leaders.

According to Universaldesign.com, it is the process of embedding choice for all people in the things we design.• Choiceinvolves flexibility, and multiple alternative means of use and/or interface.• Peopleinclude the full range of people regardless of age, ability, sex, economic status, etc.• Thingsinclude spaces, products, information systems and any other things that humans manipulate or create.

Above: Getting everyone involved in the planning process can save a property development company a lot of money.

high-spec products

22

FeaTuRe

sPeCifying the Right PRoduCts“Architects generally come up with the idea and specify products, then our development managers and facility managers start looking at the spec sheets. For example, when going through the specifications, among others questions asked is, Will the cleaning company need specialised equipment to clean the walls or floor tiles or is it an environmental friendly product?” asks Lebese.

“During product specification, we use the term ‘value engineering’ a lot. For us, this means looking at the value of a product and determining whether it can be compared to another, more cost-effective, product. We often find there are products available that are better in quality and more reasonable in cost.” Lebese also warns against specifying new or unfamiliar products. “We’ve had problems with manufactures which have stopped producing a specific product that was introduced into the market, making it difficult to source the correct product if it needs to be replaced,” says Lebese.

When it comes to aesthetics, Lebese explains that while interesting colours may be a great idea for home renovations, this isn’t always the case when creating workable environments for corporate offices.

“New corporate offices and refurbishments want to be cutting-edge, so it’s important to keep the look modern and trendy while ensuring the products last a long time. This is done not only to create a workable environment for the tenants, but also to “future-proof” the building so that one doesn’t have to refurbish the property every three years,” says Lebese.

who’s souRCing the sustainable PRoduCts?Andrew C. Hillman, former MD of Bespoke Sourcing Solutions and former MD of renewable energy company Bioenergy Africa, says that green procurement is an approach to procurement in which environmental impacts affect important purchasing decisions, not only price and quality. “Sustainable Procurement involves organisations practising procurement with a view to maximising net benefits for themselves and the wider world. Extrinsic cost considerations must be incorporated into decisions alongside the conventional procurement criteria of price and quality and are typically divided into the following groups: environmental, economic, and social, also known as the ‘triple baseline’, says Hillman.

One can argue that green product specification and green cleaning are among the “lowest-hanging fruit” for facility managers, but Lebese explains that different models need to be taken into consideration to make sure owners will see a return on their investments. “We have a duty to give clients options when it comes to energy-efficient products and products with a lower carbon footprint, but we look at various models so that tenants can see savings in their utility bills,” says Lebese.

Jennifer Steyn, Absa Sustainability Program Manager, says there are various things that a green procurement policy should include. “There are statute-driven objectives that we must meet, and then there are objectives that can only be reached by being true to our leadership principles. South African environmental and other issues are very different from the ones faced by Europe and the USA. Our approach, therefore, needs to take this into account so that we may succeed in taking care of our environment and our people,” says Steyn.

saving eneRgy veRsus woRking in the daRk?Herrero adds that specifying energy-efficient lights for shopping centres or corporate offices may reduce energy bills, but facility managers are also tasked with ensuring adequate lighting levels throughout the building – regardless of whether the tenants are saving money or not.

“Office environments have a very high level of occupancy during office hours and certain lux levels are needed for corridors, boardrooms, bathrooms and desk areas. When specifying energy-efficient lights, one needs to make sure that the necessary light levels are achieved throughout the building,” says Herrero.

Luke Osburn, former researcher at the CSIR Built Environment unit, says that fluorescent tubes should always be used where possible as they use roughly a quarter of the power that incandescent bulbs require to produce the same amount of light.

“Because the fluorescent tubes are more energy-efficient than the incandescent bulbs, they also produce significantly less heat which means that a smaller HVAC system is required and less energy is required from the HVAC systems to maintain a comfortable temperature and working environment,” says Osburn.

Various fluorescent tubes are available and care should be taken that the most appropriate fluorescent tubes are installed for the given application. High performance T8s (Super T8) are appropriate for most office environments and are able to produce up to 100 lumens per watt. T5s offer similar efficiency performance when compared to T8s but, because they are smaller, they offer better optical control. T5s are a more appropriate choice if they are to operate in a warm or enclosed space as they offer a higher level of performance than T8s at higher temperatures. T5s can also operate more efficiently; however, they are significantly more expensive than T8s.

Above: Herrero adds that specifying energy-efficient lights for shopping centres or corporate offices may reduce energy bills.

high-spec products

23

FeaTuRe

“Care should be taken to ensure that an interior space is not lit beyond what is required, so that only as much light as is required is produced and therefore no light is wasted. The Green Star SA rating tool recommends that lighting levels within office spaces are kept below 400 lux, while SANS 204 recommends a lighting level of 300 lux for low-risk commercial space. Operating in the range between 300-400 lux will provide sufficient lighting for conventional office tasks while not wasting energy,” says Osburn.

sPECIfyING DOORs AND LOCks fOR sECURITy“Managers expect long performance life from door hardware, even though some components in high-traffic areas are subject to probably the most repetitious cycling of any components in buildings. Specifiers demand that manufacturers design durability into each application following rigid architectural standards that should be included in specifications to ensure a proper balance between function and cost,” says Thomas A. Westerkamp, author of Maintenance Manager’s Standard Manual.

“Use can vary from a few cycles a day for hotel and dorm rooms to many thousands for airport entrances, large office buildings and department stores. The operating grade – grade 1 being the most robust – tells a specifier the level of service to expect. The grade must be appropriate for the operating cycles per day and yearly average for the application. For example, a large department store entrance can experience 1,5 million cycles per year. Less robust grades might cost less, but they will not be the lowest-cost solution in the long run and certainly will result in more maintenance time and user inconvenience,” says Westerkamp.

In an article entitled Door Hardware: Specifying For Security, Westerkamp writes that facilities continue to shore up their security measures in order to provide greater protection for both occupants and operations. “As central components these efforts, door locks, handles, hinges and operators are under increasing pressure to perform reliably in the most demanding conditions,” says Westerkamp.

When specifying for schools, universities, hospitals, and government and commercial buildings, one must ensure these components are able to deliver the intended benefits over the long term. Westerkamp says that, besides meeting the necessary building codes and standards, door hardware for high-traffic zones also need the following key features: an aesthetically pleasing look; durability consistent with the level and severity of use; robust designs that require minimal maintenance; support for building safety and security; and ease of use.

loCksMortise locks: • These locks are popular for high-traffic applications, such as entrance doors, where security is a major concern. The components of the lock are typically housed in an enclosed, wrought-iron cast that fits in a routed opening in the edge of the door. A newer variation of the mortise lock is the three-point mortise lock that has two additional hook bolts – one above and below connected by a bar to the centre case – that provide more rigid locking and added security. Roses (also known as rosettes):• These locks can be installed on both cylindrical and mortise lock handles on the faces of doors and covering the face holes. If added security is needed, managers can specify heavy-duty metal escutcheons.

handlesIn healthcare and educational buildings, facility managers can specify silver-based, anti-microbial agents in the hardware finish coating (this coating guards against algae, mildew and bacteria, and it can remain active for the life of the hardware).

hingesInstallation method, location and play an important role in security, and facility managers must consider height, weight, thickness and trim dimension when specifying these products. “The standard hinge location is 5 inches (12,7 cm) from the top door jamb rabbet to the top of the hinge barrel, and 10 inches (25,4 cm) from the bottom edge of the bottom hinge barrel to the finished floor surface. Additional hinges are evenly spaced between the two. One hinge every 30 inches (76,2 cm) is standard. Doors up to 60 inches (152,4 cm) high would require two hinges, those 60 to 90 inches (228,6 cm) high require three hinges, and those 90 to 120 inches (304,8 cm) high require four hinges,” writes Westerkamp.

“A new generation of improved electric-powered hinges link power from the in-house distribution system through the hinge to electrified door hardware. Power remains available regardless of door position, and the position is monitored from remote locations.These locks provide important security benefits, as well as essential data for creating an audit trail, including name, identification number, date and time, of all people who enter and leave a building. Selectable activation options include keypad, proximity sensor and radio frequency identification,” continues Westerkamp. v

Walls & Roofs would like to give thanks and acknowledgement to Thomas A. Westerkamp, DeAnna Radaj, Kulani Lebese, Juan Herrero, Luke Osburn, Andrew C. Hillman, Jennifer Steyn and Jaclyn Lovell for information contained in this article.

high-spec products

24

Incorporating a high-level conference and a design-led exhibition, Design in Hospitality (DiH) focuses exclusively on the hotel and hospitality industry, and is set to become the must-attend event for the

hospitality and design world, while giving designers and other decision makers the opportunity to grow their understanding of industry trends and to connect with their peers.

“From check-in to sleeping to bathing to eating, modern hospitality concepts need to excite, seduce and sell, and do so by balancing aesthetics with the financial,” says Cairey Slater, general manager for the project. “These are challenging, yet exciting times for the hospitality design industry as hotels are undergoing a transformation which will see their range of offerings go far beyond the basic services of accommodation and food.”

Sustainability will be integrated throughout all aspects of the event, joined by ethonomics, one of the most impactful trends emerging on the hotel design scene. Technology and connectivity will also feature strongly.

Held during the exhibition, the two-day DiH Conference, themed Designing the ultimate away experience, forms the core of the event, providing delegates with essential advice and updates from this sector.

A line-up of international industry design experts and local leading lights will share their insights on trends in their field and discuss their vision in the context of the hospitality world. Conference sessions on Day 1 will focus on hotel development and interior design; while those on Day 2 will concentrate on designing facilities and services, as well as food design.

Cairey points out that choosing The Forum at the Turbine Hall as the venue for the conference is in sync with the conference’s experience-rich ethos. “This landmark building, which started its life as a power station in the 1920s, has been transformed into a magnificent space with excellent facilities in the heart of the arts and culture precinct, Newtown.” For more information contact Samantha van den Berg, events and special projects, on [email protected]

Back By popular demand, conversations on architecture:Architects for change will be presented by Thebe Exhibitions on 18 March 2011 at the Durban International Conference Centre

Hailed as an annual networking and insight highlight, COA 2011 boasts an extended programme hosted by Hugh Fraser and featuring a stellar line-up of guest speakers including Mick Pearce, Claire Janisch, Sean Mahoney, Peter Stutchbury, George Elphick and Joy Brasler, which means that delegates can expect to be engaged, educated and inspired as today’s leading minds take to the floor and share opinions and insights in an open-discussion format.

divided into two sessions, the toPiCs of disCussion aRe: Sustainability and Environmental Responsibility: While the greening movement gains momentum, our experts explore whether the concept has become passé as ever-evolving new technology, practices and principles are implemented. Or

are we simply entering into a consistently sustainable ‘built lifecycle’ where novelty is no longer part of the picture? This will provide a platform for interesting debate, begging the questions: Where have we been? What have we learnt? Where to next?

Biomimicry: Where nature and architectural innovation meet. Considered a relatively new discipline that has evolved as an architectural practice on the rise, COA will delve into the significant strides being made through biomimicry in architecture.

As this practice gains momentum, our experts explore whether we’re using nature’s extraordinary examples to our best advantage or are we simply skimming the surface?

Conversations with our keynote speakers will provide stunning examples of successful biomimicry in practice, with a look at the process from inspiration to completion.

To book, visit decorex.co.za or contact Nicola on e-mail: [email protected]. This conference is in the process of being assessed and validated by the South African Institute of Architects for between 0.5 - 1 CPD credits.

New Design in hospitality expoThebe Exhibitions & Projects Group has announced the launch of Design in Hospitality, the first conference of its kind to be held in South Africa, taking place in The Forum at Turbine Hall, Newtown/Johannesburg, from 7-8 July 2011.

7 - 8 J u l y 2 0 1 1

high-spec products

25

high-spec products

26

MCC, which is well known for supplying specialised products suited to local markets, has developed the All-In-One range to give contractors a solution that enables the

adhesive to not only stick to tiles, but also grout at the same time. Available in selected colours only.

why all-in-one light weight tile adhesive?Labour saving• : The new product line incorporates three main benefits because the All-In-One is a grout,adhesiveandwaterproofproduct. This provides a substantial costsaving to labour, as tiling can be completed in one day rather than the industry norm being two to three days.Waterproof• : Waterproofing products such as torch-on and flurry sealed systems are often very expensive and time consuming. Such systems are not necessary as All-In-One is waterproof and can be used in interior and exterior conditions such as bathrooms, kitchens, patio’s etc.100% Active• : Tile adhesives are commonly packaged in 20Kg

bags, where over 60% of the product consists of fillers (such as sand). MCC’s All-In-One light weight adhesive provides 100% active material in their 15Kg packaging. MCC All-In-One will cover approximately 3.5m² of adhesive and grout.Transport savings• : The cost of transport becomes a challenge when transporting construction products to and from sites. Approximately 25% can besavedon transportation costs by using MCC light weight tile adhesive range, due to the fact that more bags can be transported per load and no transporting of grout is necessary.

ContRaCtoRs oPinionHarry Smit, project manager at Dykor tile centre, recently used the new All-In-One tile adhesive and grout on a project.“ We used MCC All-In-One 500 light weight and we were extremely pleased with the result. The All-In-One is an exceptional product, as not only is it more cost effective than the traditional adhesives but I didn’t have to use a torch on system either, which allowed me to concentrate on other areas of the site,” said Smit.

ALL-IN-ONE light weight tile adhesive

adveRToRIal

1 2 3 4

Multi construction chemicals (MCC), a company which has been in the industry for over 25 years, has developed an All-In-One tile adhesive range that will revolutionise the way tiling is done in the industry. The new adhesive sprouts from MCC’s highly successful light weight adhesives and incorporates MCC’s vision in developing technology driven adhesives for the tiling market.

high-spec products

27

The new technology that has been incorporated into this new range of light weight tile adhesive offers excellent workability and has a 3-5 year manufacturers guarantee when instructions are followed.

all-in-one tile RangeAll-In-One 500 Light Weight• : A general based tile adhesive suitable for fixing standard ceramics tiles.All-In-One 510 Light Weight• : Provides a professional finish that is technically superior to 500 light weight. It is recommended for challenging jobs due to its improved bond strength.All-In-One 530 Light Weight• : A high-strength tile adhesive for

fixing not only standard ceramics tiles but also porcelain and granite tiles, giving peace of mind.

Other products within MCC’s range include concrete admixtures, curing compounds, various epoxy’s joint sealants, floor hardeners, concrete grouting and many more. MCC has branches in Gauteng, Polokwane, Rustenburg and Durban. v

Multi Construction ChemicalsTel: 011 864 4654Fax: 011 864 4406E-mail: [email protected]: www.mccsa.co.za

adveRToRIal

5 6

Other products within MCC’s range include concrete admixtures, curing compounds,

various epoxy’s joint sealants, floor hardeners, concrete grouting and many more.

End product

Sika’s robust concrete admixtures have been used to strengthen the concrete structures of many large and illustrious buildings so it is no wonder that their reputation precedes them, to the extent that nothing else would do for the construction of thousands of rural VIP precast toilets for the City of uMhlathuze.

The MIG-funded project (entitled: Rural Sanitation Phase 2: Mkhwanazi South/Dube, uMhlathuze Municipality), appointed contractor Rocla, and instructed the manufacture of 5 750 VIP toilets.

These custom-built toilets were for distribution throughout the Mkhwanazi South/Dube Traditional areas within the City of uMhlathuze’s area of jurisdiction (140 square kilometres), for the improvement of hygiene services in the local community as well as for environmental purposes.

Sika’s admixtures, Viscocrete-3088 (2 000 litres) and Viscocrete-20HE (5 000 litres) were supplied to the project for use in the manufacture of precast slabs for the toilets.

Viscocrete-20HE, a high-performance, third-generation superplasticiser which is especially suitable for producing concrete mixes which require high early-strength development, powerful water reduction and excellent flow characteristics, was used to construct an early stem for the precast slabs.

Sika Viscocrete-3088, a high-range, water-reducing concrete

admixture, was used to increase the workability time. Unskilled local labourers were trained on site by Rocla to

construct a high early-strength of precast to accelerate the production time. This ensured the slabs would be set by the following day, in readiness for stripping for the next part of

production of the toilets. Sika MonoTop-610 was used for coating the steel

reinforcement bars inside the slabs. This cementitious, polymer-modified, one-component, bonding slurry and anti-corrosion reinforcement primer was applied to the steel bars as corrosion protection, as it offers excellent adhesion to concrete and steel, and provides good resistance to water and chloride penetration.

Thanks to Sika, an excellent quality was achieved in the production of these new sanitary systems and a special handover of the first toilet was conducted by the City of uMhlathuze.

The residents of the Mkhwanazi South/Dube Traditional areas were overjoyed at the opening ceremony of the toilet distribution project heralding the installation of the 5 750 concrete toilets, which will bring a new level of sanitation to their lives, uplifting their community’s hygiene and environmental standards forever.v

Sika South AfricaTel: 031 792 6500Email: [email protected]: www.sika.co.za

Sika strengthens sanitation Project in Richards Bay area

high-spec products

high-spec products

29

RETAINING WALLs at interchanges

Traffic interchanges are structures that use grade separation with ramps to facilitate rapid flow of traffic in various directions without any traffic stream directly crossing another. Interchanges become

unavoidable when regular traffic increases; they cost a fortune and often have to be squeezed into a tight space. The result is that creative engineering design has to be employed, demanding cost-effective retaining structures that can be built rapidly while offering a safe and long-lasting solution.

Mechanically Stabilised Earth (MSE), an ancient technique of using artificially reinforced earth to build stable retaining walls, is one of the prominent methods employed during construction of such interchanges.

Today, this method is well understood, tested and employed on numerous sites around the world. It is relatively easy to adapt the height and inclination of such retaining walls, depending on what type of system is being used.

Versatile Terraforce blocks are very popular for such applications. They offer the advantage of being hollow units that can be filled with crushed stone or concrete if required, while no connectors between blocks or to anchor the reinforcing material are required, which has a pull-out resistance of above industry standard.

Two interchanges using the Terraforce system were recently completed in Dubai. The first, the Mirdif interchange, is situated at the intersection of Al Khawaneej and Algeria roads in the residential area of Mirdif in Dubai and was designed and constructed to replace the existing one which could not accommodate increasing traffic volumes, generated by the devel-

opment of surrounding areas. The limited space available neces-sitated steep side slopes which were retained with Terraforce L16 (split-face) composite retaining walls and vertical Freyssinet panel retaining walls, thus minimising impact on surrounding land and facilities.

The Terraforce blocks were used to support both sides of the four ramps, as well as the approaches to the crossroads. A total of 9 300 m² of Terraforce walling was installed, reinforced with For-trac 35/20-20T geogrids with heights of between 0,5 m and 4 m.

Construction of this ZAR500-million project commenced in 2007 and was completed in Dec 2009. The second interchange, Jebel Ali, was completed shortly thereafter. v

TerraforcePhone: 021 465 1907Fax: 021 465 4047Website: www.terraforce.com

high-spec products

30

The Medupi coal-fired power station in the Limpopo province is a significant part of Eskom’s expansion program.

Construction of Medupi started in November 2008 and it is currently the largest construction project in Southern Africa, covering some 883 hectares and comprising 6 units rated at 4 788 MW installed capacity. The boiler and turbine contracts for Medupi were the largest yet signed by Eskom in its 86-year history.

ConstRuCtion ChemiCals at meduPiAn extensive range of a.b.e. Construction Chemicals products are being used in the construction of Eskom’s massive new Medupi power station at Lephalale.

a.b.e. – a Chryso Group Company – is supplying waterproofing, flooring and sealants, as well as general construction products for the building of the coal-fired power plant. Some of the waterproofing products used at the construction site include the following:

super laycryl professional liquid waterproofing compound•

super laykold rubberised bitumen emulsion •

ecofelt fibre material•

duraslurry cementitious slurry •

duraflex flexible waterproofing slurry •

Flooring and sealant products being supplied by a.b.e. include aberep cement floor repair mortar, DC 888 low-modulus silicone joint sealant, durasheet backup material, abecote epoxy tar coating, and durakol G LM polysulphide elastomeric joint sealer.

Among the a.b.e. general construction products now used at Medupi are durajoint rubber waterstops, abecote SF356 epoxy tar coating and binder, epidermix lightweight epoxy mortar, and plastergrip adhesive for the enhancement of cement screed bonding.

Medupi, which means “rain that soaks parched lands, giving economic relief”, is scheduled to commission power station units at nine-monthly intervals, in line with international practice. The first unit is scheduled to be commissioned in 2012, with the last unit scheduled for commissioning by 2015. v

a.b.e. Construction Chemicals Tel: 011 306 9000 E-mail: [email protected] Website: www.abe.co.za

Construction CHEMICALS

used at Medupi Power Station

Medupi is currently the largest construction project in Southern Africa, covering some 883 hectares and comprising 6 units rated at 4 788 MW installed capacity.A local Chryso Group Company is supplying waterproofing, flooring and sealants, as well as general construction products for the building of the coal-fired power plant.

high-spec products

31Solar Shading Industries is the sole Southern Africa distributers of Colt Solar Shading Systems Technology and Products

GAUTENG

Chris Edwards: 082 855 9776Email: [email protected]

Eric Whelan: 082 452 2257Email: [email protected]

KWA ZULU NATAL

Email: [email protected]

Fixed Solar Shading Systems Fixed & Controllable Solar Shading Acoustic Louvres

Glass Solar Shading Systems Screening Louvres, Rain Defence & Performance Louvres

glass & alumInIum peRFoRmanCe

32

FeaTuRe

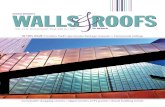

Trends and innovations in

ARCHITECTURAL glass & aluminium

the eneRgy sPaCe and thiRd wave in PhotovoltaiCs“Dangers of the remarkably fast-increasing energy demand of humankind are regularly highlighted in different media. One part of the threat is the exhaustion of non-renewable sources of energy; another part lies in the danger of carbon-dioxide emissions. Therefore it is in everyone’s interest to minimise the energy consumption of buildings. Current methods include optimising thermal insulation of buildings and passive architectural use of solar energy, through appropriate orientation of buildings for example,” said Kevin Moens, marketing manager from Solutia Europe.

Moens has over 8 years of technical and application expertise for architectural glazing as well as expertise in BIPV (building integrated photovoltaics) and thin-film PV encapsulation. Moens was speaking at Glass Africa Expo, which was held in Johannesburg in September 2010.

In the past, PVs were seen as something that could be used to generate electricity, but new technologies and advances in the industry have lead a number of researchers, PV manufacturers and design professionals to start to see PVs as a by-product of a multifunctional building. Instead of judging PVs purely on their ability to product power, one would also be able to judge the

material by looking at other criteria, such as design and structural integration flexibility.

“There’s a growing interest in building integration of PV technologies from both PV suppliers and building designers alike. BIPV only accounts for 3,7% of PV installation up to 2013,” says Moens.

Building Applied Photovoltaics (BAPV) refers to solar modules added to buildings after the construction phase. BAPV is generally considered a retrofit project.

Building Integrated Photovoltaics (BIPV) refers to integrating solar modules into the envelope and it has a dual role of being a building material and power generation system.

“Some of the key challenges concerning BIPV in the building industry include the lack of standardisation in BIPV products, integration expertise, regulation development and understanding as well as a need for new materials,” says Moens.

Organic Photovoltaics (OPVs) and dye-sensitised solar cells (DSSCs) are collectively referred to as third-generation PV technologies. According to www.plusplasticelectronics.com, as third-gen PV technology advances in terms of performance and other factors, architecturally attractive uses of PVs in the building fabric will become more commonplace.

High-performance glass and aluminium is an ever-changing niche in the professional design industry. At the beginning of the New Year, Walls & Roofs generally likes to look at the up-and-coming trends, recent high-profile projects and what professionals in the industry can look forward to. In this edition, we take a look at third-generation PV in structural glass, innovations in safety glass and some amazing international and local projects.

Picture: The enclosure is filled withdaylight due to the glass domes. Panes were fritted to avoid unnecessary heat gain. Source: www.english.dac.dk

glass & alumInIum peRFoRmanCe

33

FeaTuRe

gl

as

s &

al

um

InIu

m p

eR

Fo

Rm

an

Ce

“Unlike bulky and rigid traditional, silicon-based solar cells, third-gen PVs can be made lightweight, flexible and translucent. They can be produced in different colours and patterned, resulting in additional smart design opportunities for the integration of the PV into the building shell,” Ingo B Hagemann, architect and BIPV consultant, told www.plusplasticelectronics.com.

“The new design features of third-gen PV correspond well with current trends in architectural design, such as intensive use of colours, the use of (multimedia) screens and patterns for building façade designs. The technology also supports the rediscovery of the moulding of complex curving forms, which is a result and expression of contemporary architectural practice in which digital technologies are radically changing the way buildings are conceived, designed and produced. Printing, coating, vacuum processing and other simple, low-temperature and low-cost production processes are being developed to fabricate third-gen PVs, which will make them less costly to manufacture,” said Hagemann (www.plusplasticelectronics.com).

BIPV (Building Integrated Photovoltaics) refers to photovoltaic systems integrated with an object’s building phase. It means that they are built/constructed along with an object. They are also planned together with the object. Yet, they could be built later on. Specific task cooperation of many different experts, such as architects, civil engineers and PV system designers, is necessary. According to how and where such systems are built, whether into the facade or in the roof, the following BIPV systems are recognised:

FaVade or roof systems added after the building •was builtFaVade-integrated photovoltaic systems built along •with an objectRoof-integrated photovoltaic systems built along •with an object“Shadow-Voltaic” - PV systems also used as shadowing •systems, built along with an object or added later

Source: www.pvresources.com

Above & below: The Incheon Airport in Seoul, South Korea, demonstrates the trend for curved, structural glass. Source: www.revolutiondata-cms.com

Above: The Visionaire building in New York City features faVade-integrated photovoltaics at the mechanical bulkhead, with custom modules using blue polycrystalling cells. Source: www.cahncomm.files.wordprses.co

glass & alumInIum peRFoRmanCe

34

FeaTuRe

new tyPe of blast-Resistant glassThe US Department of Homeland Security’s Science and Technology Directorate has given a team of engineers from the University of Sydney in Australia and the University of Missouri the opportunity to create a new form of blast-resistant glass.

“Whether in a hurricane, tornado, or bomb attack, a leading cause of injury and death is often fast-flying shards of glass. Explosions and high winds can cause windows in buildings to shatter – spewing jagged pieces of glass in every direction,” reads a statement by the department.

“Installing blast-resistant glass in buildings that are potential targets for attack or in regions prone to severe weather can save lives. But current blast-resistant glass technology – the kind that protects the windows of key federal buildings, the President’s limo, and the Popemobile – is thicker than a 300-page novel – so thick it cannot be placed in a regular window frame. This makes it very difficult (and expensive) to replace standard glass windows in present structures,” says the department.

Unlike current blast-resistant windows which are made of pure polymer layers, this new design is a plastic composite that has an interlayer of polymer reinforced with glass fibres – and it’s only a quarter-inch (0,6cm) thick.

The team recently subjected their new glass pane to a small explosion. “The results were fantastic. While the discharge left the pane cracked, the front surface remained completely intact,” said Sanjeev Khanna, the project’s principal investigator and an associate professor of mechanical engineering at the University of Missouri.

The design uses long glass fibres in the form of a woven cloth soaked in liquid plastic and bonded with adhesive. The glass fibres are typically 15 to 25 micrometres in diameter, about half the thickness of a typical human hair. The small size results in fewer defects and a decreased chance of cracking.

Engineers expect the new design will be comparable in cost to current blast-proof glass panes, but lighter in weight. Khanna hopes this glass could become commercially available in three to four years.