VSL NEWS 1994 N°1

Transcript of VSL NEWS 1994 N°1

VSL

VSL NEWSN U M B E R O N E 1 9 9 4

VSL Editorial

Value – Service – LEADERSHIP

Leadership by a company within an industry has many facets and the values behindthese points can vary from company to company and from country to country.

Leadership is usually identified with impressive key figures such as volume of activity,but this is net our understanding of leadership even though in the post-tensioning field,VSL is often considered as being the world leader.

VSL'S leadership is certainly more distinctively measured by the contributions VSLmakes to the whole industry; by launching new post-tensioning systems,by improving quality of products and services, and by simplifying site procedures.These contributions have been made in anticipation of the needs of owners,designers and contractors.

Take our Composite System; the anchorage components are smaller and lighterand require shallower block-ruts, the three configurations of STANDARD, PLUS andSUPER allow adaptation to the requirements of the project. Consider also thePT-PLUS plastic duct system ; a tight encapsulation for improved corrosion protection,offering the ability to electrically test and monitor the integrity of the tendon afterstressing and throughout the life of a structure. The Composite System and PT-PLUSduct are truly the systems of the future, available to you today. Take also the VSL StayGable System 200 SSI. It allows easy Single Strand Installation procedures with lightand compact equipment and with its multiple layers of corrosion protection representsa durable product while maintaining the advantage of monitorability and replaceability,strand by strand or the whole system at any stage during the life of the structure.These are a part of VSL'S Values.

On the other hand, for us at VSL, leadership also means being local worldwide. Withour more than 60 offices in 32 countries we are well prepared to play the rote as yourpartner in the true meaning of the word. Local VSL staff know the local businessenvironment. They have grown up in the same culture, speak the same language,and are close to you. They are eager to make dialogue between you and VSL bothfruitful and effraient and to optimize cooperation for the benefit of you and your project.These are the basis of VSL'S Services.

You as our client, our partner : call on us, challenge us, and share our name Value –Service – Leadership .

Michel MaîtreChairman of the Board

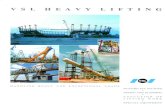

Front Cover:Segmental erection Normandy Bridge, FrancePhoto taken by J.P. BASILE, Le Havre, France

Highlights of this Issue:

3 Swedish stays

7 Thailand’s first climbform

9 Hong Kong’s high-rise

10 Bonded slabs for U.S.

13 Active slipforming

15 Normandie bridge erection

3

VSLStays: Applied Structural Technology

safety regulations during construction wereextremely strict as the steel superstructurehad to be launched over temporary sup-ports only 0.7 m above the high voltagelines.

The 18 stay Gables ranged in size from6-7 to fi-19 and fanned out from the top ofan A-shaped pylon. They are protectedby high density polyethylene pipes andwhite Tedlar tape, and are cement grou-ted. As the bridge is very sensitive todeflections, due to the glass walls, thecross sectional area of the steel strand isgoverned by stiffness rather than strengthcriteria.

Torbjörn LövgrenInternordisk SpänarmeringAB Danderyl, Sweden

Swedish Applications by Spännarmering

Hallsberg pedestrian bridge, Sweden

National Road Administration CentreBorlaenge, Sweden

In the last few years, InternordiskSpännarmering AR, VSL'S licensee in

Scandinavia, has become an experiencedand reliable stay Gable contracter both forbridges and building structures. LatelySpànnarmering has been involved in twostayed structures in Sweden.

Conference and Exhibition Centrefor the National Road Administrationin BorlaengeBased on an architectural competitionthe National Road Administration optedfor a spectacular roof construction. Theconcrete roof is suspended from staycables 6-5 and 6-7 anchored in twosteel pylons. The twelve stay cables arecomposed of 0.6" diameter individuallygreased and polyethylene sheathed steelstrands, encased in a thick walled highdensity polyethylene stay pipe. For me-chanical protection the cables are cementgrouted. The stay cables cross the pylonand are anchored at different locations insuch a way that there is no twisting effecton the pylon. Two stay Gables encased insteel tubes are arranged diagonally be-tween the pylons to provide additionalstability to the suspension structure.

Pedestrian Footbridge atHallsberg Railway StationIn the course of building the new travelcentre at Hallsberg in November 1993,one of the most important railway junc-tions in Sweden, the authorities decidedto build the footbridge connecting theparking area and the railway platforms bymeans of a cable stayed structure. The

VSL

4

Converting Research into Reality

CS SUPER: Electrically IsolatedTendons for Post-Tensioning

Aderahubel

P. S. du Milieu

PT-PLUS duct coupling

Picture an engineer inspecting a 30 yearold bridge. His task : to report on the

bridge's ability to continue to provide safepassage. The post-tensioned concretebridge was constructed using ElectricallyIsolated Tendons. The engineer moves tothe control panel containing an electricalconnection to each tendon and an earth tothe structure. He measures the electricalresistance between each tendon and thestructure - each tendon has a high resist-ance - the engineer knows that no breakin the corrosion encapsulation has oc-curred, he knows the tendons will continueto perform their designed task, he turnshis attention to other aspects.

In the US, in 1982, the engineers Schupackand Suarez were granted a patent basedon the notion of an Electrical IsolatedTendon (EIT), however the notion dia notcome with fully detailed components forthe multistrand and ground anchor fields,nor did the notion foster the use of elec-trical measurement to prove and monitorthe electrical isolation.

VSL in conjunction with other systemsuppliers in Switzerland helped in 1988 toformulate a specification for the supply,installation and acceptance of electricallyisolated ground anchors. The specificationprescribed the electrical resistance ac-ceptance limits and allowable defect rates.While this approach was a great stepforward it had limits and never absolutelychecked or provided a fully isolated tendonin the anchorage zone in the fully stressedstate. Completely isolated ground anchorswere first used in 1993 (as reported inVSL NEWS 2 - 1993). New system de-tailing provided the electrical isolation ofthe fully stressed soil and rock anchorswithout changing the established site pro-cedures of drilling and installation.

It was dear that EIT tendons had not rea-ched the end of their development.Based on the increasing demand and thedesirable attribute of service life monito-ring, VSL adopted an EIT option as oneof the development objectives for the CSSystem, and so made provision for a top

of the range option called CS-SUPER(see VSL NEWS 2 - 1992).

CS-SUPER was designed to provide :• a permanent fully encapsulating

moisture barrier that is also electricallyisolating,

• the elimination of steel strand to steelduct contact and hence elimination oftendon to duct fretting fatigue,

• components that are small and light-weight which make site work easyand quick,

• continuous life time monitoring usingelectrical resistance measurements.

There are three vital requirements thatmust be fulfilled to achieve an EIT tendon.Firstly, the duct must be able to transferthe lateral strand forces of a multistrandconfiguration to the structure without lossof isolation. PT-PLUS duct has beendesigned to transmit such forces withoutsuffering from wear-through. Secondly,

5

VSL

connections are precise, practical andtestable.

In the process of developing CS-SUPER,EIT tendons have been incorporated intotwo bridge projects in Switzerland to provethe practicality and check performance.P.S. du Milieu bridge is a highway over-pass with a length of 100 metres. all 6 lon-gitudinal tendons are electrically isolatedand use Type 59 PT-PLUS duct. Adera-hubel bridge has two spans of 30 metresand all 6 tendons (22 strands) have usedtype 100 PT-PLUS duct. The experiencegained from these two pilot projects andthe extensive in-house testing have con-duded that CS-SUPER electrically isolatedtendons are ready for full scale use. Morerecently the Swiss Federal Railways has8 specified PT-PLUS for the 127 metre longAare River Bridge, Brugg. This twin trackrailway bridge with a main span of 60metres will also include CS-SUPER / EITtendons.

Electrical Resistance Measurement of EITtendons, which is a quick and inexpensiveprocedure, should be viewed as part of alife time structural management detection

scheme. A high electrical resistanceconfirms the complete encapsulation andhence the completeness of the protection.The measurement of resistance is verysensitive to the smallest breach of en-capsulation. A failure of the encapsulationwill not mean that the tendon has lost itscapacity to function , but loss of electricalresistance will indicate the need for theintroduction of other more frequent andmore involved monitoring techniques.

Brad RathboneVSL International Ltd.Lyssach, Switzeland

The new Aare railway bridge,Brugg, Switzerland

CS anchorages installed

electrical isolation of the anchor head fromthe bearing plate must be provided whensubjected to the full tendon load. This isprovided by a special high capacity loadbearing insulation washer. Finally, positivelysealed connections of all duct and anchor-age components is a must. CS compo-nents are detailed to ensure that field

VSL

6

South East Asia / Australia

Thiong Bahru Plaza, SingaporePost-Tensioned Foundation Saves Time and Money

VSL was awarded the post-tensioningwork for Tiong Bahru Plaza in April

1993. all 3 Basement Levels, 6 storeyPodium Block and 20 storey Tower Blockare designed as post-tensioned floors withthe highlight of the project being thebasement raft foundation.

The complexity in the design of the entirestructure was made worse by the fact thatone third of the Podium Block was to reston columns provided by the existingunderground Mass Rapit Transit (MRI)station. In order to overcome differentialsettlement problems, four different typesof foundation systems were used. ThePodium Block was in part supported on apost-tensioned raft foundation, footings,and columns over the MRT station, whilethe Tower Block was seated independ-ently on bored piles.

The raft is 1250 mm thick and was de-signed for both the weight of the buildingas well as the net hydrostatic uplift ofapproximately 27 kPa due to the possiblefluctuation of water level. In the latter case,the raft was to span 40 metres betweendiaphragm walls. Straight tendons wereplaced in the top and bottom using 5-12tendons. With a total area of 5,030 sq.mthe raft was cast in five operations withpour sizes ranging from 900 cu.m to 1,500cu.m.

Construction of the raft was completed inless than two months. This was madepossible due to the reduction of time andcost of the post-tensioned construction

when compared to a conventional 1500mm thick reinforced concrete raft. Thesavings were made possible due to :– Excavation was reduced– Congestion due to steel reinforcement

was eliminated– Cost of temporary works le-g. strutting

system) were reduced due to reducedexcavation depth

– Reduction of material handling(concrete and total structural steel)

G. Sean/J. NgVSL Singapore Fte. Ltd.Singapore

The podium block raft foundation

7

VSL

The introduction of VSL Climbform intothe Thailand construction market was

heralded with the award of a contract forone of the tallest buildings ever to be builtin the centre of Bangkok. The BaiyokeTower II, with a height of 289 metres aboveground level (84 storeys), will have a corewall area of approximately 72,200 sq.m.

14 VSL (Thailand) Go., Ltd. has been awardedthe contract for climbing formwork byConcrete Constructions (Thailand) Co., Ltd.The choice of VSL Climbform for the corewall construction was also made to accele-rate the construction sequence of the pro-ject.

Work on the project began in 1992 and willtake 4 years to complete, with an anti-cipated total construction cost of around3,600 M (Thai Baht).

As one of the tallest buildings in Thailand,when completed the structure will be adominant feature of the City of Bangkok.

S. BoonprechaVSL (Thailand) Go., Ltd.Bangkok, Thailand

Thailand’s first climbform

The Maribyrnong River Bridge, Australia

Western carriageway during launching

VSL Climbform Baiyoke Tower II,Thailand

Amajor part of the 29 km Western RinRoad around Melbourne is the

Maribyrnong River bridge. A design andconstruction contract was awarded to

Transfield Construction Pty Ltd with struc-tural design by Hardcastle and RichardsPty Ltd in conjunction with VSLPrestressing (Australia) Pty Ltd.

The bridge consists of two parallel struc-tures 520 metres long with 8 spans of54 metres and end spans of 44 metres.The method of superstructure construc-tion is incremental launch based on asegment length of 27 metres.

Each structure provides three lanes oftraffic. A future provision is for a thirdstructure to be built in the gap betweenthe first two and so increase the bridgewidth to l fanes for future traffic needs.

15 VSL'S scope of works was the supply andinstallation of transverse, longitudinal con-struction and continuity post-tensioning.The VSL tendons used are 6-5 and5-5 transversely, 6-5 in the top andbottom Ranges for straight longitudinalconstruction post-tensioning and 6-31 longitudinally continuity tendonsstressed internally.

Mark Sinclair VSLPrestressing (Aust. ) Fty LtdMelbourne, Australia

8

North East Asia

Post-Tensioning Towers:VSL Shows the Gateway to Hong Kong’s Future

Robinson Road Development

Gateway Development

Rapid Construction with Precast Members

Precast building elements becomecontinuous with a second stage of post-

tensioning

VSL

Post-tensioned buildings are settingthe scene for Hong Kong's skyline.

The recently completed Gateway Devel-opment, a twin 37 storey office tower forWharf Properties, breaks the deadlock onthe aviation height limitation for buildingsin the northern region of Hong Kong Har-bour. In order to maximize net lettablearea a post-tensioned Rat slab was re-quired to enable the placement of me-chanical and electrical services in theextremely tight ceiling space imposed by

the 3.2 m floor to floor height. The 260 mmthick post-tensioned Rat slab spanning11 .5 m from perimeter columns to cen-tral core provided not only an economicalfloor system, but enabled building construc-tion to proceed on a 4 day cycle.

Hong Kong's trend for high-rise structureswith varied occupancy raises the need fora transfer plate to permit a change incolumn layout between occupancies. In1993 atone, VSL Hong Kong designedand constructed 3 post-tensioned transferplates proving it to be an economical and,effective alternative to the conventionalreinforced concrete plate. The RobinsonRoad development for Swire Propertiesconsists of 2 post-tensioned transferplates 3.2 m thick supporting 47 stories ofresidential apartments. The transfer plateshave been designed to be constructed in2 layers, the first layer 1.5 m thick, oncestressed, will support the constructionweight of the remaining 1.7 m of concreteminimizing falsework and constructioncosts. The post-tensioning enhances theshear capacity of the concrete allowing athinner and more economic structure.

Barry YoungVSL Hong Kong Ltd.Hong Kong

Just beside Fukuoka interchange onKyushu transverse highway route, a

large scale distribution warehouse com-plex is now under construction. FukuyamaTsu-un Fukuoka Distribution Centre Ware-house, which composes the main part ofthe complex, was built of precast concretemembers. The building has a width of 40 m(10 m x 4 spans), a length of 250 mil 2.5 m x 20 spans), and has three stories.

VSL

Precast concrete members are used forthe 2nd and 3rd floors.

Simultaneously with site constructionwork, girders prestressed with VSL post-tensioning tendons were fabricated in theprecast shop in nearby Kurume city,transported to the site by large trucks, andpositioned by a large capacity movablecrane. Alter placing precast sortit slabs,column-girder joints and slabs were con-

creted. When the concrete had attainedthe designated strength, a second stageof post-tensioning was applied to trans-form the columns, girders and slabs intoa continuous structure.

Compared with the conventional cast-in-situ method, this system has various adv-antages in terms of construction duration,constructability, quality, and labourenvironment. The resultant structure, with

its long clear spans, has not only superbperformance for utilization and operationof the warehouse but also excellent dur-ability and anti-seismic characteristics.

Shusuke SakataVSL Japan CorporationTokyo, Japan

In order to cope with the future increaseof international passengers and freight

to Japan, the construction of a new air-port is now in full swing. The new KansaiInternational Airport will be located 5 kmoffshore in Osaka Ray due to the lack ofavailable Rat areas and as a means ofavoiding noise pollution.

Nagataki viaduct is part of the trunk high-way which connects Osaka city and theredaimed man-made island for the airport.The viaduct has two parallel decks withspans of approximatively 29 metres. Thedecks are of post-tensioned concretevoided slabs 11.5 metres wide and1.4 metres in depth. 307 tonnes of pre-

stressing strand together with 820 tonnesof reinforcing bar were consumed for thedecks. Taisei Corporation, one of the sub-licensees of VSL Japan, started with thedeck work in January 1991 and completedthe work in December 1993. The airport isexpected to open in summer 1994.

Shusuke SakataVSL Japan CorporationTokyo, Japan

A Viaduct toKansai International Airport

9

VSL

10

USA

Bonded Beam and Slab Parking Garage

Installation ofPT-PLUS flat duct

Overall View –Hahnemann parkinggarage underconstructionThe construction of the Hahnemann

University Parking Garage in Philadel-phia, Pennsylvania, marks the introductioninto the US of the VSL Bonded Slab PTSystem for commercial structures. Addi-tionally, PT-PLUS Plastic Duct was utilizedfor state of the art corrosion protection.The VSL Bonded Post-Tensioning Systemhas an excellent record of durability in theharshest environments, and has been ex-tensively used in bridge construction overthe past 30 years, here in America andaround the world. In 1992, VSL introducedthe PT-PLUS duct system, featuring smal-ler and lighter components, enhanced cor-rosion protection, improved duct frictionvalues, and easier installation.

The project engineer agreed that bondedpost-tensioning was superior to the un-bonded system, but was concerned aboutinitial costs. Bidders were allowed to sub-mit bids on both bonded and unbondedalternatives. The bids were competitive,allowing the owner to follow the engineersrecommendation and construct the projectusing the bonded system.

The impact of the bonded system on theconstructability of the project was positi-ve. The 6 inch slabs span 22 feet, and the

16 inch x 28 inch beams span 52 feet.The slabs employ VSL SA anchorageswith 1" x 3" PT-PLUS plastic duct, encap-sulating up to 4 strands. The typical beamemploys one EC 5-12 tendon. This re-presents a 42 % reduction of end bearingarea, when compared to individual mono-strand anchorages. The use of the bondedcomponents reduced congestion (whencompared to the unbonded system) andhelped the contractor achieve an aggres-sive construction schedule.

Dan FalconerVSL CorporationPhiladelphia, FA

The Parrotts Ferry Bridge constructedbetween 1976 and 1978 over the New

Molonos Lakes in Northern California, isa 3 span, single cell, lightweight concretepost-tensioned box girder. The bridge is1290 feet long with a 640 feet main spanbuilt by the cast-in-place cantilever seg-mental method.

The original design mortel dia not accountfor the relatively high creep and shrinkagerates of the lightweight concrete used in

Parrotts Ferry Bridge Retrofit

Erecting work platforms under bridge

11

VSL

construction. As a result, a 25 inch down-ward deflection at the centre of the mainspan occurred over a ten-year period. Itwas determined by the Onwer's consul-tant that without a retrofit scheme, it wouldbe likely the bridge would deflect 12 moreinches over the next 50 years.

A number of retrofit schemes were consi-dered by the Army Corps of Engineers, asproposed by T.Y. Lin International. Thechosen method for retrofitting the structureutilized external tendons within the box

girder that protruded up to 3 feet belowthe sortit for 80 feet each direction of mid-span. The tendons in the box are sheathedin 4 inch polyethylene duct. Once belowthe sortit, the tendons are encased incurved concrete ribs.

Twelve 27-0.5 inch strand tendons passedthrough a series of deviation blocks to in-troduce the desired stresses from the post-tensioning into the structure to remedythe deflection problem. Upon stressing alltwelve tendons, 7 inches of deflection was

immediately recovered. It is anticipatedthat 85 % of the deflection will be reco-vered due to longterm concrete creep.

VSL was awarded the project in Septem-ber 1992 and the retrofit work tookapproximately 12 months to complete.

Steve RuelVSL CorporationCampbell, California

VSL'S Transit Systems Group has desi-

gned and built nineteen passenger

transportation systems since the Group's

inception in 1974. Since 1980, the Transit

Systems Group has installed, as turnkey

supplier, eight Automated Guideway

Transit (AGIj systems; two monorail and

six cable-propelled.

In August of 1992, the Transit Systems

Group contracted to install its latest AGT

system with the Mirage Corporation in Las

Vegas, Nevada. On October 20, 1993, the

Mirage system was placed into service.

In the first fourteen hours of operation, the

vehicle successfully carried in excess of

10,000 passengers between the Mirage

Casino/Hotel and the new Treasure Island

Hotel/Casino complex. The system con-

sists of a cable-propelled AGT system with

one 60 passenger vehicle (expandable toa two car 120 passenger capacity system)travelling on an elevated guideway bet-ween two terminals. The horizontal guide-way length is approximately 1,200 feet.

The Transit Systems Group is currentlyunder contract for the supply of a secondvehicle for this system which, when

installed, will provide the owner with asystem capacity of nearly 2,000 passen-gers per hour per direction.

Jeremery B. KimmelVSL CorporationCampbell, California

VSL’s Transit System Group Delivers Mirage Tram Project

Placement of precast guideway segment

Mirage vehicule in service

VSL

12

Eastern Europe / Middle East

VSL Lifts Aircraft Hangar Roof in Brunei

The Royal Pavilion aircraft hangar atBrunei International Airport serves for

the maintenance of the fleet of His RoyalHighness, the Sultan of Brunei.

The hangar roof structure, a space truss235 by 100 metres weighing 3500 tonnes,was assembled early last year on shorttemporary supports close to ground level.The roof was then lifted by means of 6 groups of VSL strand lifting units fea-

The 25 metres lin was carried out in2 stages. It was engineered and executedjointly by VSL Singapore Pte. Ltd. andVSL (Switzerland) Ltd.

Walter AlthausVSL (Switzerland) Ltd.Lyssach, Switzerland

The hangar roof during lifting and a close-up of a column with 4 srand lifting units

Bar Anchorswith Electrically Isolated Tendons

The electrically isolated tendon (EIT) re-cently introduced by VSL (Switzerland)

Ltd. (see VSL News II/(1993), continues tobe in demand. It is a reliable system toallow the owner to use efficient qualitycontrol methods to check the corrosionprotection of soi( and rock anchors. Spe-cial attention is always required in areaswhere stray currents from railways and thelike coula lead to conditions favourable forcorrosion.

Recently, VSL (Switzerland) Ltd. negoti-ated two contracts that required short highstrength bar anchors to be electricallyisolated. The first was a refurbishment of atunnel of the famous Bernina railway nearSt. Moritz where pre-injected VSL 26 mmdiameter Stressbar with a length of 10.5

qnmetres were needed. The second con-tract was in Regrouillon, near Sion. Thisproject involved an extensive excavationfor a railway and motorway that needed1200 electrically isolated passive baranchors to secure the near vertical face.The bar anchors were 40 mm diameterand varied in length from 3 to 11 metresand were detailed to meet the demandsof harsh winter conditions.

VSL (Switzerland) Ltd. is convinced thatthe recent achievements with Electricallylsolated Tendons will encourage specifiersto freely call for this type of quality product.

André GabusVSL (Switzerland) Ltd.Lyssach, SwitzerlandElectrically isolated passive bar anchor

turing central computer control of levelsand loads.

To support the lifting equipment, the 6 circular steel columns were extended by9 metres high temporary structures.These were designed by VSL Singaporeand fabricated by Singapore based struc-tural steel main contractor Yong Nam.

13

VSL

VSL has been active in slipforming formore than 25 years. The main advan-

tages of this construction method includecost savings, short construction time andhigh dimensional accuracy.

The VSL Slipform has a height of 1.25 mand it consists of standardized steel panelsand structural components. The slipformis raised by hydraulic jacks, at a speed of2 to 6 m per 24 hours. Continuous work-ing produces a monolithic structure wit-hout construction joints.

VSL engineers the slopform and providesthe equipment on a hire basis to the client.Assembly and operation are taken care ofby our specialists. The main contractorplaces rebars, post-tensioning and block-outs and pours the concrete.

A recent accomplishment of VSL Slip-forming includes 11 building cores up to65 m high for the Espace Léopold officecomplex in Brussels, executed for theAMCEL Group. Together with 6 coresslipformed previously by VSL in the samelocation for the OIC complex, this pre-sumably represents the largest buildingcore site in Europe.

Another recent accomplishment was the+j m high furnace tower for a cementdctory near Bar(, ltaly, with a slipformedsurface of 13,700 sq.m. The horizontalconcrete beams were also cast using theslipform, with no interruption to thecontinuous work.

Erich MöschlerVSL (Switzerland) Ltd.Lyssach, Switzerland

Karl HirschN.V. PROCEDES VSL S.A.28 Halle-Zoersel, Belgium

Slipforming speeds up Construction ofConcrete Towers

General view of the Espace Léopold construction site

The Unicem furnace tower near Bari, Italy

VSL

14

Western Europe

VSL Rock Anchors forEsch sur Sure Dam, Luxembourg

The dam and is new stabilising partner

To increase the overall stability of theEsch sur Sure dam, located in the

northern part of the Grand Dutchy ofLuxembourg, the utilisation of permanentrock anchors was proposed.

VSL was called to install 15 rock anchors45 metres long in the counterforts of thedam. The anchors, type 6-36, have anultimate capacity of 9500 kN and werestressed to 4310 kN. The anchors consistof individually greased and sheathedmonostrands for the free length and thewhole anchor is encased in a smooth andcorrugated plastic encapsulation. To allow

restressing and load adjustment eachanchor head is threaded.

The installation was made by means of amobile crane which lifted the completedanchor into the vertical position where the15 metre internai bond length was grouted.Alter this internai grouting and followingvisual inspection the whole anchor waslowered into the bore hole where the re-maining grouting was performed.

Roland MathysVSL France S.A.Egly, France

15

VSL

Erection of the main span segmentsof the Normandy stay cable bridge

Segment erection Normandy Bridge

The central 624 m of the world's largest cable stayed bridge(main span 856 mi is made up of prefabricated steel

segments. SDEM (the erection contractor) commissioned VSLFrance, because of its proven experience in the field of bridgesegment lifting, to carry out the lifting work.

The 32 steel box girder segments are : 19.65 m long, 21 mwide, and the streamlined profile has a depth of 3 m. Each ofthe 220 tonne segments is lifted with two fi-12 Dylorm cablesat a rate of 30 m/hr.

Planning and equipment had to take account of : a maximumwind speed of 50 km/h, a variation of barge draught of 0.5 m,and a maximum lin induced deck deflection of 2.8 m.

The cantilever construction method was used and requiredeach new segment to be lifted dear of the navigation channelas quickly as possible and to be accurately aligned to theprevious section and held in position until field welding and staycable installation and stressing were completed.

Lucien BoutonnetVSL France S.A.Eg/y, France

Retained Earth in France

VSL has for many years been amassing world-wideexperience with the VSL Retained Earth System. VSL

France has recently added to this now popular civil engineeringsolution when it completed a serres of retaining wallsassociated with a new freeway at Besançon in eastern France.

Designed by VSL France, with support from Technical CentreEurope (Lyssach), the project consisted of 7 separate wallsthat were composed of 88 different panel types with a totalarea of 1700 sq.m. The walls which were up to 5.9 metres highwere an alternative to cantilever retaining walls and providedsignificant cost and time savings for the general contractor.

Raphael LuVSL France S.A.Egly, France

Attractive retained earth walls, France

VSL

VSL

PUBLISHED BY VSL International Ltd., Bernstrasse 9, 3421 LYSSACH, Switzerland • Editor: Therese Wenger

Reprentative Office, VSL International Ltd., 41 Avenue du Centre, 78067 ST-QUENTIN YVELINES, FranceTel: 33 - 1 - 30 12 09 30, Fax 33 - 1 30 48 94 94

AUSTRALIAVSL Prestressing (Aust.)Pty. Ltd.THORNLEIGH, NSW 2120Tel 61 - 2 - 484 59 44Fax 61 - 2 - 875 38 94

VSL Prestressing (Aust.)Pty. Ltd.VIRGINIA, QLDTel 61 - 7 - 265 64 00Fax 61 - 7 - 265 75 34

VSL Prestressing (Aust.)Pty. Ltd.NOBLE PARK, VICTel 61 - 3 - 795 03 66Fax 61 - 3 - 795 05 47

AUSTRIASonderbau GesmbH, WIENTel 43 - 1 - 892 02 80Fax 43 - 1 - 892 02 80 33

BOLIVIAPrestress VSL ofBolivia Jauregui Ltd., LA PAZTel 591 - 2 - 321 874Fax 591 - 2 - 371 493

BRAZILRudloff-VSL Industrial Ltda.SAO PAULOTel 55 - 11 - 826 04 55Fax 55 - 11 - 826 62 66

BRUNEI DARUSSALAMVSL Systems (B) Sdn. Bhd.BANDAR SERI BEGAWANTel 673 - 2 - 22 91 53,

- 22 18 27Fax 673 - 2 - 22 19 54

CHILESistemas Especiales deConstruccionSA, SANTIAGOTel 56 - 2 - 233 10 81Fax 56 - 2 - 233 67 39

CZECH REPUBLICVSL Systemy (CZ) s. r. o.;PRAHATel 42 - 2 - 242 252 96Fax 42 - 2 - 242 254 31

FRANCEVSL France S.A.EGLYTel 33 - 1 - 69 26 14 00Fax 33 - 1 - 60 83 39 95

GERMANYVSL Vorspanntechnik (D)GmbHELSTALTel 49 - 33 234 - 8340Fax 49 - 33 234 - 83416

GREAT BRITAINBalvac Whitley Moran Ltd.DERBYSHIRE DE55 4PYTel 44 - 773 54 16 00Fax 44 - 773 54 17 00

GREECEVSL Systems S.A., ATHENSTel 30 - 1 - 363 84 53Fax 30 - 1 - 360 95 43

GUAMVSL Prestressing (Guam),TUMONTel 67 - 1 - 646 80 61Fax 67 - 1 - 649 08 50

HONG KONGVSL Hong Kong Ltd.Quarry Bay, HONG KONGTel 852 - 590 22 88Fax 852 - 590 02 90

VSL Redland Concr. Prod.Ltd.Quarry Bay, HONG KONGTel 852 - 590 03 28Fax 852 - 562 94 28

INDIAKillick Prestressing Ltd.,BOMBAYTel 91 - 22 - 578 44 81Fax 91 - 22 - 578 47 19

INDONESIAPT VSL Indonesia, JAKARTATel 62 - 21 - 570 07 86Fax 62 - 21 - 573 12 17

ITALYVSL Italia S. r. l.MONTESETel 39 - 59 - 98 14 13Fax 39 - 59 - 98 14 12

JAPANVSL Japan Corporation,TOKYOTel 81 - 33 - 346 89 13Fax 81 - 33 - 345 91 53

KOREAVSL Korea Co., Ltd., SEOULTel 82 - 2 - 574 82 00Fax 82 - 2 - 577 00 98

MALAYSIAVSL Engineers (M) Sdn.Bhd.KUALA LUMPURTel 60 - 3 - 242 47 11Fax 60 - 3 - 242 93 97

NETHERLANDSCivielco B.V., AT LEIDENTel 31 - 71 - 76 89 00Fax 31 - 71 - 72 08 86

NEW ZEALANDPrecision Precasting(Wgtn.) Ltd., OTAKITel 64 - 694 81 26Fax 64 - 694 83 44

NORWAYVSL Norge A/S, STAVAN-GERTel 47 - 51 - 56 37 01Fax 47 - 51 - 56 27 21

PERUPretensado VSL del Peru SA,LIMATel 51 - 14 - 76 04 23,Tel - 76 04 26Fax 51 - 14 - 76 04 77

PORTUGALVSL Prequipe SA, LISBOATel 351 - 1 - 793 85 30Fax 351 - 1 - 793 09 01

SINGAPOREVSL Singapore Pte. Ltd.,SINGAPORETel 65 - 235 70 77/9Fax 65 - 733 86 42

SOUTH AFRICASteeledale Systems (Pty.) Ltd.,JOHANNESBURGTel 27 - 11 - 613 77 41/9Fax 27 - 11 - 613 74 04

SPAINVSL Iberica S.A., MADRIDTel 34 - 1 - 556 18 18Fax 34 - 1 - 597 27 01

SWEDENInternordisk SpännarmeringAB, DANDERYDTel 46 - 8 - 753 02 50Fax 46 - 8 - 753 49 73

SWITZERLANDVSL (Switzerland) Ltd.LYSSACHTel 41 - 34 - 47 99 11Fax 41 - 34 - 45 43 22

THAILANDVSL (Thailand) Co., Ltd.,BANGKOKTel 66 - 2 - 237 32 88/89/90Fax 66 - 2 - 238 24 48

USAVSL CorporationATLANTA, GATel 1 - 404 - 446 - 3000Fax 1 - 404 - 242 - 7493

VSL Corporation DALLAS, TXTel 1 - 214 - 647 - 0200Fax 1 - 214 - 641 - 1192

VSL CorporationDENVIER, COTel 1 - 303 - 239 - 6655Fax 1 - 303 - 239 - 6623

VSL CorporationHONOLULU, HITel 1 - 808 - 682 - 2811Fax 1 - 808 - 682 - 2814

VSL Corporation MIAMI, FLTel 1 - 305 - 592 - 5075Fax 1 - 305 - 592 - 5629

VSL CorporationMINNEAPOLIS, MNTel 1 - 612 - 456 - 0985Fax 1 - 612 - 456 - 9281

VSL CorporationPHILADELPHIA, PATel 1 - 215 - 750 - 6609Fax 1 - 215 - 757 - 0381

VSL CorporationSAN JOSE, CATel 1 - 408 - 866 - 5000Fax 1 - 408 - 374 - 4113

VSL CorporationWASHINGTON, DCTel 1 - 703 - 451 - 4300Fax 1 - 703 - 451 - 0862

VIETNAMVSL North East AsiaHONG KONGTel 852 - 590 22 22Fax 852 - 590 95 93

REGIONAL HEADQUARTERS

SOUTH EAST ASIA/AUSTRALIA

VSL Prestressing (Aust.)Pty. Ltd.THORNLEIGH, NSW 2120AustraliaTel 61 - 2 - 484 59 44Fax 61 - 2 - 875 38 94

NORTH EAST ASIA

VSL North East AsiaRegional Office1508 Devon House979 King’s RoadQUARRY BAYTel 852 - 590 22 22Fax 852 - 590 95 93

USA - AMERICA

VSL CorporationCrosspointe II Plaza2840 Plaza PlaceSuite 200RALEIGH, NC 27612USATel : 1 - 919 - 781 6272Fax 1 - 919 - 781 6892

EASTERN EUROPEMIDDLE EASTAFRICA**(English speaking part)

VSL (Switzerland) Ltd.Bernstrasse 93421 LYSSACHSwitzerlandTel 41 - 34 - 47 99 11Fax 41 - 34 - 45 43 22

WESTERN EUROPESOUTH AMERICAAFRICA** (French speaking part)

VSL France S.A.110, Avenue Verdun91520 EGLYFranceTel 33 - 1 - 69 26 14 00Fax 33 - 1 - 60 83 89 95

VSL COMPANIES AND LICENSEES