V_L-3MD_P_Mon Gr Br Selection & Shaft Design

-

Upload

arijit-patra -

Category

Documents

-

view

222 -

download

1

description

Transcript of V_L-3MD_P_Mon Gr Br Selection & Shaft Design

-

Notes on Design of a Bevel-Helical Gear Box

Calculation of Loads on Shaft, Bearing Selection & Shaft Design

Important Note:Important Note:

Sample calculations are shown on a design problem of a Two stageHelical Gear box. In designing bevel-helical two stage gear boxcalculations will be similar. How to estimate loads on gears andfinally on an intermediate shafts, having the bevel gear and helicalpinion, is shown later in this note.

1

-

Design of an Industrial General Purpose Reduction Gear Unit :

Data: The TWO- stage (1st stage Bevel and

Problem for Monday Group (2014) :Data: The TWO stage (1 stage Bevel and 2nd. Stage helical) reduction gear box has the following specifications.

(20 to 22 different problems). Z1

Z3 Z4

Z2GROUP POWER

(kW)INPUT RPM

OUTPUTRPM

DUTY OVERHAULTIME LUBRICATIONSub

GroupDescription

IA, B, C, D,

12 1500 170 A,E,I,M,Q, U

Precision, Intermittent,

No shock2 years

Forced

IIE F G H

10 1800 200 B,F,J,N,R General, C ti

Oil Sump

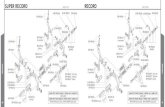

Assembled plan view(Not of the same one as below)

E, F,G,H Continuous,Medium shock

IIII, J, K, L

09 1450 125 C,G,K,O,S, V

General, Intermittent,Heavy Shock

Oil Sump

IVM,N,O,P

07 1200 125 D,H,L,P,T Precision, Continuous,

Medium Shock

Forced

V 05 1500 140

t i h ld d

Q,R,S,TVI

U, V06 950 100 Horizontal input and vertical output (Forced Lubrication)

1st. stage ratio should not exceed 3.In general non co-axial horizontal input and output (except otherwise mentioned).

22

Photographic view of 2-stage (Bevel Helical) gear box.(Top cover open)

Horizontal Input-Output.

-

A Typical Helical Gear Box Design Problem

A helical gear reduction unit has to transmit 31 Nm input torque at 1500 rpm with a total reduction of about 37 to 40.

At starting the torque may go as high as 200%.

The material for pinion is EN 19A and for Assembled plan view is of 2-stage gear box.gear wheel it is EN 18A.

The gear box may be an ordinary industrial class unit preferably with uncorrected gears.

It is continuous duty with medium shock and overhauling time is Two years.

(Alternatively -the bearing life should not be below 10,000 hours). First Stage

3

Photographic plan view is of 2-stage gear box.

-

A Typical Helical Gear Box Design Problem

1st. Step. Selection of number of stages with respect to Total Transmission Ratio.

In the present problem Total Transmission Ratio, = 37 to 40.tiConsidering not more than ratio 6 in a stage (particularly in 1st. Stage) a g g (p y g )total ratio above 6 and below 36 can be managed in two stages. For a Ratio above 36, usually three stage reduction is preferred. However, allowing a ratio little more than 6 in second stage (which is done e often to ed ce cost) a total atio of 37 to 40 is done in t o stagesvery often to reduce cost) a total ratio of 37 to 40 is done in two stages.

Now, the ratios are to be selected in a way that the size of the gear box becomes optimum. Optimization technique to be adopted in this regard. The process is tedious HoweverThe process is tedious. However, experienced designer can do it with a little manipulation and trial and error on the selection of the stage reductions

4

reductions.

Assembled plan view is of 2-stage gear box.

-

A Typical Helical Gear Box Design Problem

1st. Step (Contd). Selection of number of stages for a Total Transmission Ratio = 37 to 40i

Considering two stage reduction the numbers of teeth of pinions and gears were selected as follows:

Transmission Ratio = 37 to 40.ti

76.417812

1 ZZi

1st. Stage:

171Z

19.8161314

2 ZZi

2nd. Stage:

163Z

2 4 81 131Z Zi iiTherefore, total ratio becomes:

Assembled plan view is of 2 stage gear box

2 4

1 3 17 164.76 8.19Z Z

1 2i i

3 9 . 0 1ti

5

Assembled plan view is of 2-stage gear box.This is acceptable.

-

A Typical Helical Gear Box Design Problem

In choosing the numbers of teeth and stage ti t l th i ti i ti i

1st. Step (Contd).ratios, not only the size optimization is considered but also the roundness in centre distances with uncorrected gears is taken care* of:

2nd. Step.

In next step gears are designed as describedIn next step gears are designed as described in earlier lectures.

Estimated 1st. Stage module is 1 3nm mm4m mmd 2 d St d l i

Assembled plan view is of 2-stage gear box.2 4nm mmand 2nd. Stage module is

With a suitable selection of helix angle*, , for which and centre distances become:

1 2 11 26 52o

cos cos 0 98 and centre distances become:1 2cos cos 0.98 *1 2 1

11

(17 810.98 0.

( ) 3 3 1502 c 9

) 98

8os 2 2

nZ Z mA mm

(16 131( ) 14) 4 47Z Z

6

*3 4 22

2

(16 1310.

( ) 14) 4 4 3002 co 98 0.92

7s 82

nZ Z mA mm

and

Finalized gear data are now recorded in a tabular form (as in next slide).

-

Sl. No. DescriptionFirst Stage Second Stage

Pinion Gear Pinion Gear

Gear Data 2nd. Step (Contd) .

Pinion Gear Pinion Gear

1. ,, Number of Teeth 17 81 16 131

2. Profile Involute Full Depth, Un corrected

3 Normal module 3 mm 4 mm

Zo20

m3. , Normal module 3 mm 4 mm4. , Helix Angle

RH LH LH RH5 Addendum Height (mm) = 3 0 4 0

nm

256211 o

f 01

256211 o

5. Addendum Height (mm) = 3.0 4.0

6. Dedendum Height (mm) 3. 75 5.0

7. , Pitch Circle Diameter (PCD) (mm) 52.04 247.96 65.306 534.69

na mf nm0.1

nd mf d

nm25.1, ( ) ( )

8. , Addendum or Tip Diameter (mm) 58.04 253.96 73.30 542.70

9. Dedendum or Root Diameter (mm) 44.54 240.46 55.30 524.70

pd

ad

d

10. , Face width. (mm) 63 58 68 63

11. Material EN 19A EN 18A EN 19A EN 18A

12 S f H d (BHN) 350 300 350 300

dd

b

7

12. Surface Hardness (BHN)(Through Hardened)

350 300 350 300

p and g may be added to subscript of Nomenclature to indicate pinion and gear respectively. Similarly 1 and 2 can be added to indicate stage of Gear.

-

3rd. Step. Layout & Bearing Selection

Layout of pinion and gears is made in next step. Shafts are automatically shaped.

Then Bearing types are chosen taking into account service severity and life.

Taper Roller Bearing to be used in pair.p g pmay be used in pair or in combination.

For an example both spherical roller and

Other Bearings-

Distance between Bearing(Taper Roller) supports.

p pball bearing can be combined with cylindrical roller bearing in the other end.

Choice depends on type of loading mainly.

Spherical Roller

p yp g y

Locking of bearings with shaft and housing is to be decided at this stage.

h i f i l d b b iSpherical RollerBearing Sharing of reaction loads by bearings depends also on of bearing Locking arrangement.

8Cylindrical RollerBearing

Ball Bearing(Deep Groove)

With distance between bearing supports the shaft is considered as simply supported beam.

-

Layout & Bearing Selection (Contd..)3rd. Step:

Layout of a single stage Gear Box

Assembled plan view of a 2-stage gear box.

Plan View -Schematic

9

-

Layout & Bearing Selection (Contd..)3rd. Step:

Roller Bearings:

(Not taper roller in this case)

Assembled plan view of a 2-stage gear box.

in this case).

C id i

10 to 15 mm (Typical)15 to 25 mm (Typical)

15 to 25 mm (Typical)

Considering bearing widths,

5053

1 8

10 to 15 mm (Typical) (Typical)( yp )

finally distances are marked

Layout of Intermediate Shaft (Referring to Design Problem) 10

178 are marked.

-

4th. Step. Loads on Gear, Pinion Teeth and on Bearings.2

tp

TFd

Tangential Load: pd

tt

FF Normal Load:cos

npZ md

cossec .sectn

nn t nF F

F costnFNormal Load:

n FF n

r n nF = F .sinF i

Radial Load:

tantF

tFtF

sec . tan( tan )r t nF F

F

t n n= F sec.sec .sinn

pd ( tan )tF

sin tana n tFF F Axial Load:

Forces on Helical Spur Gear Tooth.

11

sa n t sec .secn t nF F

-

Force Diagram for Bevel Gear :2

tgpg

TFd

Tangential Load:For Your Reference.

pgd

Normal Load:

( )pg g Bevel Beveld Z m

secng tg nF F Normal Load:

R di l L d ( )

2pgd

rg tg n g

ap

F = F .tan .cos= F

Radial Load (gear):

, Axial Load (pinion).g

F

agF

F F tan sin=

ap

Axial Load (gear):

, (p )

rgFtgF

ag tg n g

rp

F F .tan sin= .F , Radial Load (pinion).n

ngF

12

As o

g p + = 90

-

For Intermediate Shaft (Referring to Design Problem)

Loads and reactions are calculated on theTorque ( ) Flow Path2nT

Calculation of Loads and Reactions on Shaft & Bearing4th. Step (Contd):

Loads and reactions are calculated on the basis of Nominal Torque & approximate bearing width = 25 mm.

2Z (81)pcd 248 mm

o que ( ) o at

RLBending Moment due to Axial Load:

22 2

240.65 0.2479 302 2p

a a

dM F Nm

914 0 0653d 5053

3Z (16)pcd 65.3 mm

g

R 3F

33 3

914 0.0653 302 2p

a a

dM F Nm

Intermediate Shaft with gears and Bearings

178

For moment equilibrium (horizontal plane) about R

VLR

HLRVRR

HRR

3rF3aF 2aF

3tF 2tF 2rF

1683 0.125 443 0.05 30 300.178 0.178 0.178 0.178

1182 124.4 168.5 168.5

HLR

= 720. 6 N3t 2t 2r

3aM 2aMFrom force equilibrium- HRR = 520 N

Similarly computing for vertical plane:3F = 4533 N F =1683 N F = 914 N

13

VLR = 3518.5 N VRR =2208 N

Applied Loads, Reactions & Moments due to Axial Loads

t 3F = 4533 N r3F =1683 N a3F = 914 N t 2F = 1193.5 N r2F =443 N a2F = 240.65 N

-

For Intermediate Shaft (Referring to Design Problem)

Torque ( ) Flow Path2nT YFXVFCP Equivalent Load Acting on bearing is expressed as:Bearing Life Estimation5th. Step:

2Z (81)

pcd 248 mm

q ( )

R

ar YFXVFCP 1expressed as:Life of Rolling Element bearing in Number of Revolution is expressed as:

CL

3Z (16)

pcd 65.3 mm

R610

PCLN Revolution

Life in hours is then estimated as: L

L

5053

17860N

HLLN

HoursLoads from Gear teeth were estimated as: F F

683F

914 N

VLR VRR3rF

3F 2aF

Intermediate Shaft with gears and Bearings (Plan View)t 3F = 4533 N r 3F =1683 N a3F = 914 N

t 2F = 1193.5 N r 2F =443 N a2F = 240.65 N Also, moments due to axial forces were

M M30 N

HLR HRR3aF 2a

3tF 2tF 2rFHLR = 720.6 N VLR = 3518.5 N

Finally Bearing reactions (radial) were estimated as:

estimated as: 2 3a aM M 30 Nm

14

3aM 2aMApplied Loads, Reactions & Moments due to Axial Loads

HL

HRR = 520 NVL

VRR =2208 N Bearing reactions (axial) yet to be estimated.

-

From details of loading resultant right b i ( di l) ti i l l t d

The Final bearing reactions:Radial reactions are not in same plane.

Bearing Life Estimation5th. Step (Contd):

bearing (radial) reaction is calculated as:

2 2 2 2VR HRR +R = 2208 +520

r RF

2268.4 NF

not in same plane.

2268.4 NIt is acting at an angle with vertical plane, Rderived as . 1tanR HR VRR R o13. 25

Bearing Reactions (& Locking)

5053 r RF a NetF

r LF

R R3rF

2 2 2 23518.5 720.6VL HLR R

r LF

3591.5 N

1 o11 57 r LF r R

FBearing Reactions (& Locking)

o13 25o11. 57

Similarly,

VLR

HLRVRR

HRR

3r

3aF 2aF

3tF 2tF 2rF

1tanL HL VLR R o1 1 . 5 7aF

o13. 25and,

Resultant axial load may act only on one bearing irrespective of its direction (i.e., direction of shaft rotation)

t 3F = 4533 N r3F =1683 N a3F = 914 N t 2F = 1193.5 N r2F =443 N a2F = 240.65 N

direction of shaft rotation).

It depends on bearing locking arrangement.

In this case it is on right bearing which is with less radial load

15Details of loading & Resultant bearing Reactions.

3 2a aF F

aa NetF F 673. 35 NHLR = 720.6 NHRR = 520 N

VLR = 3518.5 N

VRR =2208 N

with less radial load.Net axial load

-

Consider deep groove ball bearing SKF 6309

Bearing Life Estimation5th. Step (Contd):

gas both end supports of intermediate shaft:

Equivalent load on left bearing:d

=

5

5

.

3

m

m

left bearing:

1 ( ) ( )1.5 (1.0 1 3591.5 0)

r L a LC XVF YF

Y

LP X = 1 & Y = 1. 6

5053 F2255 75 NF 3620 N

aF678 N

F 2268 4NF 3591 5 N

aF= 673. 35 N

Bearing

Inner Dia.(d)

Outer Dia.(D)

Width (B)

Corner Radius (r)

Approx.

Basic Load Capacity

DynamicC

StaticC

5387. 25 N[Note: is taken as 1.5 considering medium shock load (given) on

1C r RF

2255. 75 N r LF

3620 N r RF 2268.4N r LF 3591.5 N

ea gNo.

(d) ( ) C Comm mm mm mm Newton Newton

6309 45 100 25 2.5 40130 29200

shock load (given) on the estimated load on bearings based on nominal torque.]

3 6( ) (40130 / 5387.5) 1060 (1500 17 / 81) 60

N LLN

H

L

LLife (in hrs) of left bearing:

16

60 (1500 17 / 81) 60N

60. 021880 10 hrs = 21, 880 hrs

-

Ball bearing SKF 6309 is selected for both end supports of intermediate shaft:

Similarly, estimated equivalent load and

Bearing Life Estimation5th. Step (Contd):

y, qlife of right bearing:

1.5 (1.0 1 2268.4 1.6 673.35) 5018. 64 N,RP3 6(40130 / 5018.64) 10H

R

L(1500 17 / 81) 60

H

R

6L

0. 027067 10 hrs = 27, 067 hrsNote: Estimated lives of both bearings are

l & b h50533620 N

aF678 N

aF= 673. 35 N

H

L

L 21, 880 h

r s.

more or less same & above the required specified life (10,000 hrs).H

R

L 27, 067 h

r s.

Now it can be examined the life with bearing of lower load capacity:

r RF2255. 75 N

r LF3620 N

r RF 2268.4N r LF 3591.5 N

Bearing No.

Inner Dia. (d)

Outer Dia. (D)

Width (B)

Corner Radius (r) Approx.

Basic Load Capacity

DynamicC

StaticCo

mm mm mm mm Newton Newton

g p y

As the root diameter of pinion is 55.39 mm then

6309 45 100 25 2.5 40130 29200

6308 40 90 23 2.5 31000 21400

6211 55 100 21 2.5 32100 25415

a bearing of id 55 mm (maximum) may be selected.

17

If SKF 6308 or 6211 is selected then life will be reduced by (C6309/C6308 or 6211)3 i.e., 2.17 or 1.95 times respectively, which is acceptable.

However, design with SKF 6309 will perhaps be preferred.

-

6th. Step Shaft Design Bending moment on Intermediate Shaft due to Tangential Forces (Vertical Plane)

In case of gear box the diameters of a shaft is dominated by the size (root diameter) of the

dominated by the size (root diameter) of the integral pinion and optimum bearing size mainly.

The length is determined by the placement of gear, pinion, bearings, coupling, key size,

l d h i i d

L R

seals etc. and the optimum gap required between two consecutive elements.

The a shaft is automatically shaped during first layout and bearing

53 mm 75 mm 50 mm

Layout

VLR = 3518.5 NVRR =2208 Nduring first layout and bearing

selection, as shown earlier.

Therefore, instead of designing the t 2F

= 1193.5 N

VRR 2208 N

shaft the critical sections are verified for developed stresses.

Bending Moment (respective plane) Calculation =2208 N 1014.5 N

t 3F = 4533 N Load Diagram.

3518.5 0.053 P3VBM 186. 5 Nm

3518.5 0.128 4533 0.075 G2VBM 110. 4 Nm -110. 4 Nm

e d g o e t ( espect e p a e) Ca cu at o

Shear Force Diagram (SFD).

= 3518.5 N

18

G2V

Bending Moment Diagram (BMD).

-186. 5 Nm

-

Shaft Design (Contd)

Bending Moment (respective plane) Calculation (Contd )

Bending moment on Intermediate Shaft due to Tangential Forces (Horizontal Plane)

plane) Calculation (Contd)

720 0.053 P3HB M 3 8. 2 N mL R

a2M= 30 Nm

a3M

30 N

Considering from left support Bending Moment just left of section 3-3:

720 0.053P3H-B M 3 8. 2 N m

r3F =1683 N

53 mm 75 mm 50 mm

Layout

= 30 Nm

2-23-3

P3H+BM = 68. 2 Nm= 38. 2 + 30And just right of section 3-3: r3

r2F =443 N R = 520 NR = 720 N

P3H+BM 68. 2 Nm38. 2 30

Similarly, BM just left of section 2-2:

720 0.128 1683 0.075 30 G2H-BM -4 Nm HRR = 520 NHLR = 720 N Load Diagram.

943 N

= 720 N

520 NAnd BM just right of section 2-2:

Shear Force Diagram (SFD).

943 N443 N

68.2Nm 26Nm4.1 30 G2H+BM 26 Nm

19Bending Moment Diagram (BMD).

2-23-3

-

Second Step: Resultant BendingMoment and Critical Section

6th. Step (Contd.) Shaft Design

L R

79 mm

It is to be noted that in a rotating shaft outer layer experiences maximum flexural bending stress.

53 mm 75 mm 50 mm

Layout2-23-3 3-2

As bending stress is expressed by bending moment divided by section modulus, it is necessary to verify those for probable critical sections.

-186.5Nm-110.4NmIn the Intermediate shaft, any of sections 2-2, 3-2 & 3-3 may be critical i.e., experiences

68.2Nm 26NBending Moment-Vertical Plane.

maximum bending stress.

Bending Moment-Horizontal Plane.

26Nm

2-23-3

20

-

Next: Resultant Bending Moment and Critical Section (Contd)

6th. Step (Contd.) Shaft Design

( )

L R

79 mm

Reasons are as follows:

53 mm 75 mm 50 mm

Layout2-23-3 3-2

Among these three sections, through which full torque transmits, section 3-3 has maximum bending moment, although it has also the maximum diameter.

-186.5Nm-110.4NmIt has medium stress concentration as it is roots of teeth. Sections 2-2 & 3-2 have equal diameters but diff t t t ti f t

68.2Nm 26NBending Moment-Vertical Plane.

different stress concentration factors.At section 3-2 there is step, where as at section 2-2 a there is keyway. Therefore, section 2-2 may be severe than

Bending Moment-Horizontal Plane.

26Nm

2-23-3

Therefore, section 2 2 may be severe than section 3-2 in stress concentration point of view.Again 2-2 usually experiences less BM.

21

-

Resultant Bending Moment and Critical Section (Contd) 6th. Step (Contd.) Shaft Design

L RResultant bending moment at 3-3:

79 mm2 26 8 .2 1 8 6 .5R

3- 3

B M = = 1 9 8. 6 N m

53 mm 75 mm 50 mm

Layout2-23-3 3-2

2 226 110 .4R

2- 2

B M = = 1 1 3. 4 2 N mResultant bending moment at 2-2:

-186.5 Nm

R

2 2

Resultant bending moment at 3-2 is estimated as follows:

-110.4 Nm-139.81Nm

68.2 Nm 26 N

Bending Moment-Vertical Plane.

is estimated as follows:

V

3- 2

B M = 139. 81 Nm= 3518. 5 0. 099 - 4533 0. 046

B M 23 92 N m720 6 0 099 + 30 1683 0 046

Bending Moment-Horizontal Plane.

26Nm

2-23-3

H

3- 2

B M = 2 3 . 9 2 N m= 720. 6 0. 099 + 30 - 1683 0. 046

2 22 3 .9 2 1 3 9 .8 1R

3 - 2

B M = = 1 4 1. 8 4 N m

23.92 Nm

3-2

22

-

Bending Stress and search for Critical Section (Contd)

6th. Step (Contd.) Shaft Design

L RMaximum bending stress in any section of rotating shaft (solid):

79 mm32My Mf f

d

=

5

5

.

3

m

m

d

=

5

0

m

m

53 mm 75 mm 50 mm

Layout2-23-3 3-2

3b c cyf fI d

=

(Section modulus and 4 / 64/ 2

I dy d

-186.5NmMaximum bending stress at section 3-3:

-110.4Nm-139.81Nm

stress concentration factor ).cf

68.2Nm 26NBending Moment-Vertical Plane.

3

1.5 32 198.60.0553

6

b

3- 3

= 18 10Pas

Bending Moment-Horizontal Plane.

26Nm

2-23-3

23.92Nm

3-2

cf is taken 1.5 for hob cut gear.

23

-

Bending Stress and search forCritical Section (Contd)

6th. Step (Contd.) Shaft Design

L R

79 mmMaximum bending stress at section 3-2: d =

5

5

.

3

m

m

d

=

5

0

m

m

( )

53 mm 75 mm 50 mm

Layout2-23-3 3-2

3

1 .5 32 141.840.05

6

b

3- 2

= 17. 34 10P as

cf is taken 1.5 for well designed step.

-186.5Nm -110.4Nm-139.81Nm

Maximum bending stress at section 2-2:

68.2Nm 26N

Bending Moment-Vertical Plane.3

2 32 113.420.05

6

b

3- 2

= 1 8. 5 1 0P as

f is taken 2 for milled keyway

Bending Moment-Horizontal Plane.

26Nm

2-23-3

23.92Nm

3-2

cf is taken 2 for milled keyway.

It is apparent that section 2-2 is critical.

24

-

As already mentioned earlier, in gear unit design the size of the gear shaft usually

Lastly: Verification of Overall factor of safety at Critical Section6th. Step (Contd.) Shaft Design

biased by the sizes of gears, bearing layout and centre distances. Particularly in case of shaft integral with the pinion there is little scope of pre-designing the shaft.

In such cases maximum stresses in the shaft are estimated identifying critical sections

Then a factor of safety can be estimated using the following formula, which is base on maximum shear stress theory under combined, bending, torsion and direct normal stresses.

sfIn such cases maximum stresses in the shaft are estimated identifying critical sections.

224y ym f a m

s en

S Sk

f S s enf

Where,

yS = Yield strength of shaft materialenS = Endurance strength of shaft materialgm = Mean (average) stress at considered section due to axial load.a = Maximum alternating stress at considered section due to bending.m = Maximum shear stress at considered section due to torsion.

25

m

fk = A factor considering the feature of section and severity of service. It is chosen considering on what basis has been calculated. a

-

Verification of Overall factor of safety at Critical Section (Contd)

6th. Step (Contd.) Shaft Design

L R

79 mm

d

=

5

5

.

3

m

m

d

=

5

0

m

m

Therefore, for the critical section 2-2:

y ( )In present design, the pinion is integral with shaft therefore shaft material is EN19A.

53 mm 75 mm 50 mm

Layout2-23-3 3-2

yS = 600 MPa,enS = 420 MPa (About 45% of for well

finished /ground shaft),uS

-186.5Nm -110.4Nm-139.81Nm2 2

673.520.05

am c

Ffd

60. 17210 Pas

68.2Nm 26NmBending Moment-Vertical Plane.

a 6

b

3- 2

18. 510Pas

16 16 1482Tf

0. 172 10 Pas

Bending Moment-Horizontal Plane.

26Nm

2-23-3

23.92Nm

3-2

f is taken 2 in general for milled single keyway

3 32 0.05m cf

d

61 2. 1 1 0 Pas

26

cf is taken 2 in general for milled single keyway.

-

Verification of Overall factor of safety at Critical Section (Contd)

6th. Step (Contd.) Shaft Design

L R

79 mm

d

=

5

5

.

3

m

m

d

=

5

0

m

m

y ( )

Substituting values for the critical section 2-2 is calculated as follows:

Sf

53 mm 75 mm 50 mm

Layout2-23-3 3-2

266 6 2

6

600 10 6000.172 1.5 18.5 10 4 (12.1 10 )420sf

-186.5Nm -110.4Nm-139.81Nm646.6 10

Therefore,

68.2Nm 26NBending Moment-Vertical Plane.600

46.6 sf

12. 87

Bending Moment-Horizontal Plane.

26Nm

2-23-3

23.92Nm

3-2Usually is taken as 2.5 to 3.sf

This is highly satisfactory.

27

y

-

Input ShaftThe Input Shaft is also integral with the 1st. stage pinion.

6th. Step (Contd.) Shaft Design

Therefore, the material is EN19A. Shaft design verification is done in same way as it is done for intermediate shaft.

Output ShaftpThe Output Shaft not integral with the gear. Therefore, medium carbon steel (C40 or C45, Equivalent to EN8), having ultimate strength- 560 MPa and yield strength- 280 Mpa, is taken as the

316 o

osa

TdS

material.

The Shaft diameter is initially estimated sa

In the present design considering a factor of 1.5 with nominal torque the Output torque:

on transmitted torque as follows:

1 5 31 39 1T1818 N

1.5 31 39.1oT 1818 Nm

saSConsidering allowable shear stress ( ) of material is 60 MPa.

od 53. 65 mm

Nominal

28

Considering the end bearings of ID 55 mm (Say SKF Ball Bearing 6311) Shaft design verification is done same way as is done for intermediate shaft.

o

-

Thank You

29