VITA SILHOUETTE - Stelrad

Transcript of VITA SILHOUETTE - Stelrad

Vita Series

VITA SILHOUETTE

www.stelrad.com Telephone: 0844 543 6200

z435

7-00

TYPE

P+

& K

2

posit

ion

of c

entr

al lu

g:ra

d. le

ngth

/226

726

7

radi

ator

leng

th: 1

800

to 3

000

mm

8585

133

133

radi

ator

leng

th:

400

to 1

100

mm

8585

267

267

radi

ator

leng

th:

1200

to

1600

mm

8585

TYPE

K1

8585

283

283

rad.

leng

th:

1200

to

1600

mm

8585

150

150 ra

d.le

ngth

:50

0 to

110

0 m

m

8585

117

117 ra

d.le

ngth

:40

0 m

m pos.

of c

entr

al lu

g: ra

d.le

ngth

/2 +

17

283

283

8585

radi

ator

leng

th: 1

800

to 3

000

mm

Fig. 11x p

lug

1x a

ir ve

nt

Plas

tic g

rom

met

s

+ 2

wal

l bra

cket

s(3

for

L>=

1800

)

Stel

rad

Stee

l Pan

el R

adia

tor I

nsta

llatio

n In

stru

ctio

nsA

pplic

atio

nsW

e re

com

men

d th

at S

telra

d st

eel p

anel

radi

ator

s be

only

used

on

indi

rect

hea

ting

syst

ems. T

he in

stall

atio

n sh

ould

be

in a

ccor

danc

e w

ith B

S544

9 st

anda

rd. W

hen

mak

ing

sold

ered

join

ts it

is im

port

ant t

o ch

oose

a fl

ux th

at is

read

ily so

lubl

e in

wat

er a

nd k

ept t

o th

e m

inim

um q

uant

ity o

f sol

der a

nd fl

ux a

nd th

orou

ghly

flush

ed o

n co

mpl

etio

n.

Prod

uctio

n sp

ecific

atio

nTh

e St

elra

d st

eel p

anel

rad

iato

r co

nsist

s of

a g

rille

, tw

o sid

e pa

nels

whe

n co

mpa

cted

and

indi

vidu

ally

pack

ed r

adia

tor

brac

kets

with

air

vent

, plu

g an

d pl

astic

gr

omm

ets. T

he b

rack

ets

and

hard

war

e ba

g co

ntai

ned

with

in th

e ra

diat

or a

re in

the

shrin

k w

rap

pack

agin

g.

Inst

alla

tion

of r

adia

tor

Ope

n pa

ck a

nd c

heck

con

tent

s. (F

ig 1

). It

is re

com

men

ded

on a

ll ra

diat

or ty

pes

that

the

wal

l bra

cket

s ar

e fit

ted

with

the

wid

e fla

nge

tow

ards

the

wal

l. Mea

sure

and

m

ark

on fi

wal

l rad

iato

r bra

cket

cen

tres

, ens

ure

a m

inim

um d

imen

sion

of a

100

-mm

cle

aran

ce is

kep

t at e

ither

sid

e of

fini

shed

rad

iato

r pos

ition

. Fro

m th

e flo

or

to th

e bo

ttom

edg

e of

the

brac

ket a

dim

ensio

n of

200

mm

sho

uld

be u

sed.

This

will

give

a c

orre

ct d

istan

ce fr

om th

e flo

or to

the

base

of r

adia

tor

for

heat

out

put.

Fit t

he p

last

ic gr

omm

ets

in p

ositi

on o

n ra

diat

or b

rack

ets.

Rem

ove

plas

tic tr

ansit

plu

gs fr

om th

e tw

o ra

diat

or ta

ppin

gs a

nd fi

t air

vent

and

plu

g to

the

pref

erre

d to

p LH

or

RH r

adia

tor

conn

ectio

ns, P

TFE

is no

t req

uire

d an

d ca

re s

houl

d be

take

n no

t to

over

tigh

ten.

Prep

are

radi

ator

val

ve ta

ils w

ith P

TFE

tape

and

fit t

o bo

ttom

ra

diat

or c

onne

ctio

ns. P

ositi

on r

adia

tor

to c

entr

e of

rad

iato

r w

all b

rack

ets,

mak

e ra

diat

or v

alve

con

nect

ions

, ven

t fro

m a

ir bl

eed

with

hea

ting

syst

em o

ff, ba

lanc

e ra

diat

or w

ith lo

cksh

ield

val

ve to

ens

ure

even

hea

t of a

ll sy

stem

rad

iato

rs.

NO

TE:

WH

EN F

ILLI

NG

RA

DIA

TOR

TURN

OFF

HEA

TIN

G A

ND

HO

TWAT

ER B

OIL

ER C

ON

TRO

LS, S

EALE

D

SY

STEM

S SH

OU

LD B

E RE

PRES

SURI

SED

TO

TH

E C

ORR

ECT

SYST

EM W

ORK

ING

PRE

SSU

RE.

Pote

ntia

l Haz

ards

/ Pr

ecau

tiona

ry M

easu

res

Radi

ator

s: - M

anua

l Han

dlin

g: -

Con

sult

your

em

ploy

er’s

man

ual h

andl

ing

risk

asse

ssm

ents

bef

ore

man

ually

han

dlin

g an

y ra

diat

ors.

Due

to th

eir b

ulk

or w

eigh

t, ra

diat

ors

may

be

diffi

cult

to li

ft - a

lway

s te

st th

e lo

ad fo

r wei

ght a

nd s

eek

assis

tanc

e w

hen

liftin

g he

avy

or b

ulky

load

s.

- Saf

ety:

- Fo

r you

r ow

n sa

fety

it is

reco

mm

ende

d th

at y

ou a

void

plac

ing

your

han

ds/fi

nger

s be

twee

n an

d do

wn

the

back

of t

he r

adiat

or.

Pack

agin

g: - S

uffo

catio

n:

- Ke

ep a

ll pa

ckag

ing

mat

eria

ls aw

ay fr

om c

hild

ren.

- En

sure

that

all

pack

agin

g m

ater

ials

are

disp

osed

of i

n a

safe

and

env

ironm

enta

lly fr

iend

ly m

anne

r.

6151

25

48

48

48

101 77

62

124 100 73

83

Type P+

Type K2

Type K1

RA

D.

HEI

GH

T3

00

60

07

00

A65

65

65

B119

99

99

C-

419

519

D15

34

53

55

3E

185

45

0

65

99

269

303

335

485

585

65

65

65

119

99

99

-4

19

519

15

34

53

55

3

65 99

269

303

IHF G

Type

K1,

P+

, K2

147

7

AB

11C

DE

11

25

FG

HI

E addi

tiona

l bra

cket

from

L >

=18

00

150

200

100

100

z435

7.in

dd

110

/12/

2014

14

:30:

34

z435

7-00

TYPE

P+

& K

2

posit

ion

of c

entr

al lu

g:ra

d. le

ngth

/226

726

7

radi

ator

leng

th: 1

800

to 3

000

mm

8585

133

133

radi

ator

leng

th:

400

to 1

100

mm

8585

267

267

radi

ator

leng

th:

1200

to

1600

mm

8585

TYPE

K1

8585

283

283

rad.

leng

th:

1200

to

1600

mm

8585

150

150 ra

d.le

ngth

:50

0 to

110

0 m

m

8585

117

117 ra

d.le

ngth

:40

0 m

m pos.

of c

entr

al lu

g: ra

d.le

ngth

/2 +

17

283

283

8585

radi

ator

leng

th: 1

800

to 3

000

mm

Fig. 11x p

lug

1x a

ir ve

nt

Plas

tic g

rom

met

s

+ 2

wal

l bra

cket

s(3

for

L>=

1800

)

Stel

rad

Stee

l Pan

el R

adia

tor I

nsta

llatio

n In

stru

ctio

nsA

pplic

atio

nsW

e re

com

men

d th

at S

telra

d st

eel p

anel

radi

ator

s be

only

used

on

indi

rect

hea

ting

syst

ems. T

he in

stall

atio

n sh

ould

be

in a

ccor

danc

e w

ith B

S544

9 st

anda

rd. W

hen

mak

ing

sold

ered

join

ts it

is im

port

ant t

o ch

oose

a fl

ux th

at is

read

ily so

lubl

e in

wat

er a

nd k

ept t

o th

e m

inim

um q

uant

ity o

f sol

der a

nd fl

ux a

nd th

orou

ghly

flush

ed o

n co

mpl

etio

n.

Prod

uctio

n sp

ecific

atio

nTh

e St

elra

d st

eel p

anel

rad

iato

r co

nsist

s of

a g

rille

, tw

o sid

e pa

nels

whe

n co

mpa

cted

and

indi

vidu

ally

pack

ed r

adia

tor

brac

kets

with

air

vent

, plu

g an

d pl

astic

gr

omm

ets. T

he b

rack

ets

and

hard

war

e ba

g co

ntai

ned

with

in th

e ra

diat

or a

re in

the

shrin

k w

rap

pack

agin

g.

Inst

alla

tion

of r

adia

tor

Ope

n pa

ck a

nd c

heck

con

tent

s. (F

ig 1

). It

is re

com

men

ded

on a

ll ra

diat

or ty

pes

that

the

wal

l bra

cket

s ar

e fit

ted

with

the

wid

e fla

nge

tow

ards

the

wal

l. Mea

sure

and

m

ark

on fi

wal

l rad

iato

r bra

cket

cen

tres

, ens

ure

a m

inim

um d

imen

sion

of a

100

-mm

cle

aran

ce is

kep

t at e

ither

sid

e of

fini

shed

rad

iato

r pos

ition

. Fro

m th

e flo

or

to th

e bo

ttom

edg

e of

the

brac

ket a

dim

ensio

n of

200

mm

sho

uld

be u

sed.

This

will

give

a c

orre

ct d

istan

ce fr

om th

e flo

or to

the

base

of r

adia

tor

for

heat

out

put.

Fit t

he p

last

ic gr

omm

ets

in p

ositi

on o

n ra

diat

or b

rack

ets.

Rem

ove

plas

tic tr

ansit

plu

gs fr

om th

e tw

o ra

diat

or ta

ppin

gs a

nd fi

t air

vent

and

plu

g to

the

pref

erre

d to

p LH

or

RH r

adia

tor

conn

ectio

ns, P

TFE

is no

t req

uire

d an

d ca

re s

houl

d be

take

n no

t to

over

tigh

ten.

Prep

are

radi

ator

val

ve ta

ils w

ith P

TFE

tape

and

fit t

o bo

ttom

ra

diat

or c

onne

ctio

ns. P

ositi

on r

adia

tor

to c

entr

e of

rad

iato

r w

all b

rack

ets,

mak

e ra

diat

or v

alve

con

nect

ions

, ven

t fro

m a

ir bl

eed

with

hea

ting

syst

em o

ff, ba

lanc

e ra

diat

or w

ith lo

cksh

ield

val

ve to

ens

ure

even

hea

t of a

ll sy

stem

rad

iato

rs.

NO

TE:

WH

EN F

ILLI

NG

RA

DIA

TOR

TURN

OFF

HEA

TIN

G A

ND

HO

TWAT

ER B

OIL

ER C

ON

TRO

LS, S

EALE

D

SY

STEM

S SH

OU

LD B

E RE

PRES

SURI

SED

TO

TH

E C

ORR

ECT

SYST

EM W

ORK

ING

PRE

SSU

RE.

Pote

ntia

l Haz

ards

/ Pr

ecau

tiona

ry M

easu

res

Radi

ator

s: - M

anua

l Han

dlin

g: -

Con

sult

your

em

ploy

er’s

man

ual h

andl

ing

risk

asse

ssm

ents

bef

ore

man

ually

han

dlin

g an

y ra

diat

ors.

Due

to th

eir b

ulk

or w

eigh

t, ra

diat

ors

may

be

diffi

cult

to li

ft - a

lway

s te

st th

e lo

ad fo

r wei

ght a

nd s

eek

assis

tanc

e w

hen

liftin

g he

avy

or b

ulky

load

s.

- Saf

ety:

- Fo

r you

r ow

n sa

fety

it is

reco

mm

ende

d th

at y

ou a

void

plac

ing

your

han

ds/fi

nger

s be

twee

n an

d do

wn

the

back

of t

he r

adiat

or.

Pack

agin

g: - S

uffo

catio

n:

- Ke

ep a

ll pa

ckag

ing

mat

eria

ls aw

ay fr

om c

hild

ren.

- En

sure

that

all

pack

agin

g m

ater

ials

are

disp

osed

of i

n a

safe

and

env

ironm

enta

lly fr

iend

ly m

anne

r.

6151

25

48

48

48

101 77

62

124 100 73

83

Type P+

Type K2

Type K1

RA

D.

HEI

GH

T3

00

60

07

00

A65

65

65

B119

99

99

C-

419

519

D15

34

53

55

3E

185

45

0

65

99

269

303

335

485

585

65

65

65

119

99

99

-4

19

519

15

34

53

55

3

65 99

269

303

IHF G

Type

K1,

P+

, K2

147

7

AB

11C

DE

11

25

FG

HI

E addi

tiona

l bra

cket

from

L >

=18

00

150

200

100

100

z435

7.in

dd

110

/12/

2014

14

:30:

34

t50(75/65/20ºC)

t50 is the UK’s industry standard for heating outputs, which has an operating temperature of 75/65/20ºC. If you have a low temperature heat source you may wish to consider t40 or t30 output (see your installer or system designer or download from www.stelrad.com).

K1 K2

For EN442 data, technical and installation information please visit our website: www.stelrad.com and search product downloads.

Height mm

Lengthmm

StelradUIN

Heat outputWatts Btu/h

StelradUIN

Heat outputWatts Btu/h

300500 92301105 235 802 92302205 449 1532

1000 92301110 470 1604 92302210 898 3064

1500 92301115 705 2405 92302215 1347 4596

450

400 92451104 272 928 92452204 509 1737

600 92451106 409 1396 92452206 764 2607

800 92451108 545 1860 92452208 1018 3473

1000 92451110 681 2324 92452210 1273 4343

1200 92451112 817 2788 92452212 1528 5214

1400 92451114 953 3252 92452214 1782 6080

1600 92451116 1090 3719 92452216 2037 6950

1800 92451118 1226 4183 92452218 2291 7817

600

400 92601104 348 1187 92602204 640 2184

600 92601106 522 1781 92602206 961 3279

800 92601108 696 2375 92602208 1281 4371

1000 92601110 870 2968 92602210 1601 5463

1200 92601112 1044 3562 92602212 1921 6554

1400 92601114 1218 4156 92602214 2241 7646

1600 92601116 1392 4750 92602216 2562 8742

1800 92601118 1566 5343 92602218 2882 9833

2000 92601120 1740 5937 92602220 3202 10925

Vita Series

VITA SILHOUETTE

WALL MOUNTING AND LUG INFORMATIONAll dimensions in mm. Inches in brackets.

z435

7-00

TYPE

P+

& K

2

posit

ion

of c

entr

al lu

g:ra

d. le

ngth

/226

726

7

radi

ator

leng

th: 1

800

to 3

000

mm

8585

133

133

radi

ator

leng

th:

400

to 1

100

mm

8585

267

267

radi

ator

leng

th:

1200

to

1600

mm

8585

TYPE

K1

8585

283

283

rad.

leng

th:

1200

to

1600

mm

8585

150

150 ra

d.le

ngth

:50

0 to

110

0 m

m

8585

117

117 ra

d.le

ngth

:40

0 m

m pos.

of c

entr

al lu

g: ra

d.le

ngth

/2 +

17

283

283

8585

radi

ator

leng

th: 1

800

to 3

000

mm

Fig. 11x p

lug

1x a

ir ve

nt

Plas

tic g

rom

met

s

+ 2

wal

l bra

cket

s(3

for

L>=

1800

)

Stel

rad

Stee

l Pan

el R

adia

tor I

nsta

llatio

n In

stru

ctio

nsA

pplic

atio

nsW

e re

com

men

d th

at S

telra

d st

eel p

anel

radi

ator

s be

only

used

on

indi

rect

hea

ting

syst

ems. T

he in

stall

atio

n sh

ould

be

in a

ccor

danc

e w

ith B

S544

9 st

anda

rd. W

hen

mak

ing

sold

ered

join

ts it

is im

port

ant t

o ch

oose

a fl

ux th

at is

read

ily so

lubl

e in

wat

er a

nd k

ept t

o th

e m

inim

um q

uant

ity o

f sol

der a

nd fl

ux a

nd th

orou

ghly

flush

ed o

n co

mpl

etio

n.

Prod

uctio

n sp

ecific

atio

nTh

e St

elra

d st

eel p

anel

rad

iato

r co

nsist

s of

a g

rille

, tw

o sid

e pa

nels

whe

n co

mpa

cted

and

indi

vidu

ally

pack

ed r

adia

tor

brac

kets

with

air

vent

, plu

g an

d pl

astic

gr

omm

ets. T

he b

rack

ets

and

hard

war

e ba

g co

ntai

ned

with

in th

e ra

diat

or a

re in

the

shrin

k w

rap

pack

agin

g.

Inst

alla

tion

of r

adia

tor

Ope

n pa

ck a

nd c

heck

con

tent

s. (F

ig 1

). It

is re

com

men

ded

on a

ll ra

diat

or ty

pes

that

the

wal

l bra

cket

s ar

e fit

ted

with

the

wid

e fla

nge

tow

ards

the

wal

l. Mea

sure

and

m

ark

on fi

wal

l rad

iato

r bra

cket

cen

tres

, ens

ure

a m

inim

um d

imen

sion

of a

100

-mm

cle

aran

ce is

kep

t at e

ither

sid

e of

fini

shed

rad

iato

r pos

ition

. Fro

m th

e flo

or

to th

e bo

ttom

edg

e of

the

brac

ket a

dim

ensio

n of

200

mm

sho

uld

be u

sed.

This

will

give

a c

orre

ct d

istan

ce fr

om th

e flo

or to

the

base

of r

adia

tor

for

heat

out

put.

Fit t

he p

last

ic gr

omm

ets

in p

ositi

on o

n ra

diat

or b

rack

ets.

Rem

ove

plas

tic tr

ansit

plu

gs fr

om th

e tw

o ra

diat

or ta

ppin

gs a

nd fi

t air

vent

and

plu

g to

the

pref

erre

d to

p LH

or

RH r

adia

tor

conn

ectio

ns, P

TFE

is no

t req

uire

d an

d ca

re s

houl

d be

take

n no

t to

over

tigh

ten.

Prep

are

radi

ator

val

ve ta

ils w

ith P

TFE

tape

and

fit t

o bo

ttom

ra

diat

or c

onne

ctio

ns. P

ositi

on r

adia

tor

to c

entr

e of

rad

iato

r w

all b

rack

ets,

mak

e ra

diat

or v

alve

con

nect

ions

, ven

t fro

m a

ir bl

eed

with

hea

ting

syst

em o

ff, ba

lanc

e ra

diat

or w

ith lo

cksh

ield

val

ve to

ens

ure

even

hea

t of a

ll sy

stem

rad

iato

rs.

NO

TE:

WH

EN F

ILLI

NG

RA

DIA

TOR

TURN

OFF

HEA

TIN

G A

ND

HO

TWAT

ER B

OIL

ER C

ON

TRO

LS, S

EALE

D

SY

STEM

S SH

OU

LD B

E RE

PRES

SURI

SED

TO

TH

E C

ORR

ECT

SYST

EM W

ORK

ING

PRE

SSU

RE.

Pote

ntia

l Haz

ards

/ Pr

ecau

tiona

ry M

easu

res

Radi

ator

s: - M

anua

l Han

dlin

g: -

Con

sult

your

em

ploy

er’s

man

ual h

andl

ing

risk

asse

ssm

ents

bef

ore

man

ually

han

dlin

g an

y ra

diat

ors.

Due

to th

eir b

ulk

or w

eigh

t, ra

diat

ors

may

be

diffi

cult

to li

ft - a

lway

s te

st th

e lo

ad fo

r wei

ght a

nd s

eek

assis

tanc

e w

hen

liftin

g he

avy

or b

ulky

load

s.

- Saf

ety:

- Fo

r you

r ow

n sa

fety

it is

reco

mm

ende

d th

at y

ou a

void

plac

ing

your

han

ds/fi

nger

s be

twee

n an

d do

wn

the

back

of t

he r

adiat

or.

Pack

agin

g: - S

uffo

catio

n:

- Ke

ep a

ll pa

ckag

ing

mat

eria

ls aw

ay fr

om c

hild

ren.

- En

sure

that

all

pack

agin

g m

ater

ials

are

disp

osed

of i

n a

safe

and

env

ironm

enta

lly fr

iend

ly m

anne

r.

6151

25

48

48

48

101 77

62

124 100 73

83

Type P+

Type K2

Type K1

RAD

.H

EIG

HT

300

600

700

A65

65

65

B119

99

99

C-

419

519

D15

34

53

55

3E

185

450

65

99

269

303

335

485

585

65

65

65

119

99

99

-4

19

519

15

34

53

55

3

65 99

269

303

IHF G

Type

K1,

P+

, K2

147

7

AB

11C

DE

11

25

FG

HI

E addi

tiona

l bra

cket

from

L >

=18

00

150

200

100

100

z435

7.in

dd

110

/12/

2014

14

:30:

34

z435

7-00

TYPE

P+

& K

2

posit

ion

of c

entr

al lu

g:ra

d. le

ngth

/226

726

7

radi

ator

leng

th: 1

800

to 3

000

mm

8585

133

133

radi

ator

leng

th:

400

to 1

100

mm

8585

267

267

radi

ator

leng

th:

1200

to

1600

mm

8585

TYPE

K1

8585

283

283

rad.

leng

th:

1200

to

1600

mm

8585

150

150 ra

d.le

ngth

:50

0 to

110

0 m

m

8585

117

117 ra

d.le

ngth

:40

0 m

m pos.

of c

entr

al lu

g: ra

d.le

ngth

/2 +

17

283

283

8585

radi

ator

leng

th: 1

800

to 3

000

mm

Fig. 11x p

lug

1x a

ir ve

nt

Plas

tic g

rom

met

s

+ 2

wal

l bra

cket

s(3

for

L>=

1800

)

Stel

rad

Stee

l Pan

el R

adia

tor I

nsta

llatio

n In

stru

ctio

nsA

pplic

atio

nsW

e re

com

men

d th

at S

telra

d st

eel p

anel

radi

ator

s be

only

used

on

indi

rect

hea

ting

syst

ems. T

he in

stall

atio

n sh

ould

be

in a

ccor

danc

e w

ith B

S544

9 st

anda

rd. W

hen

mak

ing

sold

ered

join

ts it

is im

port

ant t

o ch

oose

a fl

ux th

at is

read

ily so

lubl

e in

wat

er a

nd k

ept t

o th

e m

inim

um q

uant

ity o

f sol

der a

nd fl

ux a

nd th

orou

ghly

flush

ed o

n co

mpl

etio

n.

Prod

uctio

n sp

ecific

atio

nTh

e St

elra

d st

eel p

anel

rad

iato

r co

nsist

s of

a g

rille

, tw

o sid

e pa

nels

whe

n co

mpa

cted

and

indi

vidu

ally

pack

ed r

adia

tor

brac

kets

with

air

vent

, plu

g an

d pl

astic

gr

omm

ets. T

he b

rack

ets

and

hard

war

e ba

g co

ntai

ned

with

in th

e ra

diat

or a

re in

the

shrin

k w

rap

pack

agin

g.

Inst

alla

tion

of r

adia

tor

Ope

n pa

ck a

nd c

heck

con

tent

s. (F

ig 1

). It

is re

com

men

ded

on a

ll ra

diat

or ty

pes

that

the

wal

l bra

cket

s ar

e fit

ted

with

the

wid

e fla

nge

tow

ards

the

wal

l. Mea

sure

and

m

ark

on fi

wal

l rad

iato

r bra

cket

cen

tres

, ens

ure

a m

inim

um d

imen

sion

of a

100

-mm

cle

aran

ce is

kep

t at e

ither

sid

e of

fini

shed

rad

iato

r pos

ition

. Fro

m th

e flo

or

to th

e bo

ttom

edg

e of

the

brac

ket a

dim

ensio

n of

200

mm

sho

uld

be u

sed.

This

will

give

a c

orre

ct d

istan

ce fr

om th

e flo

or to

the

base

of r

adia

tor

for

heat

out

put.

Fit t

he p

last

ic gr

omm

ets

in p

ositi

on o

n ra

diat

or b

rack

ets.

Rem

ove

plas

tic tr

ansit

plu

gs fr

om th

e tw

o ra

diat

or ta

ppin

gs a

nd fi

t air

vent

and

plu

g to

the

pref

erre

d to

p LH

or

RH r

adia

tor

conn

ectio

ns, P

TFE

is no

t req

uire

d an

d ca

re s

houl

d be

take

n no

t to

over

tigh

ten.

Prep

are

radi

ator

val

ve ta

ils w

ith P

TFE

tape

and

fit t

o bo

ttom

ra

diat

or c

onne

ctio

ns. P

ositi

on r

adia

tor

to c

entr

e of

rad

iato

r w

all b

rack

ets,

mak

e ra

diat

or v

alve

con

nect

ions

, ven

t fro

m a

ir bl

eed

with

hea

ting

syst

em o

ff, ba

lanc

e ra

diat

or w

ith lo

cksh

ield

val

ve to

ens

ure

even

hea

t of a

ll sy

stem

rad

iato

rs.

NO

TE:

WH

EN F

ILLI

NG

RA

DIA

TOR

TURN

OFF

HEA

TIN

G A

ND

HO

TWAT

ER B

OIL

ER C

ON

TRO

LS, S

EALE

D

SY

STEM

S SH

OU

LD B

E RE

PRES

SURI

SED

TO

TH

E C

ORR

ECT

SYST

EM W

ORK

ING

PRE

SSU

RE.

Pote

ntia

l Haz

ards

/ Pr

ecau

tiona

ry M

easu

res

Radi

ator

s: - M

anua

l Han

dlin

g: -

Con

sult

your

em

ploy

er’s

man

ual h

andl

ing

risk

asse

ssm

ents

bef

ore

man

ually

han

dlin

g an

y ra

diat

ors.

Due

to th

eir b

ulk

or w

eigh

t, ra

diat

ors

may

be

diffi

cult

to li

ft - a

lway

s te

st th

e lo

ad fo

r wei

ght a

nd s

eek

assis

tanc

e w

hen

liftin

g he

avy

or b

ulky

load

s.

- Saf

ety:

- Fo

r you

r ow

n sa

fety

it is

reco

mm

ende

d th

at y

ou a

void

plac

ing

your

han

ds/fi

nger

s be

twee

n an

d do

wn

the

back

of t

he r

adiat

or.

Pack

agin

g: - S

uffo

catio

n:

- Ke

ep a

ll pa

ckag

ing

mat

eria

ls aw

ay fr

om c

hild

ren.

- En

sure

that

all

pack

agin

g m

ater

ials

are

disp

osed

of i

n a

safe

and

env

ironm

enta

lly fr

iend

ly m

anne

r.

6151

25

48

48

48

101 77

62

124 100 73

83

Type P+

Type K2

Type K1

RAD

.H

EIG

HT

300

600

700

A65

65

65

B119

99

99

C-

419

519

D15

34

53

55

3E

185

450

65

99

269

303

335

485

585

65

65

65

119

99

99

-4

19

519

15

34

53

55

3

65 99

269

303

IHF G

Type

K1,

P+

, K2

147

7

AB

11C

DE

11

25

FG

HI

E addi

tiona

l bra

cket

from

L >

=18

00

150

200

100

100

z435

7.in

dd

110

/12/

2014

14

:30:

34

z4357-00

TYPE P+ & K2

position of central lug:rad. length/2

267 267

radiator length: 1800 to 3000 mm

8585

133 133

radiator length: 400 to 1100 mm

8585

267 267

radiator length:1200 to 1600 mm

8585

TYPE K1

8585

283283

rad.length:1200 to 1600 mm

8585

150150

rad.length:500 to 1100 mm

8585

117117

rad.length:400 mm

pos. of central lug: rad.length/2 + 17 283283

8585

radiator length: 1800 to 3000 mm

Fig.

1

1x plug

1x air vent

Plastic grommets

+ 2 wall brackets(3 for L>=1800)

Stelrad Steel Panel Radiator Installation InstructionsApplicationsWe recommend that Stelrad steel panel radiators be only used on indirect heating systems. The installation should be in accordance with BS5449 standard. When making soldered joints it is important to choose a flux that is readily soluble in water and kept to the minimum quantity of solder and flux and thoroughly flushed on completion.

Production specificationThe Stelrad steel panel radiator consists of a grille, two side panels when compacted and individually packed radiator brackets with air vent, plug and plastic grommets. The brackets and hardware bag contained within the radiator are in the shrink wrap packaging.

Installation of radiatorOpen pack and check contents. (Fig 1). It is recommended on all radiator types that the wall brackets are fitted with the wide flange towards the wall. Measure and mark on fixing wall radiator bracket centres, ensure a minimum dimension of a 100-mm clearance is kept at either side of finished radiator position. From the floor to the bottom edge of the bracket a dimension of 200 mm should be used. This will give a correct distance from the floor to the base of radiator for heat output. Fit the plastic grommets in position on radiator brackets. Remove plastic transit plugs from the two radiator tappings and fit air vent and plug to the preferred top LH or RH radiator connections, PTFE is not required and care should be taken not to over tighten. Prepare radiator valve tails with PTFE tape and fit to bottom radiator connections. Position radiator to centre of radiator wall brackets, make radiator valve connections, vent from air bleed with heating system off, balance radiator with lockshield valve to ensure even heat of all system radiators.

NOTE: WHEN FILLING RADIATOR TURN OFF HEATING AND HOTWATER BOILER CONTROLS, SEALED SYSTEMS SHOULD BE REPRESSURISED TO THE CORRECT SYSTEM WORKING PRESSURE.

Potential Hazards / Precautionary MeasuresRadiators: - Manual Handling: - Consult your employer’s manual handling risk assessments before manually handling any radiators. Due to their bulk or weight,

radiators may be difficult to lift - always test the load for weight and seek assistance when lifting heavy or bulky loads. - Safety: - For your own safety it is recommended that you avoid placing your hands/fingers between and down the back of the radiator.

Packaging: - Suffocation: - Keep all packaging materials away from children. - Ensure that all packaging materials are disposed of in a safe and environmentally friendly manner.

6151

25 48 48 48101

7762

124100

73

83

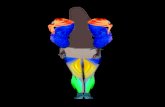

TypeP+

TypeK2

TypeK1

RAD.HEIGHT 300 600 700

A 65 65 65B 119 99 99C - 419 519D 153 453 553E 185

450

6599

269303335 485 585

65 65 65119 99 99

- 419 519153 453 553

6599

269303I

H

FG

Type K1, P+, K2

1477

AB

11C

DE

11

25

FG

HI

E

additional bracketfrom L >=1800

150

200

100

100

z4357.indd 1 10/12/2014 14:30:34

z4357-00

TYPE P+ & K2

position of central lug:rad. length/2

267 267

radiator length: 1800 to 3000 mm

8585

133 133

radiator length: 400 to 1100 mm

8585

267 267

radiator length:1200 to 1600 mm

8585

TYPE K1

8585

283283

rad.length:1200 to 1600 mm

8585

150150

rad.length:500 to 1100 mm

8585

117117

rad.length:400 mm

pos. of central lug: rad.length/2 + 17 283283

8585

radiator length: 1800 to 3000 mm

Fig.

1

1x plug

1x air vent

Plastic grommets

+ 2 wall brackets(3 for L>=1800)

Stelrad Steel Panel Radiator Installation InstructionsApplicationsWe recommend that Stelrad steel panel radiators be only used on indirect heating systems. The installation should be in accordance with BS5449 standard. When making soldered joints it is important to choose a flux that is readily soluble in water and kept to the minimum quantity of solder and flux and thoroughly flushed on completion.

Production specificationThe Stelrad steel panel radiator consists of a grille, two side panels when compacted and individually packed radiator brackets with air vent, plug and plastic grommets. The brackets and hardware bag contained within the radiator are in the shrink wrap packaging.

Installation of radiatorOpen pack and check contents. (Fig 1). It is recommended on all radiator types that the wall brackets are fitted with the wide flange towards the wall. Measure and mark on fixing wall radiator bracket centres, ensure a minimum dimension of a 100-mm clearance is kept at either side of finished radiator position. From the floor to the bottom edge of the bracket a dimension of 200 mm should be used. This will give a correct distance from the floor to the base of radiator for heat output. Fit the plastic grommets in position on radiator brackets. Remove plastic transit plugs from the two radiator tappings and fit air vent and plug to the preferred top LH or RH radiator connections, PTFE is not required and care should be taken not to over tighten. Prepare radiator valve tails with PTFE tape and fit to bottom radiator connections. Position radiator to centre of radiator wall brackets, make radiator valve connections, vent from air bleed with heating system off, balance radiator with lockshield valve to ensure even heat of all system radiators.

NOTE: WHEN FILLING RADIATOR TURN OFF HEATING AND HOTWATER BOILER CONTROLS, SEALED SYSTEMS SHOULD BE REPRESSURISED TO THE CORRECT SYSTEM WORKING PRESSURE.

Potential Hazards / Precautionary MeasuresRadiators: - Manual Handling: - Consult your employer’s manual handling risk assessments before manually handling any radiators. Due to their bulk or weight,

radiators may be difficult to lift - always test the load for weight and seek assistance when lifting heavy or bulky loads. - Safety: - For your own safety it is recommended that you avoid placing your hands/fingers between and down the back of the radiator.

Packaging: - Suffocation: - Keep all packaging materials away from children. - Ensure that all packaging materials are disposed of in a safe and environmentally friendly manner.

6151

25 48 48 48

10177

62

124100

73

83

TypeP+

TypeK2

TypeK1

RAD.HEIGHT 300 600 700

A 65 65 65B 119 99 99C - 419 519D 153 453 553E 185

450

6599

269303335 485 585

65 65 65119 99 99

- 419 519153 453 553

6599

269303I

H

FG

Type K1, P+, K2

1477

AB

11C

DE

11

25

FG

HI

E

additional bracketfrom L >=1800

150

200

100

100

z4357.indd 1 10/12/2014 14:30:34

Dimensions mm inches mm inches mm inches

Height 300 11.81 450 17.72 600 23.62

A 65 2.56 65 2.56 65 2.56

B 119 4.69 99 3.90 99 3.90

C - - 269 10.59 419 16.50

D 153 6.02 303 11.93 453 17.83

E 185 7.28 335 13.19 485 19.09

MOUNTING BRACKETSAll dimensions in mm. Inches in brackets. Floor mounting brackets available.

11 (0.43)

11 (0.43)

25 (0.98) 14 (0.55)

21 (0.83)32 (1.26)

54 (2.13)

61 (2.40)25 (0.98) 14 (0.55)

21 (0.83)32 (1.26)

11 (0.43)

11 (0.43) 11 (0.43)

A

B

DE

AB

CD

E

AB

CD

E

85 (3.35)126 (4.96)

K1 K2

51 (2.01) 73 (2.87)

63 (2.48)

51

25 48

4873

102 (4.02)

Vita Series

VITA SILHOUETTE

K1 & K2 LUG POSITIONSAll dimensions in mm. Inches in brackets.

K1 K2PANEL HEIGHT D

Dimensions mm in mm in

A 400mm 117 4.61 133 5.24

A 500 - 2000mm 150 5.91 133 5.24

B 400 - 2000mm 60 2.36 60 2.36

C 1800 - 2000mm 17 0.67 L/2 L/2

mm in mm in

300 11.81 155 6.10

450 17.72 305 12.01

600 23.62 455 17.91

700 27.56 555 21.95

1800 (70.78) - 2000 (78.74) LONG

L/2 is the length divided by two.

CONNECTIONSEach radiator comes with ½” inlet connections as standard.

PIPING OPTIONS