vicz@ims. dmt. epfl. ch b i · through terminal ports. An effort (or intensive) variable and a flow...

Transcript of vicz@ims. dmt. epfl. ch b i · through terminal ports. An effort (or intensive) variable and a flow...

Microsystem modelling using VHDL 1076.1

B. Romanowicz", C. Schotf, M. Laudon", P. Larch", P. Renaud*,

R.S. Popovic", H.P. Amann\ A. Boegli\ V. Moser\ F. Pellandini''

Switzerland

Email: bart. romano\vicz@ims. dmt. epfl. chb i

Abstract

Specification, simulation and optimization of sensors and actuators can be done throughbehavioral modeling using analog hardware description languages. The resulting models can beused in conjunction with models of the associated electronics to simulate a completemicrosystem. This paper presents VHDL 1076.1 modeling considerations applicable tomicrosystem design and simulation. The methodology will be applied in the case of a Hallmagnetic sensor.

1 Introduction

Microsystems can be defined as systems of small dimensions essentiallycomposed of sensors/actuators and a signal processing part, and are oftendescribed as micro-electro-mechanical-systems or MEMS. Usually, the sensorsand actuators are made of silicon (Si) microstructures while the signal processingfunctionality is achieved by appropriate electronics. The manufacturingtechnologies are derived from microelectronics manufacturing processes andinclude photolithography, bulk micromachining, surface micromachining, thinfilms and electroplating. The small dimensions and semiconductor substratesused in these devices produce strong physical coupling between the mechanical,thermal, electric, electrostatic and electromagnetic fields. Additionally, electricalsignal processing used on the measurands can have a strong effect on the behaviorof such devices. These different interactions have to be taken into account foraccurate simulation of such systems.

1.1 Microsystem simulation

For micro structure simulation, analytical and especially finite-element (FE)techniques are used [1-4]. For digital electronics, event-driven simulation

Transactions on the Built Environment vol 31, © 1997 WIT Press, www.witpress.com, ISSN 1743-3509

180 Simulation and Design of Microsystems and Microstructures

techniques, e.g. based on VHDL, are indicated. Analog electronics havetraditionally been simulated with SPICE-like tools. With the arrival of analoghardware description languages, behavioral simulation has become possible too.The challenge is to make simulation models and simulators for the differentdomains interact such that complete microsystems can be simulated.

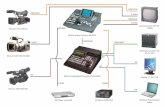

For the domain of microelectronics, most of the problems are solved, coupledtime-continuos and event-driven simulators are available such that it is possibleto perform multi-level mixed-mode simulation combining analog, digital andmixed electronics of various levels of abstraction: from behavioral descriptionsdown to post-layout simulations. Furthermore, upcoming tools allow for the co-simulation of electronic hardware and software; processors and their programscan be simulated in conjunction with surrounding electronics (fig. 1). In thepresent paper, this part - as important as it is for microsystem applicationengineers - will not be treated.

TopologyGeometryMaterialproperties

Compactdescriptionof device interms ofphysicalstatevariables

VHDL-ASIMULINKSPICE

Figure 1. Modeling and simulation flow.

There still remains the problem of the coupling of microstructure simulationwith microelectronics simulation. We have chosen to focus on a solution wherebehavioral language elements of modern HDLs (Hardware DescriptionLanguages) developed for microelectronics are used to describe the behavior ofsensors, actuators, but also of pure non-electrical devices, e.g. devices used tocomplete a control loop or a system testbench. With our choice, thecompatibility of both languages and tools for models of microstructures andmicroelectronics is implicit. Furthermore, analog HDL simulators may also beused as lumped parameter (discrete variable) analog solvers to simulatetransducers by exploiting electrical-mechanical analogies (also known as theequivalent circuit approach). The ordinary differential equations of a physicaldevice are solved by finding an electrical circuit presenting the same equations, adifficult procedure when modeling non-linear devices presenting behavioraldiscontinuities. Usually, all components are linearized around an operating (bias)point [5], limiting the validity of these models to small-signal analysis. In [6] wedemonstrate how hardware description languages (HDLs) [7] can be used toderive non-linear models of devices which are valid for large signal analysis.Current EDA tools are being adapted to cater for the needs of the microsystem

Transactions on the Built Environment vol 31, © 1997 WIT Press, www.witpress.com, ISSN 1743-3509

designer. Etching simulators, design rule checkers, electro-thermal simulators andcomponent libraries are appearing [8],

1.2 Previous work

In previous papers we have shown how to use FE techniques and physicalparameter extraction to characterize devices [9]. The resulting compactbehavioral descriptions and/or macro-models make an abstraction of geometry,material properties and continuous fields. Behavioral HDL models may then begenerated for analog simulators and mixed signal simulators to perform systemlevel simulation with all the interacting components. This approach is valid forall systems which can be modeled using discrete variables. As with all lumpedparameter systems, the generally applicable assumptions of negligible fringefields, wavelengths greater than all characteristic dimensions of a device, perfectconductors, etc. are assumed.

1.3 Hardware description language

In this paper we concentrate on VHDL 1076.1 modeling techniques [10]applicable to the simulation of MEMS devices in general [11]. VHDL 1076. 1also know as VHDL-AMS (VHDL-Analog and Mixed Signal) [12] is anupcoming standard for analog and mixed electronic devices conceived as anextension to VHDL 1076 for digital electronic devices, standardized first in 1987.The scope of the language is considerable and allows the simulation ofcontinuous and mixed continuous/discrete systems at different levels ofabstraction. Support of non-electrical disciplines is possible with the samesystem structure and behavior. However, since the standardization process is notyet completed and the tools not yet available, experiments have been conductedwith ANACAD's proprietary HDL-A™ and the VHDL 1076.1 modelsgenerated accordingly.

In the following sections we will present modeling techniques, and inparticular analog discontinuity modeling techniques supporting them with avertical Hall magnetic sensor example. Finally we present criteria for the efficientmodeling of MEMS devices and draw conclusions.

2 Modeling principles

VHDL-AMS caters for considerable flexibility in the modeling of analog (orcontinuous) systems. Lumped systems may be modeled using conservative andnon-conservative (signal-flow) semantics. Continuous behavior is described withdifferential and algebraic equations (DAEs) whose solution may includediscontinuities (the use of partial derivatives is however excluded). These may beused advantageously to model microsystem devices at different levels of detail orabstraction. Different modeling approaches are available and have a stronginfluence on the model behavior.

Transactions on the Built Environment vol 31, © 1997 WIT Press, www.witpress.com, ISSN 1743-3509

182 Simulation and Design of Microsystems and Micros true tures

2.1 Behavioral data types

Behavior knowledge of the sensor or actuator may be obtained through differentmeans. When the geometry is simple and physical coupling is limited,sensors/actuators may be mathematically modeled using ordinary differentialequations. FE analysis may be used to simulate the device behavior for givenboundary conditions; the device behavior is then a set of numerical data.Laboratory experiments may be performed to characterize existing devicesresulting in numerical data. Equations may be fitted to numerical data to obtain asimple mathematical expression. The nature of the data describing the devicebehavior will evidently influence the VHDL-AMS modeling approach selected.

2.2 Physical sensors

Smart sensor microsystems are composed of an information-capturing part (asensor) and an electronic signal processing part. In many cases, the sensor maybe viewed as a passive device from the electronic point of view; energy (with theexception of thermal losses) is not transmitted from the electrical system to theoutside world. Physical sensors such as temperature sensors, piezoresistivepressure sensors, piezoresistive fluid flow sensors, ISFETs, gas sensors,humidity sensors, Hall effect magnetic field sensors and reluctant proximitysensors fall into this classification. These sensors may all be modeled using amixed (signal flow/conservative) semantic approach where a single quantity portis used to sense an external physical stimulus, the output being modeled as anelectrical load or source using conservative interface objects called terminal ports.

2.3 Physical transducers

Actuators by definition convert energy from one form to another and aremodeled as conservative systems. Physical laws governing closed energyconserving systems are applicable. Where an internal form of energy is presentand may be expressed analytically, expressions may be derived to describe thebehavior of the device [6]. MEMS actuator/transducer devices such aselectrostatic accelerometers, electrostatic pressure sensors, resonatinggyroscopes/navigation systems, electrostatic micromotors, reluctant micro-relays, electromagnetic proximity/displacement sensors and electrodynamictransducers fall into this category. The set of DAEs that define the devicebehavior are built from the constitutive equations, the equations derived from thestructural composition of the design entities, and the equations derived from theconservative semantics. Note that SPICE simulators do not verify theconservation of energy. It is the author's responsibility to enforce conservativeconstitutive equations describing the analog behavior required.

Transactions on the Built Environment vol 31, © 1997 WIT Press, www.witpress.com, ISSN 1743-3509

Simulation and Design of Microsystems and Microstructures 183

3 Simulation of conservative systems

Electrical simulators are adapted to simulating conservative systems such asthose satisfying Kirchoff s laws. Energy exchange between models occursthrough terminal ports. An effort (or intensive) variable and a flow variable isassociated with each terminal, the product of which is a power. These variablesare called power variables in bond-graph theory [13]. The flow variable is definedas the time derivative of the state (or extensive) variable. In VHDL-AMSterminology the effort and flow variables are defined as across and throughbranch quantities and are used in the constitutive equations which define thebehavior of the model [10].

4 Conservative semantic modeling of a magnetic field sensor

In order to illustrate how behavioral models of sensors may be derived from dataobtained from device-level FE simulation, the modeling of a Hall magnetic fieldsensor is presented in this section.

4.1 The vertical Hall magnetic sensor studied

The vertical Hall device is an integrated silicon magnetic field sensor presenting avery linear behavior. The relatively low Hall coefficient of Si is offset by long-term stability, relatively low temperature cross-sensitivity and good linearity athigher magnetic fields. This is not the case for high carrier mobility compoundsemiconductors, such as InSb and InAs, generally used in high precisionmagnetometry.

The origin of the Hall effect is the Lorenz force on moving charge carriers in amagnetic field, and appears in two forms [14]. In long (current direction), thinsemiconductor strips, a Hall electric field (no current deflection) appearsperpendicular to the current and the external magnetic field. In short, thin strips acurrent deflection (equivalent to the Hall angle) is observed at the current contactinterfaces. The Hall voltage does not appear because the magnetic electro-motiveforce is short-circuited by the current contacts. These effects are known as thegeometric non-linearities, and may be modeled using the FEM.

Additionally, a non-linear behavior is present owing to a non-homogeneouscharge carrier velocity distribution. The effect is known as the material non-linearity. The geometric and material non-linearities follow a quadratic behaviorof opposite sign with the magnetic flux density at low fields.

The junction field effect (JFE) non-linearity occurs owing to a variation of thewidth of the depletion layer which is an electric potential barrier (insulator)defining the geometry of the active region in the sensor (trench). Variations of thewidth of this insulator region may be restricted by polarizing the substrate (andtherefore the sensing region) at a voltage midway between the sensing electrode

voltages [15].

Transactions on the Built Environment vol 31, © 1997 WIT Press, www.witpress.com, ISSN 1743-3509

184 Simulation and Design of Microsystems and Micro structures

o\ 12 urn 25 urn 37 urn 50 urn

Figure 2 a) Mask used to manufacture vertical Hall devices with different contact lengthsa. b) Photograph of vertical Hall device glued and wire bonded to ceramic substrate.

The vertical Hall device is used for applications where sensitivity to themagnetic field parallel to the device surface (normal to the active trench) ispreferred. The region that plays the role of the Hall sensor is manufacturedperpendicular to the chip plane so that all contacts appear on the top chipsurface. The mask used to realize the sensor contacts is presented in figure 2 a).The four different sense electrode widths (a) manufactured and simulated areshown. Figure 2 b) shows the vertical Hall device mounted using a low stressprocedure to preclude piezoresistive effects.

4.2 FE device simulation

3D FE simulations were performed using the SESES™ software [3]. Figure 3 ashows the negatively doped substrate region. Contact regions are visible on topof the silicon. The reduced semiconductor transport equation kernel [16] wasused in these simulations as the insulating region (junction) may be keptconstant. The P-doped region defining the active zone was therefore removedfrom the FE model. From left, the contacts are IL (left current ground), SL(sensor left), 1C (input source current), SR (sensor right), IR (right currentground) are visible. Hall devices are current-polarized to obtain the most linearbehavior possible (constant charge carrier flow). An input current of 1 mA wasused for all of the simulations, the sensor electrode width and magnetic fluxdensity (B) being varied. The MobArora semiconductor material mobility model,allowing fully coupled thermo-electrical simulations of Silicon based devices wasused in these simulations.

The calculated electric potential distribution is displayed in figure 4 a for amagnetic flux density of 2 T, and a Hall electrode width of 12 microns.Automatic mesh refinement (based on a local error function) occurs in the regionsof high current density near 1C contact. This feature is a great aid in modelingsemiconductors where high field gradients occur at junctions and doped regioninterfaces. It is also computationally efficient by distributing the error in an evenmanner throughout the model for a given maximum element number.

The voltage on the input source current contact (1C) was also extracted fromthe FE analyses, and is plotted in figure 4 b. A quadratic behavior is visible forincreasing strengths of the magnetic field. A strong short-circuiting behavior

Transactions on the Built Environment vol 31, © 1997 WIT Press, www.witpress.com, ISSN 1743-3509

Simulation and Design of Microsystems and Microstructures 185

manifests itself for increasing widths of the sense electrodes. By increasing thecontact surface area on the top of the chip, the apparent resistance between the1C and the IL and IR ground terminals decreases.

Figure 3 a) Detail of FE model used to simulate vertical Hall device. The trench cut intothe silicon wafer is the insulating junction around the active region. The five contacts arevisible in the center of the model, b) Simulated Hall voltage as a function of the magnetic

flux density and the width of the Hall contacts.

lagnetic (lux density [T]

Figure 4. a) Simulated Hall voltage as a function of the magnetic flux density and thewidth of the Hall contacts, b) Simulated input voltage at the 1C current terminal as a

function of magnetic flux density and the width of the Hall contacts for an input currentof 1 mA.

The simulations clearly demonstrate that the configuration of the device witha Hall electrode width of 12 microns presents the highest sensitivity andlinearity.

4.3 HDL modeling

Using the parameters extracted from the continuous field FE simulations of themagnetic sensor it is possible to create a behavioral HDL model of the device fora circuit simulator to aid in the development of linearization and driftcompensation electronics. VHDL 1076.1 will be used to model this example as adevice presenting piecewise linear defined behavior.Figure 5 presents a schematic of the approach used to model the device. At left,the B terminal represents the magnetic flux density which is read as a voltage bythe model. The nature of this terminal is magnetic. The IL and IR current groundterminals are connected as a single electrical terminal at the bottom of the model.This terminal must be grounded to corresponds to the boundary conditions

Transactions on the Built Environment vol 31, © 1997 WIT Press, www.witpress.com, ISSN 1743-3509

186 Simulation and Design of Microsystems and Microstructures

applied on the FE model. The 1C contact is visible at top in the center, andpresent a variable resistive load derived from the simulated input voltage for aninput current /,„ of 1 mA.

Figure 5. Schematic diagram of vertical Hall device behavioral model for circuitsimulators.

The Hall sense electrodes are modeled by two independent voltage sources.The Hall voltage is split equally across the two contacts and is biased by half ofthe voltage on the input current terminal 1C. This is an accurate model of thedevice behavior; the symmetry of the Hall voltage around the input voltage isseen in figure 3 b.

PACKAGE hall_pkg ISCONSTANT muO : real := 1.256e-6; -- vacuum permeability [H/m]SUBTYPE voltage IS real; -- subtypes for voltageSUBTYPE current IS real; -- and currentNATURE electrical IS voltage ACROSS current THROUGH; -- basic natureALIAS ground IS electrical'reference; -- reference terminalTYPE real_vector IS ARRAY (integer RANGE <>) OF real;

END PACKAGE hall_pkg;

Listing 1: VHDL 1076.1 constants, nature and types declaration package.

A package defining the necessary constants, natures and types is presented inlisting 1. The VHDL 1076.1 model of the device is presented in listing 2. Theentity header is visible at top, followed by the architectural declaration. Digitalsynchronization [17] is implemented to ensure accurate simulation of thepiecewise linear defined Hall voltages and input resistances for magnetic fluxdensities between 0 and 2 T. Should the value of the magnetic field be out ofrange, the model returns an error message. The process declaration is a concurrentdigital loop which triggers a simulator calculation point whenever the magneticflux density B passes a point in the lookup-table defined in the relational block.This ensures precise simulation even for rapidly changing magnetic flux densities,without the need for a limitation of the maximal time step of the SPICEsimulator.

5 Conclusions

Behavioral microstructure modeling techniques allowing system-level simulationwithout convergence problems associated with linking device and circuitsimulators have been presented. VHDL 1076.1 shows great flexibility in lumpedparameter modeling of mixed-nature analog systems. Microsystem devices maythus be modeled at different levels of detail or abstraction. Combined with

Transactions on the Built Environment vol 31, © 1997 WIT Press, www.witpress.com, ISSN 1743-3509

Simulation and Design of Microsystems and Microstructures 187

implicitly compatible models of analog, digital and mixed electronics - and evensoftware - integrated microsystems can be designed and simulated eliminating

costly prototyping steps.The different modeling approaches which are available have a strong influence

on the model behavior. MEMS actuator/transducer devices showing strongcoupling with electronics are best modeled using conservative semantics.Physical sensors may be modeled using a mixed (signal flow/conservative)semantic approach. Continuous behavior may be described using DAEs whosesolution may include discontinuities. Numerical data from laboratorymeasurement or FE analysis may also be used to describe models. Where ananalytical solutions or measurements are impossible, devices may be simulatedusing FE analysis and the parameter extraction tool presented to derive

behavioral models.

USE work.hall_pkg.ALL;ENTITY hall_pwl ISGENERIC (magfluxvals: real_vector; -- B values from FEM analysishallvals : real_vector; -- Hall voltages from FEM analysisrinvals: real_vector); -- Input resistances from FEM

analysisPORT (TERMINAL pi: electrical; -- electrical SL pinTERMINAL pr: electrical; -- electrical SR pinTERMINAL pic: electrical; -- electrical 1C and IL,IR pinsQUANTITY b : IN real); -- Magnetic flux density in (B)CONSTANT b_range : integer := hallvals'length-1;ALIAS hval: real_yector(0 TO b_range) IS hallvals;ALIAS rvals: real_vector(0 TO b_range) IS rinvals;ALIAS bval: real_vector(0 TO b_range) IS magfluxvals;

END ENTITY hall_pwl;

ARCHITECTURE pwl OF hall_pwl ISQUANTITY vhl ACROSS ihl THROUGH pi TO ground;QUANTITY vhr ACROSS ihr THROUGH pr TO ground;QUANTITY vr ACROSS ir THROUGH pic TO ground;SHARED VARIABLE isl: integer := 0; -- slice index

BEGINASSERT b >= bval(O) AND b <= bval(bval'length-1)

REPORT "B field is out of table range" SEVERITY ERROR;PROCESS -- ensure analog computation at table breakpointsVARIABLE inf: real := bval(O); VARIABLE sup: real := bval(1);

BEGINLOOP -- determine the initial slice

EXIT WHEN (b >= bval (isl)) AND (b <= bval(isl+l)); isl : = isl + 1;END LOOP;LOOP -- update slice numberWAIT ON b; IF b'above(sup) THEN isl : = isl + 1;ELSIF NOT b'above (inf) THEN isl := isl - 1; END IF;inf := bval(isl); sup := bval(isl + 1);

END LOOP;END PROCESS;vhl == hval(isl) /2.0 - ((b - bval(isl)) *

((hval(isl+l) - hval(isl))/(bval(isl+1) - bval(isl))));vhr == hval(isl) /2.0 - ((b - bval(isl)) *

((hval(isl+l) - hval(isl))/(bval(isl+1) - bval(isl))));vr == rvals(isl) + ((b - bval(isl)) *

((rvals(isl+1) - rvals(isl))/(bval(isl+1) - bval(isl)))) * ir;END ARCHITECTURE pwl;

Listing 2: Conservative semantic piecewise linear model of Hall sensor.

Transactions on the Built Environment vol 31, © 1997 WIT Press, www.witpress.com, ISSN 1743-3509

188 Simulation and Design of Microsystems and Micro structures

Acknowledgments

The research presented is funded by the Swiss National Priority ProgramMINAST under project number 4.01. We thank Alain Vachoux of the C3i-LEG-EPFL, and Markus Roos of Numerical Modeling AG for their valuable remarks.

References

[1] H. Yie, S. F. Bart, J. White, and S. D. Senturia, "A computationally practical approach tosimulating complex surface-micromachined structures with fabrication non-idealities," presentedat IEEE Micro Electro Mechanical Systems, Amsterdam, Netherlands, 1995.[2] Wachutka, Tailored modelling of miniaturized electrothermomechanical systems usingthermodynamic methods, vol. DSC-40. New York: ASME, 1992.[3] E. Anderheggen, J. G. Korvink, G. Sartoris, L. Fornera, M. Roos, and H.-U.Schwarzenbach, "SESES - a two-and three - dimensional semiconductor sensor simulationprogram," presented at NASECODE VIII, Vienna, Austria, 1992.[4] S. Crary, O. Juma, and Y. Zhand, "Software tools for designers of sensor and actuator CAEsystems," IEEE, pp. 498-501, 1991.[5] H. A. Tilmans, "Equivalent circuit representation of electromechanical transducers,"presented at Micromechanics Europe 1995, Copenhagen Denmark, 1995.[6] B. Romanowicz, M. Laudon, P. Renaud, H. P. Amann, A. Boegli, V. Moser, and F.Pellandini, "Modeling and Simulation of Electromechanical Transducers in Microsystems usingan Analog Hardware Description Language," presented at European Design & Test Conferenceand Exhibition 1997, Paris, France, 1997.[7] C.-J. R. Shi and A. Vachoux, "VHDL-A Design objectives and rationale," in Current issuesin Electronic Modeling, Issue#2: Modeling in Analog Design, J.-M. Berge, O. Levia, and J.Rouillard, Eds.: Kluver Academic Publishers, 1995, pp. 1-30.[8] J. M. Karam, B. Courtois, and M. Bauge, "High level CAD molds microsystems withfoundries," presented at European Design and Test Conference (EDAC-ETC-ASIC96), Paris,France, 1996.[9] B. Romanowicz, Y. Ansel, P. Lerch, and P. Renaud, "Global modeling and simulation ofmicrosystems," presented at Micromechanics Europe (MME'96), Barcelona, Spain, 1996.[10] B. Romanowicz, Y. Ansel, M. Laudon, C. Amacker, P. Renaud, A. Vachoux, and G.Schropfer, "VHDL-1076.1 Modeling Examples for Microsystem Simulation," presented at 2ndWorkshop on Libraries, Component Modeling and Quality Assurance, accompanying ComputerHardware Description Languages Symposium'97, Toledo, Spain, 1997.[11] B. Romanowicz, PhD. dissertation, "Methodology for the Modeling and Simulation ofMicrosystems," Swiss Federal Institute of Technology of Lausanne, 1997, pp. 135.[12] A. Vachoux, "VHDL Analog and Mixed-Signal Extensions Through Examples," presentedat ASP-DAC'97, Chiba, Japan, 1997.[13] D. Karnopp and R. Rosenberg, System dynamics: A unified approach: John Wiley & SonsInc., 1975.[14] R. S. Popovic, Hall Effect Devices: Adam Hilger, Bristol, Philadelphia and New York,,1991.[15] Ch. Schott and R.S. Popovic, "Linearizing Integrated Hall Devices," presented atTransducers 97, Chicago, USA, 1997.[16] "NM-SESES Semiconductor and Sensor and Actuator Simulation Users Manual," :Numerical Modeling GmbH, Alte Landstrasse 88, CH-8800 Thalwil, Switzerland., 1997.[17] B. Romanowicz, P. Lerch, P. Renaud, and A. Vachoux, "Modeling and Simulation ofMicrosystems, an Experience with HDL-A," presented at Workshop on Libraries, ComponentModeling and Quality Assurance, Nantes, France, 1995.

Transactions on the Built Environment vol 31, © 1997 WIT Press, www.witpress.com, ISSN 1743-3509