Vibration Analysis4

-

Upload

mister-pogi -

Category

Documents

-

view

219 -

download

0

Transcript of Vibration Analysis4

-

8/11/2019 Vibration Analysis4

1/13

LESSON

1LECTURE

MECHANALYSIS THE KEY TOMACHINERY CONDITION

SUB - OBJECTIVE

At the end of the le on the T!"#nee $#ll %e "%le to de&on t!"te "n 'nde! t"nd#n( of Me)h"n"l* # The +e* to M")h#ne!* Cond#t#on,,

1, INTRODUCTION

Have you ever heard someone say somethings wrong with this machine; itsmaking a funny noise! r; "ts natura# to associate a machines condition with the#eve# of noise or vi$ration it makes% &nd' if it shakes or ratt#es more than usua#' we$egin to sus(ect mechanica# trou$#e%

"n recent years' this idea of re#ating a machines condition to its #eve# of vi$rationand noise has $ecome the $asis of a new techni)ue for contro##ing machinerycondition% This techni)ue is ca##ed *ECH&+&L,-"-%

*echana#ysis is the contraction f the two words mechanica# and ana#ysis% This wordis used to descri$e any measurement such as machinery vi$ration' shaft movementor machinery noise . any measurement that (ermits us to determine a machinescondition whi#e it o(erates as it norma##y does%

*echana#ysis techni)ues do work; and the reasons are fair#y sim(#e;

/irst' its natura# for machines to vi$rate and make noise% Even machines in the $etof o(erating condition wi## have some vi$ration and noise $ecause of sma## minor defects% Therefore' each machine whether its a 01'111 R2* com(ressor' a steamtur$ine generator' a #athe or a vacuum c#eaner wi## have a #eve# of vi$ration andnoise which may $e regarded as norma# or inherent%

-econd#y' when machinery noise and vi$ration increase or $ecome e3cessive' somemechanica# trou$#e is usua##y' the reason% *achinery noise and vi$ration 4ust do notincrease or $ecome e3cessive for no reason at a##% -omething causes it un$a#ance'misa#ignment' worn gears or $earings' #ooseness' etc%

/ina##y' each mechanica# defect generates vi$ration and noise in its own uni)ue way%This makes it (ossi$#e to (ositive#y identify a (ro$#em $y sim(#y measuring and

noting its noise and vi$ration characteristics%

-2EC"/"C C UR-E / R E+5"+EER- *ECH&+"C&L *&"+TE+&+CE * 6ULE 078"9R&T" + &+&L,-"- : C RRECT" + LE-- + 0 2&5E 0

-

8/11/2019 Vibration Analysis4

2/13

THE MECHANICAL ANALYSIS .RO/RAM

To effective#y a((#y *echana#ysis techni)ues to contro# machinery condition' a tota#(rogram is re)uired' invo#ving 6ETECT" +' &+&L,-"- &+6 C RRECT" +%

DETECTION

The first ste( of the (rogram . 6ETECT" + . uses a (orta$#e' hand he#d meter' is%07 0 0' for taking (eriodic vi$ration and noise measurements on each critica#machine% The vi$ration (icku( is he#d against or mounted to the machine' and theamount of vi$ration noted on the meter% To measure machinery noise' /ig% 07 0

-

8/11/2019 Vibration Analysis4

3/13

0#(, 1 -1-3, .e!#od#) no# e &e" '!e&ent '44le&ent 2#%!"t#on !e"d#n( fo! dete)t#n( )h"n(e #n &")h#ne!* )ond#t#on No# e !e"d#n( 4!o4e!l* !e)o!ded

e t"%l# h )o&4l#"n)e $#th 2"!#o' fede!"l "nd lo)"l no# e !e('l"t#on ,

-2EC"/"C C UR-E / R E+5"+EER- *ECH&+"C&L *&"+TE+&+CE * 6ULE 078"9R&T" + &+&L,-"- : C RRECT" + LE-- + 0 2&5E 7

-

8/11/2019 Vibration Analysis4

4/13

*ECH&+"C&L *&"+TE+&+CE * 6ULE 07 -2EC"/"C C UR-E / R E+5"+EER-LE-- + 0 2&5E = 8"9R&T" + &+&L,-"- : C RRECT" +

-

8/11/2019 Vibration Analysis4

5/13

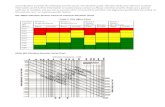

0#(, 1 -1- , .e!#od#) no# e "nd 2#%!"t#on !e"d#n( 4!o4e!l* !e)o!ded $"!n of

de2elo4#n( t!o'%le, &utomatic monitoring re)uires an instrument ca##ed a 8i$ration *onitor % & ty(ica#vi$ration monitor instrument is shown in /ig% 07 0 =% 8i$ration (icku(s are(ermanent#y insta##ed at strategic (oints on the machine to continuous#y sense thevi$ration% >hen the vi$ration e3ceeds a (resent #eve#' a re#ay in the monitoringinstrument o(erates to (rovide a warning a#arm% -hou#d the vi$ration continue toincrease to the danger (oint a second re#ay o(erates to (rovide either a shutdowna#arm or to actua##y start the se)uence that automatica##y shuts the machine down%These are the $asic functions of a vi$ration monitor% However' there are a variety of (icku(s' instruments and au3i#iary e)ui(ment to choose from de(ending u(on thety(e of (rotection desired%

ANALYSIS

8i$ration monitoring is on#y the detection (art of the tota# (rogram to contro#machinery condition% nce trou$#e has $een detected' the ne3t ste( is to determinethe nature of the (ro$#em%

This is the (ur(ose of &+&L,-"- . to (in(oint a s(ecific machinery (ro$#em $yidentifying its uni)ue vi$ration or noise characteristics%

-2EC"/"C C UR-E / R E+5"+EER- *ECH&+"C&L *&"+TE+&+CE * 6ULE 078"9R&T" + &+&L,-"- : C RRECT" + LE-- + 0 2&5E ?

-

8/11/2019 Vibration Analysis4

6/13

/or ana#ysis of machinery noise and vi$ration' an instrument such as the ana#y@er in/ig% 07 0 ? is re)uired% The ana#y@er uses the same vi$ration (icku(s Aor micro(honeB used for manua# and automatic monitoring% This instrument has a## the(rovisions necessary to measure the detai#ed characteristics of noise and vi$ration%9y com(aring this information with what is known a$out the machine' its s(eed or s(eeds' what it does' and the various causes of noise and vi$ration; the trou$#e can$e readi#y (in(ointed and corrections (rescri$ed%

CORRECTION

>ith machinery (ro$#ems detected and diagnosed in their ear#y stages' correctioncan $e schedu#ed for a convenient time% *achinery fau#ts such as $ad $earings'fau#ty gears' such as $ad $earings' fau#ty gears' #ooseness or misa#ignment can $ecorrected using (rocedure we## known $y maintenance (eo(#e throughout industry%However' (ro$#ems such as un$a#ance' resonance and noise reduction re)uiresome s(ecia# ski## and know#edge to correct%

/ortunate#y' when the machinery (ro$#em is un$a#ance' the correction can norma##y$e made in (#ace with the same $asic ana#y@er used to diagnose the (ro$#em% Theana#y@er shown in /ig% 07 0 ? is we## suited for in (#ace $a#ancing' and the(rocedures for using the instrument to $a#ance a (art are covered in detai#ed inCha(ter v % Techni)ues for reducing machinery noise and so#ving resonance(ro$#em are a#so covered in Cha(ter v%

BALANCIN/ ON A BALANCIN/ MACHINE

Tota##y enc#osed machines such as e3(#osion and s(ash (roof e#ectric motors'(um(s' com(ressors and others are not easi#y $a#anced in (#ace $ecause e3tensivedisassem$#y is re)uired in order to add or remove weight for $a#ance corrections%

Therefore' it is fre)uent#y necessary to disassem$#e the machine and remove therotor for $a#ancing on a $a#ancing machine%

The machinery manufacturer a#so $a#ances rotors such as this on a $a#ancingmachine $efore the machine is assem$#ed%

The $a#ancing machine i##ustrated in /ig% 07 0 D wi## acce(t work(ieces weighingon#y a few ounces or those weighing severa# thousand (ounds% The anti friction$earing su((orts e#iminate the need to search for $earings for each different (art'and a varia$#e s(eed drive motor (ermits $a#ancing at the most desira$#e s(eed%

The same vi$ration (icku(s' (orta$#e ana#y@er instrument and $a#ancing techni)uesused for in (#ace $a#ancing are used on this ty(e $a#ancing machine% r' s(ecia# ne Run instrumentation /ig% 07 0 ' which (rovides a direct readout of the

re)uired corrections on the very first run can $e (rovided%

*ECH&+"C&L *&"+TE+&+CE * 6ULE 07 -2EC"/"C C UR-E / R E+5"+EER-LE-- + 0 2&5E D 8"9R&T" + &+&L,-"- : C RRECT" +

-

8/11/2019 Vibration Analysis4

7/13

0#(, 1 -1-5, .e!&"nentl* #n t"lled 2#%!"t#on &on#to! 4!o2#de 35 ho'! &")h#ne!* 4!ote)t#on,

0#(, 1 -1-6, A 4o!t"%le IRD V#%!"t#on An"l*7e! # ' ed to #dent#f* 4e)#f#)&")h#ne!* 4!o%le& "nd )"n "l o %e ' ed fo! #n 4l")e d*n") %"l"n)#n(,

-2EC"/"C C UR-E / R E+5"+EER- *ECH&+"C&L *&"+TE+&+CE * 6ULE 078"9R&T" + &+&L,-"- : C RRECT" + LE-- + 0 2&5E

-

8/11/2019 Vibration Analysis4

8/13

THE BENE0ITS O0 MECHANALYSIS

The success of a com(any often de(ends on the continued' safe' (roductiveo(eration of rotating machinery% &nd' the way machines are maintained determineshow #ong they wi## run as we## as how safe and (roductive they wi## $e% >ith this inmind' consider the three genera# ways machines can $e maintained .9RE&F6 >+ *&"+TE+&+CE' 2ER" 6"C 6"-&--E*9L, &+6 "+-2ECT" +

&+6 + -TRE&* 6ETECT" + &+6 6"&5+ -"-%

BREAKDO8N MAINTENANCE

>ith $reakdown maintenance' a machine is a##owed to run unti# com(#ete fai#ure'inefficiency or (roduct s(oi#age forces a shutdown%

though many machines are maintained this way' $reakdown maintenance hassevera# disadvantages% /irst' fai#ures can $e most untime#y% &nd' there is #itt#e onecan do $efore hand to antici(ate too#' man(ower and re(#acement (artre)uirements% -econd#y' machines a##owed to run unti# fai#ure often re)ui?re moree3tensive re(air than wou#d have $een re)uired if the (ro$#em had $een detectedand corrected ear#y% -ome fai#ures can $e catastro(hic' re)uiring tota# re(#acementof the machine% This a#so suggests a safety (ro$#em to o(erators and other (ersonne#% "n addition' the added cost of #ost (roductions whi#e the unit is down can$e staggering%

.ERIODIC DISASSEMBLY AND INS.ECTION

Com(ared to $reakdown maintenance' a (rogram of (eriodic disassem$#y andins(ection has the distinct advantages of #essening the fre)uency of $reakdownre(airs and (ermitting schedu#ed shutdown% Under this (rogram' each critica#machine is shut down after a s(ecified (eriod of o(eration and (artia##y or com(#ete#y disassem$#ed for a thorough ins(ection and re(#acement of worn (arts .if any%

This a((roach to machinery maintenance' too' has disadvantages% /irst' to(eriodica##y disassem$#e every critica# (iece of e)ui(ment in the (#ant is e3(ensiveand time consuming% -econd#y' the interva# $etween (eriodic ins(ections is difficu#tto (recict% "f the (rogram is so successfu# that no machinery fai#ures occur' it may$e that the interva# is too short and money is $eing wasted% Third' a machine whichis o(erating satisfactori#y may actua##y $e ham(ered $y fre)uent disassem$#y%There is a#ways chance that a gasket or sea# wi## $e im(ro(er#y seated' $o#ts nottightened (ro(er#y' or the origina# a#ignment or $a#ance of the machine distur$edduring re assem$#y% "n addition' some machinery (ro$#ems as un$a#ance areevident on#y during o(eration%

ON-STEAM DETECTION AND DIA/NOSIS

n stream detection and diagnosis of machinery (ro$#ems is o$vious#y the mostdesira$#e way to machinery%

"f a (ro$#em can $e detected ear#y' $efore e3tensive fai#ure occurs' and if we candiagnose the nature of the (ro$#em as the machine runsG

*ECH&+"C&L *&"+TE+&+CE * 6ULE 07 -2EC"/"C C UR-E / R E+5"+EER-LE-- + 0 2&5E 8"9R&T" + &+&L,-"- : C RRECT" +

-

8/11/2019 Vibration Analysis4

9/13

0% -hutdown for re(air can $e schedu#ed for a convenient time%

-

8/11/2019 Vibration Analysis4

10/13

&na#ysis of the noise )uick#y traced the (ro$#em to a gear $o3 on one of the units'a#though an ear#ier ins(ection revea#ed that the gears were satisfactory% & vi$rationana#ysis confirmed the noise source and fre)uency' and disc#osed a very high #eve#of vi$ration at the out (ut $earing of the gear $o3% This fact' together with the noiseand vi$ration fre)uency noted indicated that the $earing Aa s#eeve ty(eB wasres(onsi$#e% & visua# ins(ection showed that $earing c#earance was e3cessive $ysevera# thousandths of an inch% Re(#acing the $earing with one having thes(ecified c#earance e#iminated the distur$ing noise and vi$ration%

CASE HISTORY 9

This incident invo#ves another com(ressor' a 111 R2* ammonia com(ressor usedin the (roduction of ferti#i@er%

0#(, 1 -1-:, IRD B"l"n)#n( M")h#ne 4e!t %"l"n)#n( " 2"!#et* of !oto! d#ffe!ent #7e ; $e#(ht "nd )onf#('!"t#on ,

0#(, 1 -1-:, The IRD Model 33 4!o2#de " d#!e)t !e"do't of %"l"n)e)o!!e)t#on on the f#! t !'n,

*ECH&+"C&L *&"+TE+&+CE * 6ULE 07 -2EC"/"C C UR-E / R E+5"+EER-LE-- + 0 2&5E 01 8"9R&T" + &+&L,-"- : C RRECT" +

-

8/11/2019 Vibration Analysis4

11/13

Here' (eriodic checks revea#ed increasing vi$ration on the tur$o e3(ander used todrive the com(ressor% & vi$ration ana#ysis traced the (ro$#em to a fau#ty cou(#ing$etween the e3(ander and com(ressor% 9y this time' the #eve# of vi$ration wassufficient#y high to warrant immediate shutdown% However' (roduction demandswere such that a shutdown was J4ust not (ossi$#e % &s a resu#t' five days after thediagnosis was made' the sus(ected cou(#ing fai#ed%

though a re(#acement cou(#ing was on hand' the forced fai#ure of the cou(#ing(#us continued o(eration at e3cessive #eve#s of vi$ration resu#ted in e3tensivedamage to e3(ander and com(ressor shafts and $earings%

Re(airs to (ut the unit $ack in o(eration re)uired = days' working around the c#ock%

Had the cou(#ing $een re(#aced at the time recommended' e3tensive damage mighthave $een avoided' and tota# down time reduced to an estimated hours for thecou(#ing change%

These case histories are on#y three of virtua##y hundreds of e3am(#es of whereroutine noise and vi$ration checks have detected (otentia##y serious (ro$#ems% "nthe one case re(orted' a warning of high vi$ration was ignored' yet the cost#y fai#urethat resu#ted is not rea##y sur(rising% E3(erience has (roven time and time againthat machinery vi$ration does ref#ect machinery condition%

ADDITIONAL A..LICATIONS 0OR MECHANALYSIS TECHNI

-

8/11/2019 Vibration Analysis4

12/13

Thus' $y inc#uding in the machinery s(ecifications the ma3imum acce(ta$#e #eve#sof vi$ration and noise' they have assurance that the unit wi## $e we## a#igned'$a#anced and in good o(erating condition ca(a$#e of giving smooth' trou$#e freeservice for a reasona$#e (eriod of time%

-

8/11/2019 Vibration Analysis4

13/13

SUMMARY

Regard#ess of the a((#ication . (reventive maintenance' )ua#ity contro#' fie#dservice' etc% . the fact remains that *echana#ysis techni)ues do work% To makethem work re)uires the (ro(er noise and vi$ration measurement' ana#ysis anddynamic $a#ancing e)ui(ment% ,our Com(any has a#ready invested in thise)ui(ment% E)ua##y im(ortant' if not more so' is the o(erator . (ro(er#y trained toeffective#y use the e)ui(ment%

The instrument wi## (rovide the necessary information a$out a machines noise andvi$ration % However' it is you who must study' eva#uate and inter(ret the data to(in(oint the (ro$#em and (rescri$e correction% To a((#y *echana#ysis techni)uesre)uires two im(ortant ski##s% The first one' which you a#ready have' is a $asicknow#edge of how machines work' the (ro$#ems common to these machines' andhow to re(air them% The second ski## is the a$i#ity to recogni@e and (in(ointmechanica# difficu#ties accurate#y and ear#y in their deve#o(ment% 8i$ration andnoise measurement and ana#ysis is the FE, to this ski## and the su$stance of thistraining (rogram%

-2EC"/"C C UR-E / R E+5"+EER- *ECH&+"C&L *&"+TE+&+CE * 6ULE 078"9R&T" + &+&L,-"- : C RRECT" + LE-- + 0 2&5E 07