Vertical Lift Bridge Project

-

Upload

prankur-sharma -

Category

Documents

-

view

477 -

download

12

Transcript of Vertical Lift Bridge Project

1

BIRLA INSTITUTE OF TECHNOLOGY AND SCIENCE, PILANI

A REPORT ON

Vertical Lift Bridge

Prepared by

Manu Dixit (2009B5A4655P) Rajiv J Nagpal (2009B5A4472P) Vijay Varma (2009B5A4657P) Prankur Sharma (2009B3A4622P) Juhi Kapoor (2009B1A4790P) Ravin Arora (2010A4PS573P)

Submitted to

Dr. K.S. Sangwan

In partial fulfillment of the requirements of the course

ME C342 Production Techniques

2

ACKNOWLEDGEMENTS We owe a great many thanks to many people who helped and supported us during the preparation of this project report. First of all, we would like to thank Prof. K.S. Sangwan for giving us the opportunity and the requisite facilities to complete our project within the stipulated time. Without him, all this would not have been possible. Sincere thanks are due to the people at BITS Workshop. We would like to convey the deepest appreciation to Mr. Mahendra Kumar Saini who continuously provided us not only with tools but also his valuable suggestions for the betterment of our project. Next are the store people who provided whatever material we demanded. Our sincere thanks goes to Mr. Madanlal Jangir, Senior Store keeper; Mr. Vishambharlal Chauhan, Mr. Vikas Soni and Mr. Harsh Kumar Sharma, Mr. Raju Saini. Sincere thanks are also due to all the skilled workers on the shop floor for their wholehearted cooperation in solving our doubts and guiding us along on the work processes. Mr. Mahendra Singh and Mr. Banwarilal Saini at Weld shop also deserve an appreciation at the completion of our project. Without their guidance and persistence this experience might not be a successful one. We would like to thank them for giving us the opportunity to work and experiment with almost all the production techniques at workshop.

3

TABLE OF CONTENTS S.No. TOPIC Page no.

1. Introduction 4-6

2. Bridge Span 7-8 3. Bridge frame 9-11

4. Chain Drive Mechanism 12-14 5. Problems Faced while working 15

6. Conclusions 16 7. References 17

4

1. INTRODUCTION A vertical-lift bridge or lift bridge is a type of movable bridge in which a span rises vertically while remaining parallel with the deck which ensures passing of ships underneath. They cost less to build for longer moveable spans. The counterweights in a vertical lift are only required to be equal to the weight of the deck. Thus heavier materials can be used in the deck, and so this type of bridge is especially suited for heavy railroad use. It is also more energy efficient, requiring comparatively less power to lift the bridge. The project is a prototype of such a bridge and utilizes a chain drive mechanism to lift the middle span of the bridge.

Lift bridges state of the art

Among mobile bridges, lift ones appear as the right answer when relatively

long spans are needed. Bascule bridges or rotating ones are more limited,

because of their overhanging decks. In France the existing lift bridge with the

longest span is “Recouvrance” Bridge in Brest, with an 87.5 meters lifting span.

But most large bridges of this kind are located in New Jersey, USA where many

waterways allow maritime traffic. The longest lifting span in the world belongs

to Arthur Kill Bridge with 170 meters, no longer in operation. Another

significant structure is the Gil Hodges Memorial Bridge , with a main span in

the range of 160 meters.

METHODOLOGY

When a handle attatched at the bottom is rotated the middle span is lifted by 2

ropes, 1 at each extremity. The ropes are attached to the 2 S-hooks which raise

the bridge span. The ropes which go over the side pulleys wrap around the

central pulley thus shortening the length of ropes and causing lifting.

MATERIALS USED

Mild Steel rods

MS plates, angles and screws

5

Wood

Aluminium sheet

PROCESSES REQUIRED

Lathe Operations, Drilling, Welding, Grinding, cutting

TECHNICAL SPECIFICATIONS

The provisional specifications of the vertical-lift bridge are specified as below:

The length of the bridge frame is 2 ft.

The height of the bridge frame is 3 ft.

The aluminium strips that form the truss are 0.5 inch in thickness and

the height of the middle span is 7 inches.

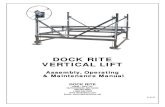

Fig 1.1

6

Fig 1.2

The main parts and components have been discussed in the

following sections.

The vertical-lift bridge is divided into the following 3 broad

categories:

Bridge Span

Bridge Frame

Chain Drive Mechanism

7

2. BRIDGE SPAN

Manufacturing processes used:

Cutting/sawing

The bridge span includes the

1. Middle Span

Function: the base of the bridge which is to be lifted.

Material: wood, aluminium, mild steel

Dimensions:

Wooden base length of 21in and width 8 inches.

Aluminium strips of 0.5 inch thickness

2 wooden Top chords of length 21in and thickness 1 inch.

2 MS connecting rods

Sequence of operations:

1. Obtained wood from scrap.

2. The required dimensions of the base and the top chords were obtained

using a hacksaw.

3. 2 holes each on the 2 chords were drilled.

4. The strips were cut from an aluminium sheet using the shape cutting

machine and they function as the webs of the truss.

5. The strips were hammered onto the base and the chords to form the

struss.

6. The top chords were machined on the lathe using the turning operation

to get the desired diameter and then fixed into the holes to connect the

top chords.

7. Finishing was done by applying primer and finally paint was applied.

2. Side Spans

Function: the extensions of the span on either side of the middle span.

8

Material: wood, aluminium

Dimensions:

2 Top chords: Length of 9.5 inches, height=1.5 inches, width=1 inch

Sequence of operations:

1. Obtained wood from scrap.

2. The required dimensions of the base and the top chords were obtained

using a hacksaw.

3. 2 holes each on the 2 chords were drilled.

4. The strips were cut from an aluminium sheet using the shape cutting

machine and they function as the webs of the truss.

5. The strips were hammered onto the base and the chords to form the

struss.

6. The top chords were machined on the lathe using the turning operation

to get the desired diameter and then fixed into the holes to connect the

top chords.

7. Finishing was done by applying primer and finally paint was applied.

9

3.BRIDGE FRAME

Fig 3.1

FIG 3.2

Manufacturing processes used:

Welding

Turning

Drilling

1. L-Brackets

Function: form the support against which the middle span of the bridge rises.

Quantity: 4

Material: Mild Steel

Dimensions: height = 3ft ,thickness=0.25 in, width=1 in

2. Supporting plates

Function: hold the L-brackets in vertical position together.

Quantity: 12

10

Material: Mild steel

Dimensions:

6 plates of length=8 in and thickness=1 in

6 plates of length=2ft and thickness=1 in

3.Pulleys

Middle pulley

Function: causes the movement of the side pulleys which in turn cause the

ropes to pull the bridge upwards.

Material: wood

Quantity: 1

Dimensions:

3 in diameter, thickness of the 2 grooves=0.25 in, total width of

pulley=1.75in

Side pulleys

Function: cause the ropes to lift the bridge by wrapping the ropes in the V-

groove machined on the pulley surface.

Material: wood

Quantity: 2

Dimensions: 3 in diameter, width = 1 in

4. Connecting rods

Function: support the pulleys

Material: MS

Quantity: 3

11

Dimensions: diameter=0.5 in, length=6 in

Sequence of operations:

1. MS angles and plates were obtained from the scrap.

2. The support plates were welded onto the angles using arc welding.(fillet

weld).

3. Holes were drilled into the frame for the 3 connecting rods as well as the

MS rod fixed at the bottom of the frame over which the the sprocket

gear rotates.

4. The connecting rods were machined on the lathe using the turning

operation to the diameter of the hole.

5. Holes were drilled into the rods and pins were used to fix the rods in

place and prevent axial movement.

6. The sprocket was welded onto the middle connecting rod.(tac welds)

Sequence of operations for pulleys

1. A rectangular block of wood was obtained from the scrap.

2. The block was machined to get a cylindrical block using the wood cutting

machine.

3. The wooden cylinder was divided into 3 parts.

4. Each part had a hole drilled into it using the drilling machine.

5. The V-grooves were machined onto the surface using a lathe.

The pulleys were attached to the rods and the rods were fixed using

washers and pins.

12

4.CHAIN DRIVE MECHANISM

Fig 4.1

Fig 4.2

Manufacturing processes used:

Drilling

Boring

welding

1.Sprocket gear

Function: cause the movement of the middle pulley.

Material: MS

13

Quantity: 2

Dimensions:

gear at the bottom has diameter 4 in with 22 teeth

gear attached to the middle pulley has dia 4 in with 18 teeth

2.Hollow pipe/Bearing/Connecting rod

Function: cause the movement of the sprocket at the bottom

Material: MS

Quantity AND Dimensions:

1 bearing of dia 1.25 in, 1 connecting rod of dia 0.5 in and length 8 in

3.Chain

Function: goes over the sprocket gears to cause their movement.

4.Handle

Function: used to rotate the sprocket gears

Material: MS

5.Ropes

Function: lift the bridge to the desired level

Material: jute

Quantity: 2

6.S-hooks

Function: lift the bridge to the desired level

Material: MS

Quantity: 2

14

Dimensions:

dia of loop=0.5 in

Sequence of operations:

1. The bushings were welded onto the sprockets.

2. For the bottom sprocket bearing was press fitted onto the pipe and the

sprocket was fixed over the pipe. The pipe with the bearing was fixed

over the connecting rod.

3. For the sprocket gear at the top a cylindrical blank was turned to fit into

the bushing.

4. A hole of diameter 0.5 in was drilled into it. The cylindrical rod was

welded onto the bushings and then onto the connecting rod for the

middle pulley.

5. Ropes were nailed onto the central pulley and passed over the side

pulleys.

6. The ropes were attached to the chord connecting rods through S-hooks

of 0.5 inch dia.

7. The chain was put over the sprockets.

8. The handle was welded onto the pipe.

15

5.Problems faced while working

Wobbling occurred while machining a long rod on the lathe machine

leading to a very high eccentricity.

Large depth of cut in turning led to poor surface finish of connecting

rods.

Lesser bridge thickness led to chipping of wood due to hammering.

16

6.CONCLUSION All the objectives and likewise procedures were completed to make this screw jack powered hand forklift. The production techniques used in the process were cutting, welding, drilling, grinding, threading, turning, and mechanical fastening. The forklift serves its purpose of lifting considerable amount of weights and transporting them over short distances. The dimensions were decided keeping in mind comfort and ease of transportation of the load. We successfully implemented various production techniques to achieve the objective of our project.

17

7.REFERENCES

1. www.stanford.edu/~piyushk/The%20Kattwyk%20Bridge.pdf

2. www.engineeringminiprojects.com/mechanicalprojects-mechanical-

engineering-projects-topics/2012/

3. Shigley. Mischke. Budynas & Nisbett, “Mechanical Engineering

Design”(2008) Ninth Edition, Tata McGraw Hill Pvt. Ltd.

4. Amitabha Ghosh, Asok Kumar Mallik(1985) Manufacturing Science, East-

West Press Private Limited