VENTURE MAGAZINE JANUARY 2007 Power in the Pipeline

Transcript of VENTURE MAGAZINE JANUARY 2007 Power in the Pipeline

V E N T U R E M A G A Z I N E _ J A N U A R Y 2 0 0 7 _ M O N I T O R _ 1 1

Designed by Venezuela’s state-owned oil company as a part of a vast new natural gastransportation system, a brand-new 300-km pipeline is being built to link the country’s west-ern region with the existing gas infrastructure and the rich, but scattered, reserves fromproducing wells in the central and eastern regions. As well as making this clean, low-costfuel available to many Venezuelans for the first time, the pipeline will enable gas to be used to boost oil production from mature wells. As part of this complex US$520 million proj-ect, Siemens is supplying a total of ten gas turbine-powered compressor trains, which will be installed by a Siemens-led consortium in compressor stations along the new pipeline.

Power in the Pipeline

Covering a total area about two-and-a-half times the size of Ger-

many, Venezuela is located on the northern tropical Caribbean

coast of South America. The diversity and sheer beauty of its land-

scape so impressed the fifteenth century explorer Christopher

Columbus that he called it the Tierra de Gracia—Land of Grace—

which has become the country’s unofficial name. In contrast to its

soaring mountains, the world’s highest waterfall, tropical forests

and silver-sandy beaches which make Venezuela a magnet for

tourists, the country’s burgeoning economy is based principally

on the oil and gas industry.

BIG OILWith proven oil reserves of around 76 billion barrels, Venezuela is

ranked as one of the world’s largest producers. However, a number

of the largest fields have been exploited for decades, with some of

the oldest wells in continuous operation for almost 100 years, and

production levels are now falling rapidly. Natural gas, co-produced

with oil from existing wells as well as from more recent finds both

onshore and offshore, is also currently being produced at an annual

rate of nearly 30 billion cubic meters, a large proportion of which is

being re-injected into fast-depleting oil reservoirs to increase their

production. In combination, this vital industrial sector accounts for

some eighty percent of the country’s export revenues and about a

third of its total earnings.

GOING FOR GROWTHAlthough the country has enormous reserves of natural gas, a lack

of adequate infrastructure, such as a national grid-system for

the transportation of bulk supplies of natural gas or an established

country-wide distribution network serving urban and rural con-

sumers, has meant that Venezuela has been unable to exploit this

resource to its full extent. Today, as the price of oil continues to

rocket, the country’s economy is booming with real growth in GDP

approaching 10 percent, allowing previously shelved government

plans for expansion to be reactivated.

In 2004 the state-owned oil company Petroleós de Venezuela S.A.

(PdVSA) awarded contracts to three local companies for the first

stage in the construction of a huge new undertaking, the 300-km

Interconnexion Centro Occidente (ICO) pipeline, known as the ICO

project. This complex infrastructure project, due for completion

in 2007, will connect gas-producing wells in the eastern and central

regions with existing wells and new gas transmission systems in

western Venezuela, partly to boost oil production and also to bring

natural gas to consumers in that part of the country for the first

time. A 106-km pipeline providing a connection between natural gas

fields in Falcon state and the PdVSA Paraguana refinery complex,

one of the largest in the world, has already been completed and will

soon be delivering between 10 and 100 million cubic meters of gas

per day, increasing progressively until it reaches 100 to 300 million

cubic meters of gas per day.

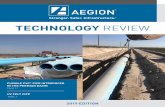

PICKING THE PATHOne of the largest and most challenging pipeline projects ever un-

dertaken by PdVSA, the ICO system for the bulk transnational

transportation of natural gas, was originally planned nearly 20 years

ago. The giant new line now under construction will comprise 230

km of 30-inch (762 mm) diameter and a further 70 km of 36-inch

diameter (914 mm) pipe. The pipe is formed from special high-

tensile steel capable of withstanding internal pressures of more

than 4,600 bar, reducing both wall thickness and the number of

welds, and is being used for the first time in Venezuela. Buried at a

1 2 _ M O N I T O R

Phot

os: S

iem

ens,

Illu

stra

tion

: Mai

ke H

amac

her

depth of about 1.2 meters in a 20-meter wide corridor, the line will

snake its way across the coastal plain, avoiding the most mountain-

ous terrain, following a precisely planned path selected as the most

favorable from no less than 14 other routes originally surveyed in

the late ‘80s. Although designed to pass close to towns and centers

of population to provide these widely scattered communities with

gas supplies for the first time, the route of the ICO pipeline also cuts

through some of Venezuela’s most environmentally sensitive

and internationally important areas, which are home to rare plant

species, unique wildlife and archaeological sites. In consequence,

consent for construction has only been granted by the Venezuelan

government after the most rigorous scientific and ecological stud-

ies, covering the project’s impact on every aspect of local environ-

ments, with continuous inspections and environmental audits on

every centimeter of the route as work progresses.

As well as routing the pipeline unavoidably through a number of

archaeological sites revealing pre-Colombian discoveries currently

being studied by experts from around the world, the construction

crews have to contend with engineering a total of eighteen separate

river-crossings, many of which are in tropical rainforest environ-

ments. Using conventional technologies, taking even large-diame-

ter pipelines across rivers does not present a significant problem.

However, official planning restrictions imposed by the Venezuelan

government to protect the delicate environmental balance in these

sensitive locations, prohibit any form of damage to all riverbank

environments, requiring the design and use by the contractors of

special-purpose systems, equipment and machines. The route also

crosses the Morrocoy National Park, necessitating a major detour

in order to follow an existing ‘service corridor’ through the park,

used as the least-damaging transit route for power lines and a wa-

ter pipeline.

PERFORMING UNDER PRESSURERepresenting one of the largest contract awards made by the state-

owned company in recent years, the three compressor stations

along the ICO pipeline will house a total of ten compressor trains

supplied and installed by Siemens. These comprise STC-SV com-

pressors supplied from the Duisburg plant, powered by 13.4-mega-

watt (MW) SGT-400 gas turbines built at the Lincoln factory in

the UK. Six of the compressor trains are being supplied as high pres-

sure units and four as low pressure trains, with all equipment

V E N T U R E M A G A Z I N E _ J A N U A R Y 2 0 0 7 _ M O N I T O R _ 1 3

shipped to site via the Siemens facility in

Houston, Texas, where the compressor

trains were assembled and specially pack-

aged for operation in a tropical environ-

ment. Three units are being installed at the

Morón compressor station, four at Los Mor-

ros and a further three at Altagracia. The en-

tire turnkey contract is being carried out by

a local consortium headed by Siemens S.A,

partnered by Caracas-based Jantesa, which

has responsibility for engineering and pro-

curement, with Confurca headquartered in

Ciudad Ojeda undertaking civil works. Siemens will also provide

full maintenance services for the turbocompressors over a four-

year contract period. The compressor stations will be monitored and

controlled remotely through an optical fiber data-communications

network being supplied by Siemens S.A. The stations will be linked

to the primary control room at Anaco and with a secondary con-

trol system in Caracas.

IMPROVING LIVESAlthough Venezuela’s investment in the ICO pipeline is intended to

boost the national economy through increased oil and gas produc-

tion, the vast, long-distance construction project is also aimed at

providing major social improvements for the

widely scattered, mainly rural communities af-

fected by the project. In line with the govern-

ment’s demand that no less than ten percent of the

entire project value must be returned to the com-

munities involved, PdVSA is not only ensuring that

gas will become available as a low-cost fuel for a

large number of people for the very first time, but

is undertaking a far-reaching social initiative affect-

ing communities along the whole length of the

pipeline. “This is the nicest and most exciting part

of this project,” says PdVSA Project Manager

Richard Tahan. “We are now able to improve the

lifestyle and raise the standard of living for literally thousands of

people, providing new facilities in areas ranging from entire towns

and villages, to scattered farms, communities and even isolated

dwellings.”

FISHING, FARMING AND FAMILIESRichard explained that the initiative is being split into four sectors.

“The first will involve building and repairing roads, building new

local medical centers, improving existing schools and re-housing

widely separated and outlying families who currently live within

2.5 km on either side of the pipeline, in modern new housing.” He

pointed out that the pipeline project involves installing electrical

power, drilling wells for water for hydro-testing operations and

installing the Siemens data-communications network. “Because all

these utilities are already being installed along the route of the

pipeline, it is quite easy for us to provide modern facilities for peo-

ple in the vicinity. They will not only be supplied with drinking

water and mains electricity, but will also have full access to tele-

phones and a broadband connection to the internet,” said Richard.

The second sector will include the development of the fishing

industry in the coastal area of Rio Seco, with the provision of fresh

drinking water and mains electricity, but also including the con-

struction of refrigerated storage and ice-making facilities to support

the local shrimping industry. The third and fourth sectors will cov-

er the modernization and expansion of locally-based agriculture in

both the Altagracia and Los Morros areas. In addition to increasing

production and efficiency, additional investment in the agricultural

and farming industry will provide future employment for local peo-

ple currently employed on the construction of the ICO pipeline.

WIN-WIN FOR SIEMENSThe Anaco project represents not just a major contract win for

Siemens, but marks a significant step forward in the further devel-

opment of the company’s oil and gas business in Latin America.

The ability to demonstrate successful implementation of both in-

dustrial gas turbines and latest-generation gas compression

solutions under a turnkey contract in a tropical environment is

providing a benchmark against which competing products and

suppliers are measured and a win-win solution for Siemens and

customers alike.

”We are able to improve the standard of living for literally thousands of people,

providing new facilities to towns and villages, to scattered farms, communi-

ties and even to isolated dwellings.”Richard Tahan, Project Manager, PdVSA