Vacuum Explosion Proof

-

Upload

industrial-vacuum-systems -

Category

Documents

-

view

220 -

download

3

description

Transcript of Vacuum Explosion Proof

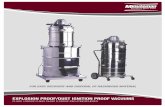

How Are Explosion Proof Vacuums Used In The Industry?

For any facility working with explosive or toxic materials such as asbestos, chemical waste,

metal or fiberglass dust, the importance of employee and equipment safety is essential.

When working in an industrial facility such as this, the risk of fire is one of the most

pressing. To combat situations such as this, explosion proof equipment is mandatory, even

in the cleaning equipment. These are messy jobs. They produce a lot of swarf and left over

debris and in the process of cleaning this debris up, sparks can fly. This is why the explosion

proof vacuum was designed for industrial manufacturers and companies.

The key to the explosion proof vacuum lies in its air filtration system. Most industrial

vacuums fitting this description will have an air filtration system constructed of a HEPA

filter, non-combustible materials and everything will be fully bound and grounded. This

eliminates the possibility of creating a spark within the machine while it is being used, which

eliminates fires from starting within said machine. In an industrial building where explosive

materials and toxic materials are common a fire can spread rapidly.

Taking proactive measures to eliminate fire hazards before they even start is mandatory.

OSHA makes it a point to regulate fire safety codes and instances. They are the ones who

began creating the explosion proof vacuum in the first place. All other manufacturers of this

machine must meet OSHA’s guidelines before marketing their product. So, companies

should shop for and purchase only those vacuums that have the OSHA seal of approval.

There are many models of the explosion proof vacuum. They come in different sizes, with

different suctioning power, and different air filtration systems. The type of industrial work

environment will determine the type of vacuum used. But, these machines are designed to

provide optimum power in all scenarios.

Industrial buildings and work areas are necessary for the economy. But, it is undeniable

that they do create fire and toxicity hazards that are dangerous for those who work in them.

That is why the explosion proof vacuum was created. To allow for optimum cleaning that

meets codes, regulations, and guidelines while creating safe equipment to use in these

environments. Using industrial cleaning equipment requires the same care and caution that

using any other industrial equipment does. The industry understands this and they have

worked to create the safest possible equipment for those who need it in their work spaces.

Most of the companies have stringent fire and other safety measures to adhere to when

they deal with chemicals and firearms, or other such materials. With the use of safe

vacuums, the floors are kept clean ensuring safety of the employees. There are multiple

service providers that deal especially in such commercial scale vacuums. You can log in and

contact them online for purchase or service of these vacuums.

Uses Of Industrial Vacuum System

The industrial vacuum systems are more complex than the average system. They are

designed to be compatible with harsh work environments such as those found in industrial

manufacturing plants. These systems are designed to clean flammable, toxic environments.

So, industries such as woodworking, metal working, food industry, chemical waste, etc. are

supposed to use these machines. This is dictated in the regulations set down by OSHA to

ensure a safe work environment in an otherwise unfriendly one. With many different

models, each one is designed to clean certain things.

What an industrial vacuum system cleans is determined by its air filtration system, body

design, and suction power. Air filtration systems control the amount of air flow and back

draft that an industrial vacuum system produces. They consist of non-flammable materials,

HEPA air filters, and non-combustion safeguards such as binding and grounding to prevent

fire hazards. Their size ranges from small portable units to stationary tabletop units. Their

suction power ranges in energy to allow optimal cleanup of various waste such as wood and

fiberglass dust, swarf, and liquids.

Classification Of Commercial Grade Vacuums

Each industrial vacuum system comes with a specific classification (i.e. Class 1 Group D or

Class 2 Group E and F) awarded by OSHA that states which work environments they are

cleared to be used in. Some are air powered others electric powered. Air powered ones are

most often used for the cleanup of both wet and dry particles while electric powered ones

tend to be used for mainly dry cleanup. In fact, OSHA was the ones to start designing such

units for commercial use. Safety and regulation compliance is essential in industrial

companies. These regulations are set down to ensure customer and employee safety and

effectiveness. A lot of time and innovation is spent on designing the best units available for

safe cleanup as it is just as important as production.

The industrial vacuum system is constantly evolving. New filters, better suction, more

compact and efficient sizes, are constantly being strived after. Millions of dollars can be

spent on designing that next best machine and it is all in the name of safety and efficiency.

Providing a safe work environment boosts productivity. In order to meet those safety

guidelines, the systems used must be designed to handle the work. With so many different

kinds of systems available there is no reason such standards cannot be met. The industrial

vacuum is the safety feature of the industrial future. Most businesses require these

commercial machines to offer quality working environs for the employees.

If you are looking to purchase or get the machines serviced, it is time to look at affordable

suppliers and get free quotes on your buy or service. After all when it is about safe working

environments, it is about investing right in your business.

Quick Facts About Industrial Vacuum Systems

Industrial vacuum systems are integral to the cleaning of an environment that produces

asbestos and waste removal. These are durable machine systems that work to eliminate

contaminants and debris from work floors and tables. They also help to enforce a clean air

environment policy. These innovative machines are designed to exceed the industry

standards that are set upon them. They each pass strict codes and guidelines to ensure

adherence to OSHA standards and the regulations of a safe work environment.

Using industrial vacuum systems cuts down on the risk on staff working in these

environments face when around certain materials for long periods of time. The pairing of a

vacuum system with strict safety protocols can all but eliminate the potential risks and

hazards that come with working in such an environment.

The key to the strength of these industrial vacuum systems lie in their filtration systems. All

machines are equipped with a system the meets the guidelines to be used in and around

highly explosive and toxic materials. They are equipped with nebulizing systems for air

control and cleaning. This helps to prevent fires and other hazardous accidents. Air control

also eliminates the amount of excess particles/dust produced during the suction process.

These industrial vacuum systems are paramount to creating a safe work environment for

those industries such as sandblasting. They are used in conjunction to the other machinery

creating a streamlined and efficient manufacturing and cleaning system.

Use Of Commercial Vacuum Systems

They are used to collect sand, grit, and other particles created on the production floor. They

are built with high efficiency motors that keep them long lasting and energy efficient. This is

an important aspect for those in the commercial industry who use them on a regular basis.

They are depended on to provide a clean and safe environment for all of those involved.

The precision and strength of industrial vacuum systems is becoming more innovative as

their production progresses. Additionally, when you source these large vacuums for your

own business, there is manufacturer’s warranty, guarantee and guarantee that ensure

standby support if something goes wrong.

The goal is increasing geared toward clean, safe, work environments that require little

energy output and ensure less air pollution within the work environment. Different systems

are designed for different situations. But, each one remains focused on the original values it

was designed for. These are the machines of the future designed to make working with

hazardous and polluting materials less risky for the individual who is working with them.

These systems establish a strict code for any business that needs to meet OSHA standards

and guidelines. This gives users a sense of reliability and credibility. You can look online for

such large vacuum systems if your business requires such equipment.

Why Invest In Industrial Vacuums?

Industrial vacuums provide the power and precision that commercial companies in the food

production and hazardous material manufacturing industries need to ensure strict

cleanliness in their buildings. Any company, who handles food including those who process

flour and grain, are require to maintain clean environments that adhere to the strict set of

regulations set down by the FDA. Any company who handles hazardous materials is required

to maintain certain cleanliness and safety measures. They have to ensure that their

products are in no way contaminated with outside, environmental contaminants and they

have to ensure that their staff and customers are safe. These vacuums are designed

specifically for use in commercial industries where cleanliness and code adherence is strictly

mandated. There are different styles and sizes, giving a wide range of options to choose

from.

An industrial vacuum is constructed according to industry standards and regulations. They

are built to provide stronger suction and precision cleaning than their household

counterparts. A commercial company will choose the type of vacuum according to the job

requirements. For example there are specific models of vacuums designed to be used in the

carpentry industry. These vacuums have a specific suction type that works best with

cleaning up particles of wood and fiberglass from the manufacturing table and floors. This is

a safety precaution ensuring that employees have an environment safe to work in for long

hours on a regular basis. Industrial vacuums can even be used in areas that have the

potential to produce high explosive, toxic dust and materials.

Varity Of Different Industrial Grade Vacuums

These types of machines will be specially certified for these instances. These vacuums

comes attachments for liquids as well. A company that produces the potential for hazardous

spills will use an industrial machine that has the suction power to clean up the spill (i.e. Oil,

emulsions, coolant, mud, sludge). Most of these machines will come with a micro-filtering

attachment for oil and emulsions.

Industrial vacuums are designed for the tough jobs that their counterparts can’t handle.

But, they are still energy efficient. Their design to meet industry standards and OSHA

guidelines are what qualify them for commercial use. In a lot of situations a normal vacuum

will not meet the specific demands of the manufacturing floor or chemical plant. The safety

of the staff who work in the environment and the safety of the customers buying the

product is paramount. The design of these industrial machines is meant to meet that

demand.

If you are looking for companies that provide such large scale vacuums, you can look online

to check the available range. This is an investment that you are making for your own

business and that is why it is good to go with an established brand. This ensures

manufacturer’s warranty and high quality cleaning apart from longer life span of the

commercial vacuum.