User Manual EDOR v.3.9 ENG (1).pdf

-

Upload

jessika-tine-dezan -

Category

Documents

-

view

277 -

download

2

Transcript of User Manual EDOR v.3.9 ENG (1).pdf

USER MANUAL

Rev.3.9

Odorization monitor

EDOR USER MANUAL Page 2 of 53 V 3.9 of 20/06/2013

TABLE OF CONTENTS

1. GENERAL ................................................................................................................................... 5

1.1. Product operation ....................................................................................................................................................................... 5

1.2. Available models ......................................................................................................................................................................... 6

1.3. Warnings ...................................................................................................................................................................................... 7

1.4. Technical characteristics .......................................................................................................................................................... 10

2. INSTALLATION ........................................................................................................................ 11

2.1. Mechanical installation of basic model.................................................................................................................................... 11

2.2. Mechanical installation with Sampling System accessory ..................................................................................................... 12

2.3. Mechanical installation with wall-mounted Sampling System .............................................................................................. 13

2.4. Quick programming and start-up ........................................................................................................................................... 14

2.5. Test measurement ..................................................................................................................................................................... 15

2.6. Diagnostics ................................................................................................................................................................................. 15

2.7. Electrical connections inside the control unit ......................................................................................................................... 15

2.8. Version with 12V power supply ............................................................................................................................................... 17

2.9. Version with 230V power supply ............................................................................................................................................. 18

2.10. Version with 4-20mA analogue outlets ................................................................................................................................ 19

2.11. Version with RS485 modbus serial outlet ........................................................................................................................... 22

2.12. Version with external RS232 interface cable ...................................................................................................................... 22

3. MAINTENANCE ........................................................................................................................ 24

3.1. Basic model calibration (manual operator calibration) ......................................................................................................... 24

3.2. Calibration with the Sampling System .................................................................................................................................... 24

3.3. Dip-switches, LEDs and Edor buttons .................................................................................................................................... 25

4. USER GUIDE ............................................................................................................................ 26

4.1. Quick application guide ............................................................................................................................................................ 26

4.2. Communication type ................................................................................................................................................................. 26

4.3. Serial Console ............................................................................................................................................................................ 27

EDOR USER MANUAL Page 3 of 53 V 3.9 of 20/06/2013

4.4. Changing the date via SMS ...................................................................................................................................................... 30

4.5. Modbus table for versions with RS485 serial outlet ............................................................................................................... 30

4.6. Direct GSM connection via SMS ............................................................................................................................................. 33

4.7. Edor events codes ...................................................................................................................................................................... 34

5. EDOR CENTRAL ...................................................................................................................... 37

5.1. Functionality .............................................................................................................................................................................. 37

5.2. System requirements ................................................................................................................................................................. 37

5.3. Installation and first start-up ................................................................................................................................................... 38

5.4. Login .......................................................................................................................................................................................... 38

5.5. User management ...................................................................................................................................................................... 38

5.6. Application configuration ......................................................................................................................................................... 39

5.7. Installation of RS232 serial modems ....................................................................................................................................... 40

5.8. Installation of USB modem ...................................................................................................................................................... 40

5.9. Remote-reading peripherals (main window) .......................................................................................................................... 41

5.10. New/Modify Peripherals ....................................................................................................................................................... 44

5.11. Exporting and printing ......................................................................................................................................................... 45

5.12. Serial Console (local programming) .................................................................................................................................... 46

5.13. Remote programming and remote-controls ........................................................................................................................ 47

5.14. Events Log ............................................................................................................................................................................. 49

5.15. Edor Diagnostics ................................................................................................................................................................... 50

EDOR USER MANUAL Page 4 of 53 V 3.9 of 20/06/2013

USER MANUAL

EDOR Last updated 20/06/2013

Language: ENGLISH

This manual is an integral and essential part of the product. Read carefully the instructions contained

herein as they provide important information regarding safety and maintenance.

This equipment is intended exclusively for the use for which it was designed. Any other use is to be

considered improper and as such dangerous. The Manufacturer declines any responsibilities for

damages caused by improper, wrong and unreasonable use.

Any intervention that alters the structure or the operation cycle of the machine must be performed or

allowed by authorized CPL staff.

CPL may not be held responsible for consequences deriving from the use of non-original spare parts

CPL reserves the right to make technical changes to this manual and to the equipment without prior

notice. In case of typos or other kind of mistakes, the corrections will be included in the new version of

this manual.

This manual cannot be reproduced without written consent by CPL Concordia.

This manual refers to the devices featuring the following firmware versions: 0.01, 1.52, 1.53, 1.55,

1.56, 1.59, 2.13, 2.14, 4.01, 4.02, 5.02, 5.03, 5.04, 6.02, 7.01, 7.02, e 8.01.

For different versions, please contact CPL Concordia to receive the corresponding manual.

CPL Concordia Soc. Coop.

Via A. Grandi, 39 - 41033 Concordia s/S (MO) - Italy tel.: +39 0535 615 511 - fax: +39 0535 615 510

http://www.cpl.it - e-mail: [email protected]

EDOR USER MANUAL Page 5 of 53 V 3.9 of 20/06/2013

1. GENERAL

1.1. Product operation

Edor is the new sensor for the remote monitoring of the amount of monitoring in natural gas, used as a

remote survey unit. It can detect three types of odorant: TBM (mercaptan compounds), THT

(tetrahydrothiophene) and EM(EthylMercaptan).

The device can be installed inside odorization plants to check the intake of odorant in gas (gas distribution

stations, or “R.E.M.I.”), or along the gas distribution network to obtain a constant measurement of the

amount of odorant reaching the user’s end points (“GRF” and “GRI” distribution stations).

The device uses electrochemical sensors, i.e. specific cells for each type of measured odorant. Typically,

the sensor is tested in presence of the gas by opening a low-energy solenoid valve once or up to 4 times a

day. The rate measured is then transmitted to the data centre once a day via SMS. In case a low dosage

of gas is detected in two consecutive measures, the device warns the on-call technician by sending an

SMS to his cell phone number and the central software EdorCentral notifies the alarm on the video screen.

The measurements are transmitted by means of remote communication device (modem) that sends data

directly via SMS (basic version), to the gas network manager, enabling him to constantly monitor and

record the network’s odorization state without the assistance of additional staff members who are usually

called to perform this verification activity every now and then.

Connection to the electricity network is not required as the device runs entirely on batteries (basic

version). However versions with solar panel power supplies are available with 230VAC and 12-24VDC.

Due to the software’s temperature compensation function, the device can guarantee accuracy of 15%1.

The temperature is detected through a PT100 probe installed next to the sensor.

With the Sampling System accessory (SS option) it is possible to achieve accuracy of less than 10%1

thanks to periodical self-calibrations with a sample gas cylinder connected to a second solenoid valve.

Without the SS accessory it is however possible to perform periodical manual calibrations (intervention of

an operator with a sample gas cylinder on the unit/station).

The device can be entirely configured directly by the user via SMS in text mode on a cell phone.

Edor Central is an application for PC Windows dedicated to the configuration and the remote-reading of

individual Edor stations. It is multi-user and multi-language software capable of saving the entire log of

the measurements and generating a report that is easily imported via Microsoft Excel for quick

consultation. Through user-friendly input screens, EdorCentral enables users to configure any operation

parameter without requiring knowledge of communication protocols. The software’s only requirement is

the connection to a dedicated GSM modem to receive and send SMS that is connected to a computer. The

proper operation of EdorCentral is guaranteed solely with these types of modem: “Siemens TC35i”,

“Cinterion TC35i”, “Siemens TC65” (all models with RS232 serial port), and “Digicom USB Wave GPRS M”,

with USB port.

Central Software for EDOR

EDOR USER MANUAL Page 6 of 53 V 3.9 of 20/06/2013

1.2. Available models

Es: EDOR H N G B S N

Code: (1)(2)(3) (4)(5)(6)

Ecom

model

Description

Remote-measurement unit

Code 1 H B E

Product version THT detection TBM detection EM detection

Code 2 N S

Measurement device Sampling System accessory absent Sampling System accessory present with sample gas cylinder included containing 1 litre of odorized

nitrogen

Code 3 G N

Modem GSM modem (basic version) without modem (for special uses)

Code 4 B L R

T

Power supply Battery power (basic version) Solar panels 230Vac network

Low voltage (12-24 Vdc)

Code 5 S M A

Communication protocol SMS protocol (basic version) RS485 Modbus (not available with battery-powered version) 4-20mA analogue outlets (not available with battery-powered version)

Code 6

N

Third solenoid valve measurement

without 3rd solenoid valve

EDOR USER MANUAL Page 7 of 53 V 3.9 of 20/06/2013

1.3. Warnings

NOTES REGARDING THE INSTALLATION SITE

We recommend you install the control unit where it will not be exposed to direct sunlight for long

hours, or alternatively, follow the countermeasures mentioned in the installations notes;

Check that the electrical cabin is free from gas leaks using a gas detector;

Check that the GSM service is available, and install an external antenna if necessary;

Check that the pressure on the gas pipeline is 25-35 mbar by using an interception valve with a

1/4” NPT F connector (the plug must be identified beforehand);

Check that the explosion risk areas have been classified and identified pursuant to local legislation

in order to install the GSM modem in a safe zone;

Check that the 4 holes in the electrical cabin have a diameter of 5 mm to fix the GSM unit and a

hole with a 24 mm diameter for the cables to pass through it.

INSTALLATION NOTES

The start-up and maintenance operations should be performed by qualified staff only;

disconnect the battery before performing any kind of operation on the device;

TBM is extremely prone to oxidation and connects to any surface until it reaches saturation. It is

therefore important you connect the Edor device to the low-absorption methane connection pipe

supplied with the device and perform a quick test. Alternately you may use an AISI 316 stainless

steel pipe with 6 mm diameter for permanent installation;

during the maintenance phase use CPL parts only; the use of parts from other manufacturers will

void the warranty;

follow the instructions regarding wiring and connection to other systems or transducers;

the internal analyser must be protected from dust and rain and from temperatures above 40°C:

secure it near the ground, in upright position, at the shaded side of the station/unit. In case of

metal cabs, provide for insulation or protect the outer sides exposed to direct sunlight via reflective

films or insulate the cabin with aluminium panels at a distance of 3 cm from the cabin itself;

the site where the monitoring unit will be installed should be absolutely free from gas leaks or from

any type of gas-related substances (traces of TBM, THT, ammonia or any other polluting

substance). The measurement cell may be damaged by the constant presence of concentrations of

chemical, sulphurous or polluting substances. Check the installation site with gas leak detectors

before installing the device;

read the ATEX manual regarding safety instructions;

loads above 60 Litres/h or excessive pressure may deteriorate the odorant-detection cell;

loads below 20 Litres/h may produce measurements with a negative rate;

excessive distances (above 1.5 m) between one monitor unit and the measured point may

negatively influence measurement accuracy;

in the basic version, make sure that the manual calibrating channel is always closed with a stopper

during normal operation to avoid leaks and misleading measurements;

the sensor also produces a signal when it detects substances other than THT; the next page will

provide an non-exhaustive list of some of the substances with their relative measurements. The

same observations apply for the TBM sensor;

complete the EDOR activation module before installation and send it via fax directly to CPL

Concordia, at the following fax number: (+39) 0535-616124;

make sure the device is perfectly calibrated before beginning large-scale measurement campaigns;

EDOR USER MANUAL Page 8 of 53 V 3.9 of 20/06/2013

if the connectors of the monitor units are disconnected, you will need to wait at least one hour

before performing measurements to allow the sensor to stabilise and 4 hours before performing

calibrations;

the measurement cell is affected by the effects of memory: many consecutive measurements (e.g.

3 measurements in 5 minutes) typically performed during the start-up phase may generate

exceeding measurements. We recommend waiting for at least 20 minutes from one measurement

(or calibration) and another;

the removal of factory tags (seals or labels) results in the expiry of the warranty. In case of a

device under inspection purposes, the device can be sold without a warranty period;

the cell has a warranty period of 6 months only in case all the warnings are followed. With average

concentrations of odorants the warranty expires, in any case, after nearly 1000 measurements

with an exposition time to gas equal to 1 minute each1;

Edor is a merely indicative, non-analytic measurement tool. Errors in measurement are due to the

inaccurate of certification of the sample cylinders, and for the presence of impurities in the gas

(that may interfere with the measurements performed by Edor, but not with a gas

chromatograph). Worth mentioning is the fact that even the gas chromatograph may produce

errors due to the sample cylinder used for the calibration;

The 15%1 accuracy rate refers to the measurement system of Edor, excluding any tolerance of the

calibration sample mixtures.

EDOR USER MANUAL Page 9 of 53 V 3.9 of 20/06/2013

Edor’s sensivity (THT version) to the substance found in gas

Edor sensitivity (TBM version) to the substances found in gas

CPL Concordia cannot be held responsible, for no reason whatsoever, for the damages to things or injuries

to persons deriving from tampering or from wrong, improper use, or in any case non-conforming to the

specifications contained in this manual.

EDOR USER MANUAL Page 10 of 53 V 3.9 of 20/06/2013

1.4. Technical characteristics

Safety

features

Electrical power centre (IP66)

EDOR head (IP 20)

Gas stream

Intake

measurement

CH4, stream of 45 l/h

10-20 mBar

Power supply 9V alkaline battery pack

7V lithium battery pack

Gas for sampling Maximum 4.5 Litres

Battery life Alkaline 5 months or Lithium 10

months

with 4 measurements per day

+ 1 SMS

Standard Modality [4 measurements + 1

SMS]

daily

Odorization

sensor

precision

From 5%1 to 30% for up to 6

months.

(no impurities in the gas) 1

Type of odorant THT, TBM, EM

Measurement

duration

From 2 to 6 minutes

Metres of cable

between the GSM

station and the

Edor head

Std: 2 m.

Maximum: 10 m.

Precision

<Sampling

system>

option

10%1 for 1 year

Self-calibration every 21 dd

Type of Modem GSM

TBM

measurement

range

Std 0-40 mg.

Communication

protocol

SMS

THT

measurement

range

Std 0-100 mg.

Working

temperature of

external unit

(modem)

-20 ÷ +60°C

Accessories Sampling System;

Output 4-20mA

Working

temperature of

internal probe

(Edor)

-10 ÷ +40°C

Connection to

the process

coupling 1/4 “ NPT on the pipe

at the intake point

Dimensions Electrical power centre

300x190x90 mm

Head 171x139x150 mm

Mass 5 Kg 1 The value is based on natural gas odorized by THT or TBM odorizants: the use of Ethylmercaptan could cause variations on it

EDOR USER MANUAL Page 11 of 53 V 3.9 of 20/06/2013

2. INSTALLATION

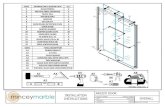

2.1. Mechanical installation of basic model

Position the Edor monitor (EDOR head) in the hazardous area, near the gas outlet connector, in the

upright position and with the cables downwards. Keep the EDOR head the closest as possible to the

sampling point (distance < 1.5 m).

Position the external electrical control unit in a safe zone, connect the 4 pole cable (Edor sensor), and the

8 pole cable (PT100 sensor and the solenoid valve) to the analyser. Enter the SIM card without the PIN

code, then connect and disconnect the battery. Do not use cables longer than 10 m to connect the unit to

the head.

Adjust the gas stream outgoing from the conduct at 40-45 L/h and connect the stainless steel connecting

pipe to the inlet of the monitor’s solenoid valve No. 1 (measurement solenoid valve).

Connection to the battery is made directly in the factory, but decay due to operation begins as soon as

the circular cables are connected (4 and 8 poles).

Monitor without self-calibration

Interchangeable

sensor cartridge

network gas inlet

sample gas inlet

(to be closed with stopper)

4 and 8 pole connectors

If necessary, follow the programming instructions (see para. 2.4 “Quick programming and start-up”).

In order to prevent battery decay, make sure that the settings of dip switches at rest are as

follows: Dip1 OFF – Dip2 OFF – Dip3 OFF – Dip4 OFF

Dip Switch EDOR are all switched downwards

Press button 1 to perform a test measurement (see para. 2.5 “Test measurement”).

Calibrate the tool if necessary (see para. 3.1 “Basic model calibration”).

For trouble-soothing, read paragraphs 2.6 “Diagnostics” and 3.3 “Dip-switch, LEDs and buttons”.

Note: the supply also includes a Rilsan pipe with related connectors for temporary installation.

EDOR USER MANUAL Page 12 of 53 V 3.9 of 20/06/2013

2.2. Mechanical installation with Sampling System accessory

Position the Edor monitor (EDOR head) in the hazardous area, near the gas outlet connector, in the

upright position and with the cables downwards. Keep the EDOR head the closest as possible to the

sampling point (distance < 1.5 m).

Position the external electrical control unit in a safe zone, connect the 4 pole cable (Edor sensor), and the

8 pole cable (PT100 sensor and the solenoid valve) to the analyser. Enter the SIM card without the PIN

code, then connect and disconnect the battery. Do not use cables longer than 10 m to connect the unit to

the head.

Adjust the gas stream outgoing from the conduct at 40-45 L/h and connect the stainless steel connecting

pipe to the inlet of the monitor’s solenoid valve No. 1 (measurement solenoid valve).

Adjust the gas stream outgoing from the conduct at 40-45 L/h and connect the stainless steel connecting

pipe to the inlet of the monitor’s solenoid valve No. 2 (calibration solenoid valve).

Connect the cable from the pressure switch, located on the sample cylinder reducer to the external control

unit. The pressure switch outlet is closed in case the cylinder is full.

Interchangeable sensor cartridge

Network gas inlet

Sample gas

inlet

Connection to the battery is made directly in the factory, but

decay due to operation begins as soon as the circular cables are connected (4 and 8 poles).

If necessary, follow the programming instructions (see para. 2.4 “Quick programming and start-up”).

In order to prevent battery decay, make sure that the settings of dip switches at rest are as

follows: Dip1 OFF – Dip2 OFF – Dip3 OFF – Dip4 OFF, as shown in the figure below

Dip Switch EDOR are all switched downwards

Press button 1 to perform a test measurement (see para. 2.5 “Test measurement”).

Calibrate the tool if necessary (see para. 3.1 “Basic model calibration”).

For trouble-soothing, read paragraphs 2.6 “Diagnostics” and 3.3 “Dip-switch, LEDs and buttons”.

Note: the supply also includes a Rilsan pipe with related connectors for temporary installation.

Monitor unit with self-calibration Sampling System

EDOR USER MANUAL Page 13 of 53 V 3.9 of 20/06/2013

2.3. Mechanical installation with wall-mounted Sampling System

1. Drill an attachment hole to the wall where the unit will be installed

2. Drill a hole to allow the measurement pipe to pass through and connect the unit to the gas

network

3. The connector for the internal process should be made with a needle valve equipped with the

measurement circuit to allow for stream regulation (calibrate at 45 l/h) using an hexameter

4. The terminal end of the needle valve is connected to a stainless steel pipe with dual ogival stopper

and a diameter of 6 mm

5. Connect the other end of the pipe to the receptacle marked in the figure below (inlet measurement

EDOR connector)

6. Open the knob (blue, in the figure) of the gas cylinder situated inside the metallic panel

Once the EDOR panel is secured to the reduction unit, connect to the receptacle that will protrude inside

the stainless steel cabinet. The connector is of ODX type with ø 6 mm dual ogival stopper that will be

connected to the pipe that runs from the sampling point on the coupling found on the gas pipeline.

Threaded coupling for gas intake

EDOR USER MANUAL Page 14 of 53 V 3.9 of 20/06/2013

2.4. Quick programming and start-up

The device can be programmed and adjusted to the customer’s needs. This is done using EdorCentral or a

simple text SMS sent to the device’s reference number. Controls, with their respective descriptions, are

contained in the EdorCentral chapter. The message is received once every day at the time configured as

the beginning of the measurements.

The machine is operative at the very first start and it uses factory settings, namely 4 measurements per

day, it receives configuration SMS messages and sends a measurement report at 7:00 am. To adjust

EDOR’s parameters to one’s own needs, it is possible to send an SMS to configure the device ID and the

GSM numbers of the data centre and on-call technician. To do so send a message with the following text:

EN00112233;A=XXXXXXXX;D=YYYYYYYYY;E=ZZZZZZZZ;

where:

00112233 is the factory ID; for all configuration operations after the first one, use the last ID sent

XXXXXXXX (max 8 digits) is the new ID

YYYYYYYYY (max 15 digits) is the GSM number of the remote-reading centre

ZZZZZZZZ (max 15 digits) is the GSM number of the on-call technician in case of alarms

Note: basic configuration does not affect the machine’s hardware functionality. In case of wrong

configuration parameters, repeat the configuration.

EDOR USER MANUAL Page 15 of 53 V 3.9 of 20/06/2013

2.5. Test measurement

The measurement process enables the machine to detect the amount of current odorant and send a

report SMS with the value detected. The length of the measurement varies from 2 to 6 minutes.

1. Make sure the dip switches are positioned as follows: Dip 1 OFF – Dip 2 OFF – Dip 3 OFF – Dip 4

OFF;

2. Press button 1 to start the measurement procedure.

The DL3 LED starts blinking to indicate that the measurement is started. After an initial adjustment

phase, the actual measurement begins (the solenoid valve clicks and gas leaks out). Once the

measurement is completed, the DL5 LED blinks to indicate that an SMS message is being sent with the

measured value.

The measurement process ends when all the LEDs are off.

2.6. Diagnostics

In case of problems, disconnect the battery, wait for a dozens of

seconds and then connect the battery again. When the device

starts again, it will perform a self-diagnosis procedure to find any

erroneous connections or damages to the hardware. The start-up

sequence is as follows:

1. Modem activation and SIM card registration notified by a DL5

LED light that starts blinking;

2. Simultaneous switch-on of the DL3, DL2, and DL1 LEDs;

3. Correct modem operation test is performed. The DL3 LED

turns off;

4. Correct temperature sensor test is performed. The DL2 LED

turns off;

5. Correct Edor sensor test is performed. The DL1 LED turns off;

6. When all three LEDs blink rapidly and simultaneously, no

errors are on the machine, whereas a fast flicker repeated 15 times indicates the presence of at least

one error. In this event, check that the cable of the LED indicator in question is connected properly.

2.7. Electrical connections inside the control unit

The terminals inside Edor, on the hazardous side, positioned in the lower part of the device includes

the following connections:

EDOR connector Colour of cable

inside the control unit

Colour of cable inside the head

Description

PT100 (I+) Grey White PT100 positive power supply

PT100 (S+) Blue White PT100 positive signal

PT100 (S-) Pink Red PT100 positive signal

PT100 (I-) Red Red PT100 negative power supply

EV (-) Brown Brown Measure solenoid valve negative pole

EV (1) White White Measure solenoid valve positive pole

EV (-) Green Green Calibration solenoid valve negative pole

EV (2) Yellow Yellow Calibration solenoid valve positive pole

DIGITAL INPUT (4) Brown N.A. Pressure switch contact

DIGITAL INPUT (-) White N.A. Pressure switch contact

EDOR (S) White White Sensor S pole

EDOR (R) Green Green Sensor R pole

EDOR (C) Yellow Yellow Sensor C pole

EDOR (-) Brown Brown Sensor pole

EDOR USER MANUAL Page 16 of 53 V 3.9 of 20/06/2013

The control unit sensor connection cable is a 4-pole Proxpecta H0110

The control unit EV,PT100 connection cable is a 8-pole Proxpecta SCH258

Always follow the polarity and order of the connection cables to avoid malfunctioning or damages to the

electronic boards.

EDOR Head without cover

EV Gas of calibration

Wire White

Wire Brown

Wire Yellow

Wire Green

EDOR internal board connector

EDOR USER MANUAL Page 17 of 53 V 3.9 of 20/06/2013

2.8. Version with 12V power supply

Edor with 12V wattage enables to power the control unit from a solar panel, a battery or any other form

of power supply with a linear power voltage output of +12VDC@1A (range valid from 11 to 14VDC).

The electrical power board is supplied with a main switch, and a fuse (1A fast) installed upstream the

fuse.

Start-up

Connect the +12VDC power supply placing careful attention to its polarity (shown in the figure) and lift

the switch inside the device, press the Edor reset button and wait for nearly 60 seconds for initialization

phase (POST).

At first start-up, it is essential you wait for the power supply condenser to be charged: in case start-up is

not performed correctly (LEDs are still inactive 2 minutes after start-up) it may be necessary to reset Edor

and start the system correctly.

Shutdown

Lower the main switch, press the reset button and wait for at least 3 minutes to let the power condensers

turn off

Reset button

Main switch Fuse External power supply: +12VDC

External power supply: GND

ext/int antenna connector

EDOR USER MANUAL Page 18 of 53 V 3.9 of 20/06/2013

2.9. Version with 230V power supply

Edor with the 230V power supply option is equipped with a 230VAC-12VDC power supply unit and can

manage a 12VDC rechargeable buffer battery (the recharge is managed by the power supply itself), in

order to guarantee the correct operation even without mains electricity.

Start-up

Connect the buffer battery, connect the 230V mains and lift the main switch found inside the device, press

Edor’s reset button and wait for nearly 60 seconds for the initialization phase (POST) to start.

At first start-up, it is essential you wait for the power supply condenser to be charged: in case start-up is

not performed correctly (LEDs are still inactive 2 minutes after start-up) it may be necessary to reset Edor

and start the system correctly.

Shutdown

Lower the main switch, press the reset button and wait for at least 3 minutes to let the power condensers turn off.

Buffer battery

230VAC power supply

Reset button

Main switch External 230V power: N

External 230V

power:

External 230V power: L

ext/int antenna connector

EDOR USER MANUAL Page 19 of 53 V 3.9 of 20/06/2013

2.10. Version with 4-20mA analogue outlets

The analogue ports, where applicable, enable to send a signal regarding the odorization rate (“O.R.”

outlet) and temperature (“TEMP” oulet) regarding the last measurement performed. Moreover, a third

outlet (“ACK”) acknowledges the user that a “new measurement was performed and completed”.

This option, available only with 230V and 12-24VDC models, is used only where an expansion module is

installed. In the 230V model, operation is ensured also without mains electricity thanks to the buffer

battery.

Start-up

Connect the buffer battery, connect the 230V mains and lift the main switch found inside the device, press

Edor’s reset button and wait for nearly 60 seconds for the initialization phase (POST) to start.

At first start-up, it is essential you wait for the power supply condenser to be charged: in case start-up is

not performed correctly (LEDs are still inactive 2 minutes after start-up) it may be necessary to reset Edor

and start the system correctly.

Shutdown

Lower the main switch, press the reset button and wait for at least 3 minutes to let the power condensers

turn off.

EDOR USER MANUAL Page 20 of 53 V 3.9 of 20/06/2013

Buffer battery Main switch External 230V power: N

External 230V

power:

External 230V power: L

Analogue outlet expansion

230VAC power supply

Reset button ext/int antenna connector

O.R. + Green

O.R. GND Brown

TEMP + White

TEMP GND Brown

ACK + Yellow

ACK GND Brown

EDOR USER MANUAL Page 21 of 53 V 3.9 of 20/06/2013

The analogue channel 1 (O.R.) has a default scale of 0mg/smc (4mA); 100mg/smc (20mA).

The analogue channel 2 (TEMPERATURE) has as a default scale -50°C (4mA); +100°C (20mA).

The analogue channel 3 (measurement confirmation completed) indicates that a new measurement had

just terminated: after the measurement, the outlet is taken to the logic value of “Uno” [One], then, after

20 seconds it is taken to the logical value of “Zero”. By default, the value corresponding to “Zero” is equal

to 5mA, while for the “Alto” [High] logical value it is equal to 15mA.

The configuration of the zero scale, of the full scale and of the level of voltage associated to the third

outlet is possible via a serial console.

Enable the serial console as shown in para. 4.3 “Serial Console”, and enter the analogue settings in the

menu via “A”:

1) lowTO[0] set the zero scale of the O.R. outlet (mg/smc)

2) highTO[100] set the full scale of the O.R. outlet (mg/smc)

3) lowTemp[0] set the zero scale of the TEMPERATURE outlet (°C)

4) highTemp[150] set the full scale of the TEMPERATURE outlet (°C)

5) ackLow[5] set the mA associated to the “Zero” logic value of the ACK outlet

6) ackHigh[15] set the mA associated to the “Uno” logic value of the ACK outlet

7) Esci&Salva exits the menu and saves changes

8) Esci senza salvare exits the menu without saving changes

Now press the number corresponding to the value to change it and then press ENTER.

The following appears:

Ins.Val.:

Now enter the desired value and press ENTER. Repeat the procedure for the desired values. Finally, exit

the menu by pressing “7” or “8”.

Temperature values have an offset of 50: to enter a full scale -50°C you must enter the 0 value, to enter

a zero scale of -10°C enter the 40 value.

The system automatically exits the menu after two minutes of inactivity.

Outlets are updated every 10 sec in the standby state and only for the 230V version (this activity can be

checked by the blinking LEDs “TX” and “RX” on the expansion module). In the 12V version, module

updating is kept to the minimum in order to reduce power (during start-up, outlet tests, parameter

configurations, and measurement).

IMPORTANT! Make sure the serial console is used by qualified staff only. Sending the wrong

commands may seriously compromise the machine’s operation and void the warranty.

EDOR USER MANUAL Page 22 of 53 V 3.9 of 20/06/2013

2.11. Version with RS485 modbus serial outlet

The version with RS485 serial outlet requires an external power supply (not battery) and features a

complementary connector for the attachment of the serial and the 12Vdc power supply.

The connector on the top right corner, called M1, has four poles with

the following signs:

+ power supply positive pole (12Vdc)

- power supply negative pole

L RS485 serial outlet negative

H RS485 serial outlet positive

The serial’s settings, which cannot be changed, are:

baudrate 4800

data bits 8

parity none

stop bits 1

Handshaking none

2.12. Version with external RS232 interface cable

In order to monitor the Edor activity without opening the device itself, a kit of cables formed by two single

pieces is available upon request and can be ordered separately.

Connection between the two pieces produces a closing towards the GND of “wakeup” input: Edor

recognizes this event and, after a period of maximum 4 minutes, it will open the serial menu.

Namely:

- Internal bar hold (code S3251786): it has 4 cables with terminals at one end to be connected to

the female terminal block with 5 poles for EDOR M3; at the other end, there is a circular military

connector with 6 IP66 poles with a panel and relative cover (for wall-mounting).

It also includes a closing cap and a seal for panel mounting.

EDOR USER MANUAL Page 23 of 53 V 3.9 of 20/06/2013

To preserve the IP66 isolation, a circular military 6 poles connector with its cover is used.

- External cable to PC (cod.S3251785): The connection of this connector with its counterpart, gives

the “wakeup” input to the Edor: the unit recognizes this event and, after a period of maximum four

minutes, it will open the serial menu.

EDOR USER MANUAL Page 24 of 53 V 3.9 of 20/06/2013

3. MAINTENANCE

3.1. Basic model calibration (manual operator calibration)

Calibration has the purpose to increase the accuracy of the device using a sample gas cylinder. This

procedure is described below:

1. make sure the dip switches are positioned as follows: Dip 1 OFF – Dip 2 OFF – Dip 3 ON – Dip 4

OFF;

2. connect the sample cylinder (use factory CPL cylinders only) with a stream set to 40L/h (like the

gas stream blowing under a domestic burner head) to the connector of the manual valve

(positioned next to the measurement solenoid valve connector) then open the manual valve;

3. press button 1 to start the calibration procedure;

4. wait for the DL3 LED to stop blinking signalling that the settling phase is complete;

5. when both the DL3 and DL4 LEDs are blinking simultaneously, open the calibration valve by

turning the upper knob. Gas will be heard leaking from the upper side of the head;

6. when both the DL3 and DL2 LEDs stop blinking, close the manual valve and disconnect the sample

cylinder.

The procedure ends with the sending of a calibration report via SMS (signalled by the blinking DL5 LED)

and all LEDs are switched off.

3.2. Calibration with the Sampling System

In this configuration the procedure is automatic and periodical (when programmed automatically, based

on the desired settings, it is performed as the first activity of the day during the months of May and

September included) or as the first activity of the afternoon - after 11 am - during all the other months).

However, if necessary, calibration may be performed through the external control unit by following the

procedure below:

1. make sure the dip switches are positioned as follows: Dip 1 OFF – Dip 2 OFF – Dip 3 ON – Dip 4

OFF;

2. connect the sample cylinder (use factory CPL cylinders only) with a stream set to 40L/h (like the

gas stream blowing under a domestic burner head) to the connector of solenoid valve No. 2,

positioned next to the measurement solenoid valve connector;

3. press button 1 to start the calibration procedure.

The procedure is totally automatic. The blinking DL3 LED indicates the stable wait zero phase, while the

successive blinking of both the DL3 and DL2 LEDs indicates that the valve is opened and the actual

calibration is initiated.

The sample cylinder is equipped with a pressure switch to prevent calibrations when the cylinder is empty

that would void the procedure and compromise the sensor’s efficacy.

The procedure ends with the sending of a calibration report via SMS (signalled by the blinking DL5 LED)

and all LEDs are switched off.

IMPORTANT: the concentration of odorant of the sample cylinder must be the same as the one

configured. In case of doubts, check the system and/or repeat the configurations.

EDOR USER MANUAL Page 25 of 53 V 3.9 of 20/06/2013

3.3. Dip-switches, LEDs and Edor buttons

Dip-switch

ON OFF

1 Slave, always active Slave in low power mode

2 Agg. Fw in local mode Agg. Fw in remote mote

3 Calibration mode Measurement mode

4 Debug serial active Minimum battery consumption

Note: to avoid compromising the battery’s lifespan, after each intervention, set the dip

switches as follows: Dip 1 OFF – Dip 2 OFF – Dip 3 OFF – Dip 4 OFF

Buttons

Dip 3 OFF

Dip 4 OFF

Dip 3 ON

Dip 4 OFF

Dip 3 OFF

Dip 4 ON

Dip 3 ON

Dip 4 ON

1

Measurement +

sms

on the GAS network

Calibration + sms Debug menu

Call for firmware

update or remote

console

2

Measurement+ sms

on Gas sample

cylinder

Calibration + sms Debug menu

Call for firmware

update or remote

console

Led Diodes

Description

DL1 Edor initial test + stable zero wait in sample gas cylinder measurement

DL2 PT100 initial test + zero wait along gas network

DL3 GSM initial test + solenoid valve opening

DL4 - reserved -

DL5 GSM modem activity

Service search = one flicker every 1 second;

Service found = one flicker every 3 seconds;

Data connection = constant light.

EDOR USER MANUAL Page 26 of 53 V 3.9 of 20/06/2013

4. USER GUIDE

4.1. Quick application guide

For basic Edor programming via SMS, i.e. to set the ID and the telephone numbers of the centre and the

on-call technician, refer to paragraph 2.4 “Quick programming and start-up”.

4.2. Communication type

Edor always communicates via SMS, both for outgoing calls (remote-reading, alarms, reports) and for

incoming calls (programming and remote controls). Typically, communication occurs between the Centre

and Edor, with the only exception for the alarm Sms messages that are sent by the device to the on-call

technician.

However, since sms messages are text messages, it is possible to use a normal cell phone as a Centre to

receive data from Edor and to send the settings, even if the messages are formatted to optimize

communication with the machine and not for an operator.

The following table presents a summary of SMS types:

Type Function I/O Recipient Content

A Daily measurement OUT Centre Dispatched: AUTOMATICALLY daily Data regarding the four measurements carried out on the last day. It is sent automatically once every day at a preset time (default: 7:00 am)

B Extemporary measurement

OUT Centre Dispatched: AUTOMATICALLY every <n> hours (optional) or UPON REQUEST Data regarding the most recent measurement carried out. It can be automatically sent after every measurement (except after the last one, which is followed by an A-type sms) or can be requested via sms (type N) or it can be commanded by an on-site operator.

C Parameters OUT Centre Dispatched: UPON REQUEST Report of Edor configuration parameters; including ID, the numbers of the centre, of the call-on operator and alarm thresholds. It is sent only if expressly requested via a command sms (N type)

D Parameters OUT Centre Dispatched: UPON REQUEST or AUTOMATICALLY (after self-calibration) Report on Edor’s configuration parameters, such as ID, cell numbers of centre, on-call operator and alarm thresholds. It is sent only if expressly requested via a command sms (N type) or, in case of the Sampling System model, it is sent automatically after the device performs a self-calibration procedure

E Events OUT Centre Dispatched: AUTOMATICALLY (after type A o type B messages, only if active) Report regarding the last 10 events performed on the equipment. Messages are sent automatically only if this functionality is enabled by the firmware, otherwise the message will never be sent.

F Totalizers OUT Centre Dispatched: AUTOMATICALLY (after type C) Report on the measurement totalisers, such as the number of measures performed by the sensor, sensor activation date and much more.

ACK Acknowledgement configuration

OUT Edor Dispatched: AUTOMATICALLY (after receiving programming sms) It indicates that Edor has received a programming sms and has processed it correctly.

EDOR USER MANUAL Page 27 of 53 V 3.9 of 20/06/2013

ALL Alarm OUT On-call operator

Dispatched: AUTOMATICALLY (after an alarm) Text sms that report the ID of the Edor device and the type of alarm detected. They are sent after each sampling if the alarm occurs twice in a row. The device recognizes the following alarms: maximum threshold exceeded and below minimal threshold.

CFG Program., Commands

IN Edor Dispatched: AS NEEDED (by the Centre to Edor) A series of programming instructions and commands that are usually sent by the Centre to the Edor unit

For the description of the communication protocol via SMS, for reading and writing parameters, request

the “Edor SMS Protocol” directly to CPL Concordia.

The ALL-type SMS is the only message sent directly to the on-call operators and signals the alarm of the

HIGH O.R. or LOW O.R. after two consecutive measurements above the high limit or below the low limit.

IMPORTANT! Programming sms should be used by quailed personnel only. The sending of

wrong commands could seriously compromise the machine’s operation and void the warranty.

4.3. Serial Console

The serial console is an Edor functionality that enables connection to any serial terminal; it is possible to

use, for instance, Hyperterminal, that is a standard accessory in Windows (it is normally accessed from

Start -> Programs -> Accessories -> Communications).

If your PC does not have a physical RS232 port, you can use a "USB-RS232" converter. The model tested

and approved by CPL, which ensures the proper functioning of the system, is the "Digitus USB 2.0 to

Serial"; different models may not work properly.

IMPORTANT! The serial console must be used by specialized staff only. The sending of wrong

commands may seriously compromise the machine’s operation and void the warranty.

To connect the device, set the PC serial

terminal to 9600 baud, parity N, 8 bit of

data, 1 stop bit (9600-N-8-1);

then proceed as follows:

1. remove the lid of the monitoring unit

and identify the DB9 connector (9 pole

board) on the PCB;

2. position the dip-switches found on the

printed circuit board as shown: Dip 3

OFF – Dip 4 ON

3. connect the Edor to the PC using a

standard serial uncrossed cable: one

end of the cable should be connected to

the RS-232 port of the computer while

the other end is connected to the DB

connecter previously identified on the

Edor;

4. check that the Edor is switched on and

correctly initiated; see para .2.6

“Diagnostics”;

5. press one of the two buttons on the PCB

next to the battery connector.

EDOR USER MANUAL Page 28 of 53 V 3.9 of 20/06/2013

Alternatively, if the kit for external RS232 interface is present (para. 2.12 “Version with external RS232

interface”), configure the serial terminal on the PC and proceed as follows:

1. Connect the female DB9 connector of the “PC interface cable” to the COM port on the PC

2. Open the cap of the military connector of the “internal bar hold”

3. Connect the “PC interface cable” to the “internal bar hold”

4. The console appears on the terminal after a time ranging between two and four minutes

Now the menu of the serial console appears in the Reception window of the serial terminal. The values in

square brackets next to some commands are the values currently saved.

i Id Edor : it sets the device’s univocal ID code;

_ SN Edor : the control unit’s serial number (reserved);

S Sensor SN: it sets the serial number of the cell installed on the unit;

W Edor Name: it sets an univocal string on the Edor. This string is displayed in the alarm messages;

d Date/time: it sets the current date and time; Edor saves this setting even when it is not used for a

period of up to 36 hours;

M Modbus address: it sets the device’s modbus address

y Settings: Edor’s advanced settings (restricted to specialized technicians only). The improper use of this

command may seriously compromise the device’s functionality;

r Reset default : with this command, the type of reset is requested. It is possible to reset configuration

parameters, calibration parameters, or both; they will be replaced by default parameters. This command

is conceived to be used only in emergency conditions and must be followed by a reprogramming

procedure of the Edor unit;

c Cell : only in the GSM versions. It sets the cell phone number of the centre (data number) or o the on-

call operator (alarm number). Entering OFF will inhibit the related calls. We recommend setting the data

number to OFF;

h Log start: this sets the date and time of the first measurement of the 4 daily measurements (7:00

am);

l Log period: this sets the minutes that elapse between one measurement and the other; the standard

setting is set to 360 minutes (6 hours);

w OR alarm thresh: this sets the high and low thresholds for the odorization rate, when these

thresholds are exceeded the device sends and alarm to the on-call operator (if the relative contact

number is set);

s Sens.calib: to access the submenu of the calibration sensor; the submenu enables different calibration

modes. This function must be used by highly specialized staff only;

b Batt.calib: to access the calibration menu of the sensor of the battery level. This function must be

used by highly specialized staff only;

t PT100 calib: to access the calibration submenu for the PT100 temperature sensor. This function must

be used by highly specialized staff only;

a Autocal: to instantly activate the self-calibration procedure; the value indicated between square

brackets indicates whether the current settings enable the command or not;

k Autoc.period: to specify how many days must elapse between one self-calibration and the next (the

Sampling System is required);

j Ref.cyl.OR. : to set the nominal O.R. setting of the sample gas cylinder used for the local self-

calibration;

f Free-run (EV0 OFF) : this activates the continuous monitoring unit of the sensors on board the Edor,

WITHOUT opening a solenoid valve (i.e. the sensor that is not in the presence of gas); the displayed

values are O.R. (pure and compensated in temperature on the THT version), the power generated by the

EDOR USER MANUAL Page 29 of 53 V 3.9 of 20/06/2013

sensor, the temperature and life of sampling battery. The monitoring continues until the user presses the

<Send> button;

g Free-run (EV0 ON) : the same as above, except that the gas sampling valve is opened;

e Free-run (EV1 ON) : the same as above, except that the Sampling System solenoid valve is opened;

m Measure: this activates the network sampling procedure on the network; the system performs a

measurement as if it were in normal operation mode;

n Measure + sms : available on GSM versions only. The same as previous point, except that the end of

the procudure is followed by measurement sms (Type B, see also para. 4.2 “Communication Type”);

N Cyl.meas+sms: the same as the previous point, but the measurement must be carried out on the

sample gas cylinder. In the models without GSM, measurement is not followed by an SMS;

p Sms di report : available only with the GSM versions. It sends a report via SMS. It is possible to

choose whether to send a configuration sms (type C) or calibration sms (type D); for further information

read para. 4.2 “Communication Type”;

q Logs : it displays the events log; then Edor’s measurement log, with related reset dates; the first log

contains 200 events, the second contains 248 measurements. Each data contained in the log is connected

to its corresponding date;

o Reset logs : it resets the events log and the measurements log;

Q Sensor&Batt.counter: it displays the counters of the sensor and battery life;

O Reset sens.counter: it resets the life counter of the installed cell;

T Reset batt.counter. : it resets the life counter of the installed battery;

v Filed GSM : available only in the GSM versions. It activates the GSM signal detection procedure

(particularly useful to exactly check the strength of the signal received by the device); in the first phase

the modem is switched on and registration is checked; then the signal is shown at regular intervals;

X Exit : it closes the serial console and returns Edor to normal operation; it is required when you need to

perform a reset of the measurement performed during the current day before disabling the serial console

(if the external RS232 interface kit is present, and no other operations should be performed, disconnect

after removing the “PC interface cable” from the “internal bar hold” and tighten the “stopper” );

Z Reset & Exit: it closes the serial console with a machine reset; all measurements are suspended until

the time of the next log (if the external RS232 interface kit is present, and no other operations should be

performed, disconnect after removing the “PC interface cable” from the “internal bar hold” and tighten the

“stopper”);

! BLoader : it resets the Edor from the Bootloader level;

C Call : available only with the GSM versions. It can programme the call to the data centre; the command

requires the entering of date, time and contact number of the data centre (it is therefore possible to

specify a different number other than the ones normally used for the remote-reading). This command is

normally used to enable communication between Edor and CPL’s technical assistance office;

D GSM Direct : available only with the GSM versions. It enables to launch a direct connection with the

GSM modem on board the device; in this way you can communicate with the modem using the normal AT

commands;

I Test EXT input : it enables to test the external wakeup input using the external RS232 interfacing

cable (para 2.12 “Version with external RS232 interface cable”);

B Stability: stability field, in bit, for the measurement period. A value that is excessively low may

produce an O.R. below the actual figures, a value which is too high may produce longer measurement

times thereby shortening battery life;

A SetOutANA : available only with models featuring analogue outlets. It enables the input in the setting

environment of the full scale “O.R.” and “Temeprature” outlets (“mg/ smc” or “°C” associated to the

minimum (4mA) and maximum (20mA) outlets) , and settings of the “Zero” and “Uno” of the outlet and

“Conformation measurement completed” (mA required for “Zero” and “Uno” levels at output) (para. 2.10

“Version with 4-20mA analogue outlets”);

EDOR USER MANUAL Page 30 of 53 V 3.9 of 20/06/2013

E TestOutANA : available only in the models with analogue outlets. It sets the three analogue ports to

the “12mA” value. When the user exits the screen, it resets the three outlets to the previous value.

There are five methods to access the remote console via GSM:

1. Dip4 ON+Dip3 ON+Button (a call is sent to the number saved in the settings)

2. Dip4 ON+Dip3 OFF+Command C from console (to set the time to call the number saved in the

settings)

3. Dip4 OFF+Dip3 OFF+Command C from console (to set the time to call the number saved in the

settings)

4. Dip4 OFF+Dip3 OFF+sms (the calling time is set together with the number to call)

5. Dip4 OFF+Dip3 OFF+riception data call (in the 230V version, the modem is kept active during the

standby status: when in this state, the Edor unit receives a data call, the console can be accessed be

entering a password (para. 4.6 “Direct GSM connection via SMS”)

By default the number is set to Cpl’s number (EdorCentral, +393351215406)

4.4. Changing the date via SMS

You can change the date of an Edor unit, with firmware releases higher than 150, by sending an SMS

having the following format;

EN<ID 8 digits>;O=<sign><number of seconds>;

example to set the time back to 1 hour: EN00020113;O=-3600;

IMPORTANT! Make sure the serial console is used by qualified staff only. Sending the wrong

commands may seriously compromise the machine’s operation and void the warranty.

4.5. Modbus table for versions with RS485 serial outlet

The RTU modbus protocol is available exclusively in the Edor version with external power supply (DC/DC),

RS485 without modem.

This functionality enables to read, via local serial mode, the values of the last O.R. measured and the

current configurations, besides changing the main operation parameters and request for measurements

and/or calibrations. This reading function is also used to have the diagnostics and the temperature of the

latest measurements performed, in addition to the gain value of the cell (indication of the life of the

sesnor).

Edor is a modbus slave device, i.e. it is always attending a query, the maximum frequency of queries is

10 per seconds.

The implemented functions are:

Reading of multiple logs: modbus 0x03 function

Writing of multiple logs: modbus 0x10 function

EDOR USER MANUAL Page 31 of 53 V 3.9 of 20/06/2013

With the 0x03 function you can read, through a single query, all the data regarding the latest

measurements and the current configurations. The 0x03 function enables a maximum number of 125

registries (more than actually needed) with a single query.

With the 0x10 function, you can reconfigure the equipment and request for extemporary measurements

and/or calibrations with one single query.

To change only one parameter, in the writing case, it is necessary to set all the registries not interested in

the NULL value (0xFFFF) and the parameter you wish to change to a valid value.

Note

Electricity and/or gas calibration parameters are available exclusively from the local serial menu. In fact,

calibration cannot be made without the presence of an operator because additional tools are required.

Modbus table

REG. R/W VALUE N.BYTE TYPE NOTE EXAMPLE

0000 R Next measurement 4 U.long Number of seconds from 01/01/01 0:00:00 12242154

0002 R Next calibration 4 U.long Number of seconds from 01/01/01 0:00:00 12242154

0004 R Current Date/Time 4 U.long Number of seconds from 01/01/01 0:00:00 12242154

0006 R Measured O.R. (current) 2 U.s.int O.R. with sol. valve opened + 100 (e.g.: 137 = 37) 137

0007 R Zero measurement 2 U.s.int O.R. with sol. valve closed + 100 (e.g.: 99 = -1) 101

0008 R Diagnostics measurement 2 U.s.int To be decoded bit by bit 0x0000

0009 R Temperature measurement 2 U.s.int Temperature °C +100 (es: 125=25°C) 125

0010 R Date/Time measurement 4 U.long Number of seconds from 01/01/01 0:00:00 12242154

0012 R Measured O.R. (current-1) 2 U.s.int O.R. with sol. valve opened + 100 (e.g.: 137 = 37) 137

0013 R Zero measurement 2 U.s.int O.R. with sol. valve closed + 100 (e.g.: 99 = -1) 101

0014 R Diagnostics measurement 2 U.s.int To be decoded bit by bit 0x0000

0015 R Temperature measurement 2 U.s.int Temperature °C +100 (e.g.: 125=25°C) 125

0016 R Date/Time measurement 4 U.long Number of seconds from 01/01/01 0:00:00 12242154

0018 R Measured O.R. (current-2) 2 U.s.int O.R. with sol. valve opened+ 100 (e.g.: 137 = 37) 137

0019 R Zero measurement 2 U.s.int O.R. with sol. valve closed+ 100 (e.g.: 99 = -1) 101

0020 R Diagnostics measurement 2 U.s.int To be decoded bit by bit 0x0000

0021 R Temperature measurement 2 U.s.int Temperature °C +100 (e.g.: 125=25°C) 125

0022 R Date/Time measurement 4 U.long Number of seconds from 01/01/01 0:00:00 12242154

0024 R Measured O.R. (current-3) 2 U.s.int O.R. with sol. valve opened+ 100 (e.g.: 137 = 37) 137

0025 R Zero measurement 2 U.s.int O.R. with sol. valve closed+ 100 (e.g.: 99 = -1) 101

0026 R Diagnostics measurement 2 U.s.int To be decoded bit by bit 0x0000

0027 R Temperature measurement 2 U.s.int Temperature °C +100 (e.g.: 125=25°C) 125

0028 R Date/Time measurement 4 U.long Number of seconds from 01/01/01 0:00:00 12242154

0030 R Measured O.R. (current-4) 2 U.s.int O.R. with sol. valve opened+ 100 (e.g.: 137 = 37) 137

0031 R Zero measurement 2 U.s.int O.R. with sol. valve closed+ 100 (e.g.: 99 = -1) 101

0032 R Diagnostics measurement 2 U.s.int To be decoded bit by bit 0x0000

0033 R Temperature measurement 2 U.s.int Temperature °C +100 (e.g.: 125=25°C) 125

0034 R Date/Time measurement 4 U.long Number of second from 01/01/01 0:00:00 12242154

0036 R Measured O.R. (current-5) 2 U.s.int O.R. with sol. valve opened+ 100 (e.g.: 137 = 37) 137

EDOR USER MANUAL Page 32 of 53 V 3.9 of 20/06/2013

0037 R Zero measurement 2 U.s.int O.R. with sol. valve closed+ 100 (e.g.: 99 = -1) 101

0038 R Diagnostics measurement 2 U.s.int To be decoded bit by bit 0x0000

0039 R Temperature measurement 2 U.s.int Temperature °C +100 (e.g.: 125=25°C) 125

0040 R Date/Time measurement 4 U.long Number of second from 01/01/01 0:00:00 12242154

0042 R Measured O.R. (current-6) 2 U.s.int O.R. with sol. valve opened+ 100 (e.g.: 137 = 37) 137

0043 R Zero measurement 2 U.s.int O.R. with sol. valve closed+ 100 (e.g.: 99 = -1) 101

0044 R Diagnostics measurement 2 U.s.int To be decoded bit by bit 0x0000

0045 R Temperature measurement 2 U.s.int Temperature °C +100 (e.g.: 125=25°C) 125

0046 R Date/Time measurement 4 U.long Number of second from 01/01/01 0:00:00 12242154

0048 R Measured O.R. (current-7) 2 U.s.int O.R. with sol. valve opened+ 100 (e.g.: 137 = 37) 137

0049 R Zero measurement 2 U.s.int O.R. with sol. valve closed+ 100 (e.g.: 99 = -1) 101

0050 R Diagnostics measurement 2 U.s.int To be decoded bit by bit 0x0000

0051 R Temperature measurement 2 U.s.int Temperature °C +100 (e.g.: 125=25°C) 125

0052 R Date/Time measurement 4 U.long Number of second from 01/01/01 0:00:00 12242154

0054 R Measured O.R. (current-8) 2 U.s.int O.R. with sol. valve opened+ 100 (e.g.: 137 = 37) 137

0055 R Zero measurement 2 U.s.int O.R. with sol. valve closed+ 100 (e.g.: 99 = -1) 101

0056 R Diagnostics measurement 2 U.s.int To be decoded bit by bit 0x0000

0057 R Temperature measurement 2 U.s.int Temperature °C +100 (e.g.: 125=25°C) 125

0058 R Date/Time measurement 4 U.long Number of second from 01/01/01 0:00:00 12242154

0060 R Measured O.R. (current-9) 2 U.s.int O.R. with sol. valve opened+ 100 (e.g.: 137 = 37) 137

0061 R Zero measurement 2 U.s.int O.R. with sol. valve closed+ 100 (e.g.: 99 = -1) 101

0062 R Diagnostics measurement 2 U.s.int To be decoded bit by bit 0x0000

0063 R Temperature measurement 2 U.s.int Temperature °C +100 (e.g.: 125=25°C) 125

0064 R Date/Time measurement 4 U.long Number of second from 01/01/01 0:00:00 12242154

0066 R/W ID Edor 4 U.long Edor ID code 00020051

0068 R/W Edor ID length 2 U.s.int Length of Edor ID code 3

0069 R/W gsm centre code prefix 4 U.long Prefix of gsm centre (with country code),

the + is added automatically

39335

0071 R/W Prefix length 2 U.s.int Length of gsm prefix code 5

0072 R/W Gsm centre number 4 U.long Gsm centre number 0342215

0074 R/W Number length 2 U.s.int Length of gsm number 7

0075 R/W Gsm on-call operator prefix 4 U.long Gsm on-call prefix code (with country code), the +

symbol is added by the Edor

39335

0077 R/W Prefix code length 2 U.s.int Length of gsm on-call prefix code 5

0078 R/W Gsm centre number 4 U.long Gsm centre number 0342215

0080 R/W Number length 2 U.s.int Length of gsm centre number 7

0081 R/W Settings 2 U.long Edor settings 0x0020

0082 R/W Time log start 2 U.s.int Time of log start 7

0083 R/W Minutes log start 2 U.s.int Minutes of log start 30

0084 R/W Log period 2 U.s.int Minutes elapsed between two measurements 360

0085 R/W Low O.R. alarm threshold 2 U.s.int O.R. below which an alarm is sent to the on-call

operator

20

0086 R/W High O.R. alarm threshold 2 U.s.int O.R. above which an alarm is sent to the on-call

operator

80

0087 R/W Gs sensor sensitivity 2 U.s.int Gs multiplied by 10 110

0088 R/W Go factory sensitivity 2 U.s.int Go multiplied by10 131

0089 R/W Calibration period 2 U.s.int Days elapsed between two calibrations 21

0090 R/W Drain period 2 U.s.int Minutes of drain before measurement 2

0091 R/W Cylinder concentration 2 U.s.int Mg/smc of the cylinder multiplied by 10 220

0092 R/W Perform gas measurement 2 U.s.int 0 = do not perform, 1 = perform 0

0093 R/W Perform cylinder measurement 2 U.s.int 0 = do not perform, 1 = perform 0

EDOR USER MANUAL Page 33 of 53 V 3.9 of 20/06/2013

0094 R/W Perform calibration 2 U.s.int 0 = do not perform, 1 = perform 0

0095 R/W New date/time 4 U.long Number of seconds from 01/01/01 0:00:00 12242154

To read all the parameters, send the command (assuming Edor with the 0x01 modbus address):

ADDR FUNC DATA

Start

Addr HI

DATA

Start

Addr LO

DATA

Bit#

HI

DATA

Bit#

LO

CRC

HI

CRC

LO

0x01 0x03 0x00 0x00 0x00 0x60 0x45 0xE2

To set the “Log Period” parameter to 15, perform a multiple writing starting from log No. 66 and writing

30 logs (where only the parameter to change is different than oxFFFF); send the packet:

ADD FUN DATA

Start

Addr

HI

DATA

Start

Addr

LO

DATA

Word#

HI

DATA

Word#

LO

DATA

byte

count

DATA

Word

HI

DATA

Word

LO

DATA

Word

HI

DATA

Word

LO

DATA

Word

HI

DATA

Word

LO

DATA

Word

HI

DATA

Word

LO

DATA

Word

HI

DATA

Word

LO

CRC

HI

CRC

LO

0x01 0x10 0x00 0x42 0x00 0x1E 0x3C 0xFF 0xFF ... ... 0x00 0x0F ... ... 0xFF 0xFF ... ...

Example on how to read all the logs with the modbus packet (Edor address: 10)

0x0A 0x03 0x00 0x00 0x00 0x5C 0x44 0x88

4.6. Direct GSM connection via SMS

Because the system is battery-powered, it is necessary to enable Edor to send a call via SMS, indicating

the telephone number to use and the “appointment” hour. The Edor unit receives the SMS sent the day

after, immediately before the measurement that occurs at the time of the “Log Start” (by default this time

is set to 7:00 am) and will configure itself for the call.

The SMS to be sent has the following format: EN<ID 8 digits>;C=yyyymmddhhnnss;<cell phone

number>;

example: EN00112233;C=20070329121000;+393355710485;

this message tells Edor to call 335 5710485 at 12:10:00 on 29 March 2007.

After receiving the message, the Edor unit will send a confirmation SMS to the centre. Once it has

checked that the message is received, you must wait for the Edor call.

Log number 83

EDOR USER MANUAL Page 34 of 53 V 3.9 of 20/06/2013

After receiving the call (and therefore after seeing the RING on hyperterminal/terminal), send the ATA

command (send). After the CONNECT 9600 string, Edor waits for the BOOT command (for firmware

updates with hyperterminl) or MENU (for the remote console with the terminal).

To send the SMS, press AT+CMGS=<number> followed by enter; the ‘>’ character appears, then digit the

message text (or use the macro) and press CTRL+Z.

In Edor 230V you will not need to send an SMS. This version, in fact, is equipped with a modem that is

active even when Edor is in standby mode (it is switched off only during measurements and free-runs).

You can therefore send a data call directly to Edor using “ATDT <Edor number>” from your own modem.

The reception of the ‘PW?’ string means that the connection with Edor has been completed successfully.

Digit the password (not followed by “ENTER”) to access the menu, or to update the firmware with

hyperterminal as required.

4.7. Edor events codes

The following codes are displayed with the “q” button on the serial console.

Code Description

1 Reset event

2 Reading from primary flash card failed (the crc calculated on the RAM after reading does not match the one in the flash)

3 Reading from secondary flash card failed (the crc calculated on the RAM after reading does not match the one in the flash)

4 Writing on primary flash card failed at HW level (the crc calculated on the RAM after writing does not match the one in the flash)

5 Writing on primary flash card failed at HW level (the crc calculated on the RAM after writing does not match the one in the flash)

6 Writing on primary flash card failed (the crc calculated on the RAM before the writing does not match the one in the flash or the one calculated in the flash card)

7 Reading from secondary flash card failed (the crc calculated on the RAM before the writing does not match the one in the flash or the one calculated in the flash card)

9 Failed configuration reading from flash card in EnosInit

10 RAM reading error

11 Error on default RAM data integrity

12 User-set data integrity error

13 SMS could not be sent for powerup error

14 Date inconsistency error

15 Measurement start event notification

16 Measurement end event notification

17 SMS reception process start notification

18 Valid SMS reception notification

19 Non-valid SMS reception notification

20 Zero stable waiting timeout elapsed

22 Stable measurement waiting timeout elapsed

24 Consecutive measurements performed during a time below 20 minutes

26 Zero overflow

28 Zero negative

30 Spontaneous self-calibration for empty sample cylinder (pressure switch)

EDOR USER MANUAL Page 35 of 53 V 3.9 of 20/06/2013

31 Extemporary self-calibration via SMS failed due to empty sample cylinder (pressure switch)

32 Gso during non-defined calibration

34 New Gs during calibration out-of -range, then the zero and the new sensitivity are immediately logged

36 Zero during calibration out-of -range, then the zero and new sensitive are immediately logged

38 pt100 out-of -range, temp. too low

40 pt100 out-of -range, temp. too high

42 Battery out-of -range

44 Error in registration start modem before fw upgrade call

46 SMS dispatch failed

47 Elimination of SMS from modem failed

48 SMS dispatch in carbon copy to CPL failed

49 Failed call for number received through wrong SMS

50 Damaged measure log index

51 Damaged event log index (ERR_LOG_INDEX_MEASURE+1)

52 Last calibration event performed with success, then the zero and the new sensitivity is logged

54 Calibration process start event

55 SMS-launched calibration process start event

56 Calibration process end event

57 Aborted SMS-launched calibration due to settings

58 Configuration event saved

59 Self-calibration start event, dte >= dteNextAutoCalib

100 100-131 GSM field, remove the 100 value to obtain it

131 Last position valid for GSM field

150 SMS dispatch failed, one of the following is always logged based on type

151 Data (daily) - type A

152 Data (sample) - type B

153 Configuration report - type C

154 Calibration report - type D

155 Alarm (received by the on-call operator, cell phone 2)

156 Alarm (received by the on-call operator, cell phone 2)

160 Attempt to send a SMS to CPL, always followed by EVN_GSM_SEND_OK or ERR_GSM_...

161 Data (daily) - type A

162 Data(sample) - type B

163 Configuration report - type C

164 Calibration report - type D

165 Alarm (received by the on-call operator, cell phone 2)

166 Alarm (received by the on-call operator, cell phone 2)

170 SMS dispatch FAILED one of the following is always logged based on type

171 Data (daily) - type A

172 Data (sample) - type B

173 Configuration report - type C

174 Calibration report - type D

175 Alarm (received by the on-call operator, cell phone 2)

176 Alarm (received by the on-call operator, cell phone 2)

180 SMS message was NOT sent to CPL, always followed by EVN_GSM_SEND_OK o ERR_GSM_...

181 Data (daily) - type A

182 Data (sample) - type B

EDOR USER MANUAL Page 36 of 53 V 3.9 of 20/06/2013

183 Configuration report - type C

184 Calibration report - type D

185 Alarm (received by the on-call operator, cell phone 2)

186 Alarm (received by the on-call operator, cell phone 2)

190 Error at GSM start, it is used as a base for the next starts

191 “sysstart” not received at modem start-up

192 Failed reply on AT button in GSM powerup

193 SIM not registered

200 The maximum allowed characters saved in the RAM was reached

201 The gap between the current date/time and the date/time of the SMS received is longer than 20 minutes

202 Communication with blocked RTC, RTC_Init failed

249 Free stack below 4 byte

250 Notification that the last measurement of the day event was re-attempted (=send daily SMS) due to a failure on check_sms

251 Notification that SMS cancellation event was completed successfully

252

Notification of event to signal that the Augusto modem was detected (notifications of this event with a date in the following format “01/01/2000 00:00:02” are normal if localised immediately before the “01” event (reset system)

255 Notification of access into console for external interface connection

EDOR USER MANUAL Page 37 of 53 V 3.9 of 20/06/2013

5. EDOR CENTRAL

5.1. Functionality