Understanding the dynamics of riser design in · PDF fileUnderstanding the dynamics of riser...

Transcript of Understanding the dynamics of riser design in · PDF fileUnderstanding the dynamics of riser...

Page 1 of 15

Understanding the dynamics of riser design in skyscrapers

How gravity, volume and thermodynamics play a role in smart riser design

By Marty Rogin, PE; Engineering Manager, Metraflex

Metraflex Technical Papers

www.Metraflex.com

Page 2 of 15

Figure 1: Riser prior to heating

www.Metraflex.com

Themodernskyscraperhasbeenaroundforoveracentury.Likeotherelementsofourbuiltenvironment,theskyscrapercanonlyexistbecauseofotherinnovationsinbuildingtechnology,namelysteelframeconstructionandsafeelevators.Eventhoughwehavefiguredouthowtobuildstrong,tallstructuresandsafelymovethepeopleinside,therearestillthechallengesofheatingandcoolingthebuilding,movingfreshwaterinanddirtywaterout,providingfireprotectionandelectricity.Defyinggravityaddsanothertwisttothechallengesofprovidingserviceswithintallbuildings.Thisarticlewillintroducesomebasicsofpiperiserdesignandperformance,explainsomeconsiderationsinusingdifferentexpansionjointsinpiperisers,andbrieflydescribesomeofthecodesandstandardsregardingguidingandsupportingrisers.

ThermalExpansionBasics

Whilethepipeisnothingspecial,gravitywillmakethingswaymoreinteresting.Considertheriserpipe(Figure1).Thepiperunstheentireheightofthebuilding,50stories.Iftheslab-to-slabheightis10feet,ourpipeis500feettall.Atypicalsupportforthispipemaybeariserclamp,maybeoneveryotherfloor.Withnotemperaturechange,theriserweightisdistributedevenlybetweenalltheriserclamps.

Figure1: RiserPriorto Heating

Page 3 of 15

Figure2:RiserAfterHeating

Let’sheatthewaterinthepipe(Figure2).Nowthepipewillexpandagainstthesupportingriserclamps.Buttheriserclampsareonlyrestrictedtomoveinonedirection–down.Therearenorestrictionstoupwardmovement.Theclampswilljustmoveupwiththepipe.Anyclampabovethebottomfloorwillnowbefloatingabovetheslab.Alltheweightofthepipe,insulationandmediaisonthebottomclamp.Mostpipeclampsarenotdesignedtosupportthefullweightofatallriser.Therearesolutions.Apipeanchoratthebottomoftheriser,designedtosupportthefullriserweight,willsolvethisproblem.Butlet’slookathowmuchthepipemoves.Let’ssayourpipeismadeofsteelandtheliquidmediumishotwaterat180°F.Likegravity,thermalexpansion(thermalstrain)ofsteelwillnotdisappearinariser.Ifweassumeanambienttemperatureof50°F,thepipewillwanttoexpand

accordingtotheequation:∆𝐿𝐿 =∝ 𝐿𝐿!∆𝑇𝑇∆𝐿𝐿 =Lengthchange(inches)∝ =Coefficientofthermalexpansion(forsteel,6.33x10-6inch/inch/°F)𝐿𝐿! =Startinglength(6000inches)∆𝑇𝑇 =Temperaturechange(180°-50°=130°F)∆𝐿𝐿 =4.9inchesTheverytopoftheriserwillmove4.9inchesup.Isthisaproblem?Itcouldbe.Canthetakeoffsattheupperlevelsmoveabout5incheswithoutbreaking?Maybe,ifthereisenoughrunoutlengthtotheequipmentconnections.Willthefieldconditionsallowthepipetomovethismuchbeforecollidingwithstructureorequipment?Maybe,butthen,whocananswerthesequestionspriortoconstruction?Usuallytheycan’tbeanswereduntilthestructureisupandthepipefittersinstallthepipesattheceilingwithalltheunplannedbendsandmodifiedrunoutlengths.

Figure2:RiserAfterHeating

Let’sheatthewaterinthepipe(Figure2).Nowthepipewillexpandagainstthesupportingriserclamps.Buttheriserclampsareonlyrestrictedtomoveinonedirection–down.Therearenorestrictionstoupwardmovement.Theclampswilljustmoveupwiththepipe.Anyclampabovethebottomfloorwillnowbefloatingabovetheslab.Alltheweightofthepipe,insulationandmediaisonthebottomclamp.Mostpipeclampsarenotdesignedtosupportthefullweightofatallriser.Therearesolutions.Apipeanchoratthebottomoftheriser,designedtosupportthefullriserweight,willsolvethisproblem.Butlet’slookathowmuchthepipemoves.Let’ssayourpipeismadeofsteelandtheliquidmediumishotwaterat180°F.Likegravity,thermalexpansion(thermalstrain)ofsteelwillnotdisappearinariser.Ifweassumeanambienttemperatureof50°F,thepipewillwanttoexpand

accordingtotheequation:∆𝐿𝐿 =∝ 𝐿𝐿!∆𝑇𝑇∆𝐿𝐿 =Lengthchange(inches)∝ =Coefficientofthermalexpansion(forsteel,6.33x10-6inch/inch/°F)𝐿𝐿! =Startinglength(6000inches)∆𝑇𝑇 =Temperaturechange(180°-50°=130°F)∆𝐿𝐿 =4.9inchesTheverytopoftheriserwillmove4.9inchesup.Isthisaproblem?Itcouldbe.Canthetakeoffsattheupperlevelsmoveabout5incheswithoutbreaking?Maybe,ifthereisenoughrunoutlengthtotheequipmentconnections.Willthefieldconditionsallowthepipetomovethismuchbeforecollidingwithstructureorequipment?Maybe,butthen,whocananswerthesequestionspriortoconstruction?Usuallytheycan’tbeanswereduntilthestructureisupandthepipefittersinstallthepipesattheceilingwithalltheunplannedbendsandmodifiedrunoutlengths.

Figure 2: Riser after heating

www.Metraflex.com

Page 4 of 15

One solutionmay be tomove the anchor tothe center of the riser (Figure3). The anchor is a hardconnection from thepipeto the structure anda point of zeromovement.The riser isnow dividedintotwosections, each250feet.Nowthemaximumpipemovementwillbehalfoftheentireriser,or2.45inches. The previous questions may be asked regarding 2.45inches of movement. If they can beansweredduring the designstage of a project, great! Ontothe next project!

Butwait.Whataboutthoseriserclamps?Abovetheanchortheywillrideonthepipe,risingabovethefloors.Butbelowtheanchor,theriserclampswilltrytorestrainthepipefrommovingdownward.Thelikelyoutcomewillbethattheclampswillslipalongthepipeasitmoves.Iftheriserclampsareweldedtothepipe,somethingwillbreak–eithertheclamporthepipe.Hopefullytheclamp,butthentheanchorwillbecarryingtheloadoftheentireriser.

Figure3: Riser WithCenter Anchor

Onesolutionmaybetomovetheanchortothecenteroftheriser(Figure3).Theanchorisahardconnectionfromthepipetothestructureandapointofzeromovement.Theriserisnowdividedintotwosections,each250feet.Nowthemaximumpipemovementwillbehalfoftheentireriser,or2.45inches.Thepreviousquestionsmaybeaskedregarding2.45inchesofmovement.Iftheycanbeansweredduringthedesignstageofaproject,great!Ontothenextproject!

Butwait.What about those riser clamps? Above the anchor theywillride onthe pipe, rising abovethefloors. But below theanchor, theriser clamps will try to restrain thepipefrom movingdownward. Thelikely outcomewill bethat theclamps will slipalong the pipe as it moves. If the riser clamps are weldedtothe pipe, something will break – either theclamp or thepipe. Hopefully theclamp, but then theanchorwillbecarryingtheloadoftheentireriser.

Figure3: Riser WithCenter AnchorFigure 3: Riser with center anchor

www.Metraflex.com

Page 5 of 15

Figure 4: Tank with 1-foot water column

Figure 5: Tank with 27.7” water column

Water Density = 62.4 lb/cu. ft.

Volume = 12.215 cu. in. (7.1 cu. ft.)

Weight of water = 441 lb.

Pressure at tank bottom - 441 lb/1018 sq. in. = 0.433 psi

12”

Tank bottom - 3 ft

Diameter - 7.1 sq. ft.

Area - 1018 sq. in.

3’

Water Density = 62.4 lb/cu. ft.

Volume = 28.199 cu. in. (16.3 cu. ft.)

Weight of water = 1018 lb.

Pressure at tank bottom - 1018 lb/1018 sq. in. = 1 psi

27.7”

Tank bottom - 3 ft

Diameter - 7.1 sq. ft.

Area - 1018 sq. in.

3’

www.Metraflex.com

RiserSpringSupports

Andwhataboutspringsupports?Thesearespecially-designedsystemsofanchors,guidesandsupportsforrisersthataredesignedtomovewiththepipe.Thespringsupportsstayincontactwiththefloorslabasthepipemoves.Asthepipemoves,thespringsstretchorcompresstoexertmoreforceonthefloorslab,whichtakesloadoffthemainanchorinthecenteroftheriser.Thesesystemsareeffectivefortakingtheloadoffthemainanchor;however,thistypeofsystemhaslimitations.Theseare:

• Thepipestillmoves!Nothingwillpreventthis.Ifweuseour500footriserasanexample,theanchorwouldbeinthecenter,andtheendswouldmovethesame2.45inches.

• Onlyoneanchorispermittedineachriser.Asecondanchorwillrestrictthepipemovement,resultingintremendousforcesintheanchorsandfloorslabswhileaddingpotentiallyhugestressesinthepipe.

• Itisunclearifthistypeofsystemcanbeadaptedtocopperrisers.Theavailablemanufacturers’literaturedoesnotspecificallymentioncopperasanacceptablepipematerialforthesesupportsystems.

Arisersystemusingpiperiserclampsorspringsupportswillhavelimitedcontrolonthepipemovement.Expansionjointsallowforbettercontrolofthepipemovement.Beforelookingatexpansionjoints,let’sconsiderwhathappenstotheinternalpressureofariser.

PressureandtheHeightofaWaterColumn

Theinternalpressurealongahorizontalpipeaxisgenerallyvariesasmallamount.Oncethatpipeistippeduptovertical,afluid-filledriserbuildspressureasthepipegetstaller.Thepressureatthebottomcanbesignificantlyhigherthanatthetop.Thisisduetotheweightofthewater.

Consideratankwith1footofwater(Figure4).Nomatterhowfull,thetankwillexperiencemoreforceonitswallstowardsthebottom.Themostforcewillbeatthebottomofthetank.Eachaddedinchofwaterinthetankincreasestheweightthatthebottomofthetankmusthold.Whentheheightofthewaterreaches27.7inches,thereis1poundoneachsquareinchofthebottomofthetank(Figure5).

Figure4: Tank with1 Foot Water Column

Figure5: Tankwith27.7" Water Column

Page 6 of 15

Now, let’s change the shape of the tank tosomething narrower (Figure 6). Aswemovethetankwallscloser, weneed less water to fill thetank to 27.7”, but the tank bottom has a smaller area. The force oneach squareinch is still 1pound.

Figure6: Smaller-Diameter Tank, 27.7" Water ColumnItdoesn’tmatterwhatshapewemakethetank,orevenifit’sapipe;ifthewatercolumnis27.7”tall,thepressureatthebottomis1psi.

Ifwestackthese27.7”watercolumns,thepressureatthebottombuildsin1psiincrements(Figure7).

Figure7: Stacked 27.7" (1psi) Water Columns

Now,let’schangetheshapeofthetanktosomethingnarrower(Figure6).Aswemovethetankwallscloser,weneedlesswatertofillthetankto27.7”,butthetankbottomhasasmallerarea.Theforceoneachsquareinchisstill1pound.

Figure6: Smaller-Diameter Tank, 27.7" Water Column

Itdoesn’t matterwhatshapewemakethetank, or even if it’s apipe; ifthewatercolumnis27.7”tall,the pressure at the bottom is 1 psi.

Ifwestackthese27.7”watercolumns,thepressureatthebottom builds in1 psi increments (Figure 7).

Figure7: Stacked 27.7" (1psi) Water Columns

Figure 6: Smaller-diameter tank, 27.7” water column

Water Density = 62.4 lb/cu. ft.

Volume = 3130 cu. in. (1.8 cu. ft.)

Weight of water = 113 lb.

Pressure at tank bottom - 113 lb/113 sq. in. = 1 psi

27.7” 27.7”

27.7”

27.7”

27.7”

27.7”

Tank bottom - 1 ft

Diameter - 0.8 sq. ft.

Area - 113 sq in.

1’

1 PSI in the middle 2 PSI

1 PSI

3 PSI at the bottom2 PSI at the bottom

Figure 7: Stacked 27.7” (1 psi) water columns

Water Density = 62.4 lb/cu. ft.

Volume = 3130 cu. in. (1.8 cu. ft.)

Weight of water = 113 lb.

Pressure at tank bottom - 113 lb/113 sq. in.= 1 psi

27.7” 27.7”

27.7”

27.7”

27.7”

27.7”

Tank bottom - 1 ft

Diameter - 0.8 sq. ft.

Area - 113 sq in.

1’

1 PSI in the middle 2 PSI

1 PSI

3 PSI at the bottom2 PSI at the bottom

www.Metraflex.com

Page 7 of 15

The pressure at the bottom of the stack increases by 1 psi for each27.7” section. Conversely, thepressure increases by 0.43 psi for each12” sectionof water. Using this logic, the pressure at the bottomof our 500 foot riser thatisonly due tothe height of the column of water will be:

𝑝𝑝𝑝𝑝𝑝𝑝𝑝𝑝𝑝𝑝𝑝𝑝𝑝𝑝𝑝𝑝 = 500 𝑓𝑓𝑓𝑓. 𝑥𝑥 0.43 𝑝𝑝𝑝𝑝𝑝𝑝 𝑓𝑓𝑓𝑓= 215 𝑝𝑝𝑝𝑝𝑝𝑝

This is referredtoas hydrostatic pressure, andit is why hydronic equipment is seldom locatedinthebasement of a tall building. This is alsowhy very tall buildings have risers that are subdivided betweenintermediatemechanical equipment rooms. For steam, gas and air, column height is not an issueduetothe muchlower density of these substances.

Riser Structural Stability Considerations

Columnbuckling is a familiar failure mode. If a long, slender bar is subjected to axial forces at each end,it will bow out (Figure8). This is a functionof the material strength, cross sectiondimensions andlengthof the bar. Apipe behaves like this too. Axial forces appliedtothe pipe ends will also makeit bow out.This canbe especially pronouncedonsmall-diameter copper pipe.

Although most of this bowingis elastic, meaningthepipegoes back to its original shapeafter theloadsare removed, this canbe a problem if the pipe bows beyondthe elastic limit of the material. Columnbuckling canalsobe a problem withbellows expansionjoints. If thetwo ends of abellows arenotwithinthe offsetmovement limits, theexpansion joint will bepermanently damaged.

Figure8: ColumnBuckling of a Double-PinnedBar (or Pipe)

Thepipemustremainalignedasittravelsthroughthebuilding.Thisisthepurposeofpipeguides,whichrestrictthepipetomoveonlyintheaxialdirectionandessentiallymakethepipemorerigid.Guidesdividethepipeintoshorter,stiffersections.

Thespacingofpipeguidesisdictatedbytheclassicalcolumnbucklingequations,calledtheEulerbucklingequations.Ifweassumethepipeispinnedoneitherend,theequationlookslikethis:

𝑃𝑃!" =𝜋𝜋!𝐸𝐸𝐸𝐸𝑙𝑙!

(𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸 1)𝑃𝑃!" = 𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚 𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐 𝑙𝑙𝑙𝑙𝑙𝑙𝑙𝑙 𝑙𝑙𝑙𝑙 𝑡𝑡𝑡𝑡 𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖 𝑏𝑏𝑏𝑏𝑏𝑏𝑏𝑏𝑏𝑏𝑏𝑏𝑏𝑏𝑏𝑏

𝐸𝐸 = 𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚 𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒 𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚 𝑝𝑝𝑝𝑝𝑝𝑝 𝐼𝐼 = 𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐 𝑠𝑠𝑠𝑠𝑠𝑠𝑠𝑠𝑠𝑠𝑠𝑠𝑠𝑠 𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚 𝑜𝑜𝑜𝑜 𝑖𝑖𝑖𝑖𝑖𝑖𝑟𝑟𝑟𝑟𝑟𝑟𝑟𝑟 (𝑖𝑖𝑖𝑖!)

𝑙𝑙 = 𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐 𝑙𝑙𝑙𝑙𝑙𝑙𝑙𝑙𝑙𝑙ℎ (𝑖𝑖𝑖𝑖)

Thisisthetheoreticalloadlimitforacolumnwiththeendsfreetorotateandloadsappliedalongthecolumnaxis.Noticethattheweightofthepipeandwaterarenotconsideredhere.Eulerbucklingisanimportantconsiderationwhenbellowsexpansionjointsarechosenforapipingsystem,especiallyrisersastheforcesarenowactingalongthepipe’slongitudinalaxis.

Thepressureatthebottomofthestackincreasesby1psiforeach27.7”section.Conversely,thepressureincreasesby0.43psiforeach12”sectionofwater.Usingthislogic,thepressureatthebottomofour500footriserthatisonlyduetotheheightofthecolumnofwaterwillbe:

𝑝𝑝𝑝𝑝𝑝𝑝𝑝𝑝𝑝𝑝𝑝𝑝𝑝𝑝𝑝𝑝 = 500 𝑓𝑓𝑓𝑓. 𝑥𝑥 0.43 𝑝𝑝𝑝𝑝𝑝𝑝 𝑓𝑓𝑓𝑓= 215 𝑝𝑝𝑝𝑝𝑝𝑝

Thisisreferredtoashydrostaticpressure,anditiswhyhydronicequipmentisseldomlocatedinthebasementofatallbuilding.Thisisalsowhyverytallbuildingshaverisersthataresubdividedbetweenintermediatemechanicalequipmentrooms.Forsteam,gasandair,columnheightisnotanissueduetothemuchlowerdensityofthesesubstances.

RiserStructuralStabilityConsiderations

Columnbucklingisafamiliarfailuremode.Ifalong,slenderbarissubjectedtoaxialforcesateachend,itwillbowout(Figure8).Thisisafunctionofthematerialstrength,crosssectiondimensionsandlengthofthebar.Apipebehaveslikethistoo.Axialforcesappliedtothepipeendswillalsomakeitbowout.Thiscanbeespeciallypronouncedonsmall-diametercopperpipe.

Althoughmostofthisbowingiselastic,meaningthepipegoesbacktoitsoriginalshapeaftertheloadsareremoved,thiscanbeaproblemifthepipebowsbeyondtheelasticlimitofthematerial.Columnbucklingcanalsobeaproblemwithbellowsexpansionjoints.Ifthetwoendsofabellowsarenotwithintheoffsetmovementlimits,theexpansionjointwillbepermanentlydamaged.

Figure8: ColumnBuckling of a Double-PinnedBar (or Pipe)

The pipe must remainalignedas it travels throughthe building. This is the purpose of pipe guides,whichrestrict the pipe tomove only in the axial directionandessentially make the pipe more rigid.Guides divide thepipeinto shorter, stiffer sections.

The spacing of pipe guides is dictatedby the classical columnbuckling equations, calledthe Eulerbuckling equations. If we assume the pipe is pinnedoneither end, the equation lookslike this:

𝑃𝑃!" =𝜋𝜋!𝐸𝐸𝐸𝐸𝑙𝑙!

(𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸 1)𝑃𝑃!" = 𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚 𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐 𝑙𝑙𝑙𝑙𝑙𝑙𝑙𝑙 𝑙𝑙𝑙𝑙 𝑡𝑡𝑡𝑡 𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖 𝑏𝑏𝑏𝑏𝑏𝑏𝑏𝑏𝑏𝑏𝑏𝑏𝑏𝑏𝑏𝑏

𝐸𝐸 = 𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚 𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒 𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚 𝑝𝑝𝑝𝑝𝑝𝑝𝐼𝐼 = 𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐 𝑠𝑠𝑠𝑠𝑠𝑠𝑠𝑠𝑠𝑠𝑠𝑠𝑠𝑠 𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚 𝑜𝑜𝑜𝑜 𝑖𝑖𝑖𝑖𝑖𝑖𝑟𝑟𝑟𝑟𝑟𝑟𝑟𝑟 (𝑖𝑖𝑖𝑖!)

𝑙𝑙 = 𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐 𝑙𝑙𝑙𝑙𝑙𝑙𝑙𝑙𝑙𝑙ℎ (𝑖𝑖𝑖𝑖)

Thisisthetheoreticalloadlimitforacolumnwiththeendsfreetorotateandloadsappliedalongthecolumn axis. Noticethat theweight of thepipeand water arenot considered here. Euler bucklingis animportant consideration when bellows expansion joints arechosen for apipingsystem, especially risersas the forces are now acting along the pipe’s longitudinal axis.

Figure 8: Column buckling of a double-pinned bar (or pipe)

Force

Force

www.Metraflex.com

Page 8 of 15

Ifthepipeisfixedatoneend (Figure9) thecriticalloadis:

𝑃𝑃!" =𝜋𝜋!𝐸𝐸𝐸𝐸4𝑙𝑙!

(𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸 2)

Figure9: ColumnBuckling of a Fixed-PinnedBar (or Pipe)

Whathappenswhenthepipeisturneduponitsend?Gravity.Theweightofthepipeandmediainsidethepipewillnowfigureintothecalculations.Ariserpipecantheoreticallycollapseunderitsownweight(Figure10).Thecriticalloadonaverticalpipewiththeendfixedis:

(𝑞𝑞𝑞𝑞)!" =7.837𝐸𝐸𝐸𝐸

𝑙𝑙! (𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸 3)

(𝑞𝑞𝑞𝑞)!" = 𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚 𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐 𝑙𝑙𝑙𝑙𝑙𝑙𝑙𝑙 𝑙𝑙𝑙𝑙 𝑡𝑡𝑡𝑡 𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖 𝑏𝑏𝑏𝑏𝑏𝑏𝑏𝑏𝑏𝑏𝑏𝑏𝑏𝑏𝑏𝑏

Figure10: Buckling of a Vertical FixedSupport Column(or Pipe) Under its Weight

Ifthepipeisfixedatoneend(Figure9)thecriticalloadis:

𝑃𝑃!" =𝜋𝜋!𝐸𝐸𝐸𝐸 4𝑙𝑙!

(𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸 2)

Figure9: ColumnBuckling of a Fixed-PinnedBar (or Pipe)

What happens whenthe pipe is turneduponits end? Gravity. The weight of the pipe andmedia insidethe pipe will now figure intothe calculations. Ariserpipecantheoretically collapseunder its ownweight (Figure 10). The critical load on avertical pipewith theend fixed is:

(𝑞𝑞𝑞𝑞)!" =7.837𝐸𝐸𝐸𝐸

𝑙𝑙!(𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸 3)

(𝑞𝑞𝑞𝑞)!" = 𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚 𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐 𝑙𝑙𝑙𝑙𝑙𝑙𝑙𝑙 𝑙𝑙𝑙𝑙 𝑡𝑡𝑡𝑡 𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖 𝑏𝑏𝑏𝑏𝑏𝑏𝑏𝑏𝑏𝑏𝑏𝑏𝑏𝑏𝑏𝑏

Figure10: Buckling of a Vertical FixedSupport Column(or Pipe) Under its Weight

Figure 9: Column buckling of a fixed-pinned bar (or pipe)

Force

Force

Figure 10: Buckling of a vertical fixed support column (or pipe) under its weight

q (Weight/Unit Length)

www.Metraflex.com

Page 9 of 15

www.Metraflex.com

Usingthe4”pipeasanexampleandsolvingforthelengthwith(ql)crequalto1.34lb/in,themaximumlengthavertical4”sch.40canbeisabout90feetbeforebecomingunstable.Forcomparison,a4”typeKcopperriserwillbecomeunstableatabout64feet.This is also the equation that determines the maximum height of a tree (neglecting the branches and assuming a prismatic trunk).

Next,considerariserhavinganexternalforcelikeabellowspressurethrustandspringforce. Ariserpipeunderanexternalloadsubjecttotheweightofthepipewallandmediainsidewillhaveacriticalloadof:

𝑃𝑃!" =𝜋𝜋!𝐸𝐸𝐸𝐸4𝑙𝑙!

− 0.3𝑞𝑞𝑞𝑞 (𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸 4)

𝑃𝑃!" = 𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚 𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐 𝑙𝑙𝑙𝑙𝑙𝑙𝑙𝑙 𝑙𝑙𝑙𝑙 𝑡𝑡𝑡𝑡 𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖 𝑏𝑏𝑏𝑏𝑏𝑏𝑏𝑏𝑏𝑏𝑏𝑏𝑏𝑏𝑏𝑏𝐸𝐸 = 𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚 𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒 𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚 𝑝𝑝𝑝𝑝𝑝𝑝

𝐼𝐼 = 𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐 𝑠𝑠𝑠𝑠𝑠𝑠𝑠𝑠𝑠𝑠𝑠𝑠𝑠𝑠 𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚 𝑜𝑜𝑓𝑓 𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖 (𝑖𝑖𝑖𝑖!)𝑙𝑙 = 𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐 𝑙𝑙𝑙𝑙𝑙𝑙𝑙𝑙𝑙𝑙ℎ (𝑖𝑖𝑖𝑖)

𝑞𝑞 = 𝑤𝑤𝑤𝑤𝑤𝑤𝑤𝑤ℎ𝑡𝑡 𝑝𝑝𝑝𝑝𝑝𝑝 𝑖𝑖𝑖𝑖𝑖𝑖ℎ 𝑜𝑜𝑜𝑜 𝑝𝑝𝑝𝑝𝑝𝑝𝑝𝑝, 𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖 𝑎𝑎𝑎𝑎𝑎𝑎 𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐 𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖 (𝑙𝑙𝑙𝑙/𝑖𝑖𝑖𝑖)

Thisequationassumestheendofthepipeisfixedandcan’trotate,thepipehasaconstantcrosssection(samesizeallthewayup)andthattheweightisequallydistributed.Thecriticalloadisreducedby30%ofthecolumnweight.Notethatthecriticalloadcanbenegative,meaningthatthetopendsupportmustbeintensiontopreventbuckling.

Thepreviousexamplesalongwiththehydrostaticpressureexplanationareimportantforguidespacinginriserswithdifferenttypesofexpansionjoints.Let’sfirstconsiderabellowsexpansionjointinatallriser.Howwouldwedeterminethepipeguidespacingforthistypeofinstallation?

WhatarePipeGuides?

Pipeguidesaredevicesthatallowthepipetomoveaxially,whilerestrictingthepipefrommovingperpendiculartothepipeaxis.Byrestrictingthepipetoonlyaxialmotion,thepipeismorerigidandwillnotbowoutorcollapse.Astheguidesareplacedcloseralongthepipe,theamountofaxialloadingcanincreasebeforethepipebecomesunstable.

CommonguidesusedforHVACandplumbingsystemsareeitherfinnedorsliding.Finnedguides,or“spider”guides,havefinsfixedtothepipeandtravelthrougharingsecuredtothebuildingstructure.Theseguidesaretypicallyfoundonsmall-diameterpipeandareusedforareaswherethelateralloadsareexpectedtoberelativelysmallcomparedtothepipeanchorloads.Inhorizontalapplicationstheseguidesarenotintendedtotaketheplaceofhangers,soaclevisorrollersupportwouldberequiredinthevicinityoftheguidetoholdtheweightofthepipe.

Amorerobustguidethatcanalsofunctionasasupportistheslidingguide.Thisdevicehasaslidingbarweldedtothepipe,withabasesecuredtostructure.ThebasehaseitherTeflon,graphiteoranelastomericpadtoreducefriction.Thistypeofguidecanhandlegreaterlateralloadsandistypicallyusedonlarger-diameterHVACpipeorprocesspiping.Aversionoftheslidingguideadaptedtorisersincorporatesanelastomercushionbetweentheslideandbasetodampennoiseandvibrationofthepipeslidingagainsttheslabpenetration.

Page 10 of 15

www.Metraflex.com

Themostcompactguideconfigurationconsistsofanelastomericsealassemblywithintheslabpenetrationtoguidethepipe.Thesetakeupnofloorspaceintheriserchaseandallowforthemostefficientspaceusage.

SpiderGuide SlideGuide

SlidingRiserGuidewithNoise-DampeningElastomer

ModularRiserGuideinSlabPenetration

Figure11:GuidesCommonlyusedinRisers

StandardsforGuidePlacementwithBellowsExpansionJoints

AccordingtotheExpansionJointManufacturer’sAssociation(EJMA)standards,guidesarerequiredwithbellowsexpansionjointsatamaximumdistanceoffourpipediametersfromthejoint,thenamaximum14pipediametersfromthefirstguideforthenextlocation.SubsequentguidesarespacedatintervalsdictatedbytheEulerbucklingequationforahalfpinned-column.WhenguidesareplacedaccordingtoEJMAguidelines,thepipeissubdividedintorigidsectionsthatshouldn’t(theoretically)buckleunderaknownendload.

Page 11 of 15

Guides withbellows expansionjoints serve twopurposes; tokeepthe pipes from buckling, andkeepthebellows from squirming (Figure12). The EJMAstandards assume a horizontal pipe, andthe bucklingformulaused divides thecalculatedlengthinhalf. For comparison, the 4” steel pipe with abellowsexpansion joint under 158 psi requires an intermediateguidespacing of 30feet. The pipe is assumedtobe horizontal, sothe weight of the pipe andmedia are not consideredinthe EJMAcalculations.

Typical model codes require risers tobe supportedroughly at every floor. This is usually accomplishedwithriser clamps. As describedpreviously, the riser clamps may move upwardandlose contact withthefloor slab, dependingon theanchor placement. Now the support is not doing its job, andall the loadiscarried by theanchor. In this case, thecodes werefollowed but theanchors may not be designedforthe entire weight of the pipe, insulationandits contents – plus any forces generatedby the expansionjoints.

Figure12: Bellows Squirm Due toMisalignedPipe

Bellows ExpansionJoints ina Riser

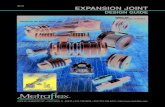

Bellows expansionjoints inrisers are very common, mostly due totheir compact shape (Figures 13&14).Theytakeupverylittlespaceperpendicular tothe pipe axis, sothey fitnicely in crowded pipechases; however, they do needtobe guided. The bellows will produce large anchor loads. This may beanecessary tradeoff, as spacein pipechases can beat apremium.

www.Metraflex.com

Figure 12: Bellows squirm due to misaligned pipe

Guideswithbellowsexpansionjointsservetwopurposes;tokeepthepipesfrombuckling,andkeepthebellowsfromsquirming(Figure12).TheEJMAstandardsassumeahorizontalpipe,andthebucklingformulauseddividesthecalculatedlengthinhalf.Forcomparison,the4”steelpipewithabellowsexpansionjointunder158psirequiresanintermediateguidespacingof30feet.Thepipeisassumedtobehorizontal,sotheweightofthepipeandmediaarenotconsideredintheEJMAcalculations.Typicalmodelcodesrequireriserstobesupportedroughlyateveryfloor.Thisisusuallyaccomplishedwithriserclamps.Asdescribedpreviously,theriserclampsmaymoveupwardandlosecontactwiththefloorslab,dependingontheanchorplacement.Nowthesupportisnotdoingitsjob,andalltheloadiscarriedbytheanchor.Inthiscase,thecodeswerefollowedbuttheanchorsmaynotbedesignedfortheentireweightofthepipe,insulationanditscontents–plusanyforcesgeneratedbytheexpansionjoints.

Figure12: Bellows Squirm Due toMisalignedPipe

Bellows ExpansionJoints ina Riser

Bellows expansionjoints inrisers are very common, mostly due totheir compact shape (Figures 13&14).Theytakeupverylittlespaceperpendicular tothe pipe axis, sothey fitnicely in crowded pipechases; however, they do needtobe guided. The bellows will produce large anchor loads. This may beanecessary tradeoff, as spacein pipechases can beat apremium.

Figure13: Externally-PressurizedCompensator

(Bellows areinsidehousing)Figure14: Internally-PressurizedBellows

Pipes inthe vertical are now subject tohydrostatic pressure variations. These variations are simple tocalculate, and will vary from thesystem operating pressure at the topof the riser tothe height dividedby 2.31 addedtothe system pressure atthe bottom ofthe riser. Usingthe500’riserasanexamplewithasystempressureof50psi,therisertopwillbeat50psiandthebottomwill beat267psi.Thisdifference inpressure is critical incalculating the anchor loads for a bellows expansionjoint.

Abellowsexpansionjointinstallednearthebottomofatallrisermustberatedforthepressureatthislocation. In theprevious example, a 150 psi expansionjoint wouldbe fine for the topsectionof theriser, but a joint near the bottom wouldrequire a higher pressure rating.

Andwhat about the anchor loads? Bellows expansionjoints createreaction forces based on twocharacteristicsofthebellows;thespringrateandtheeffectivearea.Thespringrateissimplytheamount of force requiredtocompress or extendthe bellows one inch. If a bellows has a 500 lb/inchspring rate, it will exert 500 pounds oneachanchor for every inch of movement. If thebellows iscompressed 1.5 inches, thespringforcewill be750 lb. on each anchor.

Pressure thrust may not be quite as straightforward. Anexpansionjoint is the most flexible part of thepipingsystem.Ithastobethisway. Abellows under pressure wants tostretchback toits originalshape,whichisatube.Ifleftunrestrained,abellows under pressure will extendpast its ratedmovement. This is why control rods andanchors are generally requiredfor a bellows expansionjoint.The amount of force exertedby the bellows oneither the anchors or the control rods is alsosimple tocalculate. It is thepressuremultiplied by thebellows effectivearea.

Andwhatexactlyisabellowseffectivearea?Itis the inside area of the bellows, calculatedattheaverageof thelargest andsmallest convolution diameters. Thisisalsocalledthemeandiameter. Allbellows manufacturers provide the effective areas, soit is not necessary for the specifier tocalculatethis.

Ifweuse our500’riseras anexample,abellows expansion joint at thevery top of theriser with asystem operating pressure of 50 psi anda 4” pipe (with a 4” expansionjoint) will have a pressure thrustoneachanchor of:

Figure 13: Externally-pressurized compensator (Bellows are inside housing

Figure 14: Internally-pressurized bellows

Guides withbellows expansionjoints serve twopurposes; tokeepthe pipes from buckling, andkeepthebellows from squirming (Figure12). The EJMAstandards assume a horizontal pipe, andthe bucklingformulaused divides thecalculatedlengthinhalf. For comparison, the 4” steel pipe with abellowsexpansion joint under 158 psi requires an intermediateguidespacing of 30feet. The pipe is assumedtobe horizontal, sothe weight of the pipe andmedia are not consideredinthe EJMAcalculations.

Typical model codes require risers tobe supportedroughly at every floor. This is usually accomplishedwithriser clamps. As describedpreviously, the riser clamps may move upwardandlose contact withthefloor slab, dependingon theanchor placement. Now the support is not doing its job, andall the loadiscarried by theanchor. In this case, thecodes werefollowed but theanchors may not be designedforthe entire weight of the pipe, insulationandits contents – plus any forces generatedby the expansionjoints.

Figure12: Bellows Squirm Due toMisalignedPipe

BellowsExpansionJointsina Riser

Bellowsexpansionjointsinrisersareverycommon,mostlyduetotheircompactshape(Figures13&14).Theytakeupverylittlespaceperpendiculartothepipeaxis,sotheyfitnicelyincrowdedpipechases;however,theydoneedtobeguided.Thebellowswillproducelargeanchorloads.Thismaybeanecessarytradeoff,asspaceinpipechasescanbeatapremium.

Page 12 of 15

Figure13:Externally-PressurizedCompensator

(Bellowsareinsidehousing)Figure14:Internally-PressurizedBellows

Pipesintheverticalarenowsubjecttohydrostaticpressurevariations.Thesevariationsaresimpletocalculate,andwillvaryfromthesystemoperatingpressureatthetopoftherisertotheheightdividedby2.31addedtothesystempressureatthebottomoftheriser.Usingthe500’riserasanexamplewithasystempressureof50psi,therisertopwillbeat50psiandthebottomwillbeat267psi.Thisdifferenceinpressureiscriticalincalculatingtheanchorloadsforabellowsexpansionjoint.Abellowsexpansionjointinstallednearthebottomofatallrisermustberatedforthepressureatthislocation.Inthepreviousexample,a150psiexpansionjointwouldbefineforthetopsectionoftheriser,butajointnearthebottomwouldrequireahigherpressurerating.Andwhatabouttheanchorloads?Bellowsexpansionjointscreatereactionforcesbasedontwocharacteristicsofthebellows;thespringrateandtheeffectivearea.Thespringrateissimplytheamountofforcerequiredtocompressorextendthebellowsoneinch.Ifabellowshasa500lb/inchspringrate,itwillexert500poundsoneachanchorforeveryinchofmovement.Ifthebellowsiscompressed1.5inches,thespringforcewillbe750lb.oneachanchor.Pressurethrustmaynotbequiteasstraightforward.Anexpansionjointisthemostflexiblepartofthepipingsystem.Ithastobethisway.Abellowsunderpressurewantstostretchbacktoitsoriginalshape,whichisatube.Ifleftunrestrained,abellowsunderpressurewillextendpastitsratedmovement.Thisiswhycontrolrodsandanchorsaregenerallyrequiredforabellowsexpansionjoint.Theamountofforceexertedbythebellowsoneithertheanchorsorthecontrolrodsisalsosimpletocalculate.Itisthepressuremultipliedbythebellowseffectivearea.Andwhatexactlyisabellowseffectivearea?Itistheinsideareaofthebellows,calculatedattheaverageofthelargestandsmallestconvolutiondiameters.Thisisalsocalledthemeandiameter.Allbellowsmanufacturersprovidetheeffectiveareas,soitisnotnecessaryforthespecifiertocalculatethis.Ifweuseour500’riserasanexample,abellowsexpansionjointattheverytopoftheriserwithasystemoperatingpressureof50psianda4”pipe(witha4”expansionjoint)willhaveapressurethrustoneachanchorof:

www.Metraflex.com

𝑇𝑇ℎ𝑟𝑟𝑟𝑟𝑟𝑟𝑟𝑟 𝑓𝑓𝑓𝑓𝑓𝑓𝑓𝑓𝑓𝑓 = 𝑃𝑃𝐴𝐴!

𝑃𝑃 = 𝑂𝑂𝑂𝑂𝑂𝑂𝑂𝑂𝑂𝑂𝑂𝑂𝑂𝑂𝑂𝑂𝑂𝑂 𝑃𝑃𝑃𝑃𝑃𝑃𝑃𝑃𝑃𝑃𝑃𝑃𝑃𝑃𝑃𝑃 (𝑝𝑝𝑝𝑝𝑝𝑝)𝐴𝐴! = 𝐵𝐵𝐵𝐵𝐵𝐵𝐵𝐵𝐵𝐵𝐵𝐵𝐵𝐵 𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸 𝐴𝐴𝐴𝐴𝐴𝐴𝐴𝐴 (𝑠𝑠𝑠𝑠. 𝑖𝑖𝑖𝑖. )

𝐴𝐴! = 36 𝑠𝑠𝑠𝑠. 𝑖𝑖𝑖𝑖. (𝑓𝑓𝑓𝑓𝑓𝑓𝑓𝑓 𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚)

𝑃𝑃 = 50 𝑝𝑝𝑝𝑝𝑝𝑝𝑇𝑇ℎ𝑟𝑟𝑟𝑟𝑟𝑟𝑟𝑟 𝐹𝐹𝐹𝐹𝐹𝐹𝐹𝐹𝐹𝐹 = 36 𝑠𝑠𝑠𝑠. 𝑖𝑖𝑖𝑖. 𝑥𝑥 50 𝑝𝑝𝑝𝑝𝑝𝑝

= 1800 𝑙𝑙𝑙𝑙Ifwedecidetosplittheriserandlocateanexpansionjointatthemidpoint,thepressureusedtocalculatethrustforcewillbe50psiaddedtotheheightofthewatercolumnabovetheexpansionjoint(about250feet):

𝑃𝑃 = 50 𝑝𝑝𝑝𝑝𝑝𝑝 + 250𝑓𝑓𝑓𝑓 𝑥𝑥 0.43 𝑝𝑝𝑝𝑝𝑝𝑝/𝑓𝑓𝑓𝑓𝑃𝑃 = 158 𝑝𝑝𝑝𝑝𝑝𝑝

𝑇𝑇ℎ𝑟𝑟𝑟𝑟𝑟𝑟𝑟𝑟 𝐹𝐹𝐹𝐹𝐹𝐹𝐹𝐹𝐹𝐹 = 36 𝑠𝑠𝑠𝑠. 𝑖𝑖𝑖𝑖. 𝑥𝑥 158 𝑝𝑝𝑝𝑝𝑝𝑝= 5688 𝑙𝑙𝑙𝑙

Nowlet’saddinthespringforce.Theriserwillmove2.45inchesbetweeneachsetofanchors.Ifthespringrateofthebellowsis200lb/in:

𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆 𝐹𝐹𝐹𝐹𝐹𝐹𝐹𝐹𝐹𝐹 = 𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆 𝑅𝑅𝑅𝑅𝑅𝑅𝑅𝑅 𝑥𝑥 𝑀𝑀𝑀𝑀𝑀𝑀𝑀𝑀𝑀𝑀𝑀𝑀𝑀𝑀𝑀𝑀

𝑆𝑆𝑝𝑝𝑝𝑝𝑝𝑝𝑝𝑝𝑝𝑝 𝐹𝐹𝐹𝐹𝐹𝐹𝐹𝐹𝐹𝐹 = 200𝑙𝑙𝑙𝑙𝑖𝑖𝑖𝑖𝑥𝑥 2.45 𝑖𝑖𝑖𝑖

𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆 𝐹𝐹𝐹𝐹𝐹𝐹𝐹𝐹𝐹𝐹 = 490 𝑙𝑙𝑙𝑙Frictionfromthepipesupportsmaybeassumedtobeverysmallforariser,andwillnotbefactoredintothesecalculations.Thetotalbellowsforceontheanchorswillbe:

𝑇𝑇𝑇𝑇𝑇𝑇 𝐴𝐴𝐴𝐴𝐴𝐴ℎ𝑜𝑜𝑜𝑜: 1800 𝑙𝑙𝑙𝑙 + 490 𝑙𝑙𝑙𝑙 = 2290 𝑙𝑙𝑙𝑙

𝐵𝐵𝐵𝐵𝐵𝐵𝐵𝐵𝐵𝐵𝐵𝐵 𝐴𝐴𝐴𝐴𝐴𝐴ℎ𝑜𝑜𝑜𝑜: 5688 𝑙𝑙𝑙𝑙 + 490 𝑙𝑙𝑙𝑙 = 6178 𝑙𝑙𝑙𝑙Whatabouttheweightofthepipe,waterandinsulation?Thismustbeaddedtothebellowsanchorloadstogetthecompletepicture.Andthelowerbellowsforcesactupwardsonthemiddleriseranchor,whiletheupperbellowsforcesactdownontheanchor.Itisimportanttonotonlykeeptrackofthemagnitude,butalsothedirectionoftheforcesactingonananchor.Additionally,theanchoriscarryingtheweightofthepipeandwaterfromabove.Theintermediateanchorloadingismorecomplicatediftheexpansionjointiscenteredbetweentheanchors.Wenowhaveasituationsimilartothecriticalloadingforariserunderitsownweightwithanexternalforce.Ifwelookatourcriticalloadequation(4)withpipeweight,

𝑃𝑃!" =𝜋𝜋!𝐸𝐸𝐸𝐸4𝑙𝑙!

− 0.3𝑞𝑞𝑞𝑞andsolveforthelengthusing𝑃𝑃!" =6178lb,theguideswouldrequirespacingat23footintervals,ormaybeeveryotherstory.

Page 13 of 15

www.Metraflex.com

𝑇𝑇ℎ𝑟𝑟𝑟𝑟𝑟𝑟𝑟𝑟 𝑓𝑓𝑓𝑓𝑓𝑓𝑓𝑓𝑓𝑓 = 𝑃𝑃𝐴𝐴!𝑃𝑃 = 𝑂𝑂𝑂𝑂𝑂𝑂𝑂𝑂𝑂𝑂𝑂𝑂𝑂𝑂𝑂𝑂𝑂𝑂 𝑃𝑃𝑃𝑃𝑃𝑃𝑃𝑃𝑃𝑃𝑃𝑃𝑃𝑃𝑃𝑃 (𝑝𝑝𝑝𝑝𝑝𝑝)

𝐴𝐴! = 𝐵𝐵𝐵𝐵𝐵𝐵𝐵𝐵𝐵𝐵𝐵𝐵𝐵𝐵 𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸 𝐴𝐴𝐴𝐴𝐴𝐴𝐴𝐴 (𝑠𝑠𝑠𝑠. 𝑖𝑖𝑖𝑖. )

𝐴𝐴! = 36 𝑠𝑠𝑠𝑠. 𝑖𝑖𝑖𝑖. (𝑓𝑓𝑓𝑓𝑓𝑓𝑓𝑓 𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚)𝑃𝑃 = 50 𝑝𝑝𝑝𝑝𝑝𝑝

𝑇𝑇ℎ𝑟𝑟𝑟𝑟𝑟𝑟𝑟𝑟 𝐹𝐹𝐹𝐹𝐹𝐹𝐹𝐹𝐹𝐹 = 36 𝑠𝑠𝑠𝑠. 𝑖𝑖𝑖𝑖. 𝑥𝑥 50 𝑝𝑝𝑝𝑝𝑝𝑝= 1800 𝑙𝑙𝑙𝑙

Ifwedecidetosplittheriser andlocateanexpansionjoint at the midpoint, the pressure usedtocalculatethrust forcewill be50 psi addedtothe height of the water columnabove the expansionjoint(about 250 feet):

𝑃𝑃 = 50 𝑝𝑝𝑝𝑝𝑝𝑝 + 250𝑓𝑓𝑓𝑓 𝑥𝑥 0.43 𝑝𝑝𝑝𝑝𝑝𝑝/𝑓𝑓𝑓𝑓𝑃𝑃 = 158 𝑝𝑝𝑝𝑝𝑝𝑝

𝑇𝑇ℎ𝑟𝑟𝑟𝑟𝑟𝑟𝑟𝑟 𝐹𝐹𝐹𝐹𝐹𝐹𝐹𝐹𝐹𝐹 = 36 𝑠𝑠𝑠𝑠. 𝑖𝑖𝑖𝑖. 𝑥𝑥 158 𝑝𝑝𝑝𝑝𝑝𝑝= 5688 𝑙𝑙𝑙𝑙

Nowlet’saddinthespringforce.Theriserwillmove2.45inchesbetweeneachsetofanchors.Ifthespringrateofthebellowsis200lb/in:

𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆 𝐹𝐹𝐹𝐹𝐹𝐹𝐹𝐹𝐹𝐹 = 𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆 𝑅𝑅𝑅𝑅𝑅𝑅𝑅𝑅 𝑥𝑥 𝑀𝑀𝑀𝑀𝑀𝑀𝑀𝑀𝑀𝑀𝑀𝑀𝑀𝑀𝑀𝑀

𝑆𝑆𝑝𝑝𝑝𝑝𝑝𝑝𝑝𝑝𝑝𝑝 𝐹𝐹𝐹𝐹𝐹𝐹𝐹𝐹𝐹𝐹 = 200𝑙𝑙𝑙𝑙𝑖𝑖𝑖𝑖𝑥𝑥 2.45 𝑖𝑖𝑖𝑖

𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆 𝐹𝐹𝐹𝐹𝐹𝐹𝐹𝐹𝐹𝐹 = 490 𝑙𝑙𝑙𝑙

Frictionfromthepipesupportsmaybeassumedtobeverysmallforariser,andwillnotbefactoredintothesecalculations.Thetotalbellowsforceontheanchorswillbe:

𝑇𝑇𝑇𝑇𝑇𝑇 𝐴𝐴𝐴𝐴𝐴𝐴ℎ𝑜𝑜𝑜𝑜: 1800 𝑙𝑙𝑙𝑙 + 490 𝑙𝑙𝑙𝑙 = 2290 𝑙𝑙𝑙𝑙

𝐵𝐵𝐵𝐵𝐵𝐵𝐵𝐵𝐵𝐵𝐵𝐵 𝐴𝐴𝐴𝐴𝐴𝐴ℎ𝑜𝑜𝑜𝑜: 5688 𝑙𝑙𝑙𝑙 + 490 𝑙𝑙𝑙𝑙 = 6178 𝑙𝑙𝑙𝑙

Whatabouttheweightofthepipe,waterandinsulation?Thismustbeaddedtothebellowsanchorloadstogetthecompletepicture.Andthelowerbellowsforcesactupwardsonthemiddleriseranchor,whiletheupperbellowsforcesactdownontheanchor.Itisimportanttonotonlykeeptrackofthemagnitude,butalsothedirectionoftheforcesactingonananchor.Additionally,theanchoriscarryingtheweightofthepipeandwaterfromabove.Theintermediateanchorloadingismorecomplicatediftheexpansionjointiscenteredbetweentheanchors.

Wenowhaveasituationsimilartothecriticalloadingforariserunderitsownweightwithanexternalforce.Ifwelookatourcriticalloadequation(4)withpipeweight,

𝑃𝑃!" =𝜋𝜋!𝐸𝐸𝐸𝐸4𝑙𝑙!

− 0.3𝑞𝑞𝑞𝑞

andsolveforthelengthusing𝑃𝑃!" =6178lb,theguideswouldrequirespacingat23footintervals,ormaybeeveryotherstory.

Ifacopperriserisinstalled,moreguideswouldberequired.Thebellowsforceswouldberoughlyequal,aswouldthehydrostaticpressures.Ifthebottomhalfoftheriserisonceagainconsidered,theonlydifferencewillbethematerialandcross-sectionpropertiesofthecopperpipe.Forour4”riser,thecoppermaterialandsectionpropertiesare:

𝐸𝐸 = 17,000,000 𝑝𝑝𝑝𝑝𝑝𝑝 (𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸 𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚 𝑓𝑓𝑓𝑓𝑓𝑓 𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐)𝐼𝐼 = 3.35 𝑖𝑖𝑖𝑖! (𝑇𝑇𝑇𝑇𝑇𝑇𝑇𝑇 𝐾𝐾 𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐)

Nowtherequiredguidespacingisat12.5footintervals,ormaybeateverystory.

FlexibleHoseandBraidLoopExpansionJointsinRisers

Theonlywaytoreallylimittheamountofmovementinariserisanexpansionjoint.Movementcanbelimitedtoanyacceptableamountbyanchoringtheriseratvariouslevelsandinstallinganexpansionjointbetweeneachanchorpair.

Hoseand braidexpansion joints areanother option for risers that providemany advantages overbellows expansionjoints or spring support systems. Hoseand braidexpansion joints aretypicallyconstructed of two pieces of corrugated metal hosewrapped by metal braid. Thejoint may befabricated in a‘U’ or ‘V’ shape, which provides movement in all directions. Like the other expansionjoint systems, hose andbraidexpansionjoints are life-of-building products. They require nomaintenanceor inspections onceinstalled.

Hoseand braidexpansion joints offer several advantages over bellows or springsupports:

• No pressure thrust component. Thisisdue tothe hose andbraidconfigurationandthe braidrestraining the hose from expanding.

• Hydrostatic pressureis not an issue. Hoseand braid expansion joints can bedesigned for veryhighoperating pressures incommonHVACandplumbing system pipe sizes.

• Hoseand braid sections arevery flexible. Theonly anchor forces generated by theseexpansionjoints aredueto thespringforces of thehoseand braid, which aretypically less than 100pounds for many pipe sizes. The only other loadonthe anchor will betheweight of thefullriser.

• Hoseand braid expansion joints can handleoffsets in theriser much better than bellowsexpansion joints.

Figures 15 and16 show examples of hose andbraidexpansionjoints commonly used in risers.

Page 14 of 15

www.Metraflex.com

If a copper riser is installed, more guides would be required. The bellows forces would be roughly equal,as wouldthe hydrostatic pressures. If the bottom half of the riser is once againconsidered, the onlydifference will be the material andcross-sectionproperties of the copper pipe. For our 4” riser, thecopper material and section properties are:

𝐸𝐸 = 17,000,000 𝑝𝑝𝑝𝑝𝑝𝑝 (𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸 𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚 𝑓𝑓𝑓𝑓𝑓𝑓 𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐)𝐼𝐼 = 3.35 𝑖𝑖𝑖𝑖! (𝑇𝑇𝑇𝑇𝑇𝑇𝑇𝑇 𝐾𝐾 𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐)

Now the requiredguide spacing is at 12.5 footintervals, or maybe at every story.

FlexibleHose and Braid Loop ExpansionJoints inRisers

The only way to really limit theamount of movement in ariser is an expansion joint. Movement can belimited to any acceptableamount by anchoringtheriser at various levels and installingan expansionjoint between each anchor pair.Hoseandbraidexpansionjointsareanotheroptionforrisersthatprovidemanyadvantagesoverbellowsexpansionjointsorspringsupportsystems.Hoseandbraidexpansionjointsaretypicallyconstructedoftwopiecesofcorrugatedmetalhosewrappedbymetalbraid.Thejointmaybefabricatedina‘U’or‘V’shape,whichprovidesmovementinalldirections.Liketheotherexpansionjointsystems,hoseandbraidexpansionjointsarelife-of-buildingproducts.Theyrequirenomaintenanceorinspectionsonceinstalled.

Hoseandbraidexpansionjointsofferseveraladvantagesoverbellowsorspringsupports:

• Nopressurethrustcomponent.Thisisduetothehoseandbraidconfigurationandthebraid restrainingthehosefromexpanding.

• Hose and braid expansion joints can be designed for operating pressures commonly found in HVAC and plumbing system pipe sizes.

• Hoseandbraidsectionsareveryflexible.Theonlyanchorforcesgeneratedbytheseexpansion jointsareduetothespringforcesofthehoseandbraid,whicharetypicallylessthan100 poundsformanypipesizes.Theonlyotherloadontheanchorwillbetheweightofthefull riser.

• Hoseandbraidexpansionjointscanhandleoffsetsintherisermuchbetterthanbellows expansionjoints.

Figures15and16showexamplesofhoseandbraidexpansionjointscommonlyusedinrisers.

Figure 15: Loop with 180º return Figure 16: V-loopFigure15:Loopwith180°Return Figure16:V-Loop

Theonlypotentialdisadvantageofhoseandbraidisthespacerequirement.Bellowsexpansionjointsfitnicelyincrowdedpipechases,hoseandbraidsticksout.Eventhissituationcanbeaccommodatedbymountingtheloopshorizontallyinaceilingchase.

Hoseandbraidexpansionjointssubjecttheriserstosmallreactionforces,sothebottomhalfofariserbetweenanchorsmaybeconsideredafree-standinglengthofpipe,similarFigure10.Thisconfigurationwouldthenfollowavariationofequation(3)fortheportionofriserbelowtheexpansionjoint:

𝑞𝑞𝑞𝑞 =7.837𝐸𝐸𝐸𝐸

𝑙𝑙!

Theterm(q)isknown,sothelengthforcolumnstability(andguidespacing)canbedeterminedbysolvingforthelengthl.Goingbacktotheoriginalexampleofa500foot,4”sch.40pipewithahoseandbraidconnectorinthecenter,thelowerhalfwouldbesubjecttosimilarconditionsasariserof250feetwithafixedbottom.Therequiredguidespacingwouldthenbe10.6feet.FortypeKcopper,therequiredguidespacingwouldbeonly4.1feet.For the portionof pipe above the loop, one guide at the expansionjoint wouldbe adequate. Gravity isworking ina favorable directioninthis case.

Practical Considerations

How oftenareguides placed every other story, let aloneevery singlestory in ahigh rise? Almost never.Sowhy dowe not have risers collapsing onevery project? The answer may be simple; there are alreadyguidesateveryfloor,intheformof roundslabpenetrations.Theseallowaxialmovementandrestrictlateral movement. Guideplacement would becritical in an open chase, wherepipes arerouted throughone single large floor penetrationat eachlevel.

Also,mostrisershavetakeoffsorrunoutsateachfloor.Ifthesearehard-pipedtoequipment inthevicinity ofthe riser, this arrangement can provide additional lateral support tothe riser.

Referring back toour original example of 4” steel pipe, EJMAguidelines don’t cover the case of a verticalpipe withzeroloading (like hose andbraid), andfor the bellows loading in this example, recommenda

Page 15 of 15

Figure15:Loopwith180°Return Figure16:V-Loop

Theonlypotentialdisadvantageofhoseandbraidisthespacerequirement.Bellowsexpansionjointsfitnicelyincrowdedpipechases,hoseandbraidsticksout.Eventhissituationcanbeaccommodatedbymountingtheloopshorizontallyinaceilingchase.Hoseandbraidexpansionjointssubjecttheriserstosmallreactionforces,sothebottomhalfofariserbetweenanchorsmaybeconsideredafree-standinglengthofpipe,similarFigure10.Thisconfigurationwouldthenfollowavariationofequation(3)fortheportionofriserbelowtheexpansionjoint:

𝑞𝑞𝑞𝑞 =7.837𝐸𝐸𝐸𝐸

𝑙𝑙!

Theterm(q)isknown,sothelengthforcolumnstability(andguidespacing)canbedeterminedbysolvingforthelengthl.Goingbacktotheoriginalexampleofa500foot,4”sch.40pipewithahoseandbraidconnectorinthecenter,thelowerhalfwouldbesubjecttosimilarconditionsasariserof250feetwithafixedbottom.Therequiredguidespacingwouldthenbe10.6feet.FortypeKcopper,therequiredguidespacingwouldbeonly4.1feet.Fortheportionofpipeabovetheloop,oneguideattheexpansionjointwouldbeadequate.Gravityisworkinginafavorabledirectioninthiscase.PracticalConsiderationsHowoftenareguidesplacedeveryotherstory,letaloneeverysinglestoryinahighrise?Almostnever.Sowhydowenothaveriserscollapsingoneveryproject?Theanswermaybesimple;therearealreadyguidesateveryfloor,intheformofroundslabpenetrations.Theseallowaxialmovementandrestrictlateralmovement.Guideplacementwouldbecriticalinanopenchase,wherepipesareroutedthroughonesinglelargefloorpenetrationateachlevel.Also,mostrisershavetakeoffsorrunoutsateachfloor.Ifthesearehard-pipedtoequipmentinthevicinityoftheriser,thisarrangementcanprovideadditionallateralsupporttotheriser.Referringbacktoouroriginalexampleof4”steelpipe,EJMAguidelinesdon’tcoverthecaseofaverticalpipewithzeroloading(likehoseandbraid),andforthebellowsloadinginthisexample,recommenda

www.Metraflex.com

31footspacing(orabouteverythreestories).ThisauthorhasobservedexactlyzeroriserinstallationsthatcomplywithEJMAguidelinesforguidespacing,andhasyettoseeacollapsedpiperiser.“Outofsight,outofmind”mayalsobepartoftheissue.Thepipesmayverywellbebowingelastically,butnobodycanseeit.Afterall,howmanyarchitectswilldesignwindowsonpipechasewalls?Forthatmatter,howmanytenantsreallycaretoobservetheirrisers?ConclusionAlthoughstandardsandcodesaddressrisersandguidespacinginpipeswithbellowsjoints,itisimportanttoknowthelimitationsoftheequipmentandassumptionsusedtoarriveattherecommendedstandards.Perhapsit’sappropriatetotakeacloserlookatthesestandardsandadaptthemfortallrisers.Buildingutilitieshavetobedistributedtoalllevels,ortherewouldbenopointtoaskyscraper.Assuredly,aslongverticalpipesareplacedinsidetallbuildingsgravitywillalwaysactdown,andbuildingsystemdesignersshouldbeawareoftheforcesontheseelements.Thepetroleumindustryiswellawareofthedesignconsiderationsontall,flexiblerisersthroughexperiencewithoffshoredrillingrigs.Aswebuildtallerstructures,theA/E/Ccommunitymustalsobeawareofsimilar–butnotidenticalissuesforconditionsabovethesurface.

Metraflex offers delegated design assistance and technical support.

Contact your local Metraflex representative or visit us at

Metraflex.com

ReferencesSparks, C. P., Fundamentals of Marine Riser Mechanics, PennWell Corp., 2007Timoshenko, S. and Gere, J., Theory of Elastic Stability, McGraw-Hill, 1961