UNCLASSIFIED AD 406 - DTIC · Project performance and schedule 1.3.17 76 CONCLUSIONS 1.4 77 ......

Transcript of UNCLASSIFIED AD 406 - DTIC · Project performance and schedule 1.3.17 76 CONCLUSIONS 1.4 77 ......

UNCLASSIFIED

AD 406.179

DEFENSE DOCUMENTATION CENTERF')R

SCIENTIFIC AND TECHNICAL INFORMATION

CAMERON STATION. ALEXANDRIA. VIRGINIA

UNCLASS!IFIED

NOTICE: VIen govercent or other dravings, speci-fications or other data are used for any purposeother than in connection vith a definitely relatedgovernnt procurement operation, the U. S.Goverment thereby incurs no responsibility, nor anyobligation vhatsoever; and the fact that the Govern-ment my have formulated, furnished, or in any waysupplied the said drawinp, specifications, or otherdata is not to be regarded by iplication or other-wise as in any manner licensing the holder or anyother person or corporation, or conveying any rightsor permission to manufacture, use or sell anypatented invention that my in any wvay be relatedthereto.

I 4. •TIM

' I ,

O TIMES WIRE AND CA.BL.EDIVISION OF

SMANUFACTURERS OF ENGINEERED WIRE AND CABLE PRODUCTS WALLINGFORD. CONNECTICUT

May 7, 1963

I To: Chief, Bureau of ShipsMain Navy BuildingWashington, D.C.

Via: Inspector of Naval Material, Bridgeport, Connecticut

* Subject: Letter of transmittal 2nd Progress Report, Contract NoNObsr-87678, Project SerIt-l No. SF0060306, Task 2266

This report is submitted in accordance to BurShips Contract NObsr-87678.

The watertightness techniques developed in Contract NObsr-87678 andimproved in this contract have been successfully used in the manufacture

I of modified watertight versions of RG-57/U and RG-14/U for the Under-water Sound Laboratory and a special watertight 95 ohm cable for a NavyProject at the University of Denver. All cables were watertight atI 1000 psi. We presently feel we will shortly be able to offer you acable construction that will be watertight at pressures greater than2500 psi.

If any information is desired before the next reporting date, pleaselet me know.

I Sincerely,

TIMES WIRE & CABLE DIVISION

David A. PetersonI Staff Engineer

IIII

!

I UNCLASSIFIED!INTERIM DEVELOPMENT REPORT

FOR

DESIGN AND DEVELOPMENT OF IMPROVED

WATERTIGHT COAXIAL CABLE

This report covers the period ofOctober 1, 1962 to December 31, 1962

by

TIMES WIRE AND CABLE DIVISION

THE INTERNATIONAL SILVER COMPANY, INC.

358 HALL AVENUE

WALLINGFORD, CONNECTICUT

ENG. REPORT NO. 222-B

for

NAVY DEPARTMENT BUREAU OF SHIPS ELECTRONICS DIVISION

CONTRACT NO: NObsr-87678, PROJECT SERIAL NO. SF0060306, TASK 2266

JUNE 29, 1962

I UNCLASSIFIED

Copy No.: 82II

TABLE OF CONTENTS

ParafraDh Page

ABSTRACT 1

PART I

PURPOSE 1.1 2

GENERAL FACTUAL DATA 1.2 3Identification of technicians 1.2.1 3Test procedures 1.2.2 3

P1iability 1.2.2.1 3

DETAIL FACTUAL DATA 1.3 3 - 76Sample description 1.3.1 3 - 8Sample discussion 1.3.2 SAttenuation test results 1.3.3 8 - 38Discuasion of attenuation test results 1.3.4 39 - 47VSWR test results 1.3.5 48Discussion of VSWR test results 1.3.6 48Stability test results 1.3.7 48Discussion of stability test results 1.3.8 48 - 69Watertightness test results 1.3.9 70Discussion of watertightness test results 1.3.10 70Flammability test results 1.3.11 70Discussion of flammability test results 1.3.12 70 - 72Other test results 1.3.13 72Discussion of other test results 1.3.14 72 - 74Pliability test results 1.3.15 75Discussion of pliability test results 1.3.16 75j Project performance and schedule 1.3.17 76

CONCLUSIONS 1.4 77General conclusions 1.4.1 77Conclusion from attenuation test results 1.4.2 77Conclusion from watertightness test results 1.4.3 77Conclusion from abrasion resistance test results 1.4.4 77j Conclusion from pliability test results 1.4.5 77

PART II

PROGRAM FOR NEXT INTERVAL 2.1 77Phase I 2.1.1 77Phase II 2.1.2 77

"PART III

APPROVAL SHEET 79

PROGRESS REPORT DISTRIBUTION SCHEDULE 80 - 82

pI page i

I

ILIST OF FIGURESj Page

1.1 Pliability test equipment and speciman layout 3

LIST OF TABLES

'1.1 Description of sample constructions 4 - 8J 1.2 Attenuation test results 91.3 VSWR test results 491.4 Stability test results 50 - 511.5 Watertightnese test resu~ts 01.6 Flammability test results ý1 - 721 Other tFa t est results 73 - 741. Pliability test results 75

LIST OF GRAPHS

1.1 Computed and measured attenuation of sample 1 101.2 Computed and measured attenuation of sample 2 111.3 Computed and measured attenuation of sample 3 121.4 Computed and measured attenuation of sample 4 131.5 Computed and measured attenuation of sample 5 141.6 Computed and measured attenuation of sample 6 151.7 Computed and measured attenuation of sample 7 161.8 Computed and measured attenuation of sample 8 171.9 Computed and measured attenuation of sample 10 181.10 Computed and measured attenuation of sample 11 191.11 Computed and measured attenuation of sample 12 201.12 Computed and measured'attenuation of sample 13 211.13 Computed and measured attenuation of sample 15 221.14 Computed and measured attenuation of sample 17 231.15 Computed and measured attenuation of sample 18 241.16 Computed and measured attenuation of sample 20 251.17 Computed and measured attenuation of sample 21 261.18 Computed and measured attenuation of sample 22 271.19 Computed and measured attenuation of sample 23 281.20 Computed and measured attenuation of sample 24 291.21 Computed and measured attenuation of sample 25 301.22 Computed and measured attenuation of sample 26 311.23 Computed and measured attenuation of sample 27 321.24 Computed and measured attenuation of sample 28 331.25 Computed and measured attenuation of sample 29 341.26 Computed and measured attenuation of sample 30 351.27 Computed and measured attenuation of sample 31 361.28 Computed and measured attenuation of sample 32 371.29 Computed and measured attenuation of sample 33 381.30 Measured attenuation of samples 1, 21 and 30 401.31 Measured attenuation of samples 3 and 22 411.32 Measured attenuation of samples 2v 7 and 8 431.33 Measured attenuation of samples 7, 11 and 12 441.34 Measured attenuation of samples 7, 10 and 13 451.35 Measured attenuation of samples 7 and 17 461.36 Measured attenuation of samples 31, 32 and 33 47

page ii

LIST OF GRAPHS (Continued)

1 3 Stability test results on samples 1 and 4 521.37 Stability test results on samples 2 and 5 531.39 Stability test results on samples 3 and 6 531.30 Stability test results on samples 2 and 7 551.40 Stability test results on samples 7 and 8 561.42 Stability test results on samples 7 and 10 571.43 Stability test results on samplesll and 12 581.43 Stability test results on samples 7 and 13 591.45 Stability test results on samples 7 and 15 601.46 Stability test results on samplesl7 and 18 611.46 Stability test results on samples 7 and 20 621.47 Stability test results on samples 7 and 21 631.49 Stability test results on samples 3 and 22 631.50 Stability test results on samples 7 and 23 651.50 Stability test results on samples27 and 25 661.52 Stability test results on samples26 and 27 671.53 Stability test results on sampl 28 and 29 681.53 Stability test results on samples 1 and 30 69

I

I page iii

I

I

[

ABSTRACT

The results of attenuation, VSWR, watertightness, stability,pliability and other tests on 33 various sample constructionsshow RG-214/U, RG-217/U and RG-218/U can be redesigned to be water-tight at 1000 psi and have less attenuation, better attenuationstability, be more pliable, and have better abrasion resistancethan the standard designed cable. The new designs would still becompatible with the connectors presently used on the standardcables. The size of the cable can also be decreased, if desired,but then the connector would require redesign. The resultspresented show the technique used to manufacture the braid watertightis good for pressures greater than 2500 psi. The attenuation on allRG coaxial cable can be decreased by an improved braid'design. RG-214/U,which is considered one of the better designed RG cable, has better than20% less attenuation from 10 MC to 10 GC with the improved braid design.The pliability of a cable depends almost completely upon its jacketstiffness. Pliability results are presented that show polyurethanejacketed cables are vastly more pliable at 8OOF, OF and -40OF thanpolyvinylchloride or polyethylene jacketed cables. The programfor the next interval is presented.

IT

page 1

I

PART I

1.1 PURPOSE

1.1.1 Contract - The purpose of the contract is to design andmanufacture improved versions of RG-214/U RG-217/U and RG-218/Uwhich are physically smaller, more flexible, are watertight alongtheir axis at 1000 psi and, if possible, with decreased attenuation.The development shall be carried out in thre3 phases, concluding inthe manufacture and shipment of 5000 feet of each of the improvedcables.

1.1.2 Phase I - The purpose of Phase I is to manufacture and testlengths of RG-2140/U, RG-217/U and RG-218/U and various sample con-structions of these cables manufactured with new techniques andmaterials. The test results shall be used to evaluate the effectof the new techniques and materials upon attenuation, impedance,abrasion resistance, flammability and pliability.

1.1.3 Phase II - The purpose of Phase II is to manufacture and testcables designed from the information obtained from Phase I and toapply the techniques for production of watertight coaxal cablesdeveloped under Contract NObsr-81424 to these cable designs. The

* purpose is also to develop new watertightness techniques if necessary.

S1.1.4 Phase III - The purpose of Phase III is to evaluate all thedata obtained from Phase I and II and design improved watertightversions of RG-214/U, RG-217/U and RG-218/U. This phase will also

j include the manufacture and shipment of 50CO feet of each of theimproved watertight cables to an agency to be designated by the Chief,Bureau of Ships.

1.1.5 Repo t - The purpose of this report is to present theinformation gathered and the progress made during the reporting

I period of October 1, 1962 to December 31, 1962.

P

I

'IPage 2

1.2 GENERAL FACTUAL DATA

1.2.1 Identification of technicians - The following list presentsthe engineering personnel contributing to the contract and their man-hours performed during this reporting period.

David A. Peterson Engineer 386.5 hoursNorbert Ostrowski Engineering Aide 177.5 hoursJohn Palmero Technician 186.9 hoursLarry Racow Technician 333.5 hours

1.2.2 Test prooedures- The following paragraph describes the onlychange made to the test procedures discussed in paragraph 1.2.2 of thefirst interim progress report.

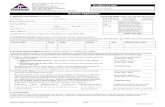

1.2.2.1 Pliability - The pliability test (paragraph 1.2.2.11 of thefirst interim progress report) was devised tS give comparable valuesto the pliability of the cable samples at 20 C, OuC, -20'C and -4OC.The equipment and test specimen was arranged as illustrated in figure1.1. The weight used to bend the sample was recorded and the timefor the sample to bend ninety degrees (to a vertical position) wasmeasured and recorded.

cable specimen

Nýtlamp

•test stand

figure 1.1 - Pliability test equipment andspecimen layout.

1.3 DETAIL FACTUAL DATA

1.3.1 Sample description - Table 1.1 pages 4 - 8, presents des-crivftions of the sample constructions. The description of the samplesof Phase I are repeated to aid in the discussion of the test results.Three new samples studied in Phase I are also described.

Page 3

L.

I

Table 1.1 Description of sample constructions

Construction

Description I - --- - -_ _

Inner OuterConductor Dielectric Conductor Jacket

S7 strands of Two braids No-contain-1G 214/U i0.026" polethylene of 3)4 ga. mnating

silver is: 0.285" silver polyvinyl-plated plated chloridecopper comper dis: 0.""

2 0% no 217/(J Bare copper polyethylene Braid of Non-contain-dia: 0.106" die: 0.370" 33 a. bae luating poly-

copper viylichloridedie: 0.51.5"

3 RG 218/0 Bare copper polyethylene Braid of 30 Non-,ontem-dtae 0.195" dia: 0.680" pgs bare inating poly-

copper viny•ilcoridedi:a .870"

4 Watertight Two braids P olyethyleneconstruction of of 34 ga. dia: 0.•1•"

RG-2111/U Same as sample #1 silverplatedcopper vith

DC 274

5 u- Watertight Silver Same as Braid of 369aconstruction of plated sample #2 silver Polyethylene

IEG-217/J copper plated copper dia: 0.0545"dia: 0.1061" with DC 274

6 Watertight Braid of Polyetbyleneconstruction of 30 ga. bare dia: 0.870"RG-218/U Same as sample #3 copper with

DC 27)4

7 Silver plated 36 ga. Braid of Same asshield over 36 ga. sample #5

S RG-217/3 core with silverpolyethylene platedjacket Same as ample #2 copper

8 Bare copper 36ga Braid ofshield over 36 ga. bare PolyetftleneEG-217/U core vith copper die: 0.450"thin polyeftylenejacket sme as sample #2

I ~page I

Table 1.1(oont.) Description of sample construction

Construction

Description Inner Dielectric Outer JacketConductor 0onductor

9 ��G-217/A Size 7 strands ofwith stranded (7) 0.036 bare

Scenter conductor copper Same as sample #7

R0 IG--27/(J Size 19 strands ofwith stranded (19) 0.0231 bare

center conductor copper Same as sample #7

Braid of 36 ga.silvered

RG-217/J Size copper (10.8with loose braided picks) over Sam as sample #7

Scenter conductor 0.090" poly-ethylene beandBraid of 36 sm.

12 IG-27/u ize silvered12 R-•-I/U Sze cpper(30.3with tight braided cksa overcenter conductor 0.090 poly- sam as sample #7

ethylene bead

13 Cellular poly- CellUlar Braid of Polyethyleneethylene dielectric Sem as polyethylene 36 ga. diat 0.475"over iG-217/A Size sample #2 dia: 0.300" silveredConductor copper

14: Cellular poly-ethylene dielectric Cellularto RG-217AJ size Rar copper polyethylenebut with larger cern dtat 0.128" dia: 0.370" Same as sample #7

- ~ ter conductor

15 Elastomeric Elastomeric ElastomericSiolyethylene Same as polyethylene Sam as polyethylene

dielectric end staple #7 dia: 0,370" sample #7 dia: 0.545"Jacket

16 Modified high mo.. 4~eIbs Modified highSlecular weight Sm=4 AI u rL.. molecular

Polyethylene I t 4W1 weight poly-dielectric and ethylene ethyleneoJacket .dia: 0.370" dla: 0.30"

I Page 5

1. Construction

• Inner Outer

Conductor Dielectric Conductor Jacket

17 RG-217T core -Braid of Pol]ethylene17 with flat copper Same as sample #7 flat dia: 0.500"

braid and poly- copperethylene Jacket

18 RG-217/U size PolyurethaneSwith polyurethane Same as sample #7 ----- . -at 0.545"

Jacket

19 RG-217ft1 size M~ ' P C 7) odified high.R with high molecu- C A XC -ý -"ED molecular

lar weight poly- Same as sample #7 -----------. weight poly'-Sethylene Jacket etbleneeadia: 0.515"

20 RG-217/L size Ilastomeric-uWith elastomeric Ipolyethylene

polyetbylene Same as sample #7 ------------. dat 0.5115"Jacket

21 RG-2143 size Braid of 36v Polyethyleneu• with single braid silvered dia: 0. 05"of 36 ga. silver Same as sample #1 copper

! plated copper

22 RG-218/U size Braid of Polyethylene2 with braid of 36 ga. dia: 0.850"

36 ga. silver Same as sample #3 silveredplated copper copper

23 Tinned copper 36ga Braid vfco shield over 36 a. Same as

RG-217/U core with Same as sample #7 tinned sample #7polyethylene O0ePe

SJacket -~-

24 Silver plated Iih 36 ga. shield over polyvl-U*'&"6.17/U core with Same a m couple #7 chloride

Type I Jacket I dia: 0.545"

Page 6

! Table 1.l(cout.) Description of sample construction

I ~~ Construction __

S~D escriptilon! •Inner Outer

DConductor Dielectric Conductor Jacket

25 Silver plated- TYP Ils36 ga. shield over polyvinyl-W27ucore with Same as sample #7q ----------- chloride

Type Ila Jacket dia: 0.545"

26 Bare copper 36 ga. Same as Same as- shield over G-217/0T sample #8 sample #2

core with Type I Same as sample #7Jacket

27 Bare copper 36 ga.shield over RG-217/-U Same as Sam ascore with Type Ila Same as sample #7 sample #8 saple #25

* Jacket

28 Tinned copper 36 ga.shield over RG-217AJ Sae W.a Same ascore with Type I Same as sample #7 sample #23 sample #24Jacket

29 Tinned copper 36 ga.shield over rG-217A/ Same as Same a,+core with Type Ila Same as sample #7 sample #23 sample ý25Jacket

Braid of30 RG-214/U size with flat silver Same as0 silver plated flat Same as sample #1 plated sample #1

* braid copper

31 oG-217.' size with Braid OfI . 35.30 braid angle Same as sample #7 36ga silver Same as

plated with sample #710 ends and7.l1 picks

32 R-217/U size with Braid of19.70 b1raid angle Same as sample #7 36 ga silver Same as

plated with Sample #710 ends and3.6 picks

Page 7

i

IITable 1.1 (Cont.) Description of sample constructions

-4 'ConstructionA o DescriptionI

Inner Dielectric Outer Jacket

n __0 Conductor Conductor

C G-27/U size Same as sample # 7 Braid of Same as33 with 180 braid 36 ga. sample

angle and high silver # 7coverage plate with

18 endsand 3.28

__. ......... ...... _ p icks

1.3.2 Samle discussion - Samples 16 and 19 were canceled because themodified high molecular weight polyethylene is no longer available.Through an identification error the first interim progress reportincorrectly reported sample 9 was manufactured and ready for test. Thesample has now been manufactured and will be tested with other phase IIcables. The first run of sample 14 was rejected because its dielectricwas extruded to the same dimension as sample 13. The impedance resultingfrom this error negated the intent of the sample, The sample is beingrerun and will be available for test during the next reporting period.Sample 31, 32 and 33 were manufactured to examine the effect of the braidangle on the attenuation braid factor. The attenuation of these threesamples were measured but no other tests will be performed. The cableswith polyethylene jackets were not subjected to the abrasion resistancetest since the polyethylene waxes the abrasive rod and makes the testmeaningless.

1.3.3 Attenuation test results - The results of attenuation measurementson the samples are presented in table 1.2 on page 9 and in graphs 1.1 to1.29. The graphs compare the measured results at 10, 50, 100, 250 and 500megacycles and 1.7, 3.0, 5.0, 8.0 and 10.0 gigacycles to a curve drawnfrom calculated results at 10, 100, 1000 and 10,000 megacycles. Thecalculated results were obtained with the following expressions:

at a,. + a,, (db/1O0 ft)Sat total attenuation (db/I0O ft)

a conductor losses =(4.33) (LOJ'ff(*+V) (db/l00 ft)

ad ~dielectric losses = (8.85) (i0)"nr fd, '- (db/l00 ft)F Fb F braid factor = 8D + 16d

f E frequency (cycles/second)Z a characteristic impedance of cables (ohms)

T d a diameter of center conductor (inches)D s diameter of dielectric (inches)df = dissipation factor of dielectric4E 5 dielectric constant of dielectricSd,= diameter of braid strand (inches)C a number of carriers in braidN w number of ends in braid

Page 8I Text continued on Page 39

Table 1.2 - Attenuation Tet Results (db/100 ft)

___ - Frequency in Megacycles

No. 10 50 T _ 100 2o 500 170o 3000 5000 80oo lo,000

1 1.46 2.18 3.46 4.814 10.82 1•4.70 2-.22 36.33 50.752 .25 0.79 1.38 2.20 3.05 7.24 11.75 24.00 65.77 92.103 0.17 0.40 0.71 1.54 1. 5.23 9.55 1.:o 47.60 64.70

04 .68 1.52 2.24 3.72 5.Z 1-.30 23.60 35 57100 71.305 0.60 0.92 1.60 2.60 3.72 10.10 13.60 23.50 62.20 81.206 0.59 0:79 0.98 1.57 2.36 6.43 9.92 18.9o 45.o 614.7o7 04 1.56 2.56 3.52 8.20 1U.3o 16.20 23.90 28.608 --- 1.1o 1.60 2.60 3.64 9.68 12.00 20.70 57.70 111.59 ---ac -- --- -- --- Ie - ccc

10 0.59 1.33 1.95 3.55 5.03 10.00 11-95 21.50 38.20 72.1011 -- 1.55 2.39 3.78 5.22 12.10 18.30 24.30 39.20 42.6012 --- 1.60 14.20 6.00 1.80 12.10 18.50 24.20 36.10 41.2013 9.36 1.24 1.72 3.00 4.00 8.00 12.00 14.50 22.20 27.00114 --- --- --- aaa --- --- ace --- --

15 4.50 9.00 20.00 47.50 75.oo 176.4 250.0 340.0 ,61.6 600.o16e na mc n ae c -- aca

-0. ;4 0.80 1.28 2.16 ;296 8. -1.2, 13.14 25.7 30.20.144 1.13 1.52 2.57 3.66 8.56 lO.lO 16.oo 25.4o 38.20

19 ace -e -a ccct w-a --- ec ac ace ace-

20 0.40 1.00 1.56 2.52 3.56 9.16 12.30 17.70 33.6o 6.2o21 o.64 1.24 2.12 3.40 4.64 10.70 13.6o. 18.5o 27.60 31.022 0.28 o.1o 0.88 1.52 2.08 5.36 9.32 13.4 16.30 22.62 --- 1.10 1.60 2.54 3.60 8.95 12.00 18.50 39.50 85.0O214 0.45 1.17 1.62 2.43 3.60 8.1o 35.15 15.6o 27.oo0 4.5o25 0.56 1.00 1.56 2.64 3.68 8.74 12.30 14-40 25.00 45.326 0.52 1.08 1.68 2.72 3.76 9.15 12.9o 17.50 46.6o 120.227 0.52 1.08 1.72 2.80 3.84 8.64 12.00 18.80 45.70 19028 0.52 1.oo 1.60 2.60 3.80 8.96 13.2 l6-10 36.4•0 9..529 0:52 1.00 1.60 2.56 3.7 8.96 13.60 15.10 140.00 76.0030 1 1 2.78 3. 8. 1.53 17.38 21.40 24.76

31 .986 1.37 2.32 3:o3 7.39 10 14.6 25.7 32.632 .40 .942 1.35 2.24 31 7.15 9.8 11.4 19.3 22.233 .398 .885 1.33 2.21 3.10 7.41 9.59 114,08 23.2 27.3

m

I

Grap 1.1- Computed and measured attenuation of sample 1

KEY

- computedxx measured

77- ,. ::: Z

------ -

0

93 9

+7 - -Z

4.' -

44

71 X..X... 1 . -- 44.- 2

4. . . . . . . .- Z: .z z X- 1

..... .... J

.1T

10 10 K10

.~ ~ rqec .n .me..4g---a14cy4-HclIIee 11

Pae1

~r -n 1. 2 - Computed and measured attenuation of sample 2

K -;

computedxx measured

10)o1- 11-

44

-= I -RIM T,.L ~ 4L

I Itt

I1 2 Z M,.~0 K.

2rqec nmgcce

Pag H]

Grap 1.3- Computed and measured attenuation of sample 3

KEY

-computed

ioc x measured

ce-+Hodýii fl H1 H _

0f T

00 til.T0

=t2

4.>1 1 16 1x41 4

*T T------ --------- ----

A. .7

II6

J+I4i

2H41 1 Hff

2- l"R I-

0w

0N1 4 1111

LIM fl

0.1113.0 2 3 4 6 6 7 o9.1o 2 3 4 6 b 7

a 9 j2 3 4 6 6 7 8 dk

Frequency in megacycles

Page 12

G~rap1,- Computed and measured attenuation of sample I4

~~KEY

computedxxmeasured

io(% -- ipi -flflf+-FflfSilIH l f I1 1Il i l 1 - --

f7 11-

Si. 1 1 11 -i l 1-+

4.1 af-

"rI

M1 -I

4 -o 1 -

4-

43~- - ---

f-H

3=1 11 U1

Frequencyil inmgcce

Page11 il 13 1 1 1 1 1 1 i I f III f I IH I H

..IV l

Graph 1.5 - Computed and measured attenuation of sample 5

KEY

-computed

x x measured1, H 11111I fiif i

0

.f4 4

4'

'ti

Ft I10"'lH4' 91 .1 -i I ifi ifti

H il ll

41-

0 -i

in'7

-1 M IH I- -- ,.- 1

T_ H I I I I:

04

10 2 3 . B911 03 4 B90 3 4 L

Frequency in megacycles

Page 14

Grap 1,6- Computed and measured attenuation of sample 6

KEY-computedx x measured

0 M1-11IT HM IIi

H 4

4I -- _- - I ,1 1 113~

10

ItH f

0.1f t1-4 fl1- 11 1

10l IM 1 4It79~ .

W NOW W Freque ncy [in me1Acle7 VPage 15

I" I " H1 111~ il,--,

Crakh .7,- Computed and measured attenuation of sample 7

KEY-computedx x measured

776- f_

4 M:

0

r* o0) -- " + -+i-ifR ~ _ _ 1f11+ -- 1 1

43- - -----6IH f f f1- 1 1 1 - - - f l

43 W ffI ff )T -- ii

... ----

77

JH 44il

01 HI

Frqecyinegcce-R,~ ~~~~~~Pg 416 T.Htf f-- A+1

Graph 1.A -m Computed and measured attenuation of sample.8

KEY- computed

x x measured

19

H I

0 . 01. it i

4.3

V2 #

0T

aU)4.) H ]-

lax

7 .. 4 - M

0,.

1.11 10 2 4- "b 4 5 A2 3

Frequency in megacycles

Page 17

Graph 1.9 - Computed and measured attenuation of sample 10

KEY

-computedx x measured

10 j - iIlM l-- -1 i IA III f i Ii 1 1 f t )I 1j 1

.T0

4T 10 11 1o1 J

4-)4.)f

H i .I I ý

7----- ...6.... ..... -B ff

4

;fNM IUI).

4 -- _4 4 1 1111i

3

1#44 4 11-

2 T 4 -t0 Ii

f +ffffli2 3 m 4 M 5 7 9 0 0 2 3 4 6 9 J

+ H ~f.- t IIft F --- b ~ i I, H H f- f II A l'+ - - -1 II iI I itI I3 1 -1 111 6 7 8 I il I i K

UUU -lit+-- -WH Frequenc H1111i n I megacyIIcleslilif 14U~ ~ ~~~~~~~~Pg '- M1 4111- +---I HiIHMISj H

Graph 1.10 - Computed and measured attenuation of sample 11

KEYcomputed

x x measured

11 -1 N fl 1 1 I

.9I-L

I4 1 1 1 1 111 1 1 1 1 111 1 1 1 1 1 1 1 11 1 1

4 l1 1 1 I G)I1 1 1 1 1 1 1 1 1 1 1 1 11 1 1 1 11 1111 1 1 1 1 11 1 1 1 1

0)

III-IH T Ill H M il 1

II I I -IH H I HM1 111 i HN I I

U9.

a U ItII I 1 F1 1 111 1

1Fl 111i'1 1.

I~ ~ ~ T ITTH HI I' II IfI iiIIJ K( <

0.1 1211T'

1 0 2 3 4 b b 76990 t 2 3 4 b. , 71 89 10 2 3 4 6 b 719 '9Ii1I

10100 1K 10K

Frequency in megacycles

Page 19

Graph 1.11 - Computed and measured attenuation of eample 12

KEY-computedx x measured

100

*1 A

I. 141- ..t J

40 i ' ,1 1ý

43 111 11 fil

0 -i

110

2* 3 5 3 4 b t h92 3 4 6

10K 4101 0

Frequncy i megaycle

2 ~ ~ ~ Pg 20 ~i~I,

Graph 1.12 - Computed and measured attenuation of sample 13

KEY,

1000 - computed-11--II-4 1111flI il flflIf11--x x meaaured - -LLJU

0-H011 J -- 11 1:11tl 1 1 11 1

0

4) 11H M ft1011i 1

6

0 4

Nl H IIIII f * ~ l~ I Il 1 -1f1 - 1 i .III li fl

U.

II

b 6 9 PO LE 4 .1 ,7k i 8ý1 2 3 4ý 91 9 1

10 001K 10K

Frequency in megacycles

Page 21

Graph 1.13 - Computed and measured attenuation of sample 15

KEY

-computed1oo ~ x x masured

100 PB T7f * +t

-1fiBi -++-ii i- -1 -i-

14H I M U + 1 1........ 1f 11i l- i 1111 - 1

.0+

.0

4.)

Bf --f + +f-_..+ _ I f

-v

0 -i I

S j

+ I+F Ff f I 11RHiIH W Hl

I-I i I -M I1 i t :

10 100 1K 10K

Frequency in megacycles

Page 22

Graph 1.14 - Computed and measured attenuation of sample 17

KEY

- computedx X measured

.... ...

XT44

0

.0

4l)9 10 +f+

4.) J- iiR A ~43

6=

T-Al

10 10 K 0

Frqunc i mgayce

P a g 23---- ...

Graph 1.15 - Computed and measured attenuation of sample 18

KE~Y

1 - oue

oi -f-l W I 111<fl i'-4T

*z 2

0)

.4 :M R IHI R14-1

2

f l

4LU 10KfINH 141 H

Frqunc i mgayceIMU~ ~ Pg 24111"14-

Graph 1.16 - Computed and measured attenuation of sample 20

KEY

-computed

x x measured100 to - -- + - 4 I-M - -111HM 1 . 1 1 -1l -1f

7 -- - -- -ii II

6~ I I

*4) 4 411 t

,0 I

04~10 10ttvt a

-- H IIf I U I HIBi i H H UH ,1 I IIIII I I i 11 1 11H l

I I7 i l . 1 1 1H lli 1 1 1 U 111 f1 1 1H I I I i IM I 11 1 I W 11

4)l fi i 11 h I H 1--1 1 1 1 l i H I i l

3 - - -_I: -fl' I- I

02#010

U 8 -

. 3 IL

01T1

10 10 h;lt11K10

Frqecyi erccePage 25

Graph 1.17 - Computed and measured attenuation of sample 21

K EY.

xxeaiuureQ -H -M- l MIIIHI

0 ._ 40

-l3r t t -110=v T 1T -fl--

U,, 14 -t - I- 1

0 til

WL .14 111 [1 111flI--l H III 4 1 I- -- F 'Il A 1111 1UI. - I-i

43l

-Cc -41III 111 14 1 tl f I -

14 31 4-111~ 64 6- 1 A H 9 O2 . lJ2 3 4 6 6 789

101111T 100 -T- 1I~l 0 1K110K

Frqunc I- megUcyclePagY2

Graph 1.18 -Computed and measured attenuation of sample 22

KEY

-computed100D= xx measured

6

0

r.0 201 tl IllI 1 111

oPfItIIIIIIIiIIil IH 1H ll I1+H A I I IIH M 1 _~ -1if. I -LF -I -f -- iH l fi 11 1 J1+ - 11 1 11 1 1 1 1 l

7 1 9ill 1 1 V I-flt l I IJM l fF - - l

H 1 1 1 1 __ . 11

H11 U11 71- f

d II I II Hil

0 i -1 t l 11 ll

o I TMIn

0

6 9I ITH ii i Hl

2 3 .111 9 9 02 30100

11 0 K 10K

Frequency in megacycles

Page 27

Graph 1.19 - Computed and. measured. attenuation of sample 23

KEYcomputed

xx measured

10 tlM1411100 1K40

Frequency -in eacce

Tj 11W Page .2 l

Graph 1.20 - Computed and measured attenuation of sample 24

KEY

- computedx x measured

100

6 - - -

0

*1M-1

0

4,)100 7 !7- - f-1tU 9

r. + I- I. 1+ -1-- l Ii - - Ti

0)

43 -l t +

4-

-:T

2~ 01 -1 1111Rm

in -

U ih L- MM1- +- f- IF fif-Hi-r------

61 - - ] I H 111H f ffI 11 1 i l I I I H f i

10 10 1K 1110K111liii iii1

Frequency in megacycles

Page 29

Graph 1.21 - Computed and measured attenuation of sample 25

KEY

-computedxx measured

0

111 I I i+ 4I

4- 0 101K00

.Feuec in .megacyo.les.Pag 30 1 H f- [fIII j_ rf-Hj l

Graph 1.22 -! Computed and measured attenuation of sample 26

KEY

-computedx x measured

1 0 - - - - i.0fl l 1- lf l f l - - 11 1 1A 1i II i 1 f i i (I I I l II 1 1 1 w l i il1 1 1 T A i

Ij IIt 1 I II I 1 - . - , i 1 iý

101 1 Hi00 1K 110K

Frequenc in Ifayc

Pae3

Graph 1.23 - Computed and measured attenuation of sample 27

KEY

1000 - computed* x x measured jI11 j-H+1 4ItIHIIiJiI II IIIf11H ft- I f-fH H ffIIIIII111 11111111f

----

4 4

0

1 4 -

41 0

T -

0 ilV 1 V 41 ----- -----

J.1 l j .... ..3~ I' M

*1 7~l -11H I I1 1 1 li tI~ lli - 14:1ii

4.,4 IT11 - AM+N 11

ini

.0 10 I r~

K u - - 1 1 t i l I 1

JU I

-

--

-

-

x 7

o I Irj IF 11iJ4-

I i t

Lift

10 100 1K 10K

Frequency in megacycles

Page 3

Graph 1.24~ - Computed and measured attenuation of sample 28

KEY

- corn utedH I i i ilt III 11H-I 1 1: i il:100 x x measured1

W I I M 11 11 -1 1 11 l -i

I d i

r 1 :4 -.1 1.-tIl---

I I Ii I! I IM IN I i

Iit

8-I-

j10 104K 0

Frequency in megacycles

Page 33

Graph 1,&5- Computed and measured attenuation of sample 29

ME

x. ea ured IM-HU -l+f+1-+"-I-+j-FI- +f+fiiflf+H [+I +f+M+f+f*f-F-j-j+I4-. -- f-j-H-4 I H I I i III I If f i A 111 111Hi t1ittu f " I f-f f 1`411 Fil- 4+1-14+++++ 1+ -iflj I I H f f, flilli-Iff-Hi H-1

-j+I-H-jH-+j--H filli-HIRIH-il --III 1111-i-fiff + I It i H Ili7,

-1444T V, f M IM I _R-J-0 1110111 11.1 tff ý_l I H- 11-1411111,11 11-------------

------- . .............11-1

4-Hj I HIM DK W.- HT 11W

0 +#H1141+ 1. 'S 411M alt I It IT ____2 4. M _ 44---

61 W.- GRIM-i+-f+IwfIFF-----f-- -1 1 111-44 1 1 HjfHHH-

I If R -14 - HfHflf f- - - I. i I*T44 FI`f fflitf f f HJ[fl I I ff I It I- - - -1i -Wifft +1 il-H] ff fli U -r-liff-F 1+111 Hii-Iflifil I IH Ifffiifft IN -: a -lad__44 T+ - fr- -"M IT V111fTR V-1-1-4- 1444t_ f V VMt It"M 410,I t -94 --MW _11V lit nlffld

+H+ ---------

4_V Ai .11M W1,11ft- ft vi HN : full:V=

t -j

0 -iCb Tj"I"go F++-+- +Hf*

-++++- +ffHj._Pr ... HfHH+f[" Iff-III-AA-1-H Ill--- +WI-MMIl +H- f[AHIV! I IliUUMUU'-

f I 1 -11 H Rf+ F ff- - - --. +H-l]f41IN-+ I

`4 _t Iý 11 H-111, H I I I- 114 it -1 111111111

0 2 - - -1 I i til I I-- Tt 111- 11 ýý111 ý .1WMM I _114T U__ J-4-1111.jv 4

MCI * f I44T 11111k f11,11 lilt IN 11 MINI

J 4.1 -A

it III ItIT1111111 I IIIIITi 11HIII 11 T1111 I III IIIIT1111IýIi A A

J, 1111 Jt J t , 1 11 1 11

14, t .11 1111 fil[ :I---1 11-1 ]i .- III -fl- 1-1 Al 111'[ 1.11111 f"ll-tilld$ '11 IT-' 111111 V 1 H-4-1

1 MidJtf

0.1 1,11i"It t[ dgo 2 3 4 5 6 7 a 210- 3 4 6 6 7 a 2 3 4 5 6 7 8 1 10-

10 100 IK IOK

Frequency in megacycles

Page 34

Graph 1,26 - Computed and measured attenuationof sample 30

KEY

-computed

x x measured10010 . .......

H-H6HM !- I H + fi iI fi

j ffF a~ lffl7 f f H -- f I

4.4,

0

10-t-+ i

4),

R T_

=I-T4.T- . X

6d

2 2

41 fil f i iHl- £ 1iI -i -H 1, H_ +-

71 -tl_ ... --

0.1 3 4 6 6 780 2 3 4b6 76a9210 2 4 0

10 100 1K 10K

Frequency in megacyclesPage 35

Graph 1.27-- Computed and measured attenuation of sample 31

KEY

-computed

':iX measured*100, -0ifl-

44-

H# 10 1

oo

.4 0ý

144

77

T T. .V -_14f~~ t t fMIV-W I t 1 . 41

WO .- . .. .---

Al fil + 1- 1

l-1. M A- -4 I65 1 --- + 4- -78 1 -- 4 - ie t

10 ~ 100 *K-HiFrqunc in aegacyIlV

.1 ~ ~ ~ ~ ~ Pg 36-1 ,-U4I- 1111- II

7 t

Graph 1.28 - Computed and measured attenuation of sample 32

-computed

x x measured

fill t VA :I T, 1- 11-1i

-2 - - -I

0

64 7f. lB .]ff , -- H Rff~lf -J I -f

2R IT

-0 -- ..... ....

t - - -

ON, T I

-1 IF I -H 1 11111 f

rf0--m Hl- H0 ff-.f 1H 11F -1 1 167902 3 4 6 0112 3 81

1K 10KFrqec inmeayce

Page HA

Graph 1.29 - Computed and measured attenuation Of sample 3~3

KEY

-~comput edx x measured

100 'i - -I11 4LLil

77 7T

o -+i- -41

-H-++ IH

f+H

4i140 4i

P-ji-

V4 2

lo 10

73 -H1

-I 1

J- t I T_ it

4'* H ~

I~~ ilk,~

01 12 4 6 678 N91- 2 3 4 2

10i 1 8i10 100 1K 10K

Frequency in megacycles

Page 38

1.3.14 Discussion of attenuation test results - Graphs 1.1 through 1.29 show themeasured attenuation of the samples is quite accurately predicted by the expressionsgiven In paragraph 1.3.3 on page 8. Graphs 1.27, 1.28 and 1.29 indicate the braidfactor does not completely describe the attenuation characteristics of the braid. Allthe graphs show a need for evaluation of the contribution of the braid to the attenua-tion at frequencies above 3 GC. The results show a silver plated braid yields a muchlower high frequency attenuation than a bare copper braid. The following paragraphsdiscuss individual attenuation test results in more detail.

1.3.4.1 Discussion of attenuation test results on samples 1, 21 and 30 - Graph 1.30,page 1.0, presents a coQmprison of the measured attenuation of samples 1, 21 and 30.Sample 1, the regular RG-214/U construction, has the highest attenuation of the threeaud increases above its calculated attenuation at frequencies above 3 OC. Sample 21,manufactured with a smaller size silver plated braid strand than sample 1, offersapproximately 4% attenuation improvement from 10 MC to 3 GC . Above 3 GC the improve-ment increases to 440 at 10 GC. This particular sample of RG-214./U (sample 1), how-ever, measured slightly higher than the averase RG-241/3 attenuation from 3 to 10 CC,so sample 21 probably does not offer quite 0 improvement to the cable design at10 GO. The measured attenuation of sample 21 closely follows its computed values.Sample 30, which is RG-_21/u core with a double silver plated ribbon braid, offersover 20% less attenuation than RG-21'I. across the entire test frequency band of 10 MCto 10 GC. The measured attenuation of sample 30 agrees with its calculated attenuationat low frequencies but Is less than calculated at higher frequencies. A comparisonof the measured and calculated attenuation curves (graphs 1.26, page 35) Indicates thedissipation factor used in the calculations is higher than actual. Note the measuredattenuation above 500 MC of sample 30 and the measured value of the RG-217/U is higherthan calculated. This shows the ribbon braid over a .285 inch dielectric yields anattenuation as good as or better than a standard braided .370 inch dielectric, asavings of 23% in core diameter. The ribbon braid also decreases the braid thickness.

1.3.4.2 Discussion of attenuation test results on samples 3 and 22 - Graph 1.31, page41, shows the measured attenuation of sample 3, which is regular EG-2/1 , and sample22, which has a silver plated braid over RG-218ft core. The two samples have approx-imately the seme attenuation from 10 MC to 3 GC. At 3 GC the attenuation of sample 3begins to increase rapidly until, at 10 MC, it is three times the attenuation of sample22, which has followed the curve of its calculated values. This shows the high fre-quency attenuation of the large (.680 inch dielectric) can be improved, even though Itis large enough to transmit higher modes at frequencies above 5.7 GC. (The TEio above5.7 GC and the TE01 above 8.04 GC) Over half the attenuation of sample 22 at 10 GCis caused by dielectric losses.

page 39

Text continued on page 42

I

Graph 1.30 - Measured attenuation of samples 1, 21 and 30 (RG-214/U size)

KEY

- sample 1 (RG-214./U)-- -- sample 21x--x sample 30

a IIt

0 -ft _ -1 M-l---

I. t- A. I- 1 1.1I-1111

40 100

1 -] ----- --II e k If ll-1

H1- I j i I F. i

11--fl t4 i -1 TIý. .Itf--fl

4 1- ,i' Ii, -. 11ý1

I~ I- r TT

10 10iKt001~~Frqec in 4-e1gacycles Ail111

I i

'Graph 1.31 - Measured attenuation of samples 3 and 22 (RG-218/U size)

KEY

sample 3 (RG-218/U)x----x sample-22

100: jH++~ýH~~ IA1 IiI

fl7fl j1 Hi11 111

----6111 M -

0 =Uo#:.. . - - -- i [ 11w0Z I---4H

p 100 1 JH

6

4

3

In Mi(V)-~ q flr f I

00 W 9A -- - -1 i-1 f 4 1 4j m 7MII

XgU 6 BRFAT *-+RU

3~~~ I -U : -I

2 I

0 112 3 4 6 6 78903 4 5 67689 10 2 3 4 6 6 7689 10

10 100 1K 10K

Frequency in megacycles

Page 41

1.3.4.3 Discussion of attenuation test results on sample 7 and 8 - Graph 1.32, page43,, presents the measured attenuation of samples 7 and 6 compared to the measuredattenuation of sample 2, which is regular RG-217/U. Sample 7 shows the improved high

'frequency attenuation characteristic of a silver plated small size braid wire over thelarger size bare copper wire. The increased low frequency attenuation of the smallsize wire is also shown. Sample 8 shows how the high frequency attenuation is in-creased when the silver plate is omitted.

1.3.4.4 Discussion of attenuation test results on samples 1U and 12 - Graph 1.33,page 41•, shows the increased attenuation or the braided center conductor constructionof samples U1 and 12 over the solid center conductor construction of sample 7.

1.3.4.5 Discussion of attenuation test results on samples 10 and 13 - Graph 1.34,page 45, shows the increased attenuation of sample 10, caused by the 19 strand, strandedcenter conductor. It also shows the attenuation of sample 13, which has the samecenter conductor as RG-217A3 but a cellular polyethylene dielectric with a smallerdiameter than RG-217/U. Sample 13 shows how a cellular polyethylene dielectric candecrease the size of the cable and yield the same attenuation. The size may be keptconstant and the attenuation decreased by the same techniques.

1.3.4.6 Discussion of attenuation test results on sample 17 - Graph 1.35, page 46,shows the improved attenuation of the flat copper braid of sample 17 compared to theattenuation of sample 7.

1.3.4.7 Discussion of attenuation test results on samples 31, 32 and 33 - Graph 1.36,Page 47, shows the braid factor does not completely describe the attenuation character-istics of samples 31, 32 and 33. Samples 31 and 32 have the same braid factor assample 7 while sample 33 has a smaller braid factor. Apparently, other variables,such as braid angle, must be considered to accurately predict the attenuation char-acteristics of a braid. The results, however, also show the braid factor predictsthe braid's contribution to the attenuation to accuracies compatible to manufacturingtolerances.

1.3.4.8 Discussion of attenuation test results on other samples - The attenuation ofsample 15 (graph 1.13, page 22) Is much too high for consideration in this application.The increased attenuation is caused by the high dissipation of the elastomeric poly-ethylene and eliminates the material for use as a coaxial dielectric, but it could beemployed in the manufasture of an isolation cable. Sample 18, 20 and 23 through 29vere manufactured for evaluation of jacketing material and their attenuation donot contribute to the discussion. Their attenuation had to be measured, however,to examine the contamination effect of the Jacketing material.

page 42

Text continued on page 418

j

Grah 132- Measured attenuation of samples 2, 7 and 8 (RG-217/U size)

KEY

sample 2 (RG-217/U)

-101 1u

0 jHf4-j -j ft+~ -1 -+ 4 I 1- 11010fH H -I1 - f fH ii HI 1111f 1 V

91 ------ fl91023 7

10MM 10 fK W11496 0

Page 4 1I3+H P 4 1 i

Graph 1.33 - Measured attenuation of samples 7, 11 and 12 (RG-2l7/U size)

KEY

-sample 7

x x sample -12

10@

I I . ..

[I0I I7 HH H5+.-+4ffH-~ fil - f

T -:::

0 . .~ 3 I I I .1 I 3 I I 1 1

10 1K --- KFrqeoyi egcce

W-MPag 44AI..0W-7f -

Graph 1.34 - Measured attenuation of sample$ 7, 10 and 13 (RG-217/U size)

KEY

-sample 7

- - - sample 10x x sample 13

10092+

.11.

T.T

N.

10 ... E U tt 1001 1K1c

EFrqunc in .megacy.c.l.

Pae4

Gra~h 1.35 - Measured attenuation of samples 7 and 17 (RG-217/U size)

KEY

- sample 7- - - sample 17

101 1 - -jff + -+ ffi+iH`fIIIfIIffIII11f Ifi Hi F

0J I

0

27 7

Im -- ::-+6 T i .t_

1 0 - tifTl

tUf). --_ --

M IS-

I-. IA

II

Gr~ph1.36- Measured attenuation of sample. 31, 32 and 33 tlIG-217/U site)

KEY

-sample 31sample 32

x x sample-33

100

0Hwf++1-t

+i- - - H + t

it i i Ii fil 1 1111 Tit 1

*4 f vmaH4+-:

100f 1 K 110KIITFrqunc In megaycle

Pag 4

1.3.5 VSWR test results - Table 1.3, page 49, lists the measuredvoltage standing wave ratio (VSWR) of the samples at 1.7, 3.0, 5.0,8.0 and 10.0 GC.

1.3.6 Discussion of VSWR test results - The VSWR of the samples,measured at the same frequency and time the high frequency attenuationmeasurements were made, indicate the cable mismatch at these frequencies.These mismatches indicate the nominal impedance of the cable, theuniformity of the cable, and the amount of the measured insertion lossthat is not caused by the attenuation of the cable.

1.3.7 Stability test results - The stability test results are presentedin table 1.4, pages 50 and 3, and in graphs 1.37 through 1.54, pages52-69. The stability is measured by comparing the measured highfrequency attenuation of the cable after manufacture, after heat aginafter flexing and after cold bending. The contamination test of MIL-C-17Cconsists of the first two steps. The graphs are arranged, with twocable stability test results on each graph, in a manner to aid thediscussion of the results.

1.3.8 Discussion of stability test results - Graph 1.40 shows thestability of sample 2, which is RG-217/U and sample 7, which is RG-217/Ucore with a silver plated 36 gauge strand braid. The much improvedstability of sample 7 indicates a silver plated braid is a more stableconstruction. Graph 1.41 shows the stability of samples 7 and 8 whichare identical constructions except sample 7 has a silver plated 6raidand sample 8 has a bare copper braid. Graph 1.49 shows this is also trueon other size cables since sample 3 is regular RG-218/U and sample 22 isa silver plated braid version of RG-218/U. Graphs 1 51 1.52 and 1.53show the difference between a contaminative type instability and insta-bility that is caused by the braid construction. Samples 24, 26 and 28have polyvinyl jackets while samples 25, 27 and 29 have noncontaminatingpolyvinyl jackets. Heat aging of samples 24, 26 and 28 caused a largeattenuation increase regardless of the braid construction; silver, bareor tinned copper. Heat aging caused little attenuation increase onsamples 25 and 29, which have silver and tinned copper braid respectively,bud did cause some on the bare copper construction of sample 27. Sample27 failed the contamination test of Mil-C-17 because its attenuation at3 GC after heat aging (14 db) is more than 15% of its original attenuation(12 db) even though 14 db is maximum at 3 GC. This is common with barecopper braided polyethylene cores. The two increases apparently havedifferent causes. In one case the polyvinyl jacket affects the attenuationby contaminating the polyethylene dielectric and increasing its dissipationfactor, while the noncontaminating jacket does not affect the dielectricbut the heat affects the bare copper braid, perhaps by corrosion.

Page 48

Text continued on page 70

I

Table 1.3 VSWR test results

Sample Frequ _nc in Gil ac ClesNo. 1,7 3.0 - 5.0 - 10.0

-1 .07 . O .. 1.15 1.27 1.402 1.06 1.08 1.14 1.26 1.343 1.18 1.15 1.02 1.14 1.184 1.10 1.10 1.19 1.20 1.405 1.12 1.29 1.20 1.24 1.316 1.02 1.06 1.03 1.12 1.277 1. 1 1.09 1.18 1.55 1.408 1.0t 1.11 1.17 1.30 1.41910 1.22 1.22 1.12 1.45 1.5511 1.21 1.12 1.09 1.32 1.4012 1.37 1.15 1.10 1.45 1.2813 1.13 1.16 1.55 1.58 1.531415 1.10 1.11 1.29 1.20 1.231617 1.02 1.13 1.20 1.50 1.4018 1.06 1.02 1.45 1.21 1.231920 1.05 1.18 1.38 1.21 1.3021 1.08 1.03 1.03 1.17 1.2222 1.34 1.52 1.58 1.29 1.6223 1.09 1.11 1.18 1.26 1.5424 1.04 1.20 1.28 1.22 1.1425 1.07 1.17 1.29 1.10 1.2226 1.04 1.09 1.28 1.36 1.2127 1.03 1.21 1.08 1.22 1.3828 1.00 1.07 1.21 1.37 1.3229 1.06 1.15 1.19 1.28 1.2730 1.13 1.24 1.39 1.54 1.59

Page 49

Table 1.4 - Stability Test Results (Attenuation In db/XO0 ft)

Frequency in GigacyclesSmile Conditioning 1

No.1.7 3.0 5.0 8.0 10.0

Manufacturing 10.82 14.70 24.22 36.33 50.75Heat Aged 10.60 15.00 18.-5 33.00 34.10Flexed 10.60 14.65 20.00 31.6o 14.6oCold Bend 156o 1 7o 2.20o 32.90 3.2

2 Manufacturing 7.24 1.75 24.00 65.70 92.14Heat Aged 9.28 16.oo 28.00 88.56 156.ooFle..ed 10.38 16..41 32.31 102.00 185.60Cold Bend 1w,-8 16.00 36.oo 1Qo9.4 160.00

3 Manufacturing 5.23 9.55 18.90 17.60 64.76Heat Aged 7.75 17.50 125.00 ---Flexed 7.58 15.33 120.00 --- 107.5Cold Bend 8.11 17.90 115.00 1•3.00 105.00

4 Manufacturing 11.30 23.60 35.40 L7.00 T1.30Heat Aged 12.11 17.02 28.00 .00 50.62Flexed 12.14 17.64 30.61 43.60 53.16Cold Bend 12.5, 16.141 26.56 112.40 1•.o

J --1 ranuf --1,s 10.10 13.60 23.50 62,2o 87.20Reat Aged 9.08 13.014 18.9 41.88 56.88Flexed 9.47 13.04 18.94 60.14 16.ooCold Bend 16,66 26.60 5.080 .32 1 6.00

6 Manufacturing 6.43 9.92 18.90 5.401 64-.7oHeat Aged 5.72 12.20 56.50 95.00Flexed 9.26 18.88 68.88 156.00 156.00C old Bend -6.18 -12,147-j1 00.0 9 5

7 Manufacturing 8.20 11.130 16.2o 23.90 28.60Heat Aged 7.75 10.65 12.30 25.00 24.20Flexed 8.10 11.40 13.4o 25.00 32.4oCold Bend 8.45 12.80 17.50 21.60 30.60

8 Manufacturing 9.68 1-2.06 20.70770 .5Heat Aged 15.30 20.90 20.00 35.-0 42.60Flexed 114.20 18.70 18.30 32.76 43.10Cold Bend 15.60 14.60 0 40o.oo00 76.00

10 minufab-,-i 10.00 14.o 21.50 38.20 72.4--Hest Aged 9.87 3.4.u 17.90 40.00 41.92Flexed 10.58 14.33 19.16 44.88 112.00C old Bend 10o.48 14.82 21.20 41.60 62.14

11 Ma 1.-ur140 18.30 21.30 39.20 42.60Heat Aged 11.90 17.90 21.90 4 .80 67.70Flexed 12.30 19.20 '32.50 1400 8T.50Cold Bend 12.40 18.80 2 .10 48.80 59.0

12 ManIufactui 12.10 18.50 2 .20 36.10 *:01.220OHeat Aged 1. 17.40 19.10 31.60 34.90Flexed 13 18.95 21.90 35.00 47.20

___Cold Bend 35014.o0o1• Ben 34, .0 17.50 24.50 3,0 &.•13 -a0j 8.00 12.00 14.50 22.20 27.00

Heat Aged 9.16 3.36 18.10 28.00 29.20Flexed 8.96 12.44 16.43 32.00 30.28Cold Bend 8.76 12.00 15.66 26.28 26.00

pae 50

15 M~anufactu~ring 176.41 250.0 31.0.0 461.6 600.0Beat Aged 180.0 26O.O 351.1 | 82.5 572.0Flexed 169.4 230.9 3k6.7 187.5 510.0ColdBend 1 3.7 .. 33.3 _o370.8 __0.0_

17 Mamufacturing 8.00 10.20 13.1.6 25.70 30.20Heat Aged 8.00 9.68 35.42 192.00 136.00Flexed 7.56 13.76 41.20 85.52 85.52

1 Cold Bend 7.1 54TO 36.oo 9756 53.11818 Manufacturing 10.10 25.10 i38.20

Beat Aged 8.96 10.97 18.52 27.43 12.52Flexed 9.16 12.15 15.13 28.00 64.88

Cold Bend 8.46 12.00 9.30 26.86 __36.283o Manufacturing 9.16 12.30 17.70 33-60 .20-

Heat Aged 8.96 12.59 15.30 35.62 54.84Flexed 9.16 12.30 16.00 36.88 68.87Cold Bend 896 12.15 16.oo 27.43 41.08

21 Manufacturing 10.70 13.60 1-.50 27.60 31.00Heat Aged 11.08 14.22 19.36 28.70 30.28Flexed 10.10 13.48 18.94 29.76 29.76Cold Bend 1.50 14.33 . 21.2 2. 30.-8

22- Manuactuingi-i 5.36 9.32 13.140 16'30- 22i.-60Heat Aged 5.00 7.50 14.70 29.:0 34.20Flexed 5.23 9.63 11.10 20.00 28.90Cold Bend 5.28 84 '19-70 31.10

23 Manufacturing 12.00 18.50 39.50Heat Aged 8.95 12.30 14.90 27.20 29.:0Flexed 8.76 12.60 15.70 29.80 36.80Cold Bend 8.8-- 8.88 13.01. 20.52 36.0 !__51?.30

.. Maufactuin 8.1io . 15..15 15.6--- 27.o.00Heat Aged 19.71 29.15 42.80 65.90 >75.0Flexed 21.45 30.82 43.90 63.75 97.50Cold Bend 21.60 30.6o 413.40 67.70 87.60

25 Manufacturing 8.-.. 12.30 4.- -.0 5.0 . . 5.3Heat Aged 8.88 11.88 19.10 35.70 >75.0Flexed 8.63 13.50 19.33 34.05 65.10Cold Bend 9.57 13.80 22.50 35.00 51.80

26 Manufacturing 9.1 12.9 -M.560 r6.60 - 00Heat Aged 24.22 36.8o 51.6o 74.20 109.1Flexed 24.22 39.20 51.20 74.20 99.4.Cold Bend 48.62 49.32 .71.11 120.00 168.0o

27 Manufacturing 86 12.00 18.80- 451.570 119.0-6Heat Aged 12.96 14.21 20.48 40.00 65.48Flexed 12.40 16.00 22.60 40.80 56.88Cold Bend 14. __ -.o 25.28 43.20 76.00

28 manufacturing - 13.-20 16.10 - 3-36.46- - 9-.$6--Heat Aged 16.50 25.38 38.00 99.7'6 156.00Flexed 18.50 26.21 38.00 70.53 168.ooCold Bend .5 2.93 --- 37.60 61.33 98.28

S Manufacturing .96 13.60 15.10 --.. 00 76.00Heat Aged 9.98 13.77 22.25 53.28 148.80Flexed 10.48 14.33 22.00 40.00 69.56Cold Bend 10.38 15.40 20.75 __8.22 69.91

30 - 4anufacturing 8*3 -1--- -173 21.40-- 24.76

Heat Aged 8.60 12.26 17.70 31.60 34.00Flexed 8.80 12.00 17.24 27.20 36.00Cold Bend 8.82 - 12.00 17.54 28.00 35.58

page 51

Graph 1.37 - Attenuation stability test results on samples I and 4

after manufacturex- x after heat aged---- after flaxcx--x after cold bend

5 .3

0 T1

43

00

2V4

3 .. .. .w: M

1 10

Freqencyin Fequecy iXiaylsggcce

Page 52

Grah 138- Attenuation stability teat results on samples 2 and 5.

KEY

-after manufacturex - x after heat aged

--after flexx --- x after cold bend

M 1

0 1 10

T :1

Frequency In Frequency ingigacycles, gigacycles

Page 53

Graph 1.39 - Attenuation stability test results on samples 3 and 6.

KEY

-after manufacturez---x after heat aged

---- after flexx ---- x after cold bend

.6-

44

............ c fl) FrquncMn , 8

TITayce gigacyles:1 w n

Pag 54mm

Grap 1.40 - Attenuation stability test results on samples 2 and 7.

KEY

-- after manufacturex-x after heat aged

--- after flexa--x after cold bend

NM T

*r44

7,:

.IX

S.C~~T 2 2.53R 4 1 It.1 .A 2253 4 85

q w:

91

gigcyle giay .les...

a0e

to111.I u

7,:6:X

+f+.H+

T T!.!! ff

..... ----

tIt

1o0.10

Frequency in Frequency ingigacycles gtgacycles

Page 55

Graph 1.41 - Attenuation stability test results on samples 7 and 8.

KE~Y

after manufacturex-x after heat aged

----after flexx --- x after cold bend

l0d0- 1111111H M IIIillif lTIiil1 U 1-1 R~ llill I 1111M11111 1 f111U14 1 M 1-4 111 11111111 l

6R M111 1U t1111iII11111111 idlýH l

WHI I0 T - 1M 1H M Uffl.il _ 11 il 111 11 1111 1 11 l!IIIl11 1 111

4411AID 4HM 11 ml-11

:1 M 431 11 tl IIddýiIi I

0 3

"4.

T=:

... ......

I w

- flý 1ftRi

4 f ] HM 11I1-11 i 1 3 1111 fi M'I II 1

111 110f11FrqecInFeunyi

11i1111y1[e1 gigcy les lPag 56

Grah 142- Attenuation stability test results on samples 7 and 10

---after manufacturel-I after heat aged

-after flexz ---:x after cold bend

1000I

I

4

63

.0

4 3

.4

... .... .....

.. .... .. . . . ......... .. . ... ......... .............

............

.4 .. .. X I .... 1

T T ...... X m M : : : : ::X I........ 1 117e

.- XIM WW.

'.5HI

.8. .1 .... ... .. .1 1 2 2.8.3 4...8? ...d

Frqel T In .... Fr q e c .In........£ipc ~ ~ ITeI gi..ycle

Pag ---7 1

Grah 143- Attenuation stability teat results on samples 11 and 12.

KE- after manufacture

x-x after heat aged--- after flex

x--x after cold bend

7

o 40

0

43. . ... ....

... 2...

.. ... ..4)

10-- - -- --

....S---

.

632 1::1 = 1

T- T

I I' 2 2.5 3 4 5 b 7 a 9 1 10 1.5 2 2.503 4 5 * 7 8 9 0

Frequency in Frequency ingigacycles gigacycles

Page 58

Graph 1.4.4 - Attenuation stability test results on samples 7 and 13.

KEY

- after manufacturex -x after heat aged

after flex--x after cold bend

10. ...

......_M --------7--- t VV1 :4

4-U I Mif~i

-- - -- --- - -------- - -- $Q 4

R - ---- 1111U I Uij1111;

1 1011 H -1ý 44I

Frqecyi rqunyigigacclesgigaycTe

43PageA59

Graph 1.4 -Attenuation stability teat results on samples 7 and 15.

KEY

-after manufactureX -X after heat aged

---- after flex

-xafter cold bend

11 11 M 1 :4 i l I il!'1i1 1 1 1 i

..... ... M 4 If.V0

4-4 444-l.11

o 3UM W

431

M. .

HUM.1

10.MM'0i T: U X

4 ...... ........

3.

I . BUIj

I.1 2 2.5 3 4 5 6 7 19 16- 1.5 2 2.5 3 4 5 6 7 8 9 1f

10Freqencyin Fequecy i

gigacycle. gigacycle.

Page 60

-Grph .46- Attenuation stability test results on samples 17 and 18.

KEY

-after manufacturex - x after heat aged---- after flex--x after cold bend

100 - M M 1MM1 11uI iIIHCM1111I-11 lAIIM~~~~~~~~~~~~ ~~~~~ T]11 111111111111 l 1414 4- IJ1III H1il

7 -- 7 111 11 1 ill J1 I1a1 I f H

2.T6

4,ý

o 1.6

Il Hillfl j

10 011.Frqunc in NO Frequency11 inM111IM

-1:41g0Igacycles 41111M1 111111-. 1T 111 g ~igaylesl ýif i~iHI11 1U 11 111 MNM 1 lIt ~ ~ ~ ~ ~ Pg 61Mf 1 II 1Nfl HiM i:l!ýtliIý1II0 11I ~

Graph 1.4~7 - Attenuation stability test results on samples 7 and 20.

KEY- after manufacturex -x~ after heat aged

--after flexx--x after cold bend

6 I I I H i 1 I TII IIIHAII

IT I

'-8 11- Hr11 11 11 11H 111 l ý1 H -

0

4.,

1-

9.1+++ IillFrequency 111111f111 11111- 1+l in4 Freq ue c I M11,1A inlIl1 Tl!l1 -11gigacyclesT~ giayce

Page 62i tI-T iI1 ýt :1 ýI,111I ,1iý

Graph 1,48 - Attenuation stability test results on samples 1 and 21.

KEY-after manufacture

x -x after heat aged-after flex

x -x after cold bend

1061

5-4

0

r.9

Ill

1 1 1 1 11H l .111 M Il 1111 Hi I I 1T H I

filll

1i lb 2 2,5 3 4 6 6 0a9210 1.5 2 2.5 3 4 5 6 7 8 9

10 4

Frequency in 1 Frequency ingigacycles gigacycles

Page 63

L

Graph .LO~ - Attenuation stability test results on samples 3 and 22.

-after manufacturex -- x after heat aged

;--after flexx--x after cold bend

40. . . .. . . .

---------

..... ..

=XMIX ....

1.3. ......... ......... ...

........

4M3

:111111X

......... .......S X T : Z =1 Xm Z 1

X1 .... ..

.......... .... T..6

... . --- --- ---

1.5 I 2.5 4 81 9 1.5 2 2.5 3 4 5 6 7 8 9

Frequency in, Frequency ingigacycles gigacycles

Page 64

Gr_&Dh 1.50 - Attenuation stability test results on samples 7 and 23.

-L after manufacturex - x after heat aged

---after flexx--x after cold bend

.0

4J)

.4E

.. . . . .2 .

9ttftt-t11

i H H H

6 .. .. .. ..

...5..

......4. . . . . ... . :j= - : 1

aX

1.5 2 , 2.3 4 5 6 7 10 10 1.5 9 2.5 3 4 5 67 a 9t0

Frequency in Frequency in

gigacycles gigacycles

Page 65

Grah 151- Attenuation stability teat results on samples 24 and 25.

M after manufacturex - xafter heat aged--- after flex

x --x after cold bend

0

* I

00

o II i f*Hfri ---

0T1-11+H14 -4H+

-141

VI

764 fXTX5 MN,

II.I

I .A 2 2.5 3 a 6 17 S0 jb 1.5 2 2.5 3 4 5 6 1 8 1fd0

Frequency in 1Frequency ingigacycles gigacycle.

Page 66

Graph 1.52 - Attenuation stability test results on samples 26 and 27.

KEYafter manufacture

x - x after heat aged-after flex

x---x after cold bend

10

MIAI

1M 00 2 E 1111 1 H 1111 811;1 1 !

0 1.Frqunc in Fr q e c i1ný-_ --------

Jayce gMI N01-jM1111 4 IgayM e

t ON .Page..67

Grah 153- Attenuation stability test results on samples 28 and 29.

KEY=-after manufacture

x -x after heat aged--- after flexx -x after cold bend

* I,

IV1 II NI-j,I

..A:... .

0 3 M"1

RIIIIIIIIIII- II. t

I II

I~ ~ ~ ~~I I ~ .....---

2.fl

I it I li[

Frequency in Frequency ingigacycles gigacycles

Page 68

ra~h 1.54 - Attenuation stability test results on samples 1 and 30.

KEY-after manufacture

x -- x after heat aged----. after flexx -- x after cold bend

t -t

04

It

24 4

1,81 t

F u in F u

gJ1acclel .. gacycles

Pag 9i

II

Frequency in Frequency ingigacycles glgacycles

Page 69

1.3.9 Watertightness test results - Table 1.5, this page, lists the watertight-ness test results after eanufacture and after conditioning on samples U,, 5 and 6.

1.3.10 Discussion of watertightness test results - The watertightness resultsshow the techniques for making a cable with a solid center conductor and a dia-meter of less than 500 mile over the braid is acceptable for 1000 psi applicationsbut the technique to watertight stranded center conductors and the techniquesused on larger cables must be improved. A stranded center conductor increasesa cable's attenuation and really does not make the cable more flexible because ofthe stiffness of the Jacket. Improving the vatertighting techniques on this typeconstruction, hovever, should be investigated because the techniques used onsolid center conductor cables make the cables watertight at pressures greaterthan 2500 psi but the smooth solid center conductor extrudes out of the core onshort lengths. The stranded center conductor might improve this bond strength.Attempts to watertight without the tape over the braid should be investigatedsince cable could be manufactured with a smoother Jacket if the polyethylene tapeculd be eliminated.

Table 1.5 - Watertightness Test Results

Sample After Manufacture I After Conditioning

4 100psi for1hr. noleakage 00 psifor1hr. noleakage200 psi for 21 hr., no leakage 200 psi for 1 hr, no leakage300 psi for 2 hrs, no leakage 300 psi for 1 hr, no leakage400 psi for 2 hr.. no leakage 400 psi for 140 min, 20c c500 psi for 1 hr, no leakage

*500 psi for 15 hr., 1 cc

5 l0O psi for 1 hr, no leakage l00 psi for j hr, no leakage200 psi for 1 hr, no leakage 500 psi for 2 bra, no leakage500 psi for 2 hr., no leakage 1000 psi for 2 hra, no leakage

1000 psi for 2 hrs, no leakage1000 psi for 2 hrs, no leakage

6 1*100 plsi for 30 mina, 10 cc leaked immediately

*pressure dropped to 160 psi during time, leakge occurred aroundcenter conductor.

**pressure dropped to 0 psi during time, leakage occurred throughbraid.

1.3.11 Flamiability test results - Table 1.6, pages 71 and 72, lists the flam-mability test results.

1.3.12 Discussion of flammability test results - The results show that all theJacketing materials burn or melt but the polyInyls are self extinguishing whilepolyethylene and polyurthane jackets are not self extinguishing. The resultsalso indicate the noncontaminating polyvinylchloride is a little harder to ignitethan the standard type polyvinylehloride (about same to ignite as polyethylene)but the standard type extinguishes itself sooner.

page 70

Table 1.6 - Flamability Test Results

Time to f Time to Type of Flae JacketiIATIe ignite extinguish smoke Travel material

(m:n-s) (mmu-sec) (inches)

A1 2:10 I t 50 Black smoke 3.00 noncontaminatingB 2t07 2:03 and soot 3.00 polyvinyloblorideC 2 L45 j 2:.00 - 2.50o50A2:2 1:572- Black smoke 2.75 noncutaminatingB 2:31. 2:06 and soot 2.50 polyviny1.chloridec 2:07 2:01 2.50

3iS5 1:50 Black smoke 2.50 noncontaminating3 2:05 2:00 and soot 2.50 polyvinylohloridec -1; 8 2:01 _2.-3oCa 2;l. Lgh ok Entire3 2:05 ---- and soot length of polyethyleneC 1:59 sa,,ple

5A 2:0 Light smoke Entire3 2:10 Wand soot length of polyetbyleneC 2:09 -sample

- 2t]18 Light smoke Eire3 2:10 .... and soot length of polyethyleneC 2:13 sLmkn e

7A 1:58 - Light ____ -eB 2:08 ---- and soot length 6f polyethyleneC 2:10 sample

2:05 Light smoke Entire"S 1:58 ---- and soot length of polyethyleneC 2:10 _sample ....

I 2t 2:21 Light smoke EntireS 2: ---- and soot length of polyethyleneC 2: 0 sa le .,__

1LA 2:s9 Light moke Entire

S2:1 ---- and soot length of polyethyleneC 2:03 Osapl5e12A _-T1 5Light moke Entire

3 1% ---- and soot length of polyethyleneC 2:01 sample

f3A 2:i Light smoke Entire3 2: .... and soot length of polyethylenea 2:1 sample _________

D 2:15 ---- and soot length of polyethyleneC 2:0o6 sample __

31:51 --- and soot length of polyethylene,

C lth5 _ _ - __sample __ _•_ 18A - -is20 Ligth smke ... niiriB 1: 30 ---- and soot length of po3.yuzthSae

C 1:28 ___________ _ sampl~e ______

II 7

Table 1.6 - PlamabilitY Teat Rehits (cat.)

Time to Time to Type of Flawe JacketSample ignite extin uih smoke travel materil"(m,-e.w) (mm-,ac) i (inches)

20AW 2:1 Light smoke Entire jelastomericB 2:09 and soot length of polyethylene

2: 07 ...... mample .... . ......2:01 Light smoke Entire 1

f 2s16 .... and soot length of pol.ethyleneC 2s:3 a t mapie

S2A 17 Light smoke Entire..1:. and soot length Of polyethylene

C 2:11 ____________

23A 2s17 Lihimk Entire3 2:13 and soot length of polyethlbeneC 9:q MAeile ______94A 1:10 0:53 Black amoke 2.503 1:10 1:11 and soot 2.50 poly•viylablorideC 1; 0'L 0:925

95A 2:06 1 1:49 Black amoke 3.00 RnoMtau .etIC....B 2:25 2:05 and soot 2,.25 polvinylohl~oldeC 2:10 1:30 2.50"1:06 0:3 . Black umoke 2.00B 1:1 5 0:56 and soot 2.50 polyvinrylclorideC 1:12 1 1:15 2.30 ______

-W 2:o6 I:55 Black m . 2.2 " iau.Imut.ngB 2:25 2:05 and soot, 3.00 polyvinyl.blorld4eC 210 o 2:10 2. 03R

28 1:08 0:51 Black smoke 2025B 1:23 0: Z5 and soot 2.50 pol~wrinyloblo'ldeC 1:12 1:01 2.O0

2h1:145 2:10 Black smoke 2.0 naonanteMIDAUDSnB 2:oo 1: C0 and soot 2.50 polytwnIcloridA.C 2:4 1:14 G 3.00___

3W i- 2:0- 1:58 Black smoke --- *----.25 nanoon~iIiB 2: 10 1:56 and aoot 2.25 polyvinylchlorideC 2:07 I 2:01 2.23

1.3.13 Other test reaits - The results of the dimensional measuriemets, capsaitanoesIpedance, cold b~end abrasion and corona test results are lasted in Table 1.7,page 73 MAd 711.

1.3.14 Discussion of other test results - The abrasion results mit be ompensatedfor Jacket wail thickeess and braid construction but the results show an outstandingabrasion resistance for polyurtbane. The abrasion resiatance test Mn polyethylenvas meaningless as the wax like material filled the abrasive rods and then wouldnot wear because of its low coelcient of friction. Several samples failed the coldbend test but a pattern of failure was not established.

page 72

Ii

04 ^0 010 -40 NNW 001 0 r-I .40 -*to %0

.. IW*$ 0(%OO O^I ~v;9!.. '0* 0 % 0tci!ýiI 00 i0 " m

-H H Hq tu 41- F- 0'C F4 r-IH1 HrIir A A.- A r'' A 4 A :$jm

rq H H a i s rI0 o

00~~~~~~ 0i 0'0 0' 10 41 0'1000 N -4 a 0 0 4 NO HN 0 0 0000'0%0 0% 00'0 0'38 4'0 1010 0' ()ýh N MC-8 q~c~m% 0"o,0

00 %U^ % 100C-lnN'%4e Ni§2* = *1ý-I 1C'3C- 4N%0 0'0 N'-1O0

gig 0* @ O CS O O ~ . e *0 0 0 S Cý0% 0LA U%t "% S 00%0 0%100 M1N.- HN SO

1t~00s 010 0 8 0 UWIOs OM N 0ot'U %0,0t S10ý10 % 0 0t0

r4 48 &k

C--0%00 1^4ar '0 ('-10 ww 100 1 0 00'' 0110000800000 O&00000000 00 000 0000 00 *08:

A tAA H 0 %V- ' Hir-I I& cA r. miii gill 8i O ~ e S.it

V4 0000'&t 0000 0000 4 00 00 000 8-4C Nl0N -C t -'0 10100

E-~ 0 M,1Ur44Y'IONN -lt ~ t:13tf% rrr NrI N. r--*UU N'e to 1^~v NNN H ""CI- L "0'10000

UN r- CVS . ~ S e0g4 e1-N ee ee' e e C4u% 8Cv , w M a C, I -i A eck

U~~~~~s-I~~~~ 100AC' C--, C''% C-' '1 0 'C- 0C- - 10

*.s4.k^ 0 1^ ON O NO 00 t % 04 o MCI-t o o 86~ -~ go%'Q~O4~~~~~~, .4 s>44 00 NC0.4V* (ri, o'N4' rr1NrI caC- 1auNi fg'0 - o El -t-i , I- m001010RC-C- 01 C- '3 Z.- I(I%r0I0u~4 gtm0'1-%t0% C-1O %

C-N OOOONOO &9 0 90 10 0 *'. 0 4 10 0 *0 6 N 00 4 0 4 'OH90

[ 0 QI A 0, HrE-I- 00 i-s- Hi-I A 8s I -li8-II Ii-rI00H-aI 10,H~r A-H-'-. ofA(78 nIA 1

pe tt *0r tSO .O *cn 04SS~ m m* oc F, -R IX t- O W^*NI egg.ieC-C to tot - V s900 %% k S cvw0%w0',

0H 0 _ _W_$4 "4 gao~ NN IN0.NO% N Mo n nonMaV)e~ n I c MMV

04 - . 0 - NO - N - -C -nL% 0 H H H--t H)Oq

I..

MNN~co CNO44 -f ". N N N RN 0M

j.0 1 4- 4 4,

0%I!nNo!ýqo aan Oto 00 N.I-0 nr04 NOTe-Irom

0 100 '0 t% 0

I n I n * - 0

s~- -II . iJ'0Iruiv a; al z 10 0 ONO'-I- !21r0 NO N 00 * ~ rS c 'o o0 8SO S3oo-O 8 8C e8 SC 88 00 C8 o 08 68(888

O~00OAM M0 00 0 0 %V% 00N 0000cco

000oi w O~Ar 04 0l to wt 00 00 00 100 0 00 tol

4-iA%0 OH c---t ton~ iW% k^ r-4& &;N mil mN'~''

0000 0000 0 00 00 00 00000 00

r o* tot00~ 101- oo t00 00 800 00

'0 C4 " C' MOCY NI NON 0 C41 o4 toto t#c o _t t

on0

0-o~ mNlA% ( r t t4 m

*O'NtO 0~o MO'NNO '0U NO HONR -0 tof .qo.r% -i% -i- lA WlAU Hi- 4lA HA~ 4 l , N

.N MM WN OM Nvb .-r- -% C.- 0 %0 -1:g go ee SC C

%0 oc%--% *0~ c~r % c-c -. o tow

H. r -4 MMl MM 0o'rINN '00MM , MM MM1 H MM MM N

H cm u--b NMM'r R cm 1 4 m

i:1.3.15 Pliability test results - Table 1.8, this page, listethepliability test results

table 1.8 - Pliability test results

[orature oop -.. 4 - F

Sample weight time weight time weight time Jacket Jacket(lbs) (sec) (lbs) (sec) (lbs) (sec) *Mat. Dia.

1 1 16 7 28 8 35 NCPVC 42 4 35 9 74 too stiff NCPVC .5455 4 45 9 75 too stiff Pd]y .5457 4 30 9 58 too stiff Poly .5458 4 26 10 47 too stiff Poly .450

10 4 29 10 42 too stiff Poly .54511 4 35 9 63 too stiff Poly .54512 4 41 9 72 too stiff Poly .54513 4 32 9 63 too stiff Poly .47515 4 34 10 42 too stiff EPoly .54517 4 35 10 61 too qtiff Poly .50018 4 30 4 39 41 57 Urt .54520 4 28 10 47 too stiff E~oly .54521 4 29 10 38 too stiff Poly .4522 15 40 36 78 too stiff Poly 5023 4 58 8 86 10 I 77 Poly .545

4 35 9 70 too stiff PVC .5454 56 8 69 too stiff NCPVC .545

26 4 43 8 59 too stiff PVC .54527 4 31 9 61 too stiff NCPVC .54528 4 28 9 40 too stiff PVC .54529 4 18 9 29 too stiff NCPVC .54530 4 31 9 31 too stiff NCPVC .425

*NCPVC - noncontaminatin4 polyvinylchlorideSPVC polyvinylchloridePoly - polyethyleneEPoIy - elastomeric polyethyleneUrt - polyurethane

1.3.16 Discussio lity test lt - The pliability testresults show the p lab lity or a ca) e, at thd present state of the art,depends mostly upon the jacketing material. The results on sample 18compared to results on other samples, show polyurethane is more pliablethan any of the other material tested. The effect of solid vs strandedconductor stranded braid vs. ribbon braid i hidden by the stiffnessof the polyethylene Jacket. The effect might be noticeable on sampleswith polyurethane Jacket. The results also show the polyurethauejacketed sample was not much stiffer at -40OF than it was at 807F.

Page 75

i ~TIME~S WIRE AND CABLE DIVISIONInternational Silver Company

I 1.3.17 PROJE~CT PERFORMANCE AND SCHEDULEProject Serial No. SF006306U56, -Task 2266

IContract No. : NObsr-87678 Date: March 19 1963

Period covered - 10/1/62 to 12/31/62

I Imrov watrtPHASEI

Manufacture orfliminary &abe

Test adevaluate retiinay cabples

Test samplesEvaluate-results

W atertg t&tet staddcne-w

Ipoewatertightns of21/ eqialnWtRt-1/ if teR-11 euvln

Manur agtre pnrelimitnterym Rabeos

PHSEIIimr e Pagel76

1.4 CONCLUSIONS

1-.41 General conclusions - While the results are not completelevaluated it can be concluded that with slight design changes allthree cable types can be manufactured watertight at 1000 psi andhave decreased attenuation, decreased size, more abrasion resistanceand greater flexibility.

1.4.2 Conclusion from attenuation test results - The attenuation ofRG-21H4/U, RG-217/U, and RG-218/U can be slightly decreased across thefrequency range of 10 MC to 10 GC by designing to a minimum braid factorand can be decreased considerably by using a flat ribbon braid. ;Thehigh frequency attenuation can be greatly improved by using silverplated braid strands.

1.4 .3 Conclusion from watertightness test results - All the cables can bemanufactured watertight at 1000 psi if RG-214/U is redesigned with asolid center conductor. Since a solid center conductor tends to extrudeout of the dielectric core at higher pressures it is necessary tocontinue to improve the watertighting techniques on stranded centerconductors in the hope the stranded conductor will have better bondstrength to the core and produce watertight cables at even higherpressures.1.4.4 Conclusion from abrasion resistance test results - A Dolyurethane

Jacket has vastly better abrasion resistance than any of the otherJacketing materials investigated. The size of the cable can beecreased by using a thinner wall of polyurethane and still have greater

abrasion resistance than cables manufactured with the usual wall thicknessof polyethylene and polyvinylchloride.

1.4.5 Conclusion from pliability test results - While polyethylenejacketed cables are more pliable at room temperatures and cold tempera-tures than polyvinylchloride jacketed cables, a polyurethane jacketyields a cable that is much more pliable at all temperatures.

PART II

2.1 PROGRAM FOR NEXT INTERVAL

2.1.1 Phase I

2.1.1.1 Evaluate test results on study samples - The test resultspresented in this report will be completely evaluated during the firstportion of the next reporting period.

1. 2.1.2 Phase II

2.1.2.1 Desiln of preliminary cables - All preliminary cables will beIj designed and manufacturing will be started.

2.1.2.2 Improve watertightness - Techniques will be perfected formaking stranded center conductors watertight. Techniques will also beperfected to make RG-214/U and RG-218/U watertight at 1000 psi. Thetechniques will be similar to those used to make RG-217/U watertight at1000 psi. Advance cable designs similar to RG-214/U, RG-217/U and RO-218/Uwill lb manufactured in an attempt to make cable watertight at 2500 psi.

2.1.3 Schedule - The schedule for this program is given in theProject Performance and Schedule Chart of page 76.

Page 77

[i[IiFI

IZI APPENDIX

I

I

II

i Page 7 8

I

I1'

iiI

F APPROVAL SHEET

TIMES WIRE & CABLE DIVISION

THE INTERNATIONAL SILVER COMPANY,

358 Hall Avenue

Wallingford, Connecticut

CONTRACTORS APPROVAL

Inspected for Microfilm by: Date:

Approval for Microfilm by: Date:

Reports Microfilmed: Date:

j

"I GOVERNMENT INSPECTORS APPROVAL

•I Reports examined and found satisfactory by:

Date: .. . .... .

SPage 79

!

!

PROGRESS REPORT DISTRIBUTION SCHEDULE

AGENCY OR ACTIVITY NO. COPIES COPY NO.EACH

Chief, Bureau of ShipsWashington 25 D. C.Attn: Code 681A2B IAttn: Code 335 1 2Attn: Code 525R 1 3

Chief, Bureau of WeaponsWashington 25, D. C. 1

Commander New York Naval Shipyard (Material Lab)Brooklyn L, New York 1 5Attn: Code 951

Director, Naval Electronics LaboratorySan Diego 52, California 1 6

Director, Naval Research LaboratoryWashington 25, D. Co 7.

Commanding Officer and DirectorU. S. Navy Underwater Sound Laboratory 1 8New London, ConnecticutAtt: Code 1316

Commanding GeneralU. S. Army Signal Research and Development Labs 1 9Fort Monmouth New JerseyAttn: SIGRA/SL-PEE

Commanding GeneralFrankfort Arsenal 0Philadelphia, Pennsylvania

Commanding General 0Redstone ArsenalHuntsville, Alabama

Commanding Officer , 0Diamond Fuse LaboratoriesConnecticut Ave., and Van Ness Street, N. W.Washington 25, D. C.

Page 80

1

L

AGENCY OR ACTIVITY NO. COPIES COPY NO.EACH

Commanding General 1 10Wright Air Development CenterWright-Patterson Alir Force Base, OhioAttn: Mr. Leslie Brewster

Commanding General 1 11Rome Air Development CenterGriffiss Air Force Base, New YorkAttn: Mr. Gubbins

Commanding General 0Air Force Cambridge Research CenterAir Research and Development CommandL. G. Hanscom FieldBedford, Massachusetts

Electric Boat Division 1 12General Dynamics CorporationGroton, Connecticut

Advisory Group on Electronic Division 5 13-153+6 BroadwayNew York, N. Y.Attn: Mr. W. A. Miller

Commanding Officer 1 16Mare Island Naval ShipyardVallejo CaliforniaAttn: 6ode 270

Commanding Officer 1 17"Pearl Harbor Naval ShipyardPearl Harbor HawaiiAttn: Code K70

Commanding Officer 1 18Portsmouth Naval ShipyardPortsmouth, New HampshireAttn: Code 270

Page 81