Un-Coop Your Poop: Build a Chicken Tractor

-

Upload

chelsea-green-publishing -

Category

Documents

-

view

218 -

download

0

Transcript of Un-Coop Your Poop: Build a Chicken Tractor

-

7/30/2019 Un-Coop Your Poop: Build a Chicken Tractor

1/10

Harvey Ussery

An all-natural approach to raising chickensand other fowl for home and market growers

ith information on building

soil fertility, replacing

urchased feed, and working

with poultry in the garden

Te Small-Scale

Poultry Flock

FOREWORD BY JOEL SALATIN

-

7/30/2019 Un-Coop Your Poop: Build a Chicken Tractor

2/10

If you day-range your flock, or use temporary fenc-

ing anchored on the henhouse to rotate the flock over

fresh plots, the birds always return to the same shelter

at night. If you pasture them farther afield, however,

you will need a mobile shelter of some sort to rotate

them to new ground, and to shelter them at night or

when it rains. Ive seen hundreds of mobile coops,

and no two are ever the same.1The design you come

up with will depend on the size of your flock, how

you intend to use their services, leftover material

from other projects begging to be used, the nature o

your climate and groundperhaps on how whimsi

cal you happen to be feeling.

The first movable shelter I built was a copy of th

11 | MOBILE SHELTERS

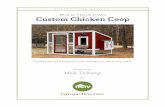

Fig. 11.1 My friend Jon Kinnard combined whimsy, utility, and the urge to recycle into this micro-flock mobile shelter. It is entirely sel

contained, with feed storage and nest in the bin under the hinged metal roofing and roosts in the rest of the shelter. PHOTO COURTESY OF DEBORA

MOORE

-

7/30/2019 Un-Coop Your Poop: Build a Chicken Tractor

3/10

M O B I L E S H E L T E R S 109

classic Polyface designa contemporary example is

shown in figure 11.2. If Joel Salatins mobile pens can

produce tens of thousands of market broilers a year

to put money in the bank, surely all of us creative

amateurs can come up with shelters that allow our

birds continual access to fresh grass while protecting

them from opportunists on the prowl.

Designing a Pasture Shelter

Below are some issues to ponder as you plan your

mobile shelter project. It could help with your

planning to have a look as well at appendix C for

design and materials considerations and step-by-step

construction of my most recent all-purpose pasture

shelter.

Pasture Pens and Pasture SheltersMicro-flocks on lawn or pasture are often confined

entirely to the shelter, which is moved frequently to

new grass. The larger the flock size, however, the

larger the protected foraging space you will want to

provide the birds. As discussed in the previous chap-

ter, I use electric net fencing for giving my birds an

extensive area to roam outside the shelter. If you do

not use electronet, however, you might provide a

pasture penusing a set of light wooden frame panels

with chicken wire, easily locked together using bolt

with wing nuts, and just as easily disassembled fo

moving. Whether you need to attach a frame ove

the top of the pen will depend on aerial predation

where you are.

Cody, a friend of mine, came up with an inge

nious pasture shelter-and-pen set for her flock of hal

a dozen layers, shown in figure 11.4: She mounted

a small shelter (2 by 3 feet) on a landscaper

wagon, complete with roosts, nests, and a ramp sh

lowersusing a nylon strap attached to the ramp tha

runs right through the shelterto release the flock in

the morning. She made a separate 8-by-8-foot pen, 4

feet high and with a cover of wire over the top, and

mounted on small wheels for moving. Framed into

one side is a narrow opening into which the door o

the shelter docks. In the morning Cody moves the

pen onto fresh grass; wheels the shelter into dock

ing position; then lowers the shelters ramp to releas

the hens into the pen. At dusk they retreat into the

shelter on their own, and Cody pulls the ramp into

place with its remote-control strap, to guard agains

unwanted night visitors.

Trade-Offs: Size, Weight, and Stability

The size of the shelter will be determined by the size

of the flock it will shelter and its intended use. At the

low end of the scale, a shelter could be designed as a

Fig. 11.3 As you can see, it is possible to build the same-sized pe

with much lighter framing, making good use of diagonal bracing.

Fig. 11.2 A movable pasture shelter based on the classic Polyface-

style broiler pen. Note the 2-by-4 constructionthis was a first project

for its builders and is overstructured.PHOTO COURTESY OF SAMUEL MATICH

-

7/30/2019 Un-Coop Your Poop: Build a Chicken Tractor

4/10

110 B A S I C C A R E

chicken tractor, holding six to ten tiller chickens and

sized to work a single garden bed.

As with the main coop itself, size has everything to

do with whether it will be sleeping quarters only for

a flock that is ranging outside during the day, or will

confine the birds full-time. As said, the first mobile

shelter I used was a copy of the classic Polyface model,

10 feet by 12 (see figure 11.2)I used it to raise

fifty comparatively inactive Cornish Cross broilersat a time, about 2 square feet each. When I later

used that same shelter for confined layers, I limited

the number of hens to sixteen7 square feet each.

Remember that you will be more likely to rotate your

birds to fresh grass as frequently as you should if its

easy to move their shelter. It might make sense to split

the flock into two smaller shelters rather than keep

ing them all in one large one that is more difficult to

move.

The heavier a shelter, the more difficult, and possibly

the more dangerous, it is to move. On the other hand

the lighter it is, the more likely it is to be tossed into

the next county by a rambunctious wind. Of course

it would be possible to anchor even the lightest shelte

to the ground; but again, the more difficult we makea moveundoing and redoing a complex anchoring

routinethe more inertia will inhibit frequent moves

Shape also plays a part in stability in heavier winds

I have found the boxier-type shelters with a highe

profile catch the wind, while hoop or A-frame shape

tend to keep their feet on the ground. (The classic

Fig. 11.4 Cody Leesers ingenious design for a small wagon-mounted shelter and a separate wheeled pasture pen. She moves the pen eac

morning, then docks the shelter onto the pen and releases her hens for the day.

-

7/30/2019 Un-Coop Your Poop: Build a Chicken Tractor

5/10

M O B I L E S H E L T E R S 111

Polyface model, 10 by 12 feet, is indeed rectangular in

shape, but it is only 24 inches high and stable even in

strong winds.) Materials choices (see below) have the

biggest impact on weight of the shelter.

Remember that diagonal bracing greatly reduces

weight of the frame. I framed my first shelters in 2-by-

4s exclusively, all at right anglesclumsy, inelegant,and balky about moving. I discovered that even large

shelters could be made with much lighter but well-

braced framing, like the Polyface-style pen in figure

11.3. I also found that smaller shelters do not need

full 2-by-4 framing even for the bottom rails. For a

shelter of this sizeat present I have two of about

8 by 4 foot, another 10 by 3I now rip 2-by-4s to

2 inches to use as the bottom rails. The remain

ing 1-inch strips I use for the verticals and diagona

bracing; that is to say, the weight of the entire frame

is now not much more than the bottom rails alone

before this modification.

Note as well that you can reduce weight bypositioning bracing where possible to do double

duty as roosts. In a larger A-frame, for example

you will want to include collar ties, the horizonta

pieces that tie the rafters together, providing greate

rigidity. Position them low enough below the peak to

allow use as roosts by two or three hens. Horizonta

Andy Lee introduced the idea of the chicken

tractor (or as I call it, a cruiser)a small, easily

moved chicken shelter sized to fit a single garden

bed, a key to putting chickens to work in the

garden. A few laying hens inside till and fertilize

the bed while finding free food in the form of

worms and slugs and snailsand laying eggs

but have no access to immediately adjacent beds.

Since a tractor gets maneuvered in tight

spaces and needs to be moved frequently, it is

better to make it small and nimble. Dont forget

to provide enough cover on parts of the sides

and top for shelter from blowing rain, and for

shade in hot weather.

Chicken Cruiser

Fig. 11.5 My most recent chicken cruiser, made for

maneuvering in tight garden spaces.

Fig. 11.6 A cruiser keeps the chickens working in a single

bed while preventing access to adjacent ones. The lids on this

unitone aluminum roofing, the other wire on wood framing

are separately hinged for access to any part of the interior.Nestboxes are recycled plastic milk crates attached to the

framing.

-

7/30/2019 Un-Coop Your Poop: Build a Chicken Tractor

6/10

112 B A S I C C A R E

stringers reinforcing the frame can also be positioned

for use as roosts.

A final option for reducing weight is to use

chicken wire as much as possible in lieu of solid

material, consonant with the need for protection

from rain, sun, and sharp chilly winds in part of the

shelter. In many shelters wire mesh replaces at least

part of the roof, and much of the sides. Use of wire

has the further advantage of maximizing airflow and

sunlight into the interior.

Wheels

I prefer wheels for all my larger shelters. Instead of

installing axles across the entire width of the shelter,

I permanently install half-inch bolts in the bottom

rail at each corner, using nuts, flat washers, and lock

washers. Its easy to use a single set of wheels for

multiple shelters, popping them onto the bolts and

locking them down with wing nuts. If your ground

is nice and even, an 8-inch wheel might work foryou. I found that, with an 8-inch wheel, the bottom

rear rail of the shelter hung up on tussocks of grass.

The additional clearance with a 10-inch wheel makes

moving much easier on my pasture.

If wheels are to be permanently installed, bicycle

wheelsor other large wheels looking to be recycled,

like the front wheels from an old tractormak

moving over uneven ground easiest of all.

Does Your Shelter Need a Floor?The whole idea of using a mobile shelter is to give it

occupants access to fresh grass, so it usually make

sense to make the shelter floorless. Some manage

ment choices, however, might make a floor advisable

For example, young birds are easier to move with no

risk of injury from the rear bottom rail (see below) i

on a floor. If you do install a floor in your shelter, I

recommend using wire or plastic mesh, as dropping

will accumulate on a solid floor, requiring frequen

clean-out from the tight confines of the interior.

Predators

If the shelter is inside an electric net perimeter, you

will not have to worry about digging predators

However, if there are large owls in your neighbor

hood, close the shelter at nightnocturnal owls hun

on the wing, but also land and walk around looking

for prey.

If the shelter is not inside an electric net, remem

ber that raccoons and dogs may tear a hole in chicken

wirein the case of 2-inch mesh, a raccoon may

feed on its victim by tearing it apart right through

the wire. If you are designing for such threats, use

half-inch hardware cloth instead, well secured to the

framing. Foil digging predators with a wire mesh floo

(2-by-4 welded wire allows both access to the gras

and protection from digging predators)or by laying

18-inch panels of chicken wire on light wood framing

flat on the ground, entirely around the shelter.

The best option of all is to wire for defense, a

in figure 11.8: Run some single-strand electric wire

around the entire shelter, standing it off from thesides with plastic or porcelain insulators, one at nose

level and ideally another about 12 inches up. An

inexpensive charger powered by a 9-volt battery i

sufficient to charge such a small run of wire. Whethe

dog or raccoon or digging fox, the exploratory probe

of choice is the supremely sensitive noseonce it hit

Fig. 11.7 Diagonal framing in this A-frame shelter provides

rigidity without excess weight. Note the collar ties, set low enough

to serve double duty as roosts.

-

7/30/2019 Un-Coop Your Poop: Build a Chicken Tractor

7/10

M O B I L E S H E L T E R S 113

the wire, the visitor will seek dinner or entertainment

elsewhere.

Nests and Other ThoughtsIf the shelter will house layers, you should add nest-

boxes, which can be mounted above ground level on

existing framing pieces. A hinged doorto shield the

nest from rain but give you access from the outside

is a better option than crawling into the shelter to

collect eggs. If hens are inclined to roost and poop

in the nest, an additional hinged cover to swing into

place at night may be in order.

Install a doorin the shelter even if you rarely use

it (such as when the shelter is inside an electric net).

Latching it will help you get ready to move the shelter

from one electronetted area to another, do a census or

selection, or isolate birds for culling.

In smaller, rectangular shelters, often the only

door is a hinged lid giving access to the interior.

Remember that the lid can be popped open by a wind

gust, maybe even ripped off the hinges, and providea positive catch for locking it shut. (The country-boy

version is a heavy rock set on the lid.)

Even a shelter heavy enough to withstand ordinary

winds may flip when a gale blows. When weather

predictions here are for winds well beyond the ordi-

nary, I temporarily nail my shelters down using an

earth anchoressentially, an abbreviated auger screw

on the end of a steel rod with an eye hook on its top

end. Once the rod is screwed solidly into the earth

I tie or wire one of the bottom rails to its eye hook

Another way to temporarily secure a shelter is to hang

a couple of 5-gallon buckets from the framing inside

and fill them with waterthats over 80 pounds

using a garden hose. Just empty the buckets when it

time to move the shelter.

Remember your chickens need to dust-bathe

Since there is no opportunity for them to do so i

constantly on fresh grass, either provide an onboard

dustboxor set one out for them on the pasture anytime

there is no possibility of rain.

Most shelters are designed to be used in the warmeparts of the year only. If you are going to house your

birds in the shelter in winter as well, you will need to

make at least the part where they sleep a good dea

tighter against the winter winds, snow, and rain. A

noted in chapter 6, however, the shelter should stil

allow a lot of airflow.

Fig. 11.8 Wiring for defense keeps predators away.

Fig. 11.9 Hinged access from the outside makes it easy for Annec

and Camille to collect eggs from my latest A-frame shelter.

-

7/30/2019 Un-Coop Your Poop: Build a Chicken Tractor

8/10

114 B A S I C C A R E

Materials

Mobile shelters have been made in just about every

material other than titanium. Which materials you

choose will depend on which you feel comfortable

working with, what might be in your recycle pile, and

considerations of weight and climate.

Wood

I am more comfortable working with wood, so all my

shelters have had wooden frames, with one exception

a hoop structure based on half-inch solid fiberglass rods

as purlins and as arches, anchored into a wooden foun-

dation frame. I dont use any pressure-treated wood

anywhere on the place remotely connected to produc-

ing food. To help prevent rot, I coat all framing pieces

in direct contact with the ground with nontoxic sealer,

renewed periodically as needed. Using a highly rot-

resistant woodeastern red cedar in my areawould

be a better option if you can get it. You might design so

that the bottom railsthe parts most subject to rot

can be replaced without taking apart the entire shelter.

Or mount the frame on plastic rails. (See below.)

When out of service over the winter, a wood-frame

shelter should always be set up on blocks. You might

even want to block each corner after each move, to

keep the rails out of contact with the ground.

PlasticBeginners often think of lightweight 1-inch plas-

tic pipe or the like for framing a shelter. Ive never

seen one that inspired much confidencesuch plas-

tic is pretty fragile and breaks down in sunlight.2

Heavier plastic pipe (Schedule 40 PVC, for example)

is another matterIve corresponded with many

flocksters who have used it for shelters that are bothsufficiently rugged and easily moved. (See figures 6.8

and 6.9 for examples that could be scaled down for

smaller shelters.) Ive never used plastic pipe myself.

This year I experimented with recycled plastic

decking3 to make two 6-by-10 pasture shelters for

nurturing young birds through the vulnerable (to

aerial predation) phase. I framed them entirely in thi

recycled material, on the assumption that it would las

a lot longer than wood. The jury is still out regarding

how well plastic decking serves as structural material

It certainly is heavythe lighter one (24 inches high

to accommodate chickens) will move without wheels

with some persuasion; the heavier (36 inches high

for geese) requires wheels. So far even the heavies

winds havent fazed them.

Im especially pleased with the new chicken tracto

I made last spring and used the entire growing season

Its mounted on recycled plastic decking boards to

prevent rot in its wooden frame and to make it easier

to slide the shelter down the garden beds.

Metal

Electrical conduit is light and easily shaped. You may

see references to its use for framing mobile shelters

but most reports Ive read about it have been nega

tive. Both angle iron and rebarconcrete reinforcing

rods made of soft ironmake sturdy frames for thos

with welding skills and equipment.

Ive heard from a lot of flocksters who use cattle

panels to frame hoop-style shelters, either secured to

a wooden base or welded to metal runners. The stan

dard length of these panels is 16 feet; height varie

by species of livestock, but in this application likely

52 inches; steel wire should be heavy enough (likely

4-gauge) to make a semirigid fencing section welded

into a 6-by-8-inch mesh. Typically the panels are

attached to one side of a wooden frame (or welded

onto a metal one); bent in the long dimension into

a hoop attached to the frame on the other side; and

covered with a tough, flexible, opaque cover. The

result has the usual trade-offs among weight, mobil

ity, and stability in the wind but typically has considerably more capacity than shelters framed in othe

materials.

Covers

If light plastic pipe is a bad idea, such pipe covered

with lightweight plastic tarps makes absolutely th

-

7/30/2019 Un-Coop Your Poop: Build a Chicken Tractor

9/10

M O B I L E S H E L T E R S 115

worst combination. Not only do such tarps break

down in sunlightand shred, and blow in the

windbut the combination is so light, even a sneeze

will move it.

Heavy canvas tarps, like the one in figure 6.8, are

tough and weatherproof and make a better choice

than plastic tarps. There is one option in plastic

covering worth considering, however: 24-mil woven

polyethyleneincredibly tough, durable plastic

sheeting interwoven with a fiber mesh. Its available

in semi-translucent white and a number of colors,

including one that is black on one side, silver on the

other. The side you face to the outside depends on

whether you need to reflect or gain solar heat to the

interiorin my climate, putting the reflective sid

out is the obvious choice.4Did I say tough? I onc

had an 8-by-8 A-frame shelter covered in woven

poly, which got smacked tumbling by a gust of wind

through 30 yards of underbrush. The result was on

broken strut only (a testament to diagonal bracing)

but not a single tear in the poly.

I have used metal roofing for the solid covering on

a number of my shelters. Aluminum roofing is lighte

but more expensive; steel, heavier but cheaper. Stee

roofing is available either as plain galvanized, or with

a baked-on enamel finish guaranteed for twenty-fiv

years. Though the galvanized is cheaper, the pain

you would have to apply to extend service life would

Fig. 11.10 An 8-by-8 A-frame mobile shelter covered with 24-mil woven poly. Ten years old at the time of this photo, it is still going strong.

-

7/30/2019 Un-Coop Your Poop: Build a Chicken Tractor

10/10

116 B A S I C C A R E

over time cost more than the initial investment in the

baked finish.

I used baked-enamel steel roofing as the cover on

the shelter in figure 11.9. See as well appendix C for

my reasons for choosing metal roofing over 24-mil

poly.

Fasteners

I strongly advise against assembling your mobile

shelter with nails, which work loose over time as the

frame is yanked around; use screws instead. I prefer

the self-drilling types such as coarse-threaded deck-

ing screws, which dont require pilot holes (as do

conventional wood screws) and thus save time. (I do

drill a pilot hole for a deck screw going into the last 3

inches of a framing piece, to prevent splitting.) Deck

screws with Phillips heads are available galvanized or

coated. The best screws of all are stainless-steel deck-

ing screws with star-drive heads. Though a lot more

expensive than the alternatives, their faster, slip-

free drilling and rustproof durability are important

considerations for a shelter requiring a lot of screws

and facing prolonged weathering.

Moving the Shelter

Twisted wire or cable, run through a piece of scrap

garden hose, makes a convenient pull for moving

the shelter. A wire pull can be permanently attached

to both ends of the shelter; or a single pullwith

twisted loops at either end that slip into open eye

hooks screwed into the bottom railcan be used on

multiple shelters.

When moving a floorless shelter with young o

careless birds inside, watch the trailing edge of the

bottom frame. Usually the chooks come running a

fresh grass is exposed, but those who dither at the

rear may get a leg caught between the ground and

the moving rail. Actual injuries are rare if you pul

slowly, and stop and release a hapless bird at the firs

shriek of distress.