Two-Dimensional Modeling of Volatile Organic Compounds Adsoprtion Onto Beaded Activated Carbon

-

Upload

imranul-islam -

Category

Documents

-

view

3 -

download

0

Transcript of Two-Dimensional Modeling of Volatile Organic Compounds Adsoprtion Onto Beaded Activated Carbon

Two-Dimensional Modeling of Volatile Organic CompoundsAdsorption onto Beaded Activated CarbonDereje Tamiru Tefera,† Masoud Jahandar Lashaki,† Mohammadreza Fayaz,† Zaher Hashisho,*,†

John H. Philips,‡ James E. Anderson,§ and Mark Nichols§

†University of Alberta, Department of Civil and Environmental Engineering, Edmonton, AB T6G 2W2, Canada‡Ford Motor Company, Environmental Quality Office, Dearborn, Michigan 48126, United States§Ford Motor Company, Research and Advanced Engineering, Dearborn, Michigan 48121, United States

*S Supporting Information

ABSTRACT: A two-dimensional heterogeneous computational fluid dynamicsmodel was developed and validated to study the mass, heat, and momentumtransport in a fixed-bed cylindrical adsorber during the adsorption of volatileorganic compounds (VOCs) from a gas stream onto a fixed bed of beadedactivated carbon (BAC). Experimental validation tests revealed that the modelpredicted the breakthrough curves for the studied VOCs (acetone, benzene,toluene, and 1,2,4-trimethylbenzene) as well as the pressure drop andtemperature during benzene adsorption with a mean relative absolute error of2.6, 11.8, and 0.8%, respectively. Effects of varying adsorption process variablessuch as carrier gas temperature, superficial velocity, VOC loading, particle size,and channelling were investigated. The results obtained from this study areencouraging because they show that the model was able to accurately simulatethe transport processes in an adsorber and can potentially be used for enhancingabsorber design and operation.

■ INTRODUCTION

Adsorption onto activated carbon has been widely used forcontrolling emissions of volatile organic compounds (VOCs) atlow concentrations because of its cost effectiveness, highcapturing efficiency, and regenerability of the adsorbent forreuse.1,2 The fixed bed is one of the most widely used reactorconfigurations in both small and large scale VOC adsorptionunits. Therefore, detailed knowledge of transport phenomenain such an adsorber is essential for its proper design,performance analysis, and optimization. Earlier studies3−7 thatmodeled fixed bed absorber dynamics in the gas phase focusedon axial variation of adsorption and flow parameters. However,there is still a need for models that can accurately predict thetwo-dimensional variation of transport variables, particularlyduring adsorption from dilute gas streams. Experimentalinvestigations have confirmed that conventional one-dimen-sional models are not sufficient to describe transportphenomena in a fixed bed adsorber due to the radial variationof flow dynamics in addition to the axial one.8−10 Thetemperature, velocity, and concentration gradients in the radialdirection are significant and need to be accounted for,particularly when the particle to bed diameter ratio is lessthan 30.11,12 Daszkowski and Eingenberger13 also showed thatthe radial heat transfer could be accurately modeled only ifradial flow variation is taken into account. Measurements of

radial velocity and concentration profiles showed a significantdifference between the center and periphery of the reactor.14,15

Measuring radial variation of flow parameters is difficult.Therefore, developing a mathematical model that canaccurately predict the two-dimensional variation of transportphenomena during adsorption of VOCs, particularly fromdilute gas streams, is useful for improved design andoptimization of fixed bed absorbers.Automotive painting booths are the main source of VOC

emission during vehicle manufacturing. These emissions, whichare typically captured using adsorption, consist of organiccompounds containing different functional groups and having arange of boiling points and adsorption and desorptionproperties.16,17 Hence, it is useful to understand the adsorptiondynamics of VOCs and the effect of operation conditions onthe adsorber performance. The main objective of this study isto develop a comprehensive model that can accurately simulatetransport phenomena during VOC adsorption in a fixed bedadsorber. For this purpose, a two-dimensional model, solvedusing the finite element method, was developed and validated

Received: May 28, 2013Revised: August 28, 2013Accepted: September 17, 2013Published: September 17, 2013

Article

pubs.acs.org/est

© 2013 American Chemical Society 11700 dx.doi.org/10.1021/es402369u | Environ. Sci. Technol. 2013, 47, 11700−11710

Table 1. Model Parameters

parameter description value/equation unit source parameter descriptionvalue/equation unit source

b temperature-dependentLangmuir affinitycoefficient

m3/kg ref 32 kr radial thermaldiffusioncoefficient

W/m K eq 22a

bo pre-exponentialconstant inLangmuir isotherm

3.38 × 10−7 for acetone, 1.45× 10−7 for benzene, 1.38 ×10−7for toluene, and 1.54 ×10−11 for TMB

m3/kg SupportingInformation

kw wall heattransfercoefficient

(2.4/dp)Kbed +0.054(Kf/dp)(1 −(dp/Dp))RepPr

1/3

1 ref 38

c gas phaseconcentration

kg/m3 eq 1 IP ionizationpotential

eV ref 33

CF empirical correctionfactor forForchheimer’s dragcoefficientcalculation

1 eq 32 MA andMB

molecularweight ofadsorbateand air,respectively

g/mol

co inlet gas concentration 1000 ppmv user defined N number ofdata points

cs adsorbed phaseconcentration

kg/m3 eq 7 P pressure Pa eq 26

cse equilibrium adsorbedphase concentration

kg/m3 eq 9 Peo molecularpecletnumber forheat transfer

VsρfCpfdp/Kf 1 ref 39

cso adsorbed phaseconcentrationequilibrium withinlet gas phaseconcentration

kg/m3 eq 10 Pr Prandtlnumber

μfCpf/kf 1 ref 38

cpf gas heat capacity 286.9(3.33 + 0.000575T2

−(1600)/(T2))J/kg K ref 34 Q gas flow rate 10 SLPM

Cpp adsorbent particle heatcapacity

706.7 J/kg K ref 35 qe adsorbentequilibriumcapacity

g/g eq 17

Cv effective volumetricheat capacity of thesolid−gas system

J/(m3 K) eq 20 qm adsorbentmaximumequilibriumcapacity

g/g SupportingInformation

D symmetric massdispersion tensor

cm2/s eq 5 r variable radialdistance

m

DAB molecular diffusivityof the adsorbate inair

cm2/s eq 15 R radius of theadsorber

Db/2 m

Dax axial dispersioncoefficient

cm2/s eq 6b Rep particleReynoldsnumber

ρfVsdp/μf 1 ref 19

Db reactor diameter 0.01524 m measured Rg ideal gasconstant

8.314 J/(molK)

Deff effective diffusioncoefficient

cm2/s eq 14 S momentumsink

N/m3

Dk Knudsen diffusivity cm2/s eq 16 Sc Schmidtnumber

μf/(ρfDAB) 1 ref 19

dp average particlediameter

0.00075 m ref 17 Sh heat source J/(m3 s) eq 24

Dr radial dispersioncoefficient

m2/s eq 6a Sm mass sink kg/(m3 s) eq 1

F body force N/m3 eq 26 t adsorptiontime

s eq 1

ΔHad heat of adsorption kJ/mol eq 25 T temperature K eq 19

ΔHvap adsorbate heat ofvaporization

kJ/mol refs 33−35 Tinlet gas inlettemperature

300 K BC

J shear stress N/m2 eq 27 Tw walltemperature

295 K BC

K bed permeability m2 eq 30 u gas flowvelocityvector

m/s eq 26

kax axial thermal diffusioncoefficient

W/m K eq 22b |v| resultantvelocity

m/s eq 28

kb stagnant bed thermalconductivity

W/m K eq 23 Vpore adsorbent porevolume

0.57 cc/g measured

kef symmetric thermaldiffusion coefficient

W/m K eq 21 Vs superficialvelocity

4Q/(π(Db)2) m/s calculated

Environmental Science & Technology Article

dx.doi.org/10.1021/es402369u | Environ. Sci. Technol. 2013, 47, 11700−1171011701

using measured data. The model was also used to examine theeffect on the adsorber performance of variation of relevantoperation conditions, such as carrier gas temperature, super-ficial velocity, adsorbate loading, and adsorbent particle size.

■ MODEL DEVELOPMENT AND VALIDATION

Physical Model and Assumptions. The simulatedadsorber consisted of a reactor with a 0.76 cm inner radius(R) containing a 12-cm-long fixed bed of BAC with 0.75 mmmean particle diameter (dp). A 10 standard liters per minute(SLPM) air stream containing 1000 ppmv of the VOC enteredfrom the top of the reactor at a superficial velocity (Vs) of 0.914m/s and exited from the bottom of the reactor. Majorassumptions used in model development include negligiblevariation of flow properties in the angular direction, negligibleadsorption of the carrier gas, ideal gas behavior, and symmetricflow conditions and geometry along the adsorber center plane.Governing Transport Phenomena. Adsorbate Mass

Balance. Derivation of the governing equation for the masstransport is based on the concept that the fixed bed of porousadsorbent particles consists of a stationery (solid adsorbent)phase and a mobile (gas) phase. The adsorbate is transported inthe mobile phase by convection and dispersion. The advection-dispersion transport equation is derived based on theconservation of adsorbate mass flux entering and leaving asmall representative element of the bed (eq 1). Definitions andvalues of the model input parameters and variables arepresented in Table 1.

ε ε∂∂

− ∇ ∇ + ∇ + =Ct

D c uc S( ) ( ) 0r r m (1)

The bed porosity, εr, varies with radial distance from the reactorcenter (eqs 2, 3, and 4)18

ε ε= + * −⎛⎝⎜⎜

⎛⎝⎜⎜

⎞⎠⎟⎟⎞⎠⎟⎟f

R rd

1 exp 6r bp (2)

where

ε = +−⎜ ⎟

⎛⎝

⎞⎠

0.3790.078

1.8Dd

bb

p (3)

εε

=−

f1 b

b (4)

and

=D

DD

0

0r

ax (5)

where the radial and axial mass dispersion coefficients19,14 aregiven by eqs 6a and 6b, respectively.

αε

= +⎛⎝⎜

⎞⎠⎟D

ScRe D8r 0

p AB

b (6a)

αε

= +⎛⎝⎜

⎞⎠⎟D

ScRe D2ax 0

p AB

b (6b)

The governing transport equation in the solid phase(adsorbent) is similar to that in the gas phase except that thecontribution of convection and dispersion to the adsorbatetransport is negligible and the main mass transport takes placeby diffusion of the adsorbate in the porous adsorbent particles.Such diffusive transport takes place by pore and/or surfacediffusion, which can be modeled at the individual particle levelbut is time-consuming and computationally intensive. Alter-natively, an approximation using the linear driving force(LDF)20 model can be used (eq 7) to describe the diffusionof the adsorbate in the adsorbent. The LDF has similaraccuracy to more complex diffusion models in predicting masstransfer in the adsorbent particle.20−29 Coupling of the solidand gas phase governing equations is made through source/sinkterms, whereby the mass sink in the gas phase is equal to themass source in the solid phase.

Table 1. continued

parameter description value/equation unit source parameter descriptionvalue/equation unit source

kf air thermalconductivity

(1.521 × 10−11)T3 − (4.8574× 10−8)T2 + (1.084 ×10−4)T − 0.00039333

W/m K ref 36 wmic averagemicroporewidth

1.02 nm measured

kov overall mass transfercoefficient

1/s eq 10 Z axial distance m

kp adsorbent particlethermal conductivity

0.17 W/m K ref 37

Greek symbols

parameter description value/equation unit source

α polarizability cm3 × 10−24 ref 33

α0 empirical correction factor for mass diffusion terms 20 1 ref 19

β Forchheimer’s drag coefficient kg/m4 eq 31

γ surface tension mN/m ref 33

εb bulk bed porosity 1 eq 3

εp particle porosity 1 eq 11

εr bed porosity as a function of radial distance from the center eq 2

μf gas viscosity Pa s COMSOL material database

ρb bulk bed density 606 kg/m3 measured

ρf gas density kg/m3 COMSOL material database

ρp particle density kg/m3 eq 12

τp particle tortuosity 1 eq 13

(∑v)A, (∑v)B atomic diffusion volumes 1 ref 30

Environmental Science & Technology Article

dx.doi.org/10.1021/es402369u | Environ. Sci. Technol. 2013, 47, 11700−1171011702

∂∂

=Ct

Ssm (7)

Sm is proportional to the adsorbed phase concentrationgradient, and mass transfer will take place until equilibrium isreached (eq 8).

= −S k c c( )m ov se s (8)

ρ=c qpse e (9)

The overall mass transfer coefficient, Kov, accounts for theexternal (gas−solid interface) diffusion, pore diffusion, andsurface diffusion mass transfer resistances:19

ε

τ=k

C D

C d

60ov

p o eff

p so p2

(10)

ε ρ= Vp pore p (11)

ρρ

ε=

−1pb

b (12)

τε

= 1p

p2

(13)

The effective diffusion coefficient is the resultant of molecularand Knudsen diffusion coefficients:

= +D D D1 1 1

eff AB k (14)

where DAB30 and Dk

31 are expressed as

=∑ − ∑

−

+

D TP v v

10(( ) ( ) )

M MM M

AB3 1.75

A0.33

B0.33 2

A B

A B

(15)

=D rT

M9700k p

A (16)

A temperature-dependent Langmuir isotherm (eq 17) was usedto model the equilibrium conditions because of its accuracy atlow concentrations.32

=+

qq bc

bc1em

(17)

=−Δ⎛

⎝⎜⎜

⎞⎠⎟⎟b b

HR T

expoad

g (18)

Energy Balance. In balancing the energy fluxes from andinto a small representative element of the bed, two basicassumptions were made, namely, thermal homogeneitybetween the solid and gas phases and negligible viscous heatdissipation. Heat transport takes place by convection anddiffusion (eq 19), similar to mass transport.

ρ∂∂

+ ∇ − ∇ ∇ =CTt

C u T k T S( )v pf f ef h (19)

The effective heat capacity of the solid and gas phases, Cv, iscalculated using eq 20.

ε ρ ε ρ= − +C C C(1 )v b p pp b f pf (20)

Kef is the symmetric thermal diffusion tensor:

=KK

K

0

0efr

ax (21)

The axial and radial thermal dispersion coefficients (Kax and Kr)account for the stagnant bed conductivity, Kb, and the effect ofconvection on the thermal conductivity (the second term in eqs22a and 22b).18

= +K K Pe k18r b o f (22a)

= +K K Pe k12ax b o f (22b)

ε ε= − +K k k(1 )b b p b f (23)

Because other sources such as viscous dissipation areconsidered negligible, the main heat source to the systemduring adsorption is the heat of adsorption (eq 24):

= −ΔS Hdcdt

( )h ads

(24)

The heat of adsorption is dependent on the properties of theadsorbate and adsorbent:33

α γΔ = + + Δ − −

−

H H

w

103.2 1.16 0.76 3.87IP 0.7

26.1

ad vap

mic (25)

Momentum Balance. The gas is assumed Newtonian, andits flow behavior in porous media depends on properties of thesolid matrix and the flowing gas and the flow velocity. Theporous matrix is stationary, and its linear momentum isnegligible; hence the most significant interaction forcescontributing to momentum dissipation are the friction forcesthat the gas encounters at the boundaries of the pore. In thisstudy, a modified momentum balance equation (eq 26) whichaccounts for Darcy and Brinkman viscous terms, Forchheimerinertial term, and Navier−Stokes’ convective term18 was usedto model the non-Darcy gas flow in the BAC.

ρε ε

∂∂

+ ∇ = −∇ + ∇ − +⎜ ⎟⎛⎝⎜⎛⎝

⎞⎠

⎞⎠⎟

ut

uu

P J S F( )f

r r (26)

where the shear stress is defined in terms of gas viscosity (eq27).

εμ μ= ∇ + ∇ − ∇⎜ ⎟

⎛⎝⎜

⎛⎝

⎞⎠⎞⎠⎟J u u u I

1( )

23

( )r

fT

f(27)

The momentum sink of the flow in a fixed bed of porousadsorbent is accounted for by Darcy’s friction loss,Forchheimer’s inertial term, and an adsorption sink:

μβ

ε= + | | +

⎛⎝⎜

⎞⎠⎟S

Kv

Suf m

r (28)

The continuity equation accounts for the compressibility of thegas and the adsorption sink:

ε ρρ

∂∂

+ ∇ =t

u S( )

( )r ff m (29)

The bed permeability (K) is a function of particle diameter andbed porosity:18

Environmental Science & Technology Article

dx.doi.org/10.1021/es402369u | Environ. Sci. Technol. 2013, 47, 11700−1171011703

ε

ε=

−K

d

150(1 )b

3p

2

b2

(30)

Forchheimer’s drag coefficient (β) is a function of bedpermeability and particle and bed diameter:18

β ρ=C

KfF

(31)

= −⎛⎝⎜⎜

⎛⎝⎜

⎞⎠⎟⎞⎠⎟⎟C

d

D0.55 1 5.5F

p

b (32)

Initial/Boundary Conditions and Input Parameters. Formass transfer, a concentration boundary condition (BC) at theinlet and a flux boundary condition at the outlet were used. Forheat transfer, a temperature boundary condition at the inlet, aconstant flux (outflow) boundary condition at the outlet, and aconvective heat flux at the wall were specified. For momentumbalance, a normal velocity boundary condition at the inlet, andan atmospheric pressure were specified at the outlet as shownin Table 2.Parameters used in the current simulation and their

respective sources are provided in Table 1.

Solution Method. Simulation of the coupled mass, energy,and momentum balance and constitutive equations wasperformed using COMSOL Multiphysics version 4.3a wherethe developed governing equations were solved numericallyusing the finite element method. COMSOL’s built-in modelsfor mass transfer in a porous adsorbent assume instantaneousequilibrium between the gas and the adsorbent and negligiblemass transfer resistance, which is not the case for adsorptionfrom dilute streams where the mass transfer resistance issignificant. Hence, simulation of mass transfer was performedusing equation-based modeling through COMSOL’s PDEinterface and coupled to the built-in energy and momentumtransport models. Best modeling practices suggest the use ofhigher order elements; at least second order element and evenhigher order element should be used for the convective term toavoid solution instability.40−42 In this study a second-orderelement for concentration, temperature, and pressure and athird-order element for velocity field were used with systematicmesh refinement until a grid-independent solution wasobtained, as confirmed by the calculated 0.42% relative errorin concentration using 13 847 elements and 26 772 elements.

Experimental Method. To validate the model, breakthroughexperiments were performed using four selected VOCs. Astainless steel tube with a 0.76 cm inner radius and a height of

Table 2

physics inlet (Z = H) outlet (Z = 0) adsorber wall (r = R) initial condition (t = 0)

mass transfer c = co, cs = cso boundary flux, −n(D▽c) = 0, −n(D▽cs) = 0 zero flux c = 0, cs = 0heat transfer T = Tinlet −n(K▽T) = 0 qo = kw(Tw − T) T = 295 Kmomentum transfer normal velocity (Vs = 0.914 m/s) P = 1 atm no slip P = 1 atm, u = 0

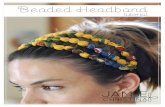

Figure 1. Comparison of the modeled and experimental breakthrough curves of (a) acetone, (b) benzene, (c) toluene, and (d) 1,2,4-trimethylbenzene on BAC. MRAE and RMSE were 2.0 and 1.2% for acetone, 0.4 and 1.1% for benzene, 4.0% and 1.0% for toluene, and 4.0% and0.7% for TMB, respectively.

Environmental Science & Technology Article

dx.doi.org/10.1021/es402369u | Environ. Sci. Technol. 2013, 47, 11700−1171011704

15 cm was filled with 13.3 g of microporous BAC. The reactorwas loaded in such a way that the net height of the BAC bedwas 12 cm. A 1.5-cm-thick glass wool layer was used at the topand bottom of the reactor to support the bed. The effect of theglass wool layer on the flow and adsorption was considerednegligible. The BAC had a BET area of 1390 m2/g, microporevolume of 0.51 cm3/g, and total pore volume of 0.57 cm3/g.The concentration at the outlet of the reactor was measuredusing a flame ionization detector (Baseline Mocon, Series9000).For the validation of the temperature profile, a 0.9 mm

thermocouple (Omega) was inserted at the center of thereactor to measure instantaneous temperatures duringadsorption. The pressure drop across the adsorbent bed duringadsorption was determined as the difference between thepressure drop across the reactor (measured with a mass flow

controller, Alicat Scientific) with and without the BAC. Adetailed description of the experimental setup was presentedelsewhere.17

The nonzero data points from the model and experimentwere compared and evaluated using the mean relative absoluteerror (MRAE).43

∑=| − |

×N

MRAE1 experimental value modeled value

experimental value100

N

1(34)

When calculating the MRAE between measured andmodeled temperatures, the temperature was expressed indegrees Celsius to avoid apparent low relative error bias fromexpressing the temperature in Kelvin.

Figure 2. Solid-phase concentration of benzene on BAC indicating earlier saturation at the bed periphery compared to the bed center. (a) Progressin bed saturation with benzene over time and (b) the radial adsorbed phase concentration of benzene in the mass transfer zone (Z = 90 mm from theoutlet, t = 33 min).

Environmental Science & Technology Article

dx.doi.org/10.1021/es402369u | Environ. Sci. Technol. 2013, 47, 11700−1171011705

The overall error in predicting the concentration andtemperature was also evaluated using the root-mean-squareerror (RMSE) normalized by the influent stream concentration(in ppmv) and temperature (in °C), respectively: 44

∑=−

×

⎛⎝⎜

⎞⎠⎟N

RMSE1 experimental value modeled value

influent stream value

100

N

1

2

(35)

■ RESULTS AND DISCUSSION

Model Validation. Breakthrough experiments were usedfor validating the model performance because the concentrationprofile is coupled to the other flow variables such as flowvelocity, pressure, and temperature. Figure 1 shows modeledand measured breakthrough curves of individual organicadsorbates selected based on their range of boiling points:acetone (56 °C), benzene (80 °C), toluene (111 °C), and1,2,4-trimethylbenzene (TMB; 170 °C). The model predictedthe experimental breakthrough curves for the selected VOCswith an overall MRAE of 2.6% and RMSE of 1.0%. Theagreement between the model and the experimental results isencouraging, as the model only uses independently determined

properties of the adsorbent and adsorbate and the adsorbergeometry and operating conditions.

Figure 3. Temperature distribution during adsorption on BAC: (a) bed temperature profile 33 min after the start of benzene adsorption and (b)radial temperature profile during adsorption of acetone, benzene, toluene, and 1,2,4-trimethylbenzene in the respective mass transfer zone and (c)comparison of modeled and measured temperature profile at the center of the reactor (r = 0.0 cm, z = 8.0 cm) during benzene adsorption.

Figure 4. Variation of pressure and axial velocity in the bed duringadsorption of benzene at 33 min after the start of adsorption.

Environmental Science & Technology Article

dx.doi.org/10.1021/es402369u | Environ. Sci. Technol. 2013, 47, 11700−1171011706

The model and experiments revealed a sharper breakthroughcurve for acetone (Figure 1a) and a more gradual breakthroughcurve for TMB (Figure 1d). This is because among the selectedadsorbates, acetone is the smallest in size with the lowestdiffusion resistance while TMB is the largest with the highestdiffusion resistance. The good agreement supports the accuracyof the model assumptions, equations, and parameters. It alsosuggests that the model could be used to study the adsorptiondynamics of a wide range of adsorbates, including the VOCs inpaint emissions which consist of a large number of organiccompounds with a range of functional groups and physicalproperties.16

Adsorbed Phase Concentration Distribution. Figure 2shows the variation of axial and radial adsorbed-phaseconcentration for benzene. As the adsorbate is fed into thebed, the inlet portion of the bed becomes saturated, and themass transfer zone moves down the bed until the entire bed issaturated. The variation of the adsorbed phase concentration inthe radial direction shows that the wall region of the bed issaturated earlier than the bed center because of channellingnear the wall. This would be seen as an earlier breakthroughthan if the model was a one-dimensional model along the bedcenter line.

Temperature Distribution. The model results for two-dimensional temperature distribution during benzene adsorp-tion reveal that the thermal wave advances through the bedwith the mass transfer zone (MTZ) but at a higher velocity(Figure 3a). At t = 33 min, the MTZ is at 30 mm from thereactor inlet (Figure 2a), whereas the heat transfer zone is atabout 40 mm (Figure 3a). Adsorption is an exothermic process,and the bed temperature could increase depending on theadsorbate loading and heat of adsorption. The BAC bedtemperature was highest for 1,2,4-trimethybenzene followed bytoluene, benzene, and acetone (Figure 3b). This order is thesame as the order of the heat of adsorption for the selectedcompounds. Figure 3b reveals that the bed temperature duringadsorption also varied across the bed and is higher at the centerthan at the periphery due to the convective heat transfer at thewall. The results obtained using this model are consistent withprevious experimental measurements,9,39,45,46 which supportsthe reliability of this model to predict instantaneous radial andaxial temperature profiles accurately for the VOCs evaluated.Similarly, the model predicted the transient temperature profileat the center of the bed (r = 0.0 cm, z = 8.0 cm, Figure 3c) witha MRAE of 0.8% and RMSE of 3.9%.

Pressure Distribution and Velocity Field. Pressure dropis mainly influenced by the porosity of the adsorbent bed. The

Figure 5. (a) Effect of carrier gas temperature on benzene breakthrough, (b) modeled effect of inlet benzene concentration on bed temperature, and(c) modeled effect of superficial velocity on benzene breakthrough curve.

Environmental Science & Technology Article

dx.doi.org/10.1021/es402369u | Environ. Sci. Technol. 2013, 47, 11700−1171011707

lowest pressure drop during benzene adsorption occurs at theoutlet of the reactor and the maximum at the inlet (Figure 4).The modeled net pressure drop across the bed after 33 min ofadsorption is about 3.0 kPa, which is comparable to theexperimentally measured one (3.4 kPa). The MRAE (11.8%)could be due to the use of gas viscosity instead of effectiveviscosity47,38 in the model and/or experimental error inmeasuring the pressure drop. The axial variation of pressuredrop reflects axial variation of velocity (Figure 4). The axialflow velocity decreased sharply in the inlet region because theflow encounters high bed resistance and further reduction inthe MTZ (40 mm from the inlet at 33 min) due to theadditional momentum sink during adsorption and increasedtoward the outlet as the pressure drop linearly decreased andenabled the gas to expand (Figure 4). The higher pressure dropat the top of the reactor stabilizes the flow and allows sufficientcontact time for mass transfer and reduces the effect ofchanneling (Figure 2a). This agrees with Chahbani andTondeur’s conclusion on the importance of pressure drop infixed-bed adsorption.45

Parametric Study. In typical industrial applications,absorbers are often downstream of the plant, and the absorber’sperformance could be affected by the performance andvariation in process parameters of upstream plant operations.Therefore, it is useful to understand how the adsorber

performance is affected when its operational parameters andinput conditions are varied.

Effect of Adsorbate Loading, Carrier Gas Temper-ature, and Superficial Velocity. The effect of carrier gastemperature on the adsorption of benzene was modeled andexperimentally validated. Increasing the inlet gas temperaturefrom 300 K to 308 K resulted in a 22.5% reduction in the bedservice time (defined as the time when the outlet adsorbateconcentration is 1% of the inlet, i.e., the 1% breakthrough time)because a higher temperature lowers the adsorption capacity ofthe adsorbent (Figure 5a). Good agreement was observedbetween the model and experimental results.To investigate the effect of adsorbate inlet concentration on

the bed temperature, the benzene concentration in the inlet airwas incrementally increased from 1000 ppmv to 30 000 ppmvin the model. The maximum adsorption temperature attainedfor each case is plotted against the inlet concentration in Figure5b. The increase in the adsorbent temperature is directlyproportional to benzene concentration because of theproportionately higher heat released per unit of gas flowthrough the adsorber. This result is consistent with earlierexperimental measurements.48

To investigate the effect of the superficial velocity, all otherconditions and parameters were kept constant, and the basecase superficial velocity was increased and decreased by a factorof 2. The 5% breakthrough time decreased by 55% for 2Vs

Figure 6. Effect of halving and doubling the adsorbent particle size (base case, dp = 0.75 mm) on adsorption dynamics of benzene: (a) breakthroughprofile, (b) radial velocity profile at the mass transfer zone, and (c) bed pressure drop.

Environmental Science & Technology Article

dx.doi.org/10.1021/es402369u | Environ. Sci. Technol. 2013, 47, 11700−1171011708

while it increased by 109% for Vs/2 (Figure 5c). A slight changein the shape of the breakthrough curve was also observed asindicated by the throughput ratio (TPR), which is the ratio of5% breakthrough time to the 50% breakthrough time. The TPRdecreased from 0.93 to 0.87 as the superficial velocity increasedfrom Vs to 2Vs, indicating a relatively shallower breakthrough,while it increased to 0.94 when the superficial velocitydecreased to Vs/2, indicating a relatively steeper break-through.49 This is because the lower the superficial velocityis, the longer the contact time is and the more efficient the masstransfer. These results are consistent with previous find-ings.50−52

Effect of Particle Size. Activated carbon adsorbents arecharacterized by their micropores into which the adsorbatemolecules need to diffuse. As the adsorbent particle sizeincreases, the mass transfer resistance increases since theadsorbate needs to travel a longer path to reach the deepestmicropores. Hence, some of the adsorbate molecules wouldpenetrate the adsorbent bed before it is saturated, and thebreakthrough curve becomes shallower. On the other hand, asthe adsorbent particle size decreases, the mass transfer of theadsorbate becomes faster, the overall rate of adsorptionbecomes higher, and the breakthrough curve becomes sharper(Figure 6a), resulting in more complete bed utilization, possiblyallowing a reduction in operational costs. Further research isstill needed to confirm the model results.The variation in the radial velocity as a result of variation in

the radial bed porosity is related to the adsorbent particle size.The maximum radial velocity was obtained at about oneparticle diameter from the wall of the reactor due tochannelling (Figure 6b), which is also consistent with previousmeasurements.46 Reducing the particle size by half reduces thechanneling effect, while doubling the particle size increases thechannelling effect (Figure 6b).Decreasing particle size increases the bed utilization

efficiency, which will decrease adsorbent or servicing costsbut increase the pressure drop and energy consumption. Thepressure drop increases because the bulk bed porosity decreasesand the flow resistance through the bed increases. Increasingparticle size has the opposite effect (Figure 6c).The results obtained in this paper are encouraging, as they

show that the model can accurately predict the mass, heat, andmomentum transfer using adsorbate and adsorbent properties(without the need for fitting parameters) and the adsorber’soperating conditions. Hence the model could be used tooptimize operational parameters and the adsorbent materialduring the design of an adsorber in order to minimize overalloperational costs.

■ ASSOCIATED CONTENT*S Supporting InformationAdditional methodological details, linearized form of Langmuirisotherm, and Langmuir isotherm parameters at 25 °C. Thismaterial is available free of charge via the Internet at http://pubs.acs.org

■ AUTHOR INFORMATIONCorresponding Author*Tel.: +1-780-492-0247. Fax: +1-780-492-0249. E-mail:[email protected].

NotesThe authors declare no competing financial interest.

■ ACKNOWLEDGMENTSThe authors would like to acknowledge financial support forthis research from Ford Motor Company and the NaturalScience and Engineering Research Council (NSERC) ofCanada. We also acknowledge the support of infrastructureand instruments grants from Canada Foundation forInnovation (CFI), NSERC, and Alberta Advanced Educationand Technology.

■ REFERENCES(1) Hunter, P.; Oyama, S. T. Control of Volatile Organic CompoundEmissions: Conventional and Emerging Technologies; Wiley: New York,2000.(2) Parmar, G. R.; Rao, N. N. Emerging control technologies forvolatile organic compounds. Crit. Rev. Environ. Sci. Technol. 2009, 39(1), 41−78.(3) Fournel, L.; Mocho, P.; Brown, R.; Le Cloirec, P. Modelingbreakthrough curves of volatile organic compounds on activatedcarbon fibers. Adsorption 2010, 16 (3), 147−153.(4) Joly, A.; Perrard, A. Linear driving force models for dynamicadsorption of volatile organic compound traces by porous adsorbentbeds. Math. Comput. Simul. 2009, 79 (12), 3492−3499.(5) Murillo, R.; García, T.; Aylon, E.; Callen, M. S.; Navarro, M. V.;Lopez, J. M.; Mastral, A. M. Adsorption of phenanthrene on activatedcarbons: Breakthrough curve modeling. Carbon 2004, 42 (10), 2009−2017.(6) Puertolas, B.; Lopez, M. R.; Navarro, M. V.; Lopez, J. M.; Murillo,R.; García, T.; Mastral, A. M. Modelling the breakthrough curvesobtained from the adsorption of propene onto microporous inorganicsolids. Adsorpt. Sci. Technol. 2010, 28 (8−9), 761−775.(7) Chuang, C. L.; Chiang, P. C.; Chang, E. E. Modeling VOCsadsorption onto activated carbon. Chemosphere 2003, 53 (1), 17−27.(8) Benenati, R. F.; Brosilow, C. B. Void fraction distribution in bedsof spheres. AIChE J. 1962, 8 (3), 359−361.(9) Vortmeyer, D.; Winter, R. P. Improvement in reactor analysisincorporating porosity and velocity profiles. Ger. Chem. Eng. 1984, 7(1), 19−25.(10) Schwartz, C. E.; Smith, J. M. Flow Distribution in Packed Beds.Ind. Eng. Chem. 1953, 45 (6), 1209−1218.(11) Cohen, Y.; Metzner, A. B. Wall effects in laminar flow of fluidsthrough packed beds. AIChE J. 1981, 27 (4), 705−715.(12) Mohamadinejad, H.; Knox, J. C.; Smith, J. E. Experimental andNumerical Investigation of Two-Dimensional CO2 Adsorption/Desorption in Packed Sorption Beds Under Non-ideal Flows. Sep.Sci. Technol. 2003, 38 (16), 3875−3904.(13) Daszkowski, T.; Eigenberger, G. A reevaluation of fluid flow,heat transfer and chemical reaction in catalyst filled tubes. Chem. Eng.Sci. 1992, 47 (9−11), 2245−2250.(14) Cohen, Y.; Metzner, A. B. Wall effects in laminar flow of fluidsthrough packed beds. AIChE J. 1981, 27 (5), 705−715.(15) Yin, F.; Wang, Z.; Afacan, A.; Nandakumar, K.; Chuang, K. T.Experimental studies of liquid flow maldistribution in a random packedcolumn. Can. J. Chem. Eng. 2000, 78 (3), 449−457.(16) Wang, H.; Jahandar Lashaki, M.; Fayaz, M.; Hashisho, Z.;Philips, J. H.; Anderson, J. E.; Nichols, M. Adsorption and desorptionof mixtures of organic vapors on beaded activated carbon. Environ. Sci.Technol. 2012, 46 (15), 8341−8350.(17) Lashaki, M. J.; Fayaz, M.; Wang, H.; Hashisho, Z.; Philips, J. H.;Anderson, J. E.; Nichols, M. Effect of adsorption and regenerationtemperature on irreversible adsorption of organic vapors on beadedactivated carbon. Environ. Sci. Technol. 2012, 46 (7), 4083−4090.(18) Nield, D. A.; Bejan, A. Nield, D. A.; Bejan, A. Convection inPorous Media; Springer: New York, 2006.(19) Dantas, T. L. P.; Luna, F. M. T.; Silva, I. J., Jr; Torres, A. E. B.;De Azevedo, D. C. S.; Rodrigues, A. E.; Moreira, R. F. P. M. Modelingof the fixed-bed adsorption of carbon dioxide and a carbondioxidenitrogen mixture on zeolite 13X. Braz. J. Chem. Eng. 2011,28 (3), 533−544.

Environmental Science & Technology Article

dx.doi.org/10.1021/es402369u | Environ. Sci. Technol. 2013, 47, 11700−1171011709

(20) Sircar, S.; Hufton, J. R. Why does the linear driving force modelfor adsorption kinetics work? Adsorption 2000, 6 (2), 137−147.(21) Farooq, S.; Ruthven, D. M. A comparison of linear driving forceand pore diffusion models for a pressure swing adsorption bulkseparation process. Chem. Eng. Sci. 1990, 45 (1), 107−115.(22) Sircar, S.; Hufton, J. R. Intraparticle adsorbate concentrationprofile for linear driving force model. AIChE J. 2000, 46 (3), 659−660.(23) Liaw, C. H.; Wang, J. S. P.; Greenkorn, R. A.; Chao, K. C.Kinetics of fixed-bed adsorption - new solution. AIChE J. 1979, 25 (2),376−381.(24) Basagaog lu, H.; Ginn, T. R.; McCoy, B. J.; Marino, M. A. Lineardriving force approximation to a radial diffusive model. AIChE J. 2000,46 (10), 2097−2105.(25) Giraudet, S.; Pre, P.; Le Cloirec, P. Modeling the heat and masstransfers in temperature-swing adsorption of volatile organiccompounds onto activated carbons. Environ. Sci. Technol. 2009, 43(4), 1173−1179.(26) Raghavan, N. S.; Hassan, M. M.; Ruthven, D. M. Numericalsimulation of a PSA system using a pore diffusion model. Chem. Eng.Sci. 1986, 41 (11), 2787−2793.(27) Do, D. D.; Rice, R. G. Revisiting approximate solutions for batchadsorbers: explicit half time. AIChE J. 1995, 41 (2), 426−429.(28) Hartzog, D. G.; Sircar, S. Sensitivity of PSA process performanceto input variables. Adsorption 1995, 1 (2), 133−151.(29) Jiang, L.; Biegler, L. T.; Fox, V. G. Simulation and optimizationof pressure-swing adsorption systems for air separation. AIChE J. 2003,49 (5), 1140−1157.(30) Logan, D. A. Estimating physical properties for controlequipment design. Environ. Prog. 1997, 16 (4), 237−242.(31) Shi, Y.; Lee, Y. T.; Kim, A. S. Knudsen Diffusion ThroughCylindrical Tubes of Varying Radii: Theory and Monte CarloSimulations. Transp. Porous Media 2012, 93 (3), 517−541.(32) Giraudet, S.; Pre, P.; Le Cloirec, P. Modeling the temperaturedependence of adsorption equilibriums of VOC(s) onto activatedcarbons. J. Environ. Eng. 2010, 136 (1), 103−111.(33) Giraudet, S.; Pre, P.; Tezel, H.; Le Cloirec, P. Estimation ofadsorption energies using the physical characteristics of activatedcarbons and the molecular properties of volatile organic compounds.Carbon 2006, 44 (12), 2413−2421.(34) Smith, J. M.; Van Ness, H. C.; Abbott, M. M. Introduction toChemical Engineering Thermodynamics, 7th ed.; McGraw-Hill: Boston,2005; pp xviii, 817.(35) Bowen, D. H. M. HIST 15-Perry’s heavyweight handbook forchemical engineers. Abstr. Pap.Am. Chem. Soc. 2008, 236.(36) Kannuluik, W. G.; Carman, E. H. The Temperature Depend-ence of the Thermal Conductivity of Air. Aust. J. Sci. Res., Ser. A 1951,4 (3), 305−314.(37) Kuwagaki, H.; Meguro, T.; Tatami, J.; Komeya, K.; Tamura, K.An improvement of thermal conduction of activated carbon by addinggraphite. J. Mater. Sci. 2003, 38 (15), 3279−3284.(38) Bey, O.; Eigenberger, G. Gas flow and heat transfer throughcatalyst filled tubes. Int. J. Therm. Sci. 2001, 40 (2), 152−164.(39) Kwapinski, W. Combined wall and thermal effects during non-isothermal packed bed adsorption. Chem. Eng. J. 2009, 152 (1), 271−276.(40) Oliemans, R. V. A. ERCOFTAC’s role in promotingcomputational fluid dynamics. Houille Blanche 2000, 7−8, 43−46.(41) Hutton, A. G. Quality and trust in industrial computational fluiddynamics. Houille Blanche 2001, 3−4, 25−28.(42) Oberkampf, W. L.; Trucano, T. G. Verification and validation incomputational fluid dynamics. Prog. Aerospace Sci. 2002, 38 (3), 209−272.(43) Jahandar Lashaki, M.; Fayaz, M.; Niknaddaf, S.; Hashisho, Z.Effect of the adsorbate kinetic diameter on the accuracy of theDubinin-Radushkevich equation for modeling adsorption of organicvapors on activated carbon. J. Hazard. Mater. 2012, 241−242, 154−163.

(44) Williams, L. E.; Barnett, M. O.; Kramer, T. A.; Melville, J. G.Adsorption and transport of arsenic(V) in experimental subsurfacesystems. J. Environ. Qual. 2003, 32 (3), 841−850.(45) Chahbani, M. H.; Tondeur, D. Pressure drop in fixed-bedadsorbers. Chem. Eng. J. 2001, 81 (1−3), 23−34.(46) Negrini, A. L.; Fuelber, A.; Freire, J. T.; Thomeo, J. C. Fluiddynamics of air in a packed bed:velocity profiles and the continuummodel assumption. Braz. J. Chem. Eng. 1999, 16 (4), 421−432.(47) Breugem, W. P. The effective viscosity of a channel-type porousmedium. Phys. Fluids 2007, 19, 10.(48) Pre, P.; Delage, F.; Faur-Brasquet, C.; Le Cloirec, P.Quantitative structure-activity relationships for the prediction ofVOCs adsorption and desorption energies onto activated carbon.Fuel Process. Technol. 2002, 77−78, 345−351.(49) Hashisho, Z.; Rood, M.; Botich, L. Microwave-swing adsorptionto capture and recover vapors from air streams with activated carbonfiber cloth. Environ. Sci. Technol. 2005, 39 (17), 6851−6859.(50) Chern, J. M.; Chien, Y. W. Adsorption of nitrophenol ontoactivated carbon: isotherms and breakthrough curves. Water Res. 2002,36 (3), 647−655.(51) Pan, B. C.; Meng, F. W.; Chen, X. Q.; Pan, B. J.; Li, X. T.;Zhang, W. M.; Zhang, X.; Chen, J. L.; Zhang, Q. X.; Sun, Y.Application of an effective method in predicting breakthrough curvesof fixed-bed adsorption onto resin adsorbent. J. Hazard. Mater. 2005,124 (1−3), 74−80.(52) Benjamin, M. M. Water Quality Engineering: Physical/ChemicalTreatment Processes; John Wiley & Sons: Inc.: Hoboken, NJ, 2013.

Environmental Science & Technology Article

dx.doi.org/10.1021/es402369u | Environ. Sci. Technol. 2013, 47, 11700−1171011710