Turnkey Solutions & Customised Machines for EPC Contracts · 2020-01-14 · and services rotary...

Transcript of Turnkey Solutions & Customised Machines for EPC Contracts · 2020-01-14 · and services rotary...

1

EPC - MINING SOLUTIONS

Turnkey Solutions & Customised Machines

for EPC Contracts

COMPRESSORS, BLOWERS & VACUUM PUMPS

Mining Industry

Gardner Denver is a leading global provider of compression, vacuum and associated aftermarket equipment with more than 150 years of experience. Gardner Denver has manufacturing facilities in more than 30 countries worldwide, with the headquarters based in the USA.

Gardner Denver. Overview

Industrials Segment

OneAir. A single source industrial airCollaborating with a single source supplier can help reduce costs, streamline administrative processes and improve operational efficiencies. With a world-renowned brand portfolio, the Industrial Group is able to help you with all your industrial air needs – delivering quality and efficient compressed air, vacuum, high-pressure and low-pressure solutions.

Energy Segment

The Gardner Denver Industrials Segment delivers the broadest range of compressors and vacuum products, in a wide array of technologies, to end-user and OEM customers worldwide in the industries it serves. The Segment provides reliable and energy-efficient equipment that is put to work in a multitude of manufacturing and process applications. Products ranging from versatile low- to high-pressure compressors, to customised blowers and vacuum pumps serve industries including general manufacturing, automotive, and wastewater treatment, as well as food & beverage, plastics, and power generation.

Gardner Denver’s Energy Segment delivers a range of compressors, blowers, vacuum pumps, and fluid transfer equipment, to a variety of end markets. Our team of trusted brands delivers reliable and efficient equipment, designed to stand up to the most demanding process applications. Serving a variety of industries, including mining, oil and gas, power generation, and water/wastewater treatment, our products are backed by a comprehensive suite of aftermarket products and services that are designed to help you protect your investment.

Gardner Denver designs, manufactures, markets and services rotary screw, liquid ring, reciprocating and sliding vane compressors in addition to multistage, positive displacement and centrifugal compressors, plus blowers and vacuum pumps. The OEM and end-user market sectors served are primarily Oil & Gas, Power Generation, Chemical & Petrochemical, Mining and other industrials industries such as Enviromental, Industrial Manufacturing and others. Gardner Denver delivers the broadest range of compressors and

vacuum products, in a wide array of technologies, to end-user and OEM customers worldwide.

In order to service the Engineering, Procurement and Construction (EPC) market, Gardner Denver has established specialised centres to ensure we are able to deliver our solutions worldwide. Our commitment focuses on delivering successful outcomes, a wide range of compressed air and vacuum machines, industrial engineered solutions and customised projects.

• Lower Costs

• Optimised Maintenance

• Intuitive Partnership

• Choice

GARDNER DENVER | MINING SOLUTIONS

2 3

5

EPC focus. Why our expertise mattersBased on the extensive experience we have built-up with EPC companies, we have the capacity to carry out complex projects for our customers with bespoke and custom requirements. Whatever details matter to you, Gardner Denver machines are designed to meet your needs exactly. Engineered specifically for the Mining Industry, our equipment is built to offer you maximum efficiency, reliability and uptime.

Find out how Gardner Denver products and services can improve operational efficiency and help you enjoy significant savings in your mining project.

Contact us today.

Turn-key ProjectsGardner Denver offers turnkey project solutions to the Engineering, Procurement and Construction (EPC) companies. We provide a complete solution based on design, project management, commissioning and start-up. We are able to accommodate the most demanding technical requirements for bespoke projects, in addition to ensuring compliance with the strictest quality requirements – ISO regulations included.

Customised MachinesAt Gardner Denver, we know that every customer has unique requirements. Every machine can therefore be tailored to the particular needs of each customer, ensuring that we deliver equipment and solutions that fit the brief perfectly. We are able to deliver customised design, change electrical equipment and drive, plus engineer the machines to perfectly fit with environmental conditions, in addition to developing speciality and custom options.

Customised PackagingGardner Denver can custom design and manufacture your equipment package, which can include: structural bedplate, machinery mounting pads, piping, tubing, electrical wiring, instrumentation, and controls. The different installation types are custom-designed in accordance with customer specifications and applicable ISO/API standards and to major international codes and standards.

FlexibilityMaximum flexibility in all project processes enables us to adapt to any customer requirement.

Project ManagementProject management team of expert engineers control the whole process throughout: from the design, through assembly, to commissioning and start-up, including technical & quality management.

DocumentationAfter this detailed engineering step, the main documents (machinery assembly, P&ID, electrical diagrams, instrumentation lists, etc.) are ready to be reviewed if necessary, by the client or engineering contractor, and then progressed into production.

PLCComplete assembly of the package, including piping and control of the installation (PLC). This PLC, programmed by Gardner Denver, controls the compressor according to demand (with the network pressure as the reference variable).

Unique Team. Global SupportFor more than 155 years, Gardner Denver has been a leading global provider of compressors, blowers and vacuum pumps. With global teamwork, we are committed to caring for our customers, around the world and around the clock.

Aftermarket & WarrantyWe take customer care very seriously and have developed our aftermarket capabilities year on year. Today, Gardner Denver is known globally for its excellent service and support. In addition, a completely FREE, simple and flexible extended warranty scheme is available from Gardner Denver brands.

GARDNER DENVER | MINING SOLUTIONS

4

6 7

Project management team of expert engineers control the whole process throughout: from the design, through assembly, to commissioning and start-up, including technical & quality management. Advanced engineering (AutoCAD, 3D modelling) and management tools (Microsoft Project) are used. The sales team, together with the Project Management Manager, work closely with both the technical staff from the client side and the engineering companies, with the following targets:

Project Management

Quality Management

Customised ConfigurationIn design phase, the main documents: machinery assembly, P&ID, electrical diagrams, instrumentation lists, etc. are revieweded by the engineering contractor. After that, they are progressed into production. Quality and effective operation is guaranteed by testing not only the individual components, but also the whole equipment solution. All machinery parameters are tested under real conditions based on customer’s requirements.

In order to be able to test the whole machinery set before being supplied, Gardner Denver’s Engineering Department integrates all auxiliary systems on the installation type, as per customer requirements.

DESIGN Project Management

Commisioning & Start-Up

• Machines testing• Delivery & start-up• Customer training

• Detailed Engineering• Documentation• Manufacturing & assembly

• Analysis of specification• Product configuration• Project integration

Definition of electric and I&C diagrams

Configuration of the complete installation

Analysis and study of the customer’s requirements

GARDNER DENVER | MINING SOLUTIONS

Design

• Basic and detailed design engineering• Compressor modification to customer requirement• Project integration• Quality, environmental and safety management• Feasibility studies, market studies and technical, economic and financial consultancy• Compressor, blower, vacuum pump design and modification to project specification

Project Management

• Documentation to customer requirements (mechanical, electrical, I&C, quality, logistics, etc.)• Quality documentation to client requirements and country of destination• Preparation of as built drawings: P&ID, general arrangement, sectional drawings and 3D modelling• Complete assembly of the package, including piping and control of the installation (PLC)• Preparation of installation, operation and maintenance manuals• Protection against severe ambient conditions• Purchasing, inspection, expedition and logistics management• Inspection tests (mechanical, hydrostatic, packing…) and final tests

Commisioning and start-up

• Construction, assembly, pre-commissioning, commissioning and start-up• Marking and packaging of the whole supply• Shipping• Customer training

The perfect technology for every mining challengeWith more than a century of applications experience and a range that covers every major technology, we can advise on, design, and supply the right machine for the Mining industry.We help you maximise your operational efficiency and profitability with air compressors, vacuum systems or blowers for all your mining applications. This can help extend the longevity of critical mining equipment and reduce any downtime needed for maintenance.

GARDNER DENVER | MINING SOLUTIONS

Compressors Vacuum Systems Blowers

Compressed Air for RoadheadersInstalled directly behind the roadheader in the powetrain, our compresor allows for the extension of

compressed air lines without interrupting the operation of the roadheader. •

Lithium MiningWith the highest electrochemical potential of all metals, lithium and its chemical compounds exhibit a broad range of beneficial properties. Our vacuum pumps & compressors are ideal for dewatering and

also help produce a technical grade of lithium concentrate.• •

Methane Gas ExtractionThe accumulation of methane gas can lead to dangerous, explosive and potentially deadly conditions.

Gardner Denver products and systems are specially designed for this application to prevent the accumulation of methane gas in underground mining operations.

• • •

Vacuum Filtration

In this application, the moisture from the filtrate receiver of a vacuum filter is collected and fed back into the system. If a system upset occurs, such as the failure of the filtrate pump, slugs of liquid can

carry over into the vacuum system. Soft solids from the filter can also enter the vacuum system. In both cases, the liquid and soft solids will not damage the liquid ring vacuum pump, improving the overall

reliability of the vacuum filtration system.

•

Pneumatic Tools and Transportation

Compressed air is used for the safe operation of ventilation systems in hazardous mine environments. Rotary lobe blowers are used to provide necessary air ventilation into coal mines. •

BlastingCompressed air systems offer safer mediums for use in blasting operations. High velocity compressed

air streams can be vital in some mining situations. •

CleaningCompressed air is used for purging unwanted particles from filters and other spaces amid the dirt and dust of the mining operation. In addition to that, compressed air is used for reverse air jet purging to

keep filters clean while extending lifetime and reducing downtime.•

Ventilation Systems Compressed air is used for the safe operation of ventilation systems in hazardous mine environments. • •

Fluidization of productCompressed air is mixed with products such as coal dust to cause fluidization. As a result these prod-

ucts are better suited for material handling and conveying. •

Ore flotation

Froth flotation, also called ore flotation when used in mining applications, is a method for physically separating particles by having air bubbles selectively adhere to specific surfaces. The particles with

attached air bubbles are carried to the surface and removed. Multistage centrifugal blowers are custom made and designed to deliver a specific airflow and pressure, offering an efficient way to produce con-

stant forced with reliable and dependable performance.

•

Coal Bed Methane RecoveryCoal bed methane is emerging as a source of clean energy. Extracting the coal bed methane allows min-

ing at greater depths while improving safety and providing higher mining output. Pumps and blowers can work, making it ideal for coal bed methane recovery.

• • •

Forced Air Oxidation In Wet FGD

In wet Flue Gas Desulfurization (FGD) systems, a scrubbing liquid containing an alkali reagent is used to enhance the absorption of SO2 and other acid gases. The wet FGD scrubber is designed for constant re-circulation of the reagent slurry, and is designed to operate at or near 100% capacity at all times. To

maximize power production at all times, only minor variations in the flow should affect the forced oxida-tion blowers. To meet this demanding task, plants have trusted Gardner Denver blowers.

•

8 9

www.gardnerdenver.com

GARDNER DENVER | MINING SOLUTIONS

Rotary Screw Compressors

CompAir lubricated rotary screw compressors incorporate the very latest technological advances and guarantee a continuous supply of high quality compressed air. The screw compression element is the heart of the compressor and therefore CompAir keeps the design and manufacture in-house, using the latest CNC rotor grinding machinery, coupled with online laser technology.

• Premium airend providing high reliability• Low installation costs thanks to the compact design• High quality air• Safe and economical operation• Excellent accessibility contributing to the low maintenance costs

• Flow rate: up to 3,000 m3/hr (FAD)• Operating Pressure: up to 10.5 barg• Power: up to 250 kW

Reciprocating Compressors

Our reciprocating compressor packages are known for their excellent energy efficiency, and we have consolidated and at the same time, consistently developed this proven technology to maintain its cutting edge. High-quality, robust construction along with excellent efficiency means that payback times are short.

High pressure air compressors supply the world’s major industries. Our products utilise the leading high pressure compressor technology to provide solutions to a wide range of global industries. Our status as a premium, high pressure compressor manufacturer is based on over 250 years of combined design and manufacturing expertise and experience.

High Pressure Compressor Package

• Robust and durable technology• High reliability• Easy to maintain• High quality oil-free air• Comprehensive electronic control• Open or with noise-reduced housing

• Market leading efficiency• Maximum uptime• Wide range of options• Proven reliability• Outstanding accessibility

An efficient and smart air solution is more than a line of high-quality compressors. It is a combination of air generation, filtering, drying, condensation and purification expertise and products. Gardner Denver’s complete compressed air systems provide not only compression packages, but a full range of air treatment systems.

Air Treatment

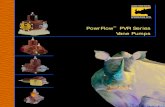

Customised Liquid Ring Technologies

Robuschi is constantly researching and developing new equipment and technical features for customised packages that will match your specific requirements. We deliver liquid ring vacuum pumps as well as liquid ring compressors. These customised machines can been supplied including piping, valves, tank separators, seal water cooler, controllers, ejectors and other required equipment.

Our blower packages are customised and adapted with different kinds of features and accessories to meet your individual needs. Minimise the operational costs with easy maintenance and maximise efficiency with the many available options. In support of the group, we can add separator cyclones and filters, to prevent traces of liquid, powder and solid impurities and other required accessories, years of combined design and manufacturing expertise and experience.

Customised Blower Package

• They are designed for the most extreme conditions• Extended the life of all package components• Customised according to technical requirement• Optimal performance• Maximum uptime with consistent quality and reliability in

every application•Air treatment equipment is designed for optimum performance and life with a sensitive watch on energy consumption• Each Gardner Denver product has been designed to offer

reduced energy usage or to include energy saving features

• Reduced water consumption• Low noise and vibrations• Minimum maintenance• Capable of sucking gas and vapors without contamination

from lubricants and with nearly isothermal gas compression

• Flow rate: 4.9 to 4094 m3/hr• Operating Pressure: 2 to 414 barg

• Duty point: 8,000 m3/h• Vacuum up to: 300 mbar(a)• Power: 250 kW (2 motors)

• Capacity: 5,000 m3/h• Pressure up to: 200 mbar(a)• Power: 110 kW (2 pumps)

• Flow rate: 4.9 to 5028 m3/hr• Operating Pressure: 2.5 to 414 barg• Power: up to 325 KW

Rotary vane compressor

To ensure that the operation of roadheaders in underground coal mining does not need to be interrupted repeatedly so that compressed air lines can be extended as necessary, Wittig developed a compressor that is specifically approved for underground mining work. The compressor is installed directly behind the roadheader in the power train. The design complies with ATEX zone M2.

Cost Efficiency• High efficiency at high availability• Low energy consumption• Generating low heat at about 80° C• Heat recovery of up to 75 % of the shaft power• Exceptional safety standard• Up to 100,000 operating hours without overhaul• Long service life of bearings and rotors• Bearings can be changed on site• Easy to install

Customised• Customer specific design of systems• Implementation of special solutions• Design, planning and manufacturing of complete system solutions for numerous gas and offshore applications

• Capacity up to: 3,000 m³/hr• Pressure from: 3.0 to 15 bar (abs.)

Engineering excellenceThe screw compression element is the heart of the compressor and therefore CompAir and Gardner Denver keep the design and manufacture in-house, using the latest CNC rotor grinding machinery, coupled with online laser technology. The resulting reliability and performance ensures that operating costs will remain low throughout the compressor’s life.

Premium efficiency airendThe high output airend with slow rotational speed reduces energy costs. In addition to this, the innovative design of the fail safe shaft seal, integrated oil filter and oil regulation valve, ensures external hoses are reduced to a minimum to guarantee that the highest levels of quality and reliability are achieved. Under the free Assure warranty the airends are covered up to 44,000 hours.

Exceptional reliability & performance• Large surface after cooler• High performance separator filter• High efficiency electric motor• Thermostatically controlled motor driven fan• Automatic motor lubrication• Highest quality connections

1110

Self-contained compressor packages for mobile applications • Motor power: 5.5-75 kw • Capacity: 0.5-12.2m3/min 7 bar • Electric or hydraulic driven version

Tamrotor CT compressor works in underground mining application. Even in the harshest and the most demanding of environments, Tamrotor CT Series Self-contained Compressor Packages excel for reliability and energy efficiency. • Steep operation inclination angle• Compact unit allows installation in numerous applications• Enduro air end and Tempest design

In addition, Tamrotor Enduro air ends and OEM kits are great fit in the mining industry, they are suitable for surface and underground mining applications. Tamrotor air ends and OEM kits allow flexible layout according to your individual requirements. Tamrotor air ends and OEM kits are utilised for flushing the drilling hole, and also for providing compressed air for rock drills lubrication. You can choose OEM air end modular construction for limited space.

gardnerdenver.com/en/hoffmanandlamsonwww.gdnash.com

We are the leaders in the EPC markets we serve, by continuously improving all business processes with a focus on flexibility and global supportability.

GARDNER DENVER | MINING SOLUTIONS

Engineered Vacuum SolutionsEngineered & Package SolutionsWe’ll never forget our roots. As the original Nash Engineering Company, and today operating as Gardner Denver Nash, we know customised engineered solutions.

We offer a wide array of pre-engineered, configurable, and engineered-to-order systems. Whether it’s a standard pre-engineered liquid ring vacuum system for general industry, an application specific package for the power industry or a complete engineered-to-order hybrid system for the chemical industry; nobody has more experience and expertise than Nash.

Applications & TechnologiesNASH 2BE Series Liquid Ring Vacuum PumpsThe NASH 2BE4 liquid ring vacuum pump and compressor series have been optimized to deliver a 6-8% efficiency improvement over previous 2BE models. Based on the proven reliable flat sided liquid ring vacuum pump design the 2BE4 has a polyisoprene lined body, flexible inlet and discharge connections, and a large inspection port for improved performance and reliability. With capacity ranging from 1,200 to 19,000 ACFM (2,000 to 32,300 m³/h).

Split Vacuum CapabilityThe 2BE4 pumps allow efficient operation over the entire vacuum range without the need to change the pump’s internals. When equipped with a center shroud, split vacuum operation up to 12 inHg (400 millibar) differential can be achieved. The advantage of this is significant because it allows the use of fewer vacuum pumps–which saves space and installation costs.

NASH Vectra Liquid Ring Vacuum Pumps & SystemsThe NASH Vectra liquid ring vacuum pump and compressor series delivers optimum performance with unprecedentedproduction efficiencies. Designed to stand up to harsh environments, the Vectra XL is available in 12 modelsand offers capacity ranging from 30 to 5,200 ACFM (50 to 8,900 m3/hr).

Engineered for Demanding EnvironmentsVectra XL pumps and compressors are designed to stand up to the harsh environments found in the oil & gas industries.Engineered to excel in applications that require discharging against a positive back pressure. Available in both ductile iron and stainless steel. Can accommodate a variety of mechanical seals.

Anchored in tradition, the HOFFMAN & LAMSON Engineered Vacuum System line-up continues a century-long commitment to providing customers with innovative design, a comprehensive product line, quality manufacturing, and ongoing advances in efficiency and sustainability.

No other company has the capability, reputation, and dedicated engineering expertise to deliver the most advanced and dependable products available today such as our Flux Recovery and Self Contained Vacuum Systems.

Our Engineered Vacuum Systems are designed to be the ideal solutions for any Housekeeping, Pneumatic Conveying, Product Reclamation, and Hazardous Dust Control Operations.

Applications & TechnologiesMultistage Centrifugal BlowerHigh Flow InletHoffman & Lamson’s high capacity line of blowers and exhausters deliver reliable, proven performance. The high capacity multistage blowers is optimal for large mining applications.

• Inlet Flow: 2,000 to 10,000 CFM (3,400 to 26,800 m3/h)• Discharge Pressure: 2 to 19 psig (0.14 to 1.3 bar g)• Vacuum Range: 3.5 to 17 inHg (120 to 580 mbar)

Multistage Centrifugal Blower50 HzOur 900 series is the first line of a multistage centrifugal blowers with a true 50 Hz design. The optimized design offers up to 8% higher efficiency and high pressure capabilities when compared to 60 Hz blowers that are modified for 50 Hz operation. Constructed of cast iron with a carbon steel shaft and aluminum impellers, our 50 Hz multistage centrifugal blowers are designed for optimum performance.

• Inlet Flow: 2,600 to 39,300 CFM (4,400 to 66,800 m3/h)• Discharge Pressure: to 23 psig (to 1.6 bar g)

12

Advanced Aftermarket ProgrammeOur customers rely on us day after day to keep their systems running cost-effectively and at optimum performance.

We take customer care very seriously and have developed our aftermarket capabilities year on year. Today, Gardner Denver is known globally for its excellent service and support.

Of all the things you can supply to a customer, nothing compares to peace of mind. The reason why thousands of companies around the globe put their trust in Gardner Denver. It is not something that magically appears. Peace of mind has to be earned. It comes from years of trusted performance. Customers see first-hand that you deliver on promises -- that you do what you say you will do.

iConn. Smart Proactive real-time monitoringThe new iConn service* provides compressed air users with in-depth and real-time knowledge about their system. The system generates and delivers insight and statistics that keeps compressed air users informed of the performance of their installation, highlighting potential issues before they become a problem.

Benefits of proactive real-time monitoring and insight• Real-time monitoring, alarms & warnings to reduce the risk

of downtime• Browser-based system for monitoring remote sites• On-time maintenance as required optimising costs and

ensuring longer machine life• Optimal performance with machine parameter and over-

time trend analysis• Enabled for energy efficiency and production optimisation• Gardner Denver remote monitoring and efficiency audits as a service option

* iConn is available in machines of Industral Group

14

GARDNER DENVER | MINING SOLUTIONS

Turn-key customer support agreementsOur customised plans offer regular maintenance and testing that allows you to manage your budget with predictable costs, while avoiding unplanned downtime and repairs.

Worldwide service networkOur customers are comfortable in the knowledge that there is help available when they need it. Nearby service and support is available to them wherever they are in the world, with real experts offering valuable help and advice, and product able to be quickly and efficiently shipped to them.

Factory-trained service engineersCalls to service centres mean talking with a factory-trained service engineer who will provide timely solutions to your parts and service challenges.

Free extended warranty programsProtect yourself from costly unexpected repairs through cost-effective warranty plans. Gardner Denver has the best-extended warranty programs you can find in the market. Our top quality equipment ensures Gardner Denver customers receive many years of complete peace of mind.

Equipment audits & analysis Operational integrity and minimal unplanned maintenance is delivered with regular system audits & analysis performed by a Gardner Denver Service Technician. With annual equipment audits, we can make suggestions to optimise performance, and recommend a specific maintenance plan to keep your process running smoothly.

Recommended spare partsBy using genuine spare parts, you are using components manufactured to the highest specification for total peace of mind. Non-genuine parts might seem like a cost-effective solution, but could lead to an expensive breakdown at a later date.

1415

16

Gardner Denver Project Team. EMEAI & AMERICAS

Avda. La Recomba, 6 - P. I. La Laguna.28914 Leganés (Madrid) - Spain.Tel: +34 91 649 92 00www.gardnerdenver.com/industrials

Global Expertise

Gardner Denver CEP (Custom Engineered Product) & ETO (Engineering to Order). APAC

Room No. 704, Kolon Digital Tower Aston, #212, Kasan Digital Road 1, Keumchon-ku, Seoul, 08502 - Korea

Tel: +82 2 853 5000 www.gardnerdenver.com/industrials

Industrial Segment

Energy SegmentEnergy Segment has an expanded our product portfolio to offer a complete range of vacuum solutions including liquid ring vacuum pumps and compressors, dry vacuum pumps, steam and air ejectors, rotary vane compressors and vacuum pumps.

The Gardner Denver Industrials Group designs, manufactures, markets and services rotary screw, reciprocating and sliding vane compressors in addition to multistage and positive displacement, centrifugal and blowers.

Other locations: Houston (US), Alabama (US), Westlake (US), Sao Paulo (Brazil), Cheshire (UK), Noord(Holland), Bavaria (Germany), Lyon (France), Manama (Bahrain), Dubai (Dubai), Maharashtra (India), Singapore (Singapore), Si Chuan (China), Beijing (China), Shandong (China), Shanghai (China), GuangDong (China), New South Wales (Australia), Seoul (South Korea).

GARDNER DENVER | WORLDWIDE LOCATIONS

Gardner Denver Nash - Australia

13 Arnott Pl, Wetherill Park NSW 2164, AustraliaTel: +61 2 9725 5199www.GDNash.com

Gardner Denver Nash - Nürnberg

Katzwanger Straße 150 90461Nuernberg, Germany Tel: +49-91-11-454-0www.GDNash.com