TURN KEY DELIVERY AND VALIDATION OF A PROCESS …€¦ · Case study Pfizer FC2 CONTACT US Turn key...

Transcript of TURN KEY DELIVERY AND VALIDATION OF A PROCESS …€¦ · Case study Pfizer FC2 CONTACT US Turn key...

Case study Pfizer FC2

After a thorough investigation Pfizer selected Agidens to design and build a completely new sterile formulation process at their plant in Puurs. Agidens took the challenge as an EPC contractor and delivered in close cooperation with Pfizer a turn key solution. From start (conceptual design) to finish (validation of entire the installation), Agidens’ approach was driven to provide the client with a single point of contact.

AGIDENS IN LIFE SCIENCES

COUNTRIES:

» Belgium (HQ) » The Netherlands » Switzerland » France » Germany » United States

FOCUS MARKETS:

» Pharmaceuticals industry » Medical equipment » Hospitals and laboratories » Distribution of pharmaceutical products » Biotechnology » Blood and tissue banks » Cosmetics » API

TURN KEY DELIVERY AND VALIDATION OF A PROCESS INSTALLATION FOR PFIZER

INTEGRATED APPROACH BY DEDICATED AGIDENS-PFIZER TEAM

Blue chip pharmaceutical companies such as Pfizer expect their suppliers to work accord-ing the highest standards possible. They want a team that can think along, adds know how to the process and guarantees a high quality GMP compliant installation. Therefore both parties set up a joint project team in which Pfizer engineers added specific product & process know how to the existent process & automation expertise of the Agidens engi-neers.

This innovative approach with an integrated on-site engineering team resulted in a top-level project performance and allowed one dedicated Agidens-Pfizer team to take up all necessary services involved:

» Joint Project Team (with a single point of contact for the client)

» Conceptual design of the process and the installation

» Basic & detailed engineering (including 3D visualisation)

» Delivery and installation of the entire process chain (tanks, piping, skids, pumps, valves,...)

» Automation (including Software, Electrical & Instrumentation, SCADA, etc.)

» Commissioning

» Validation of all equipment installed

Case study Pfizer FC2

CONTACT US

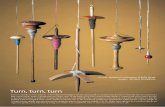

Turn key delivery of a formulation installation

CHALLENGES

Agidens has a long experience in building, automating and main-taining sterile production facilities for pharmaceutical companies. Nevertheless, fully automated projects such as these generate specific challenges. In these cases, it is the flexibility and deter-mination of our teams that make the difference. Several high level challenges needed to be resolved during the course of the project:

» In close collaboration with the client, we took the challenge to draw up the process flow and process chain. A fruitfull co-opera-tion and open communication between the engineering depart-ments of both teams allowed us to proceed continuously.

» Certification, documentation and traceability of all components in the installation makes project administration a key challenge. The application of internal Agidens standards combined with the standards from the client provided the team with fully ap-proved document files very quickly.

» The limited space in which the installation had to be built, re-quired us to prefabricate skids off-site. For the installation of these skids by crane, parts of the roof of the building were re-moved and reinstalled afterwards.

» To be able to clean an aseptic formulation process a Cleaning in Place and Sterilisation in Place system was installed. Agidens has a standardised CIP/SIP solution, easily integratable into var-ious kinds of process installations.

DELIVERABLES

Procurement and Construction was an integral part of the project scope. We constructed several skids and connected them on site, to deliver a completely functional installation that contains a.o.:

» Solution, suspension and holding tanks, several of which are mobile

» An in line blending system including an in-line mixing device

» An isolator to add products manually

» All software necessary for automation and integration of the process

» A CIP/SIP system for various parts of the installation

» SCADA visualisation systems according the Pfizer standards

» Filtering systems in various parts of the process installation

KEY BENEFITS FOR THE CLIENT

» Agidens’ design and build approach itself creates several benefits:

» Engineering, construction and validation by one team facili-tates collaboration. The validation team thinks along during construction, thus saving time in the validation phase. » A single point of contact for the client makes communication easy and fast. » No liability conflicts between different contractors during the construction process. » Agidens’ involvement in engineering allows early phase pro-curement of long term delivery items.

» Joint engineering between Agidens and Pfizer guarantees the pharmaceutical company to keep ownership of the process

» Agidens is capable of delivering high quality GMP compliant mixing and blending systems

» 04/2016

INTERNATIONAL HEADQUARTERS Baarbeek 1 BE-2070 Zwijndrecht T +32 3 641 17 70 F +32 3 641 27 70

THE NETHERLANDS Stephensonweg 64207 HB Gorinchem

Suikersilo-West 301165 MP Halfweg (Amsterdam)

T +31 183 64 33 44F +31 183 64 33 45